Building block cutting, feeding and conveying mechanism

The technology of feeding mechanism and conveying mechanism is applied in the field of block cutting feeding and conveying mechanism, which can solve the problems of low automation degree, low production efficiency and unstable cutting of production line, achieve good stability, improve adaptability, and expand utilization range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

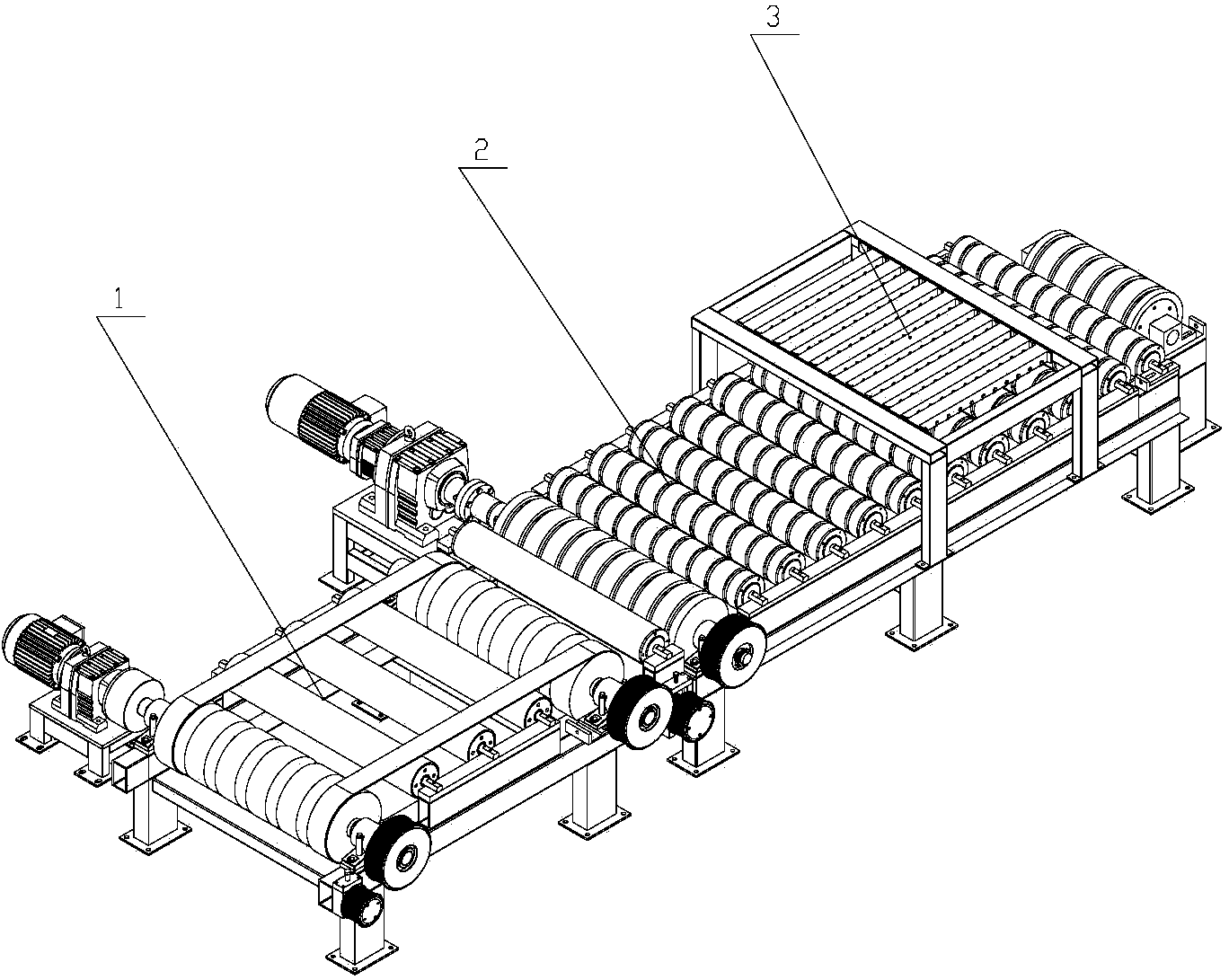

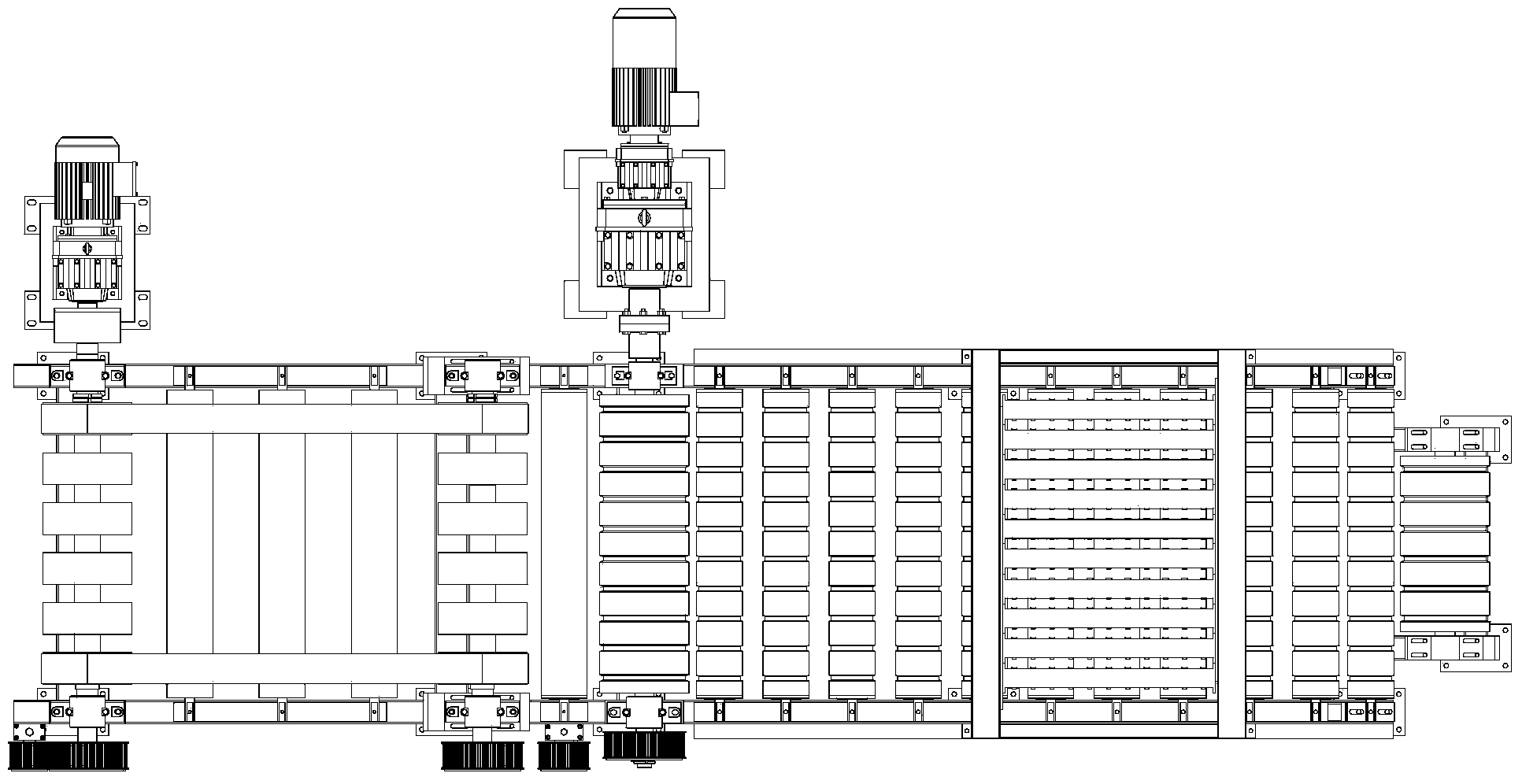

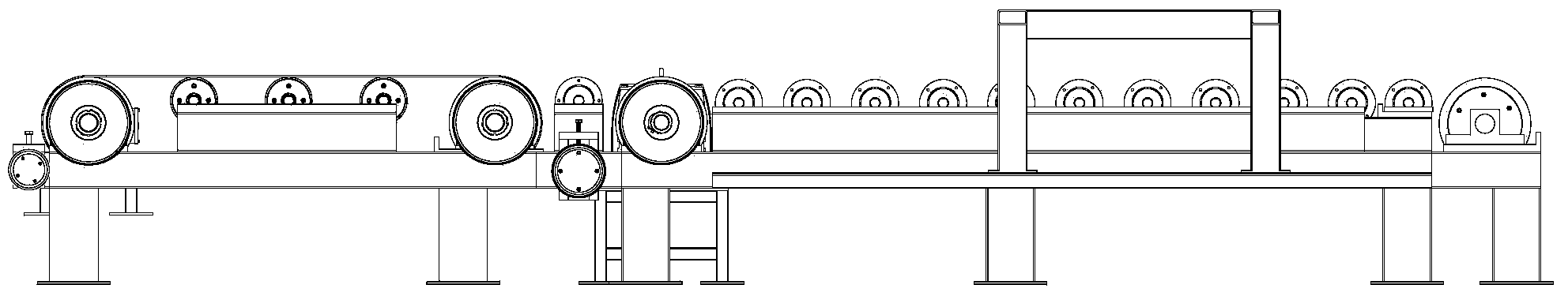

[0030] Embodiment 1 A block cutting feeding conveyor according to the present invention includes a conveying mechanism 1, a feeding mechanism 2 and a pressing mechanism 3, and the end of the conveying mechanism 1 is fixed to the front end of the feeding mechanism 2; The pressing mechanism 3 is installed above the feeding mechanism 2; the conveying mechanism 1 includes a conveying mechanism frame 11, a conveying motor fixing frame 12, a reduction motor 13, a first roller 14, a first synchronous belt Wheel 15, the deceleration motor 13 is installed on the conveying motor fixed frame 12; the first roller 111 and the second roller 112 parallel to each other are respectively installed on the bearings at the two ends of the conveying mechanism frame 11, the first The same end of the roller 111 and the second roller 112 is equipped with a first synchronous pulley 113 respectively, wherein the other end of the first roller 111 is connected with the output shaft of the reduction motor 1...

Embodiment 2

[0042] Embodiment 2 Combined with the figure, the present invention includes a set of feeding mechanism, which is powered by a motor and connected with the driving roller through a coupling, and the driving roller is cut with a V-belt groove, so that the V-belt can be installed and can ensure that the V-belt is in motion. The V-belt bypasses the first tensioning roller and the second tensioning roller respectively, while the first tensioning roller is fixed on the slide plate and is slidably connected with the fixed plate. When the bolt is rotated, the slide plate is driven to drive the second The tensioning roller moves to play the role of tensioning; the second tensioning roller is fixed on the supporting seat, and the supporting seat is slidingly connected with the fixed plate. When the bolt is rotated, the supporting seat is pulled and the second tensioning roller is driven to move. So as to play the role of tension; the first tension roller is installed on the frame of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com