Patents

Literature

45results about How to "Avoid tooth skipping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

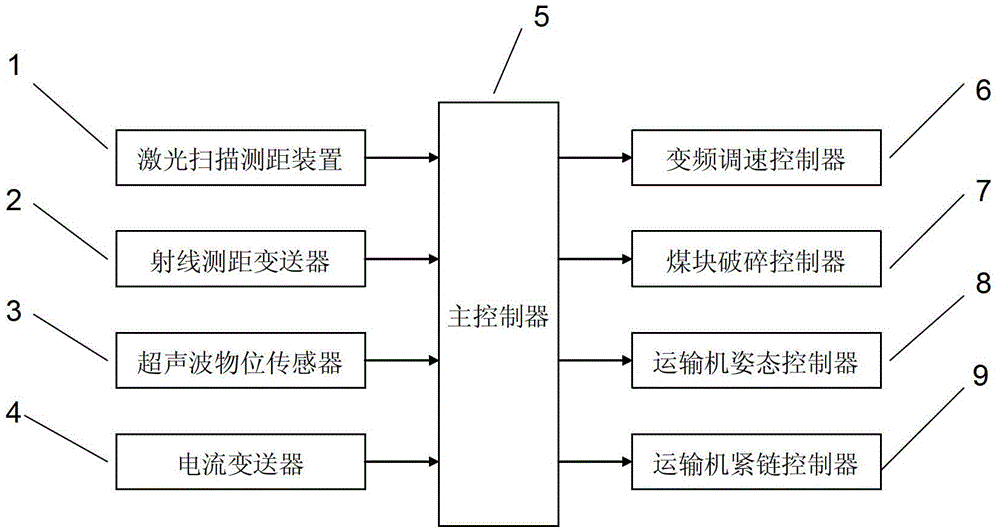

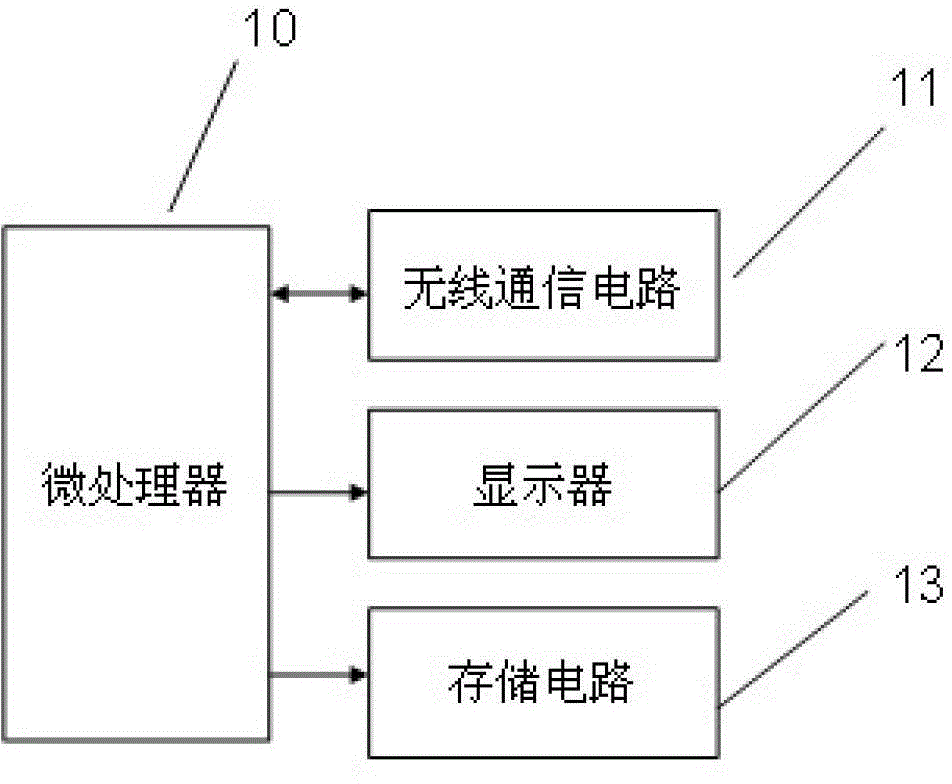

Intelligent control system and control method for scraper conveyer

InactiveCN103144936AAdjust posture in timeAvoid tooth skippingControl devices for conveyorsCurrent transducerAttitude control

The invention provides an intelligent control system and a control method for a scraper conveyer, which belong to the intelligent control systems for coal mine exploitation. The intelligent control system for the scraper conveyer comprises a laser scanning ranging device, a ray ranging transmitter, an ultrasonic level sensor, a current transducer, a master controller, a variable frequency and speed regulation controller, a coal crushing controller, a conveyor gesture controller and a conveyor chain stretching controller, wherein the laser scanning ranging device, the ray ranging transmitter, the ultrasonic level sensor and the current transducer transmit detection signals to the master controller in a wireless communication manner, and the master controller sends control instructions to the variable frequency and speed regulation controller, the coal crushing controller, the conveyor gesture controller and the conveyor chain stretching controller in the wireless communication manner. The running state of the scraper conveyer is mastered at any time and corresponding devices are controlled timely through monitoring of the laser scanning ranging device, the ray ranging transmitter, the ultrasonic level sensor and the current transducer, so that the scraper conveyer can be operated in an optimum running state.

Owner:CHINA UNIV OF MINING & TECH

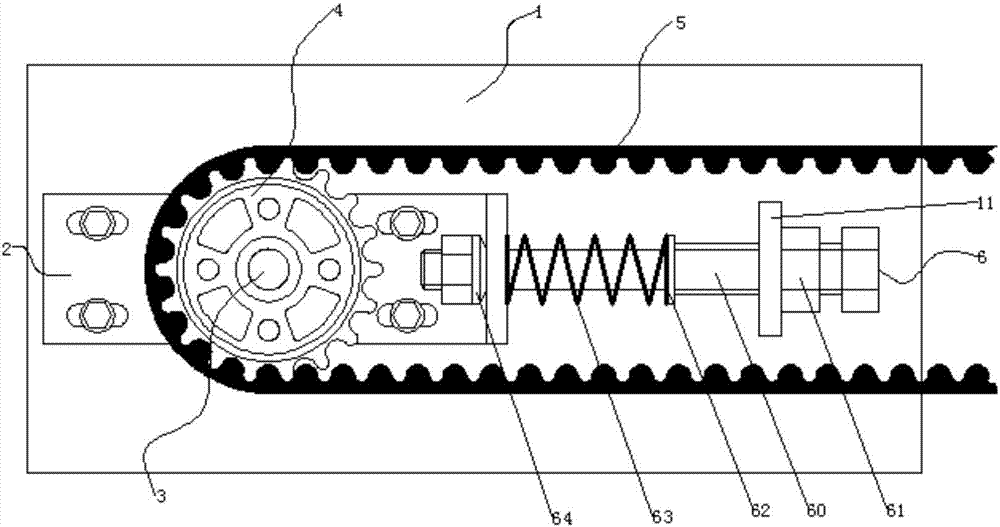

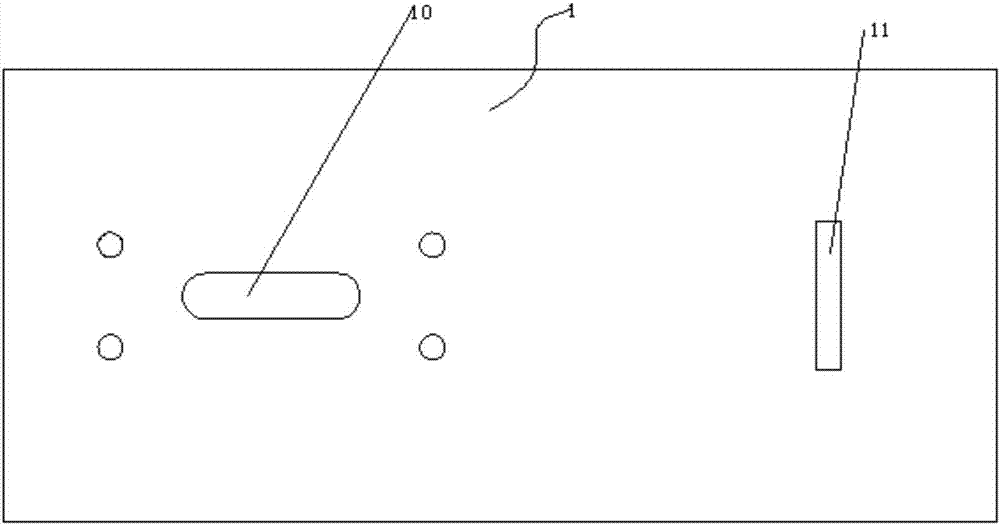

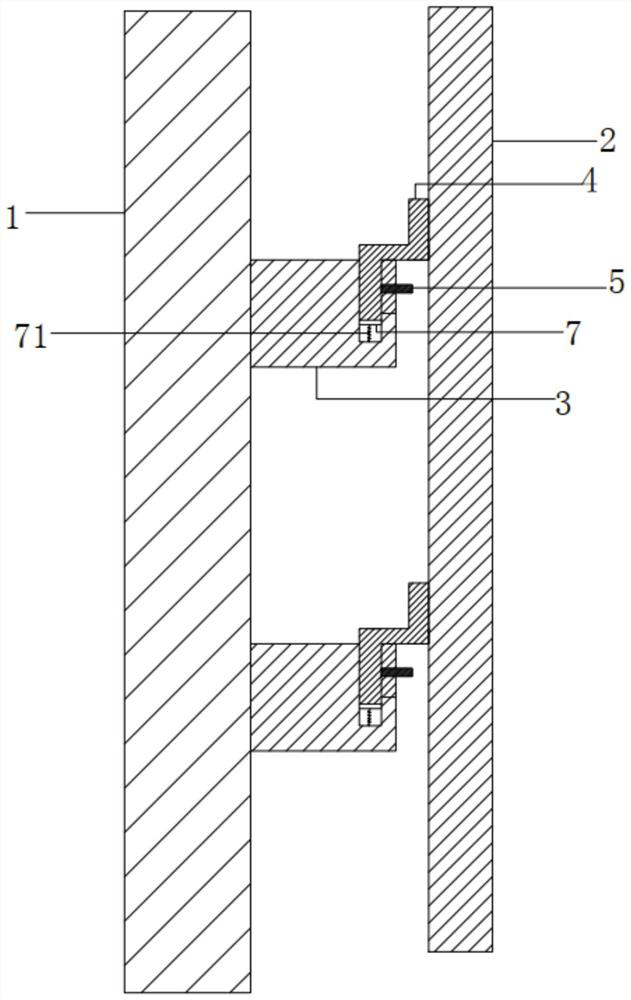

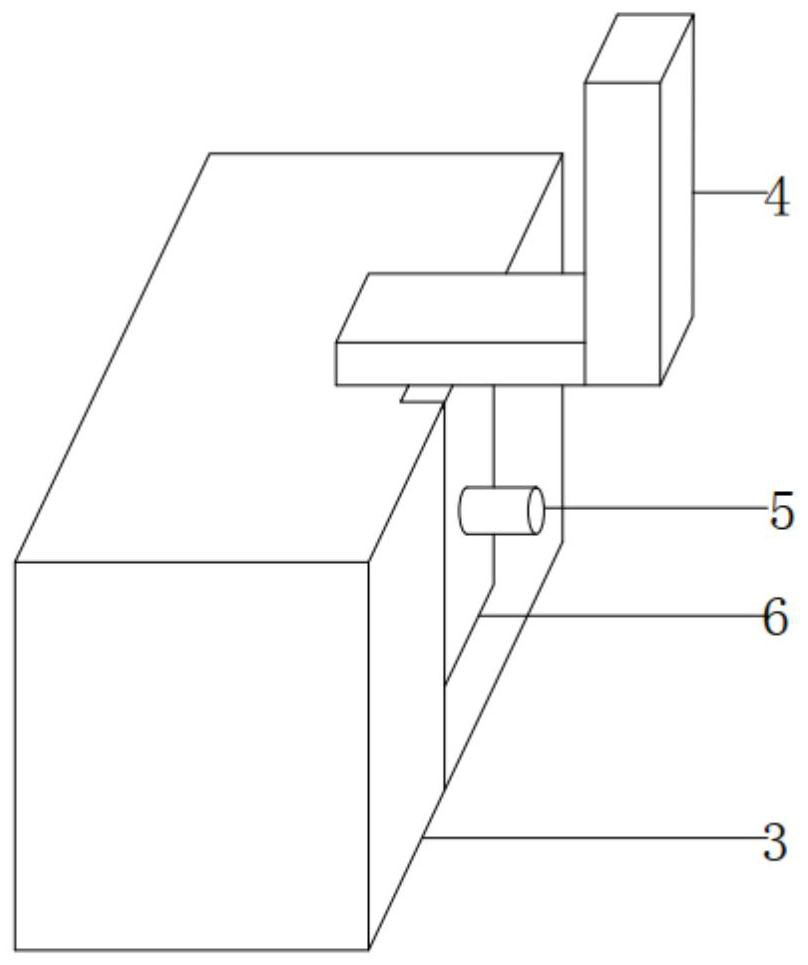

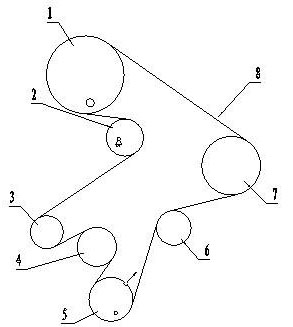

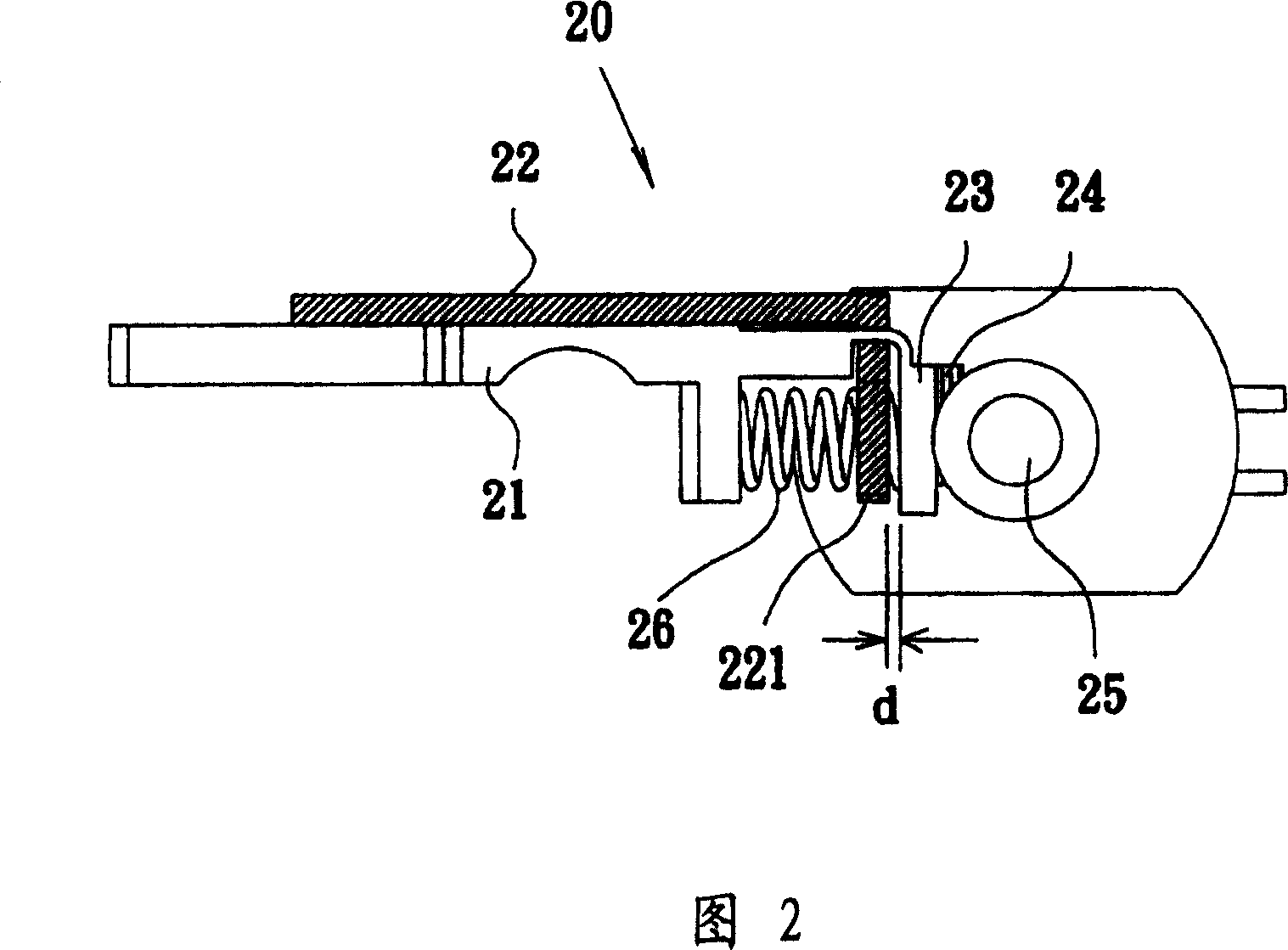

Synchronous belt anti-vibration tensioning device

PendingCN107202137AFirmly connectedAvoid mechanical interferenceGearingStructural engineeringMachine

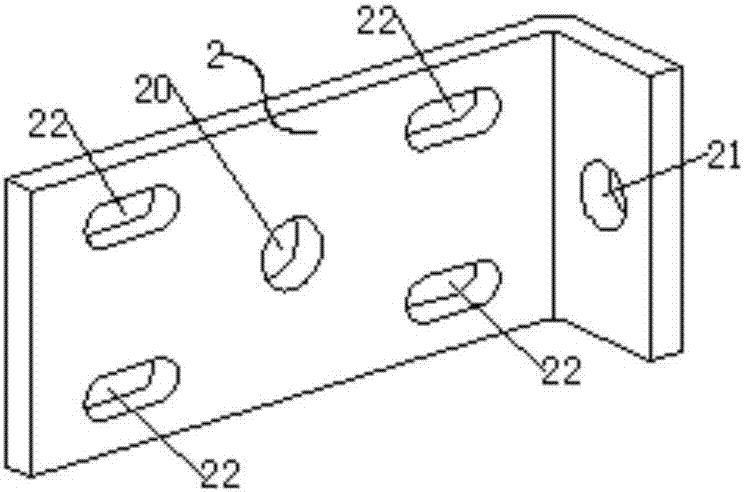

The invention discloses a synchronous belt anti-vibration tensioning device. The synchronous belt anti-vibration tensioning device comprises a machine base plate, an adjusting plate, a drive rotating shaft, a synchronous belt wheel, a synchronous belt and an adjusting structure; a first long groove hole and an adjusting fixing plate are arranged on the machine base plate, a shaft hole is formed in the middle of the adjusting plate, an adjusting hole is formed in the adjusting plate, four second long groove holes are formed in the adjusting plate, the adjusting plate and the machine base plate are connected in a manner that bolts penetrate the second long groove holes, the position of the shaft hole corresponds to the position of the first long groove hole in the machine base plate, the drive rotating shaft penetrates the first long groove hole and the shaft hole to be connected with the synchronous belt wheel, the synchronous belt is connected with the synchronous belt wheel, and the adjusting structure is composed of a bolt part, a first tightening nut, a blocking piece, a spring, a membrane spring and a second tightening nut. According to the technical scheme, wear of the synchronous belt is reduced, tensioning reliability and mechanical vibration resistance performance are ensured, and the phenomenon that tooth jumping appears in the synchronous belt is avoided.

Owner:王萌

Film combining machine

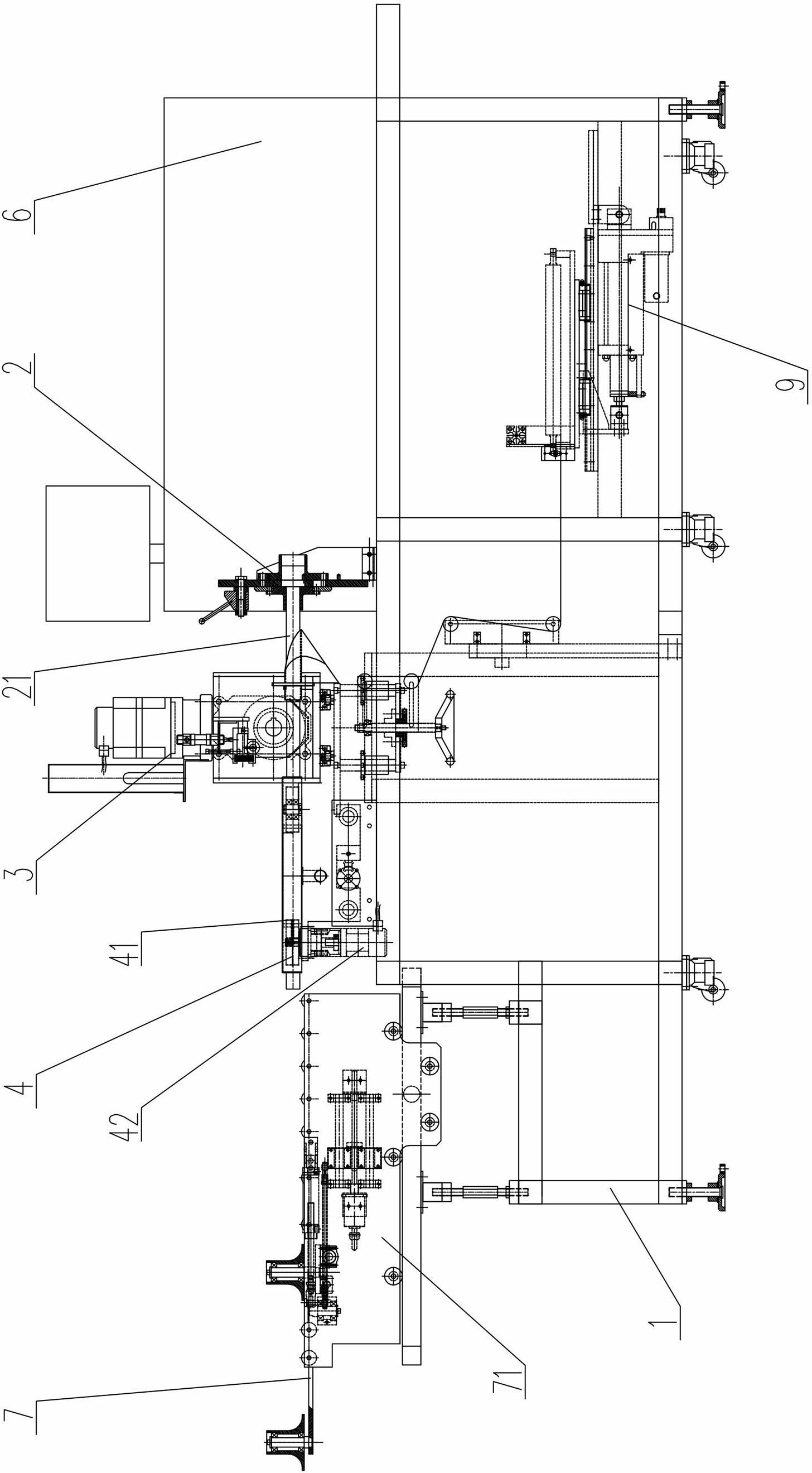

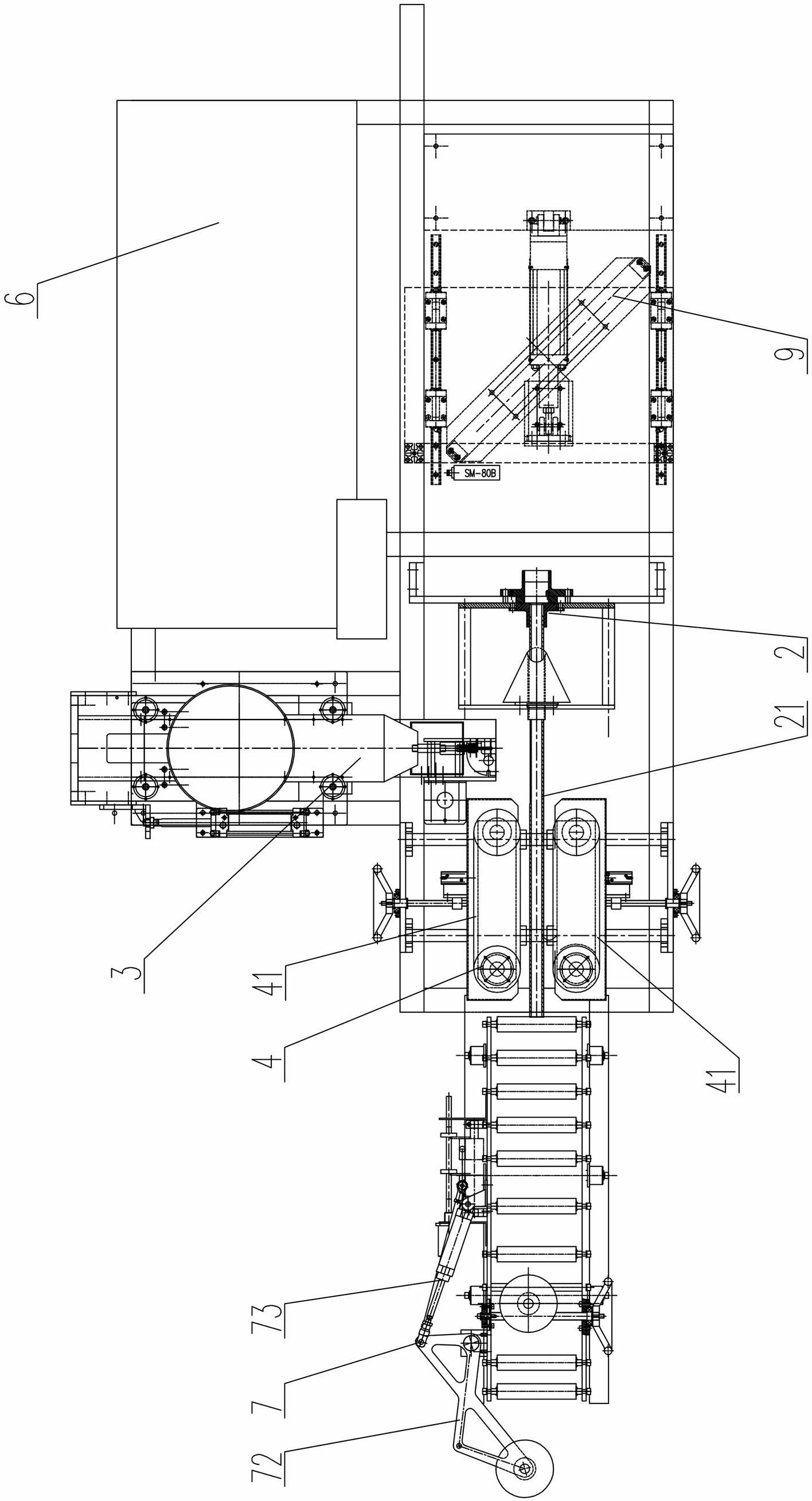

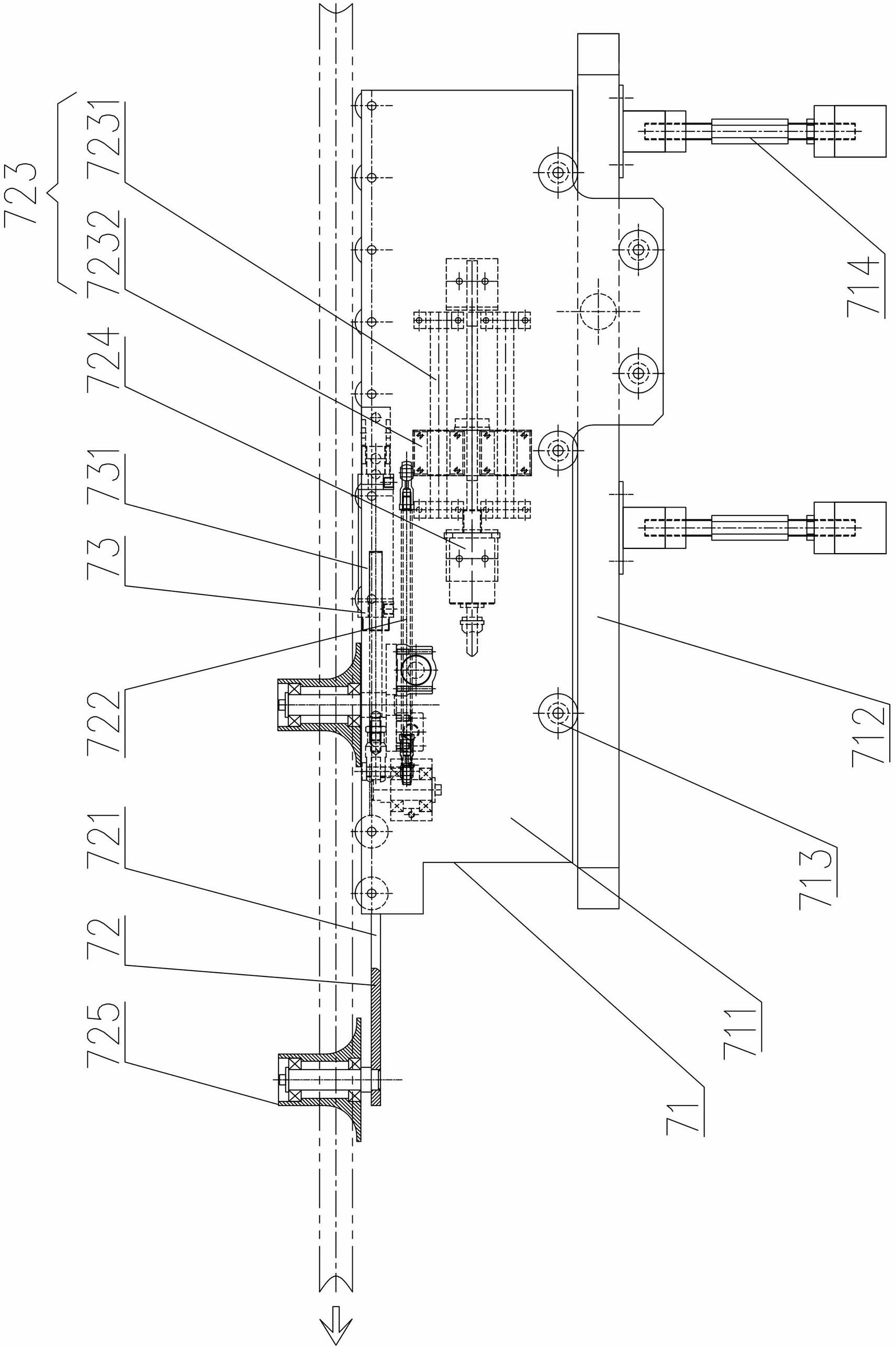

ActiveCN102424153ASimple structureSimple actionWrapping material feeding apparatusWrapper twisting/gatheringEngineeringElectric control

The invention discloses a film combining machine, which comprises a forming device, a glue coating device, a material driving device, an electric control device and a speed synchronization device, wherein the forming device, the glue coating device, the material driving device, the electric control device and the speed synchronization device are arranged on a machine frame, the glue coating device comprises a glue outlet mechanism and a glue extruding mechanism for supplying glue to the glue outlet mechanism, the glue outlet mechanism is directly connected with a glue outlet of the glue extruding mechanism, and the glue extruding mechanism is arranged on a horizontal driving mechanism so that the glue outlet mechanism only moves in the horizontal direction for coating the glue. The film combining machine has the advantages that the structure is simple, the cost is low, the reliability and the harmony are high, the installation and the debugging are convenient, the production capacity and the production efficiency are greatly improved, and the like.

Owner:HUNAN KENON AUTOMATIC EQUIP

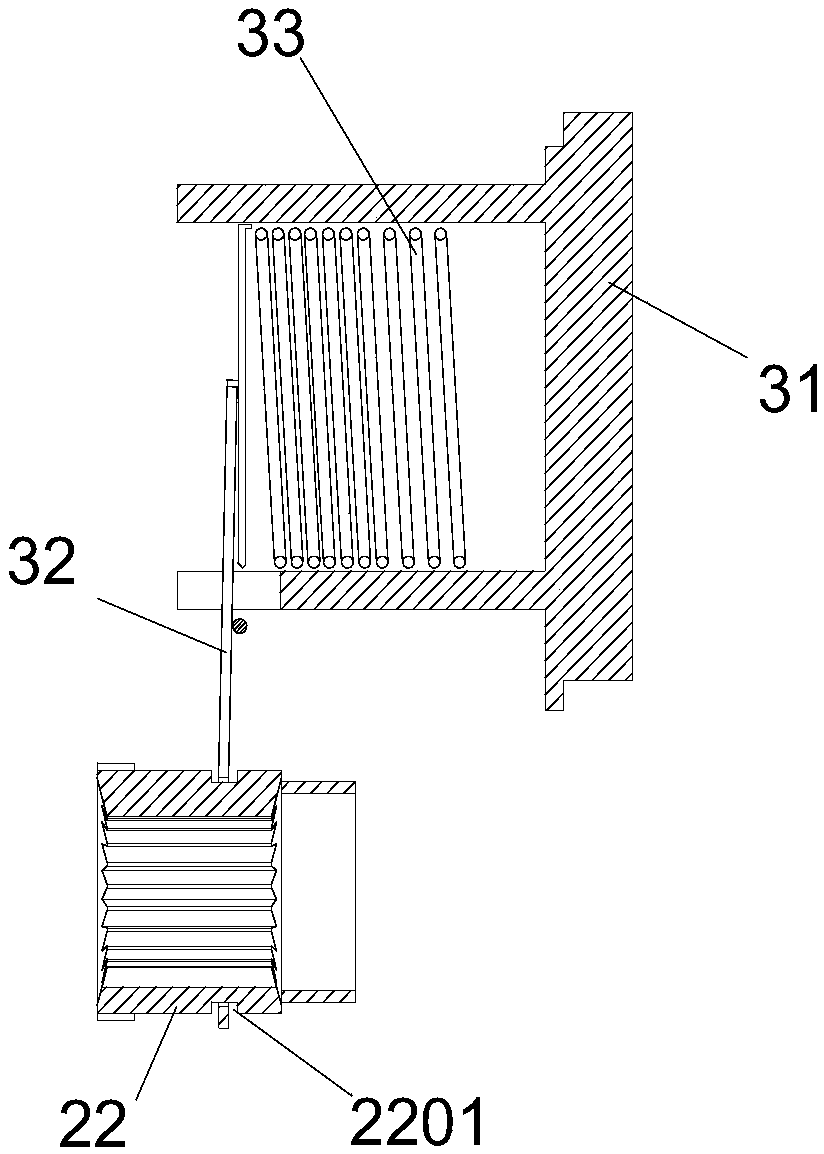

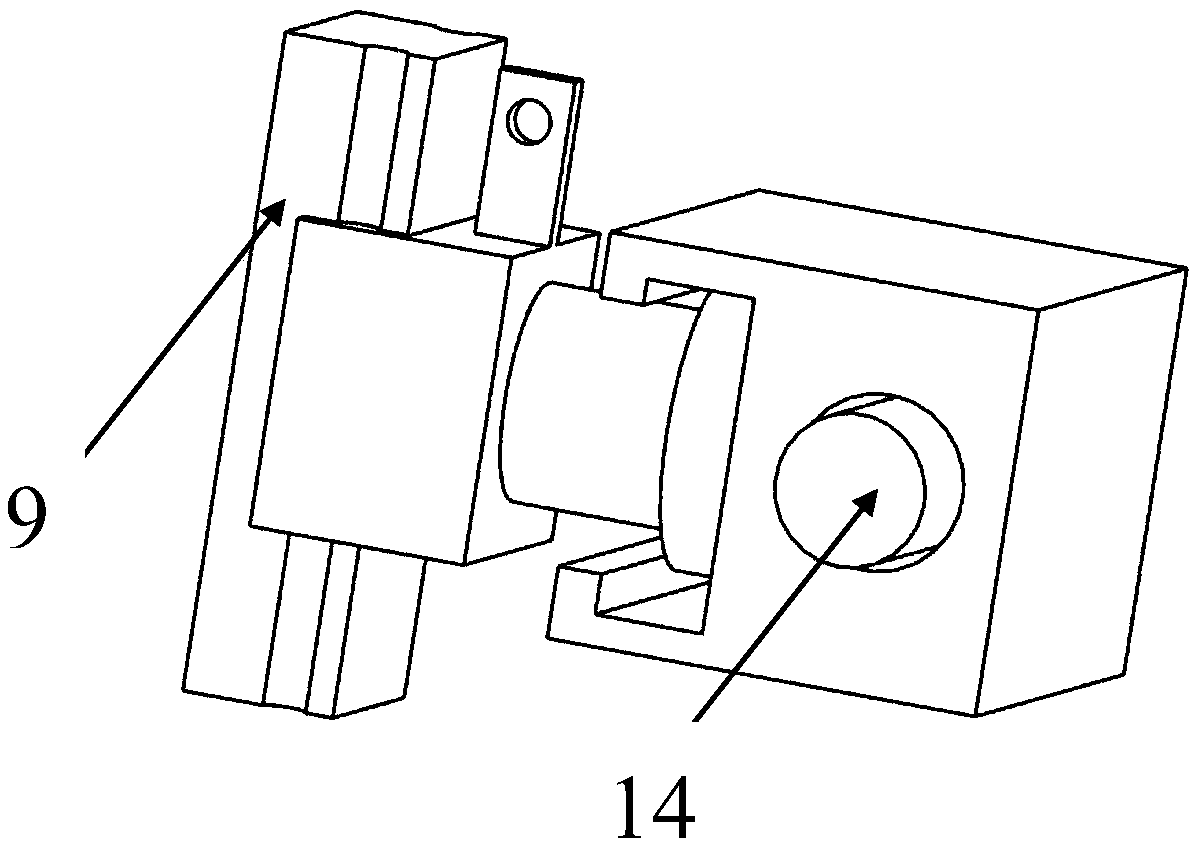

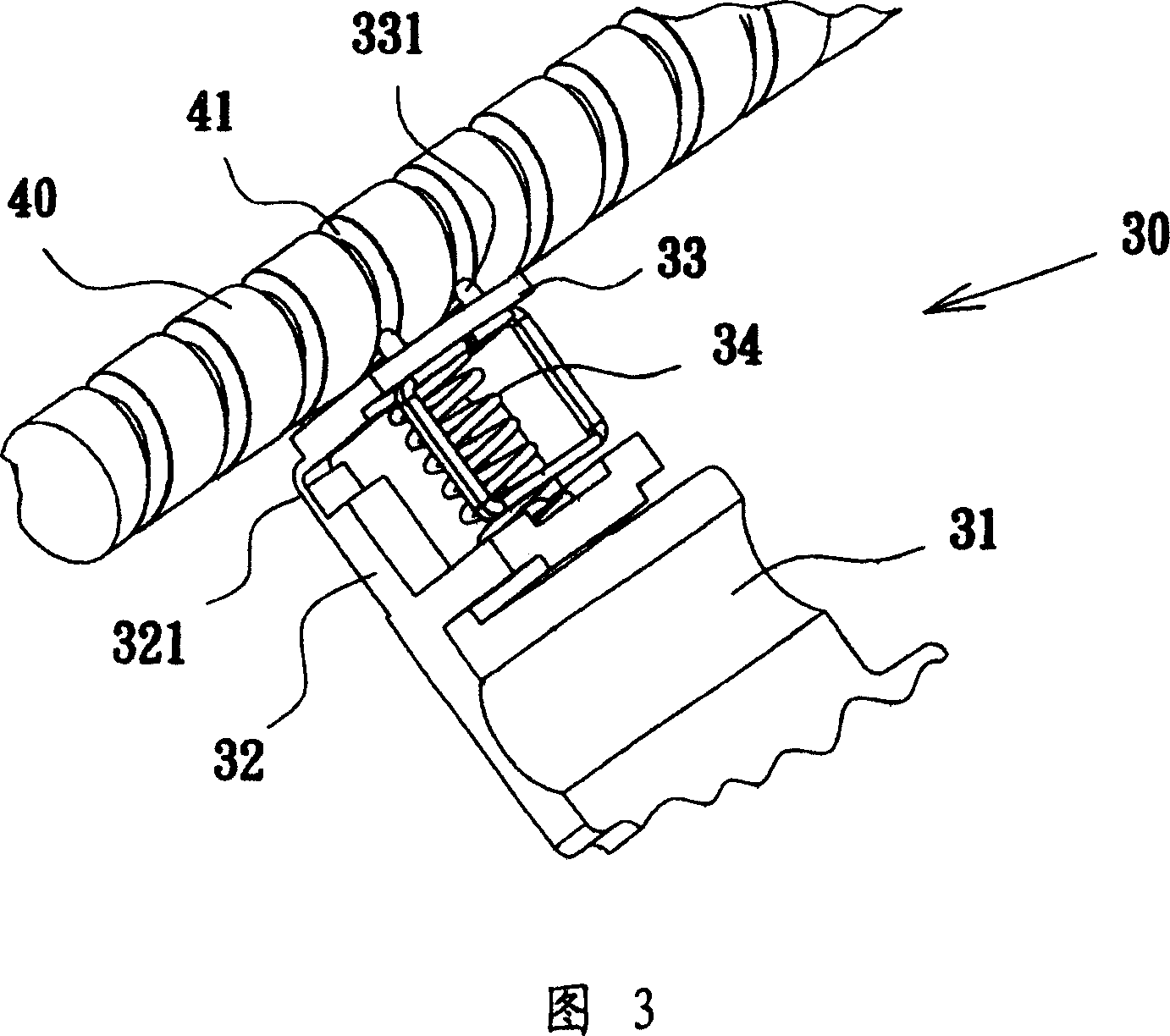

Variable stiffness tension device and working mode thereof

InactiveCN104742994APlay a buffer roleAvoid wear and tearEndless track vehiclesVariable stiffnessEngineering

The invention discloses a variable stiffness tension device. The variable stiffness tension device comprises a piston rod, a support seat, a small stiffness spring, a small locking nut, a sleeve, a locating plate, a large stiffness spring and a large locking nut, wherein the piston rod penetrates through one end of a cylinder barrel in a telescopic mode, the support seat penetrates through the other end of the cylinder barrel in a telescopic mode, the small stiffness spring is arranged on the outer side end surface of the cylinder barrel in a sleeving mode, the small locking nut is connected with the support seat, the sleeve is arranged on the outer side end surface of the small stiffness spring in a sleeving mode, the locating plate is fixedly arranged at the end of the sleeve in a sleeving mode, the large stiffness spring is arranged on the outer side end surface of the sleeve in a sleeving mode, and the large locking nut is connected with the locating plate. By using the variable stiffness tension device, when the borne load is smaller, the external force is transferred to the piston rod, the piston rod transfers the force to the support seat and the small stiffness spring, and the small stiffness spring plays a buffer role; when the borne load is gradually increased, the support seat makes contact with the locating plate, the locating plate transfers the load to the large stiffness spring, and the large stiffness spring and the small stiffness spring jointly bear the load.

Owner:SANY HEAVY MACHINERY

Mounting design structure of assembled three-dimensional carved slope modeling background wall

Owner:GOLD MANTIS FINE DECORATION TECH SUZHOU CO LTD

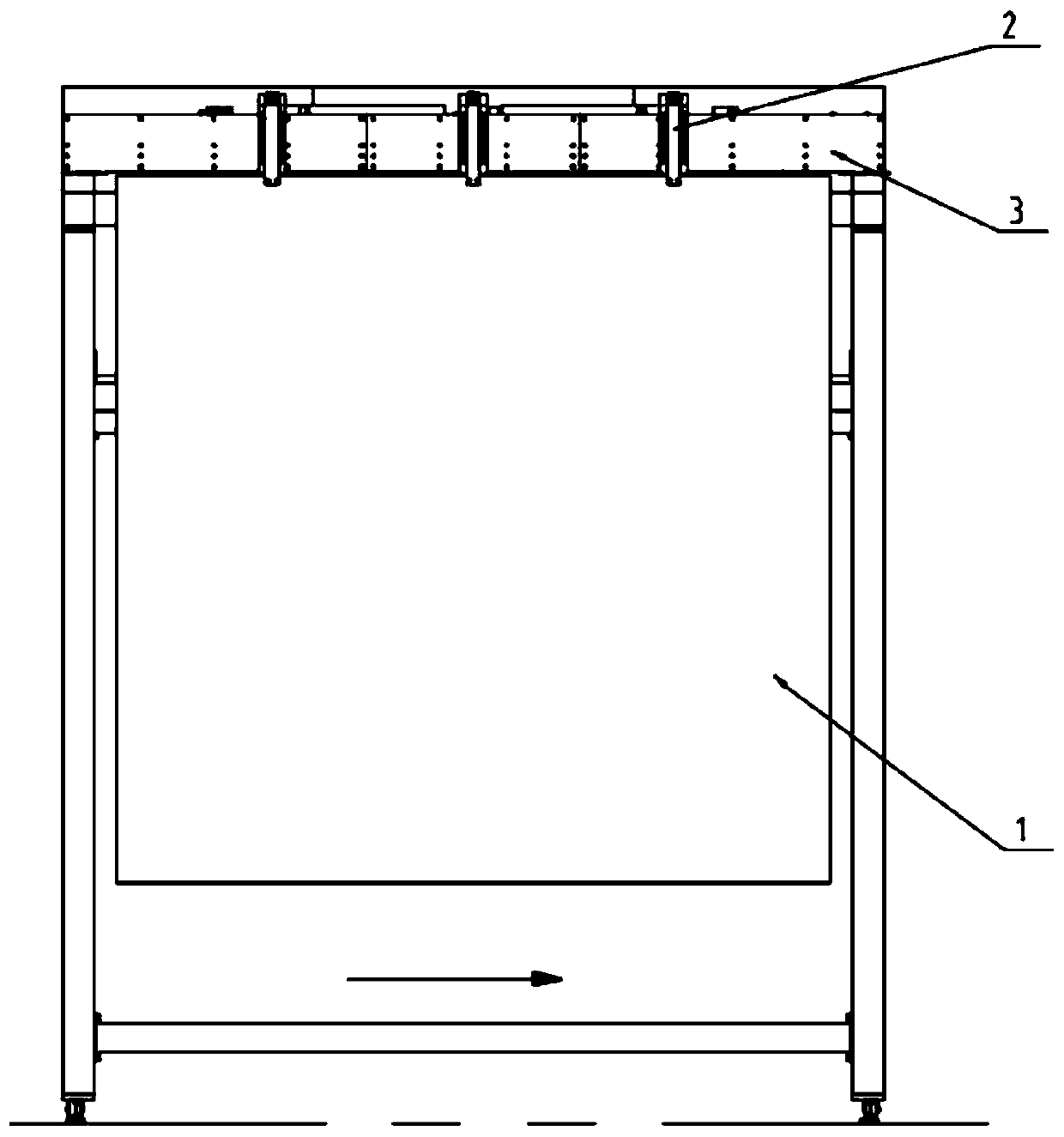

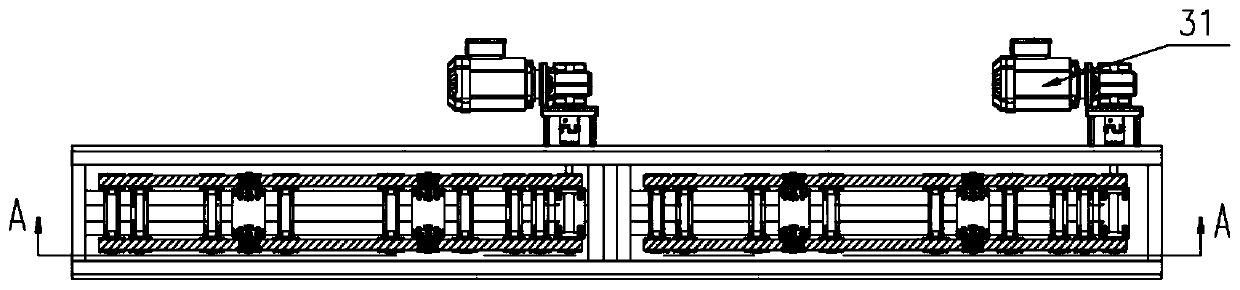

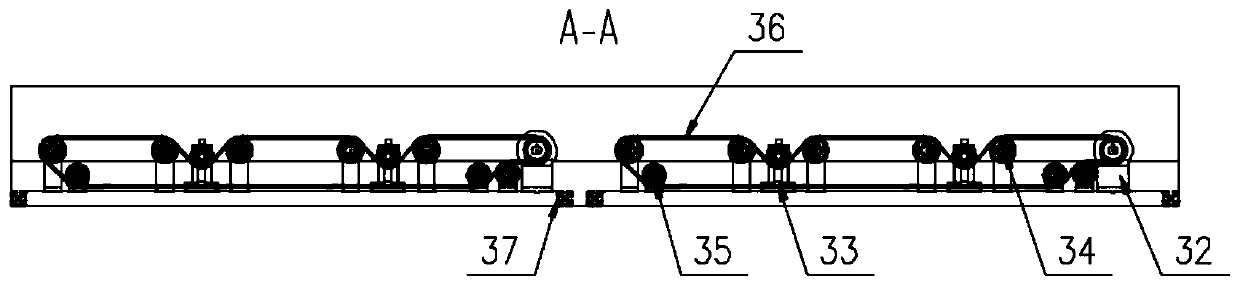

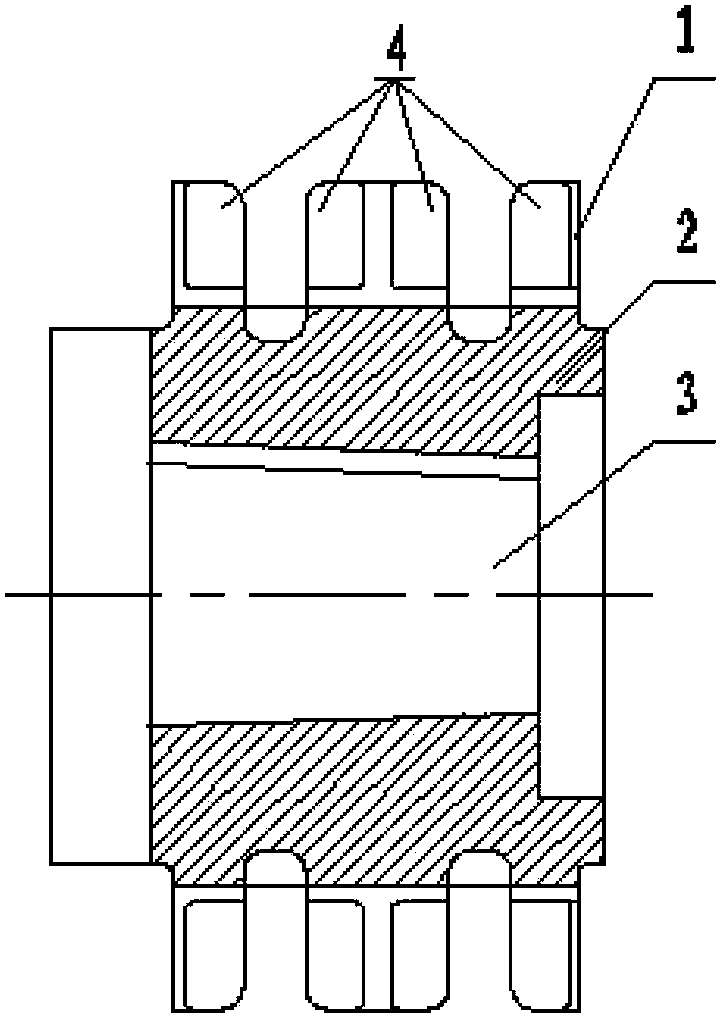

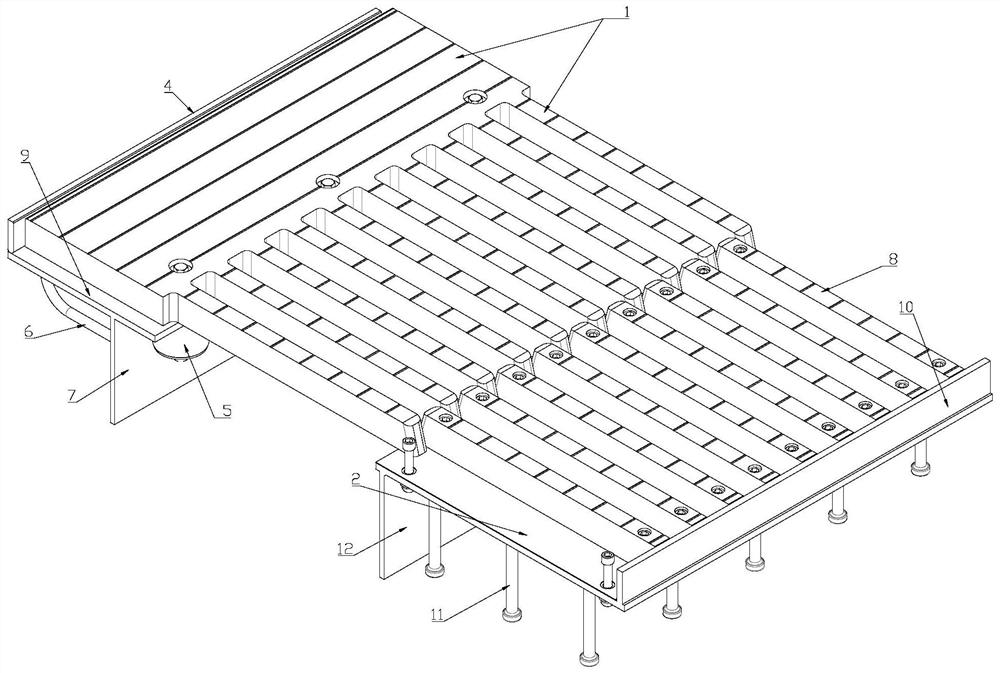

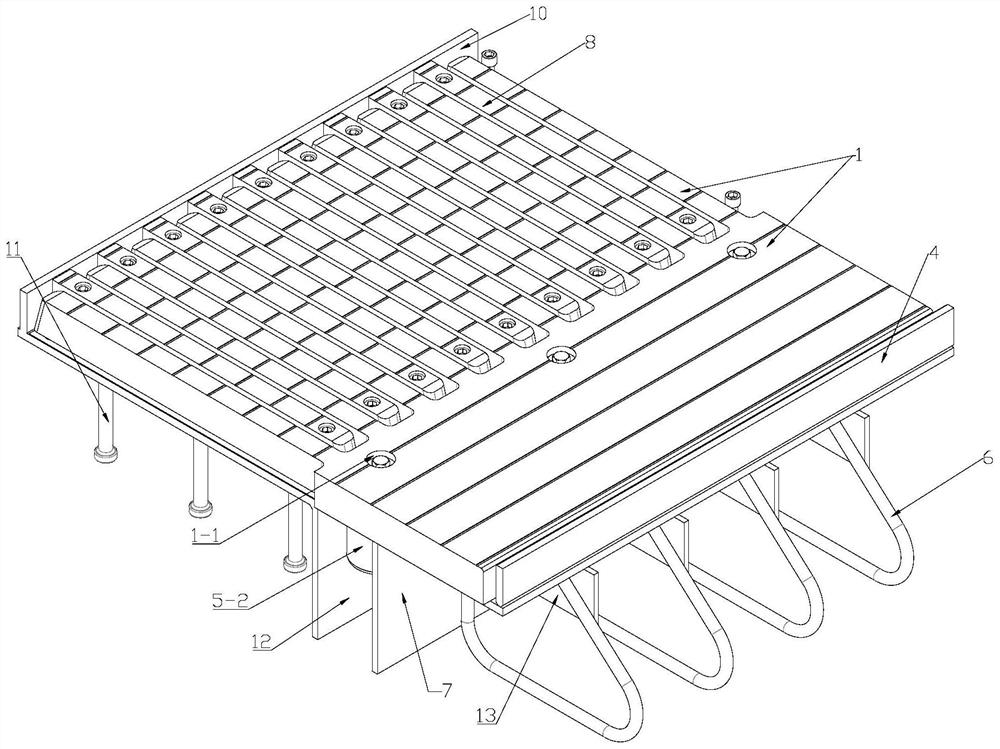

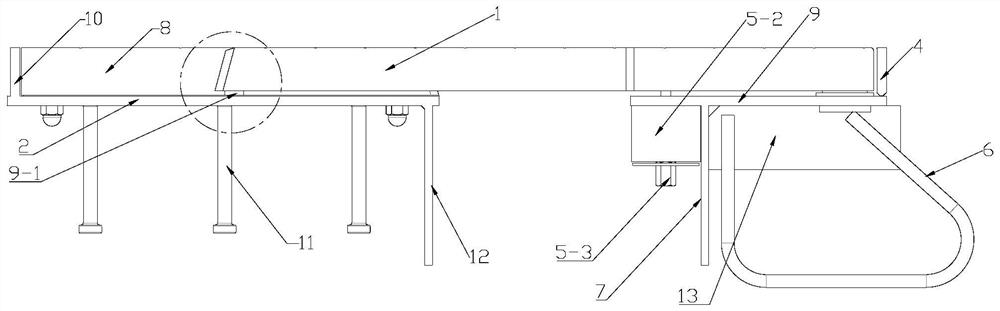

Synchronous belt conveying structure for glass tooling plate trolley handling

PendingCN111017491AImprove stabilityIncrease the number of meshing teethConveyorsCharge manipulationDrive shaftEngineering

The invention discloses a synchronous belt conveying structure for glass tooling plate trolley handling. The synchronous belt conveying structure comprises conveying line bodies. Each conveying line body comprises a driving shaft assembly, tensioning assemblies, upper idler assemblies, lower idler assemblies and a synchronous belt, wherein the driving shaft assembly, the tensioning assemblies, theupper idler assemblies and the lower idler assemblies are connected in series through the synchronous belt. The tensioning assemblies from top to bottom are mounted at intervals of a certain distance, the number of teeth, engaged with idlers, on the conveying side on each synchronous belt is increased, thus the slippage phenomenon caused by asynchronous rotation of the synchronous belts and the idlers during fast starting and stopping is avoided, and the conveying stability of tooling plate trolleys is improved; by improving the structures of the driving shaft assemblies and the idler assemblies, assembling, disassembling and maintenance of the synchronous belts are more convenient and faster, the tensioning assemblies only need to be loosened, driving shafts are disassembled, then the synchronous belts can be drawn out from gaps between the idlers and profiles, assembling and disassembling of more structures are not needed, and the manpower cost and the time cost of maintenance of the synchronous belts are reduced; and vibration noise of original chain transmission is avoided.

Owner:NANJING PANDA ELECTRONICS +1

Method for adjusting tensioning wheel indicator of timing system of engine

ActiveCN102494091AAvoid tooth skippingPrevent looseningValve arrangementsGearingEngineeringTiming system

The invention relates to a method for adjusting a tensioning wheel indicator of a timing system of an engine, which is used for solving the problems that the tensioning wheel indicator is easily unjammed and a tensioning force becomes small by adopting a traditional method for adjusting the tensioning wheel indicator of the timing system of the engine. According to the method, the best initial position for adjusting the tensioning wheel indicator is found out through a sampling test, and then, the position of the tensioning wheel indicator of the timing system is adjusted according to the actual indicator adjustment range found out by the sampling test, thereby, a mesh clearance between an engine wheel set and a belt is offset, so that the indicator is unjammed to a nominal range after the engine normally wears in and is cooled. By adopting the method, the adjustment position of the tensioning wheel indicator of the timing system can be accurately determined, thereby, the tensioning wheel indicator of the timing system is prevented from being unjammed, and the engine is prevented from generating a slippage phenomenon.

Owner:长城汽车股份有限公司平湖分公司

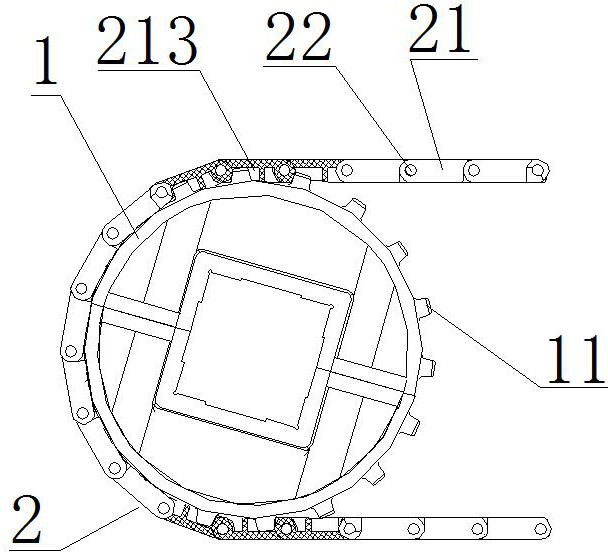

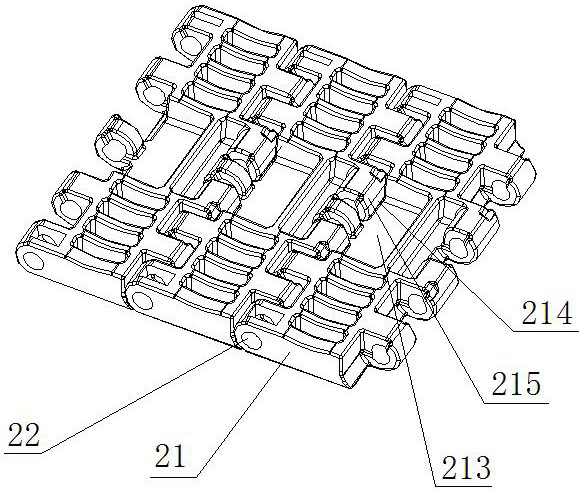

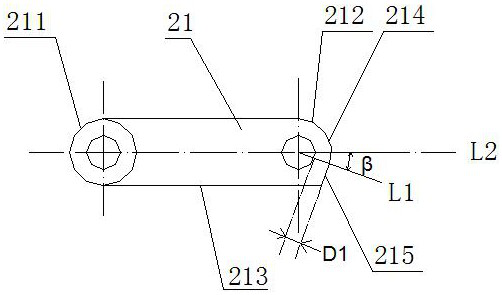

Net chain conveying system suitable for whole vehicle conveying and corrugated paper logistics conveying

The invention relates to a net chain conveying system suitable for whole vehicle conveying and corrugated paper logistics conveying, and belongs to the technical field of conveying equipment. A planefor meshing with teeth of driving sprockets is arranged on lugs of chain links, and is kept paralelly attached to the tooth surfaces of the gear teeth in the meshing driving process. By means of the surface-to-surface abutting, meshing between the plane and the teeth is constantly surface contact, and line contact in the prior art is changed fundamentally. Therefore, the design can effectively prevent tooth skipping, and avoid fluctuation of the conveying surface of a conveying network chain in the conveying process, so that the conveying effect is effectively improved, and the service life ofthe whole system is also prolonged.

Owner:吴翔

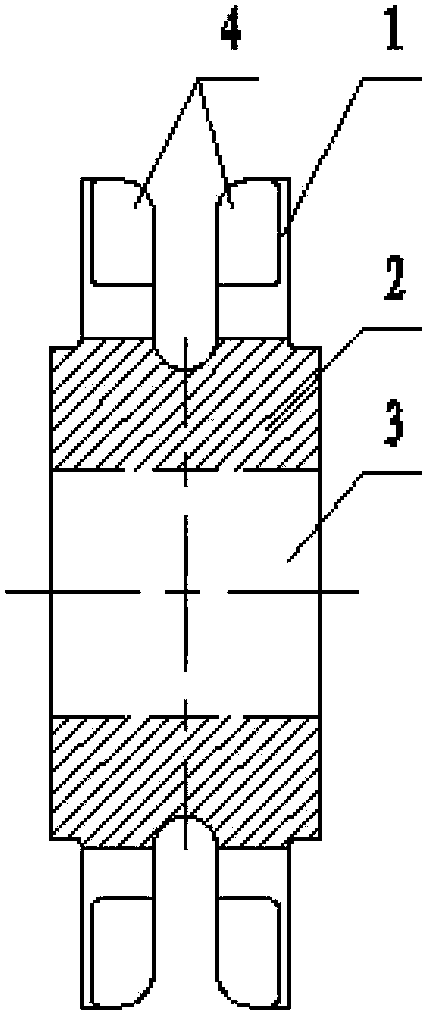

Sprocket with function of preventing tooth slipping

InactiveCN103453112APrevent slippageImprove fitPortable liftingGearing elementsSprocketFront and back ends

The invention relates to a sprocket with a function of preventing tooth slipping. The sprocket comprises a wheel provided with a shaft hole in the axial center. The outer surface of the wheel is provided with a plurality of circles of chain teeth at intervals. Both the front and rear ends of each chain tooth are provided with antislip grooves. The sprocket is reasonable in design, simple in structure, easy to produce, convenient to use and highly practical; tooth slipping can be avoided in use of the sprocket; normal operation of a chain is guaranteed; dangerous accidents are prevented; safety of a user is ensured; the sprocket is especially suitable for pulling a hatch of a vessel.

Owner:TIANJIN BAO HONGYUAN MACHINERY MFG

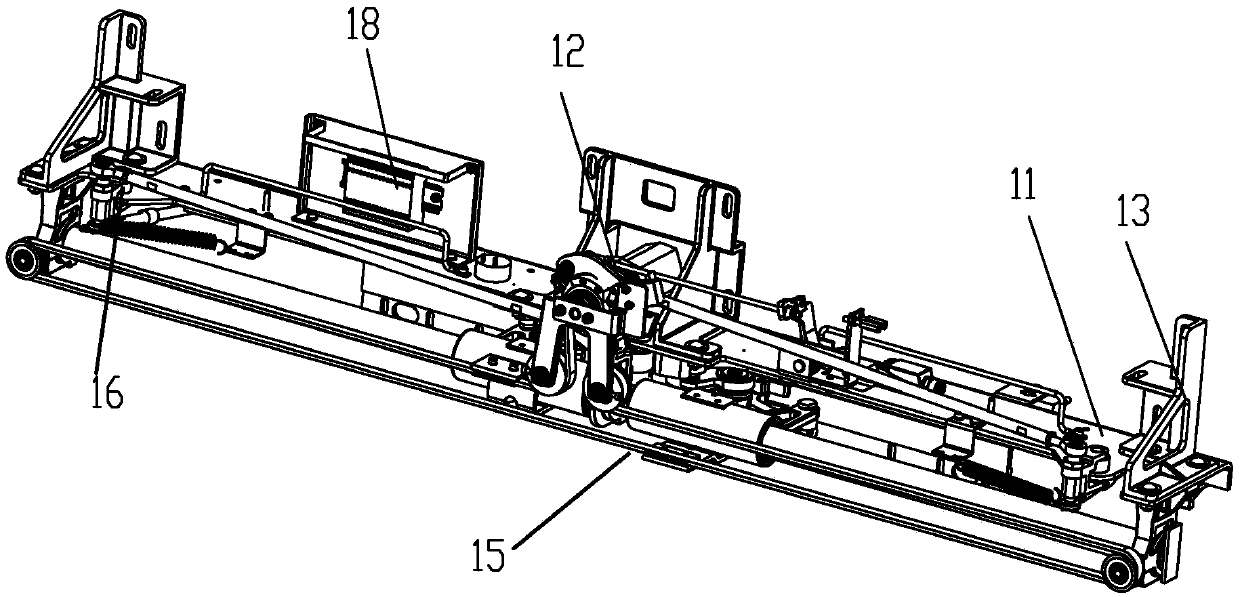

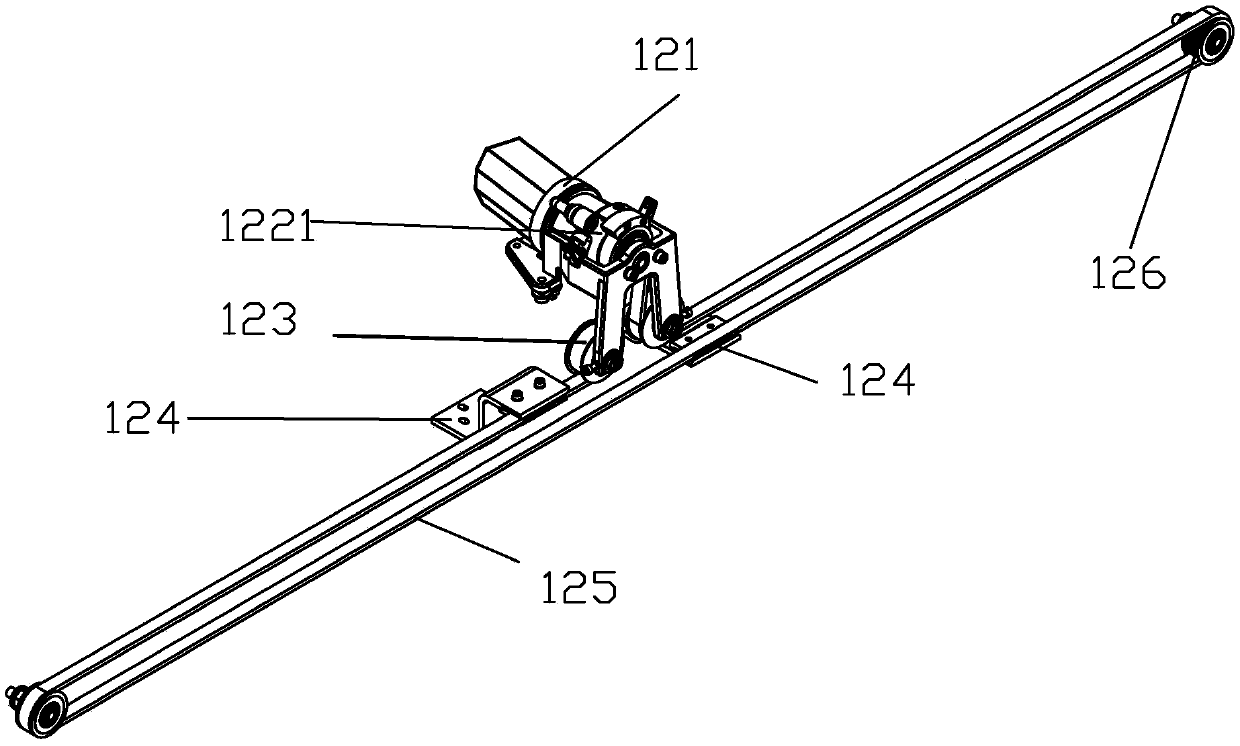

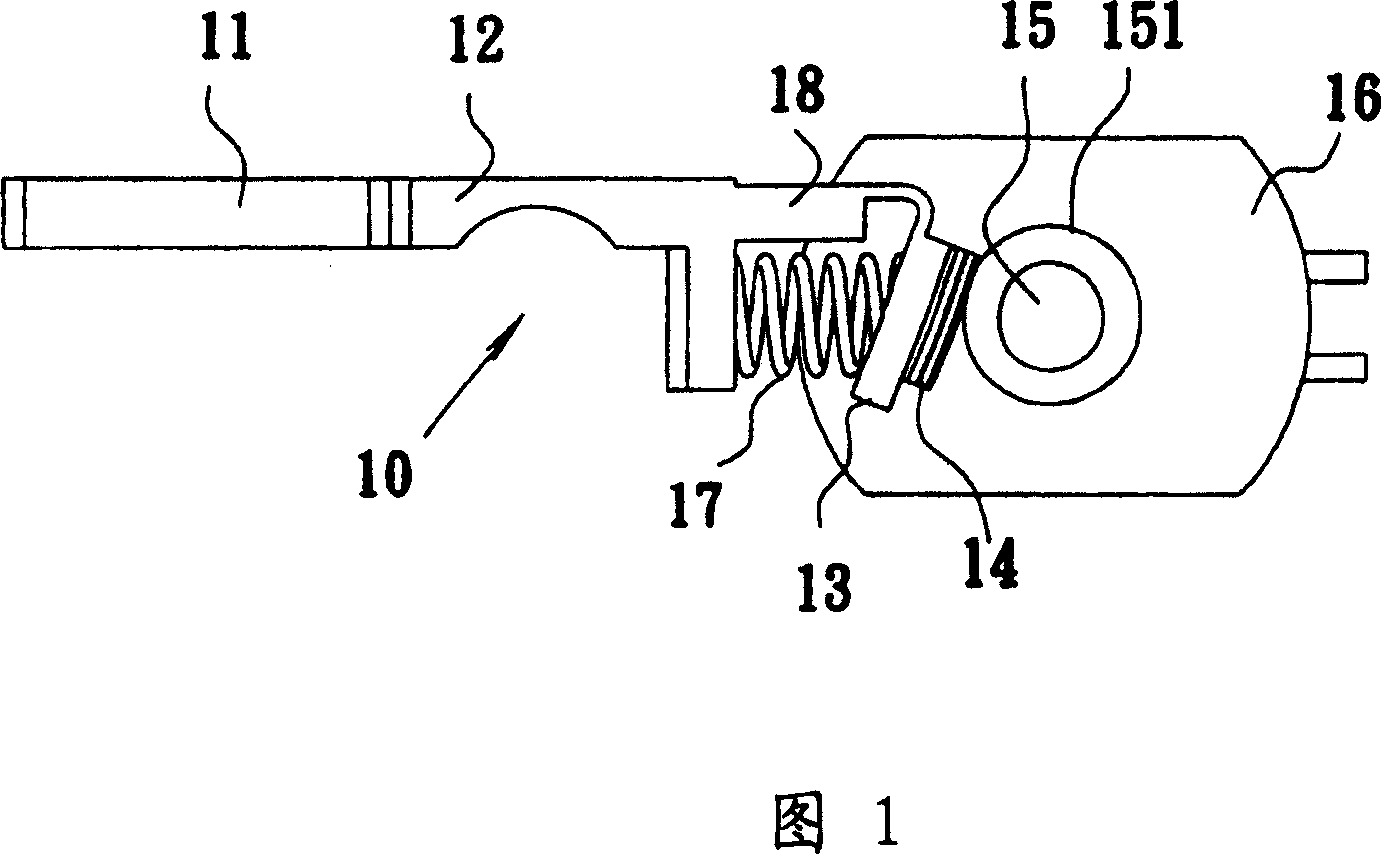

Sliding plug door transmission device

PendingCN110552581AImprove stabilityConsistent transmission forceGearingPower-operated mechanismClosed loopDrive motor

The invention relates to a sliding plug door transmission device. The device comprises a driving motor, a motor support, two belt pulleys and two belt clamping plates; the driving motor is arranged inthe middle position, and a swinging disc and a motor tooth-shaped belt pulley are arranged at the front end of the driving motor, wherein the swinging disc is connected with a stator of the driving motor, and the motor tooth-shaped belt pulley is connected with an output shaft of the driving motor; the motor support is used for supporting the driving motor, and two reversing wheels are symmetrically arranged on the left side and the right side of the front lower end of the motor support and are used for performing tensioning and reversing on belt transmission; the two belt pulleys are symmetrically arranged on the two sides of the reversing wheels, and a belt is arranged on the belt pulleys and the motor tooth-shaped belt pulley of the driving motor in a closed-loop surrounding mode; andthe two belt clamping plates used for outputting rectilinear motion are arranged on the belt in a skew symmetry mode along the two sides of the driving motor. According to the sliding plug door transmission device, the driving motor is arranged, the belt pulleys are symmetrically arranged on the two sides of the driving motor, the belt is arranged between the belt pulleys and the driving motor ina closed-loop surrounding mode, and the belt clamping plates are arranged on the belt, so that the transmission power output by the belt clamping plates is ensured, and the identity, the harmony and the synchronism are provided; and the motor support with an ingenious structure is arranged, so that the installation stability of the motor is improved.

Owner:北京天乐泰力科技发展有限公司

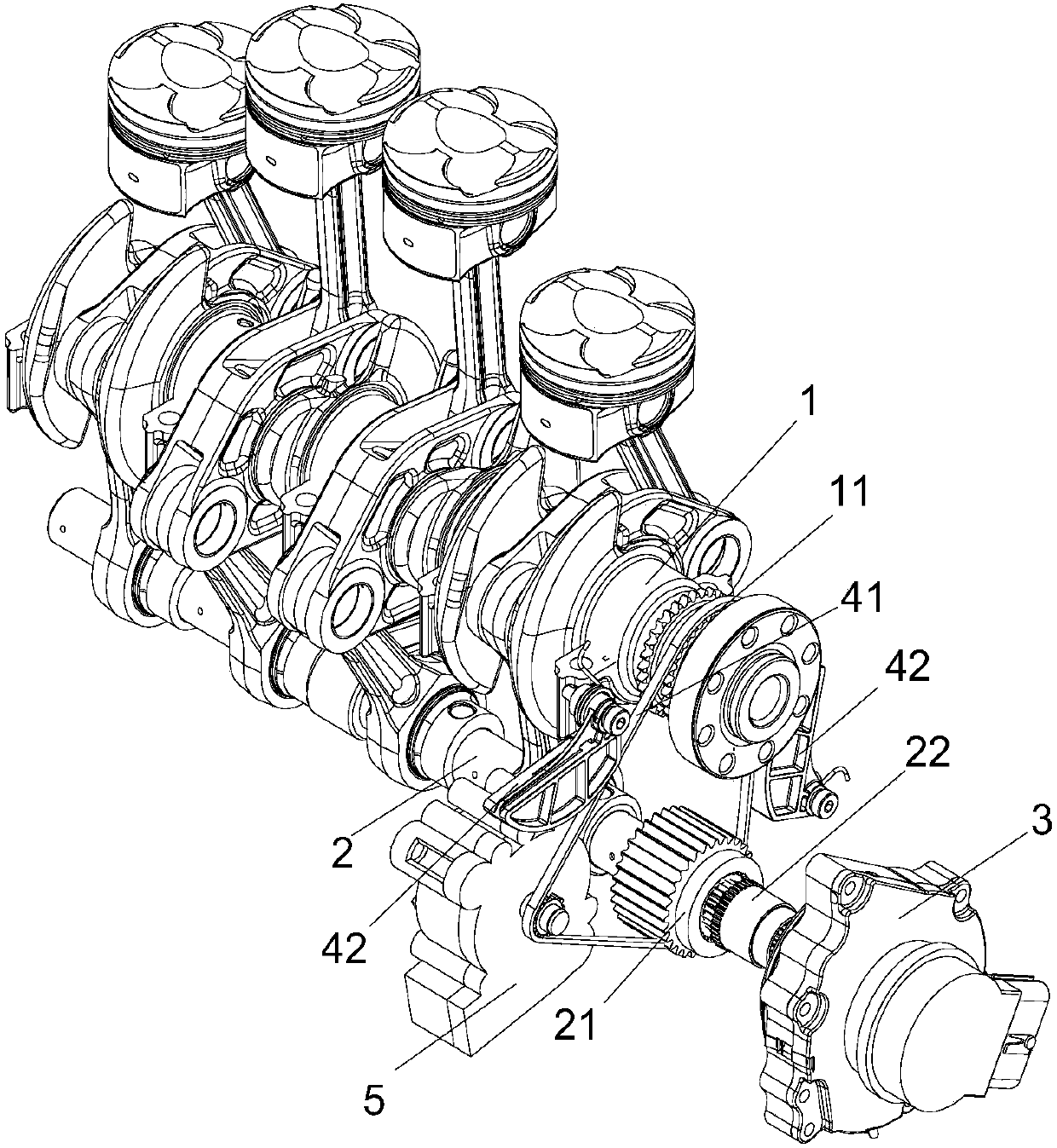

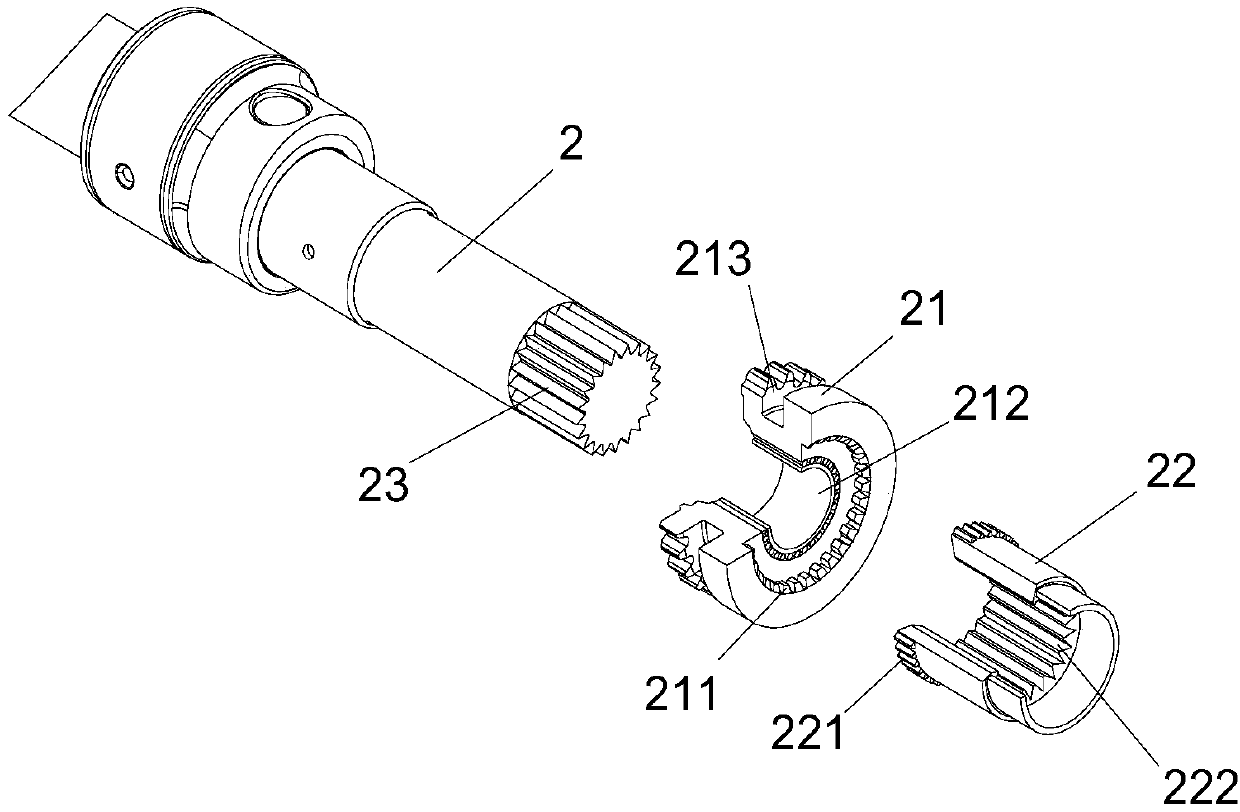

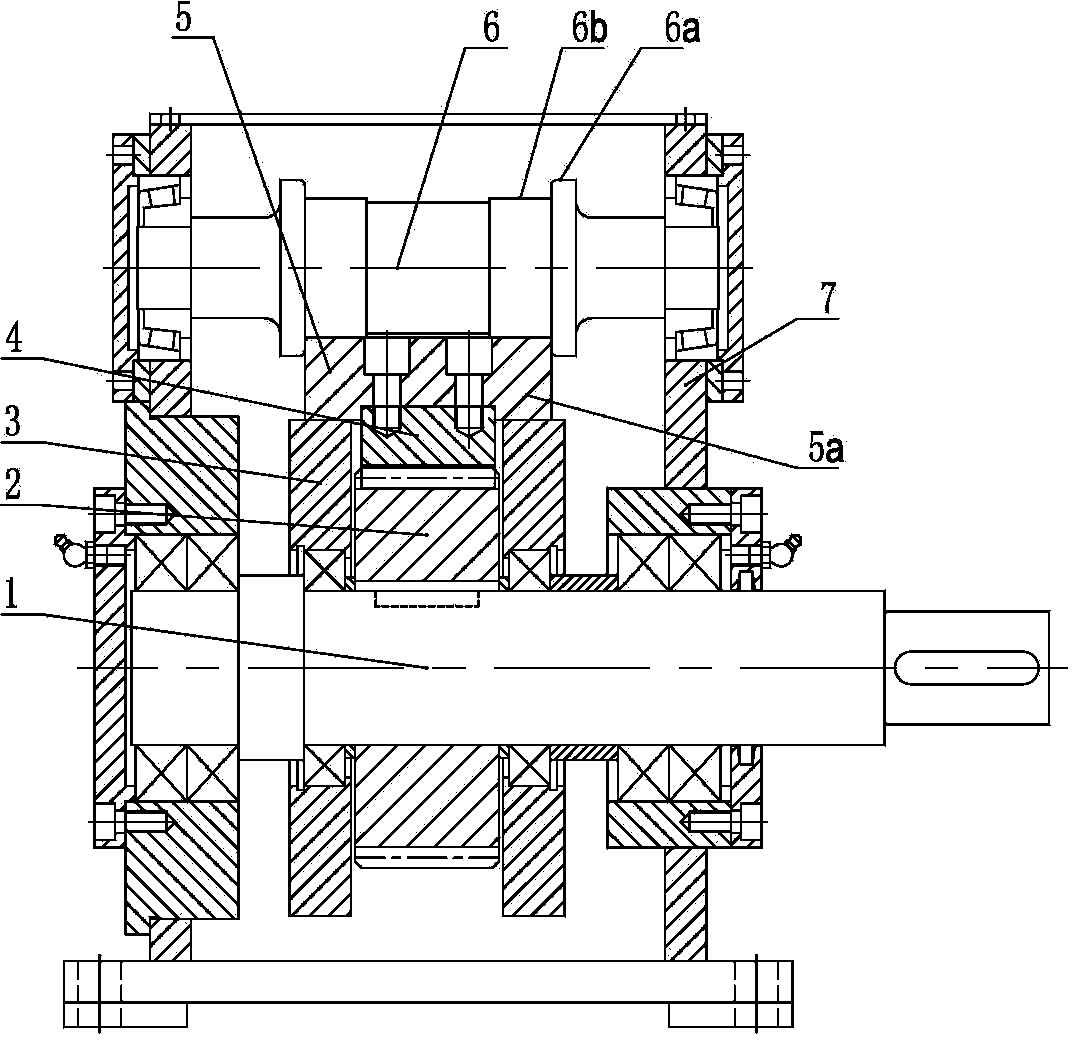

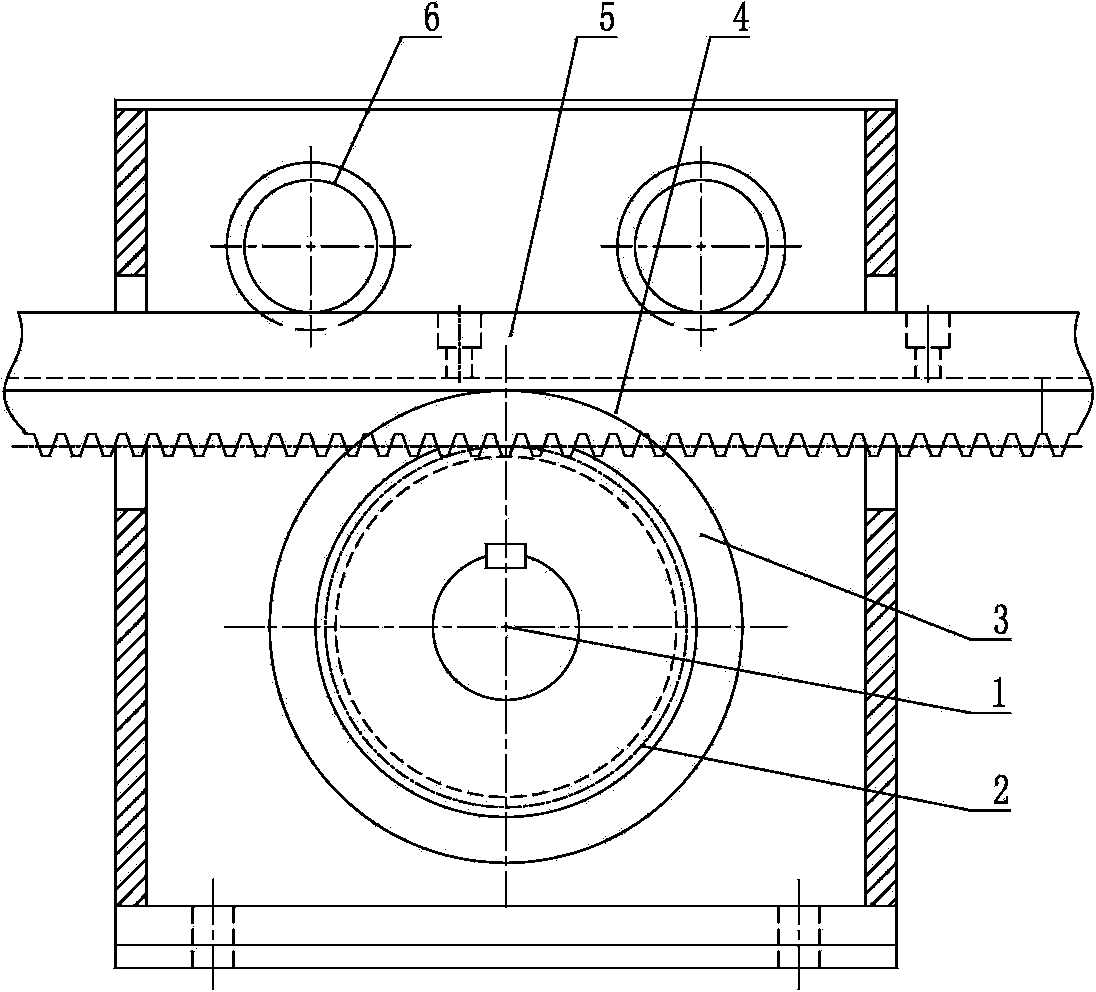

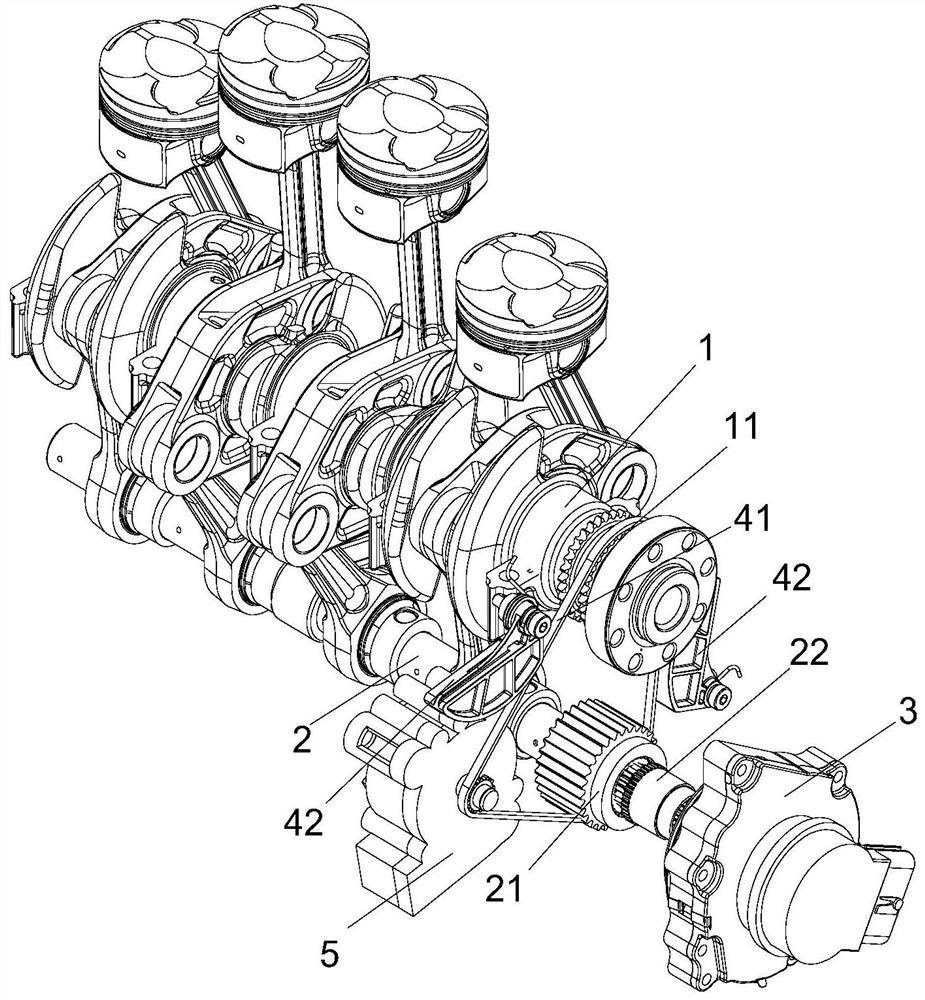

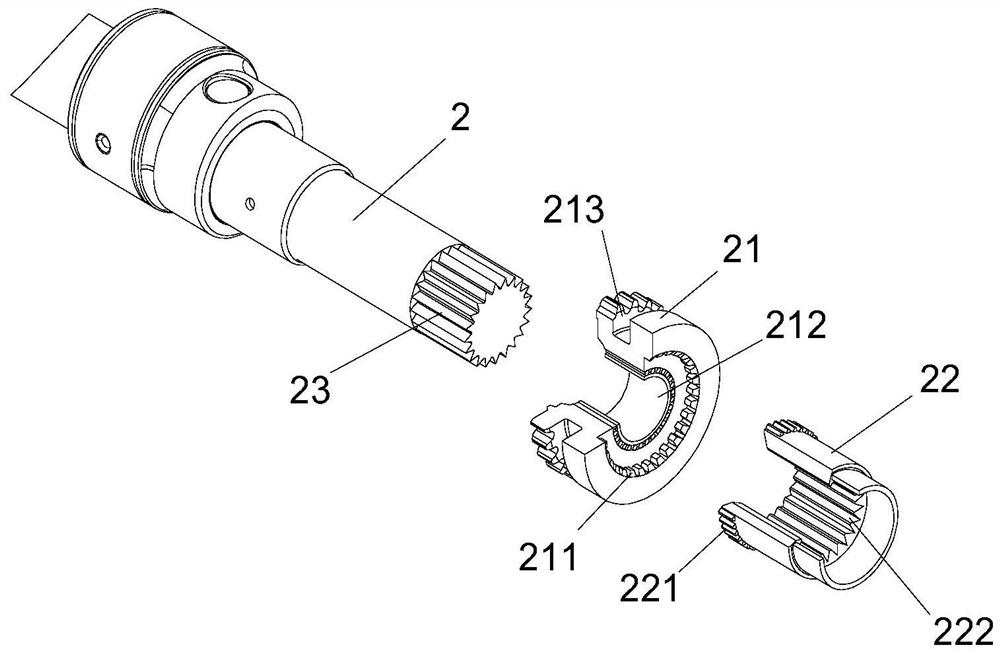

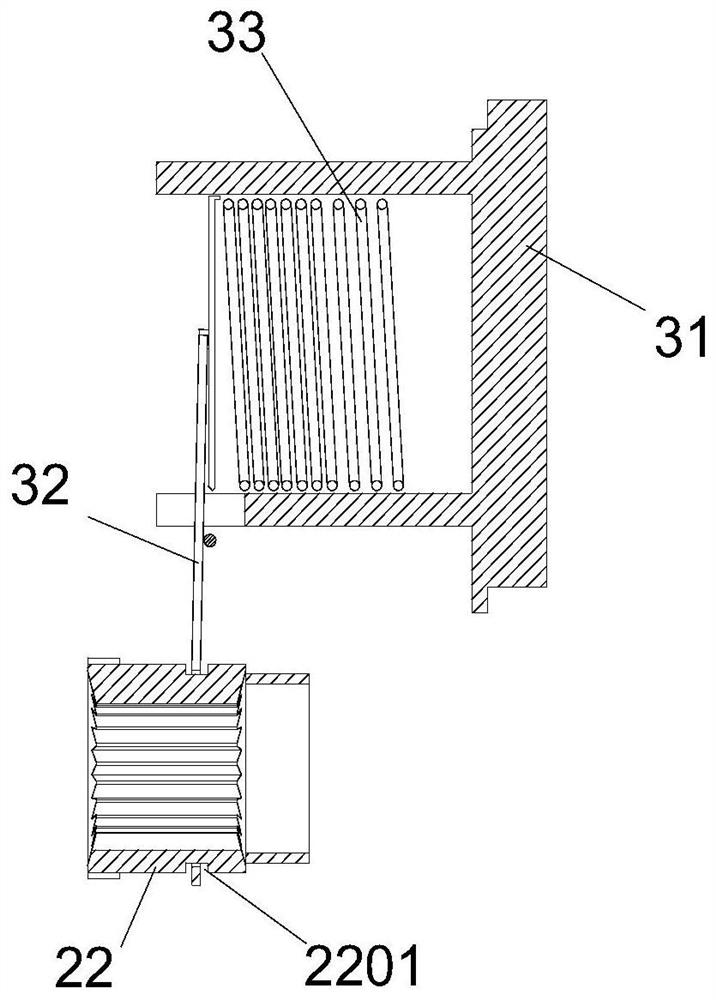

Eccentric shaft driving mechanism and variable compression ratio mechanism

ActiveCN110966088AAchieve compression ratioSimple structureEngine controllersMachines/enginesStructural engineeringCylinder block

The invention provides an eccentric shaft driving mechanism and a variable compression ratio mechanism. The eccentric shaft driving mechanism is used for undertaking driving of a crankshaft so as to drive an eccentric shaft to rotate, comprises a following part arranged at one end of the eccentric shaft in a sleeving manner rotatably, a transmission part on the outer side of the following part andarranged on the eccentric shaft in a sleeving manner and a control part fixed to an engine cylinder body bearing the eccentric shaft and further comprises a transmission connecting part arranged on the transmission part and the following part. The following part is in transmission connection with the crankshaft, the transmission part and the eccentric shaft synchronously rotate, the transmissionpart is driven by a control mechanism to be in transmission connection with or separation from the following part, and therefore through rotation of the crankshaft, the eccentric shaft is driven to rotate. The eccentric shaft driving mechanism drives the eccentric shaft to rotate through rotation of the crankshaft, the angle of the eccentric shaft is changed, the compression ratio of an engine canbe achieved, the driving mechanism drives the eccentric shaft to rotate directly through the crankshaft, an outer power device is not needed, the structure is simple, arranging is easy, and good practicability is achieved.

Owner:GREAT WALL MOTOR CO LTD

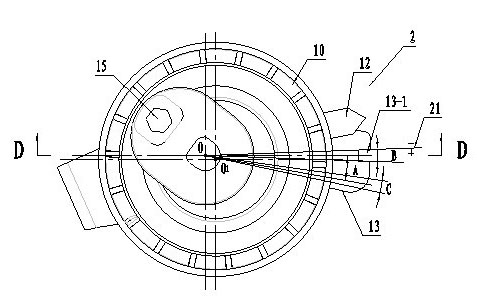

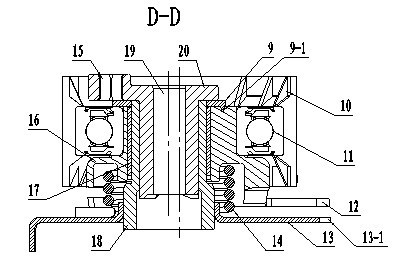

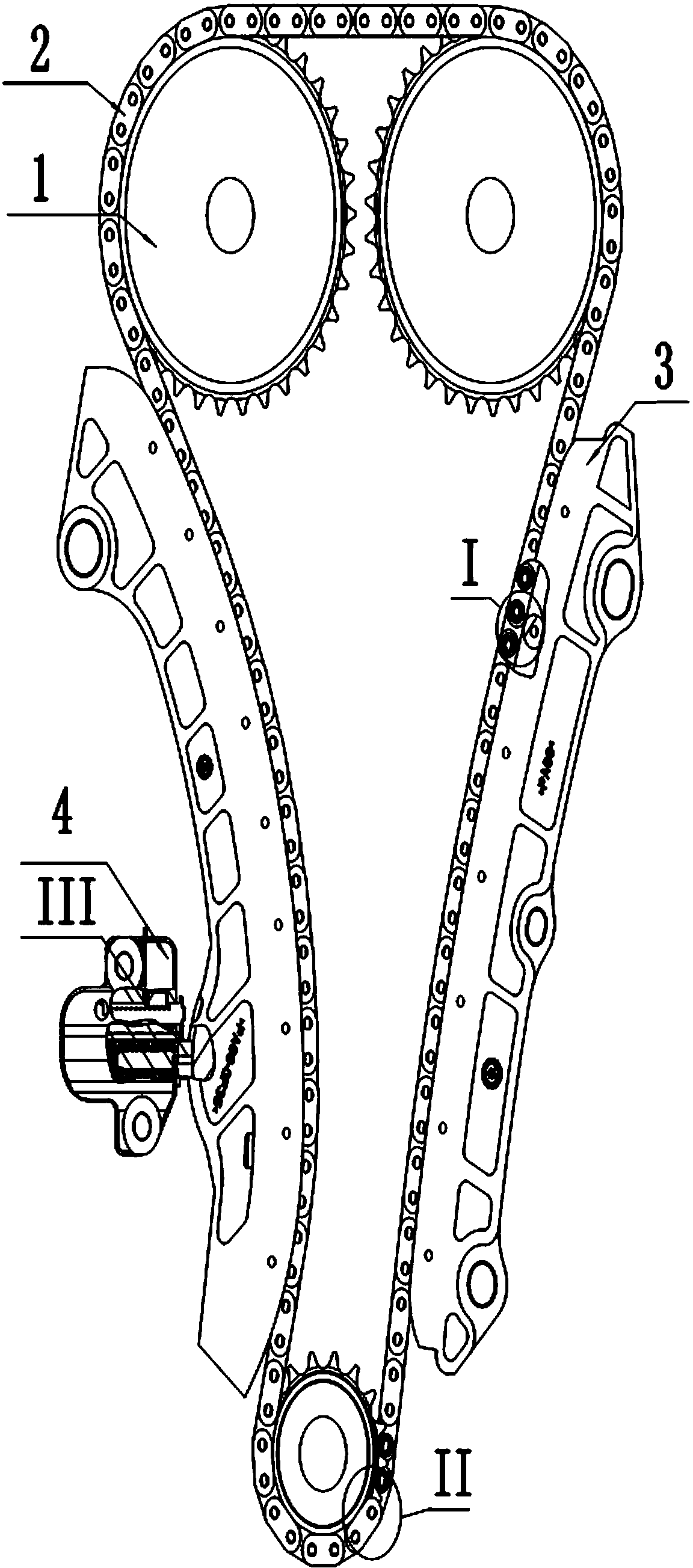

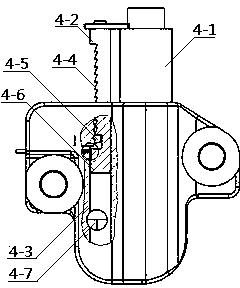

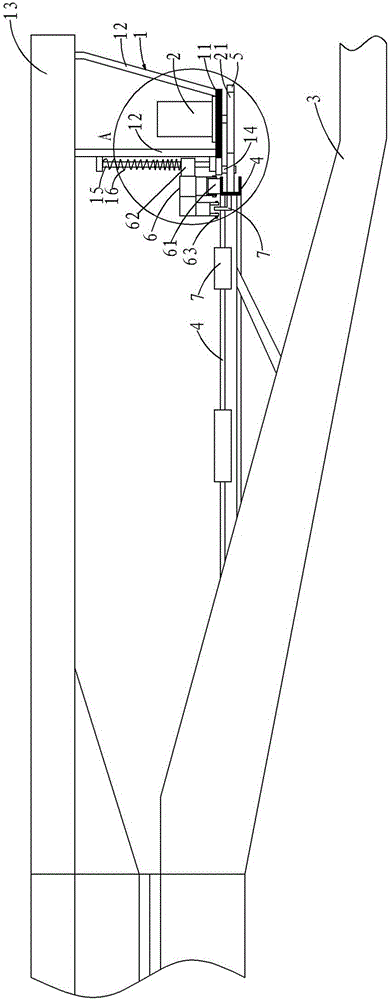

Engine chain timing system

ActiveCN104989479AReduce vibrationAvoid tooth skippingValve arrangementsGearingRolling resistanceFriction loss

The invention relates to a device used for an engine and acting on a timing belt or chain, in particular to an engine chain timing system. A high-intensity nylon chain wheel structure is adopted, so that original steel-steel contact between a chain and chain wheels is converted into nylon-steel contact; oil-resistant rubber is arranged below the position, between every two adjacent teeth of the chain wheels, of the tooth root circle; in the process that the chain is pinched into the chain wheels, a chain connection board makes contact with the oil-resistant rubber firstly, and then rollers are pinched into the chain wheels, so that the pinching impact between the rollers and the chain wheels is greatly reduced, the NVH of the chain timing system is improved, and the system moves more stably and silently. Idler wheels are additionally arranged on a guide rail, so that sliding fiction between a chain plate on the chain and a guide rail in the prior art is changed into rolling friction between the rollers and the guide rail, the friction loss of the system is reduced, and the fuel utilization ratio of the engine is increased. A sensor used for detecting whether a plunger bounces up completely or not is also additionally arranged in an expansion machine and can remind a driver of replacing the chain timing system in time, and major quality accidents of the engine are avoided.

Owner:BRILLIANCE AUTO

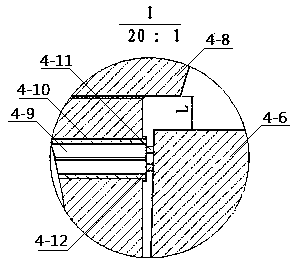

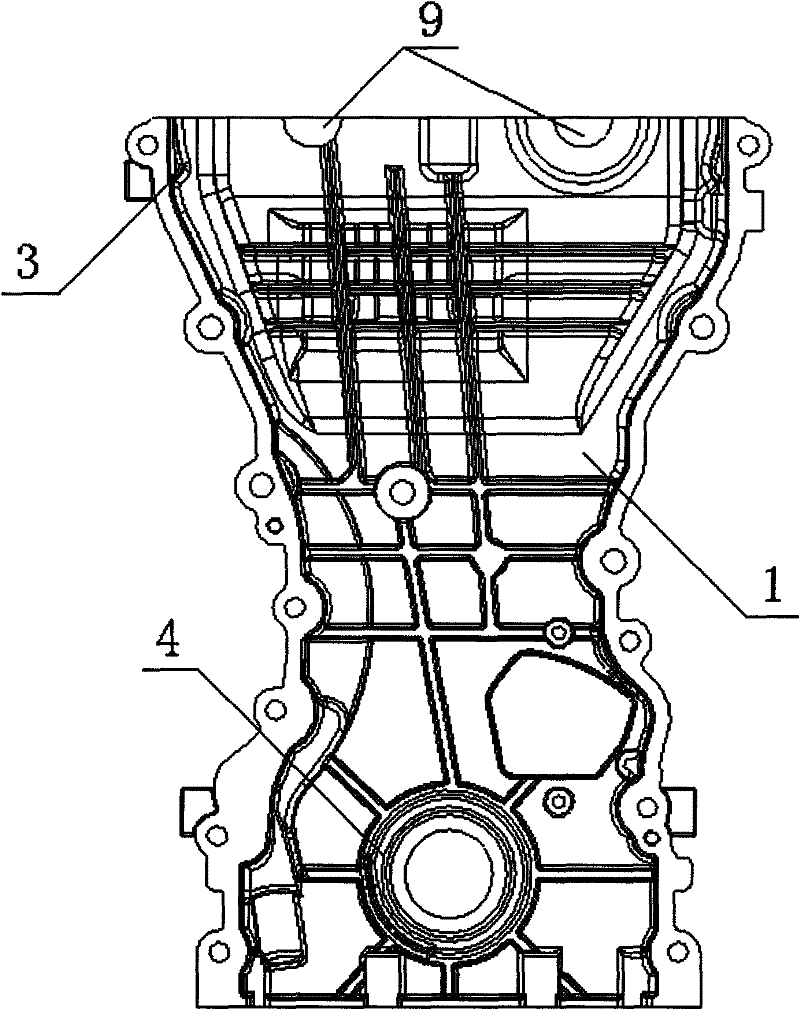

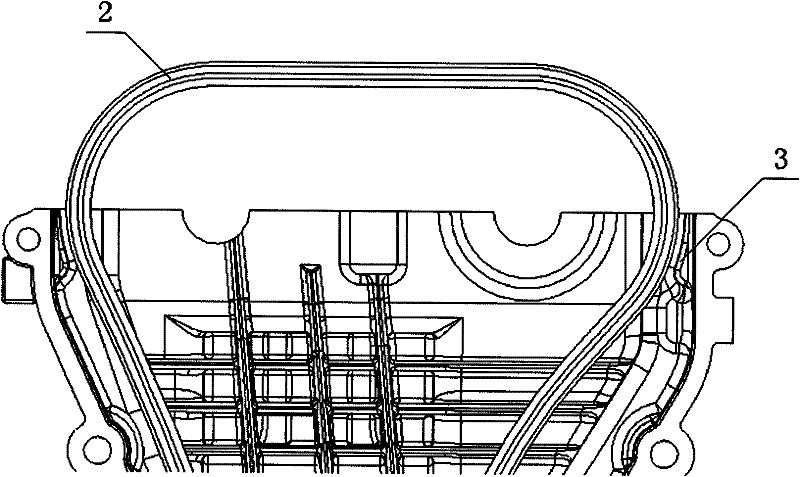

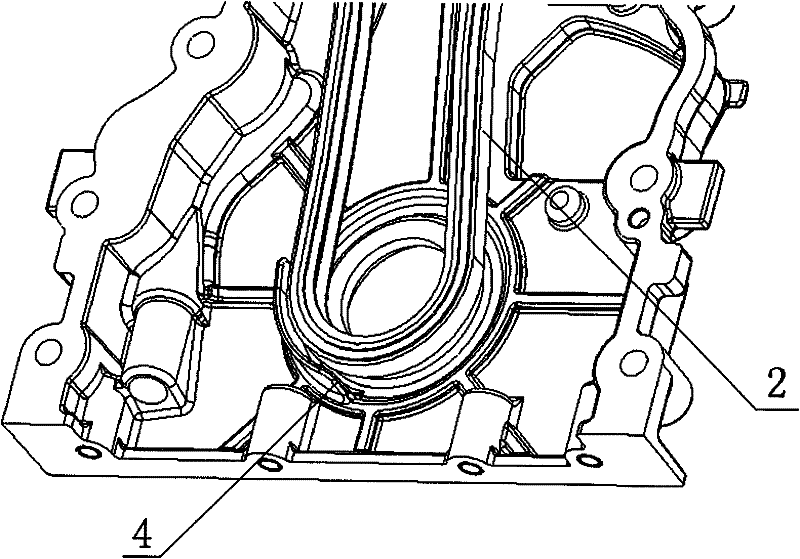

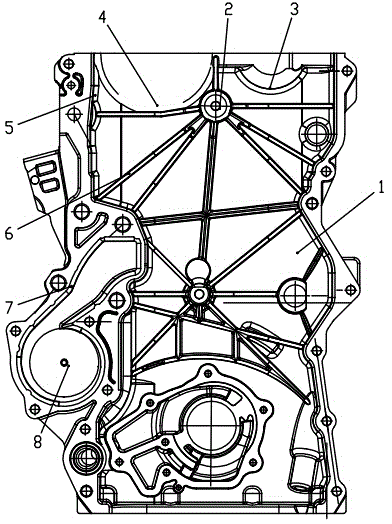

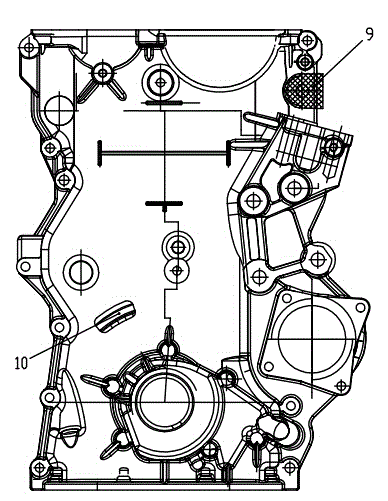

A multifunctional timing sprocket cover

Owner:安庆福莱克斯动力科技有限公司

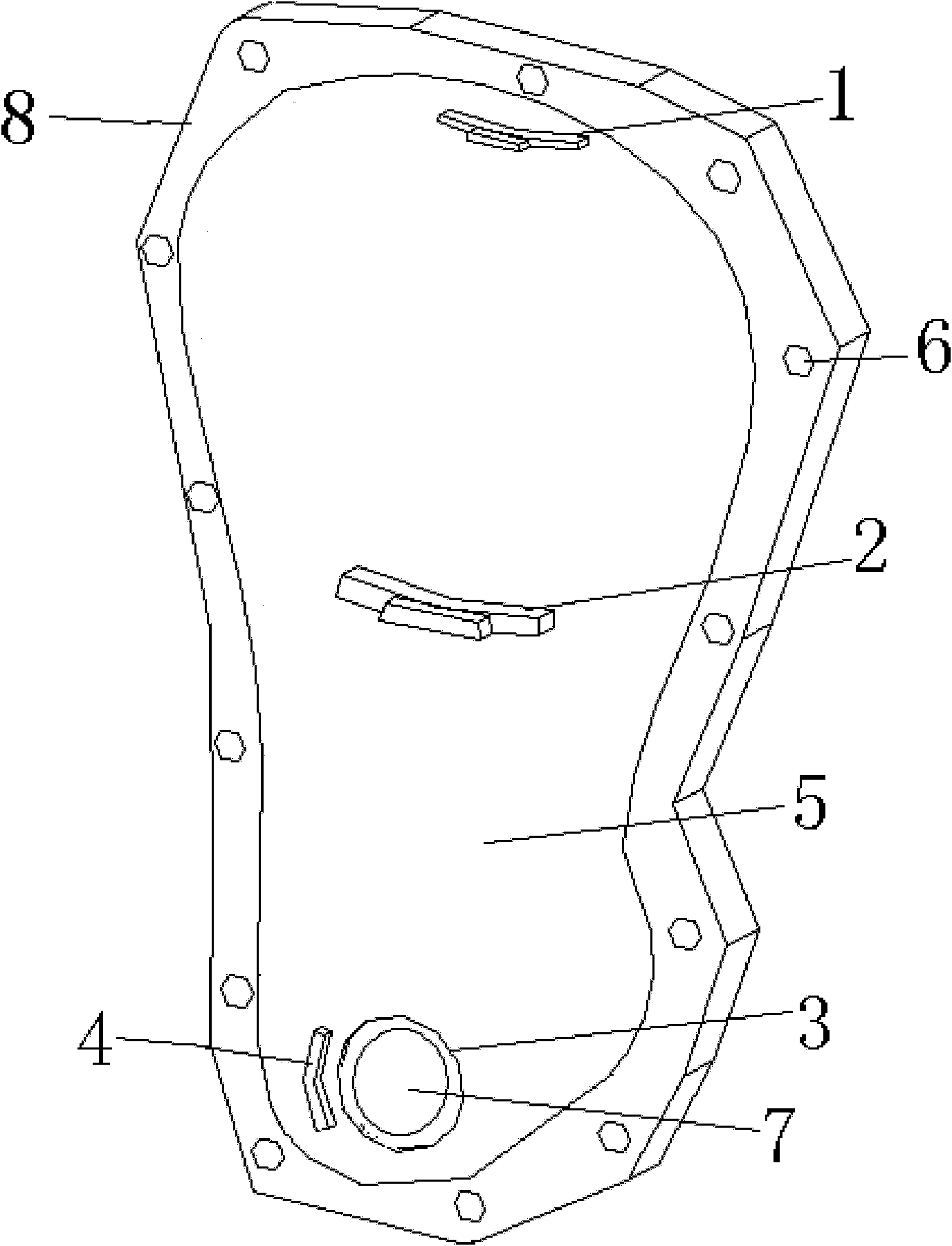

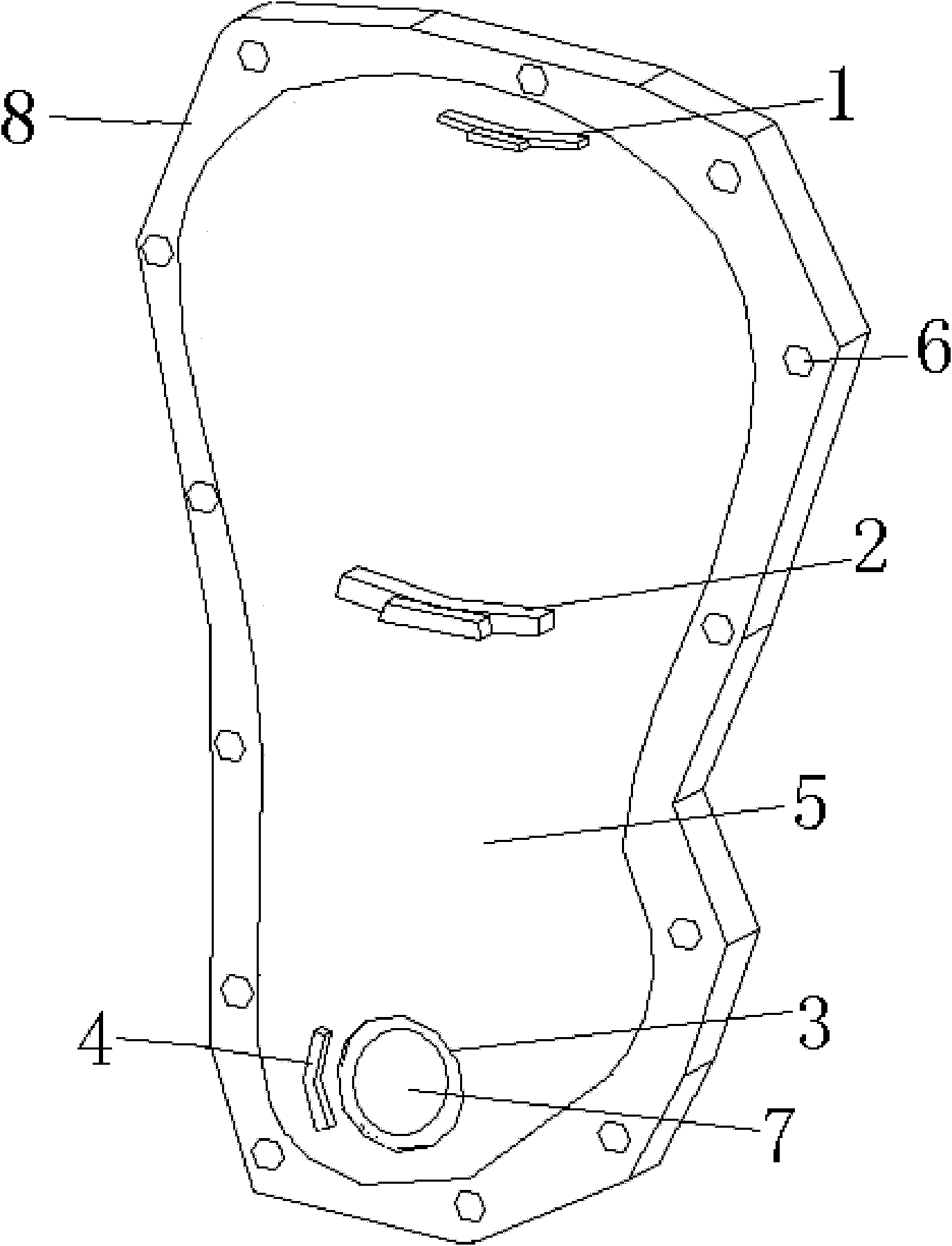

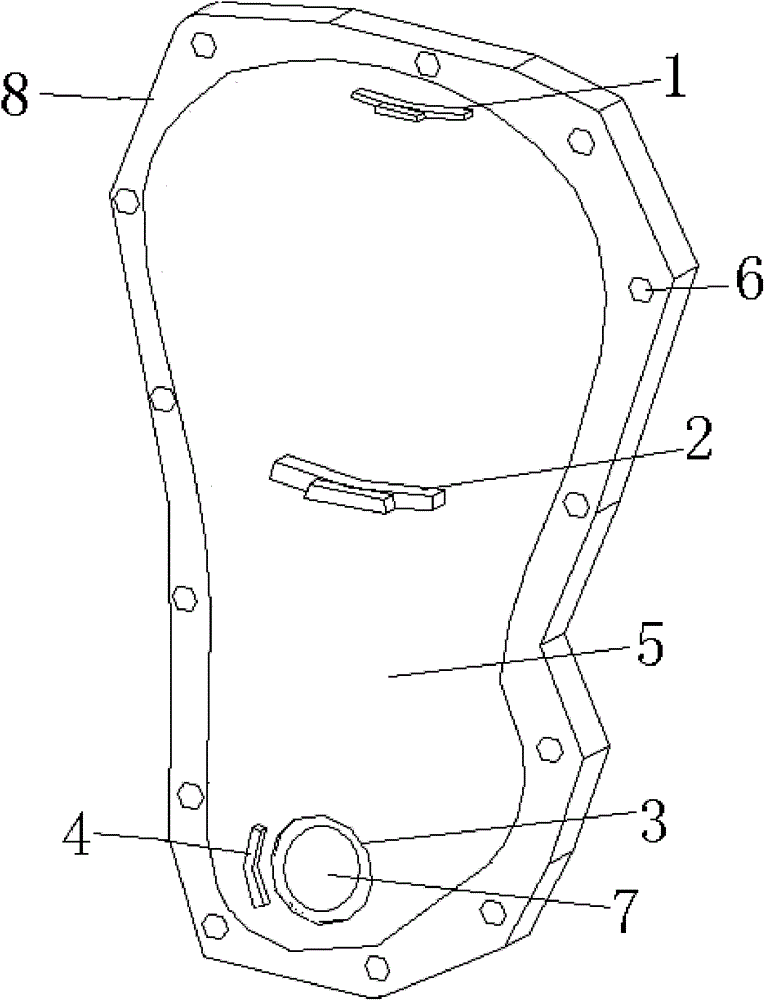

Timing cover of engine

ActiveCN102022219ACompact structureHigh strengthValve arrangementsCasingsSteel platesAutomotive engineering

The invention discloses a timing cover of an engine, comprising a cover body (8), wherein the cover body (8) is provided with an engine oil collecting groove and a crankshaft hole (7); the periphery of the crankshaft hole (7) is provided with an oil seal installing step (3) for installing an oil seal; the cover body (8) is provided with a slippage baffle (4); and the timing cover body (8) of the engine is provided with a sound-absorbing coating (5), and the timing cover of the engine is punched and molded by steel plates and is used for a timing chain driving engine and a timing belt driving engine. In the timing cover of the engine, the structure is compact, the strength is higher, the noise of the engine can be effectively reduced, the processing cost can be saved, multiple functions are achieved, the engine configuration is more reasonable and more compact, the volume is small, the weight is light, and the comport of the whole vehicle can be effectively improved.

Owner:CHERY AUTOMOBILE CO LTD

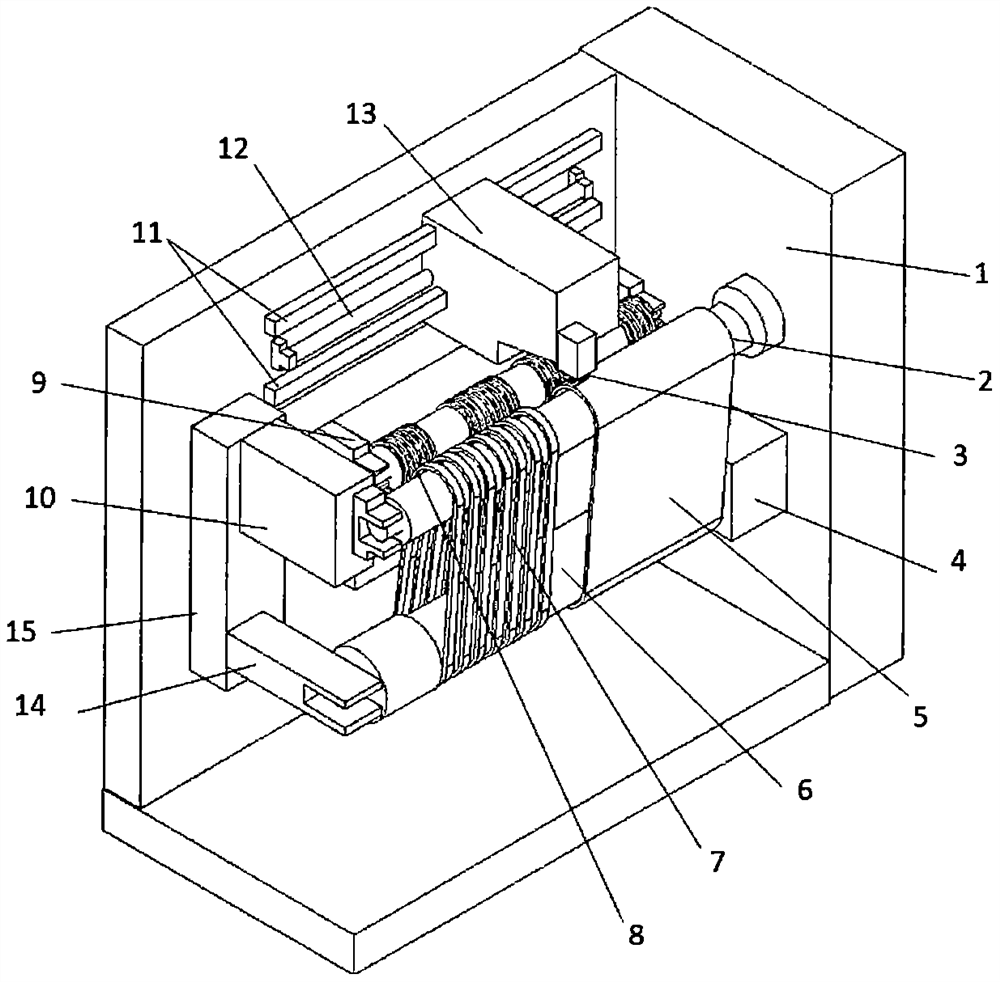

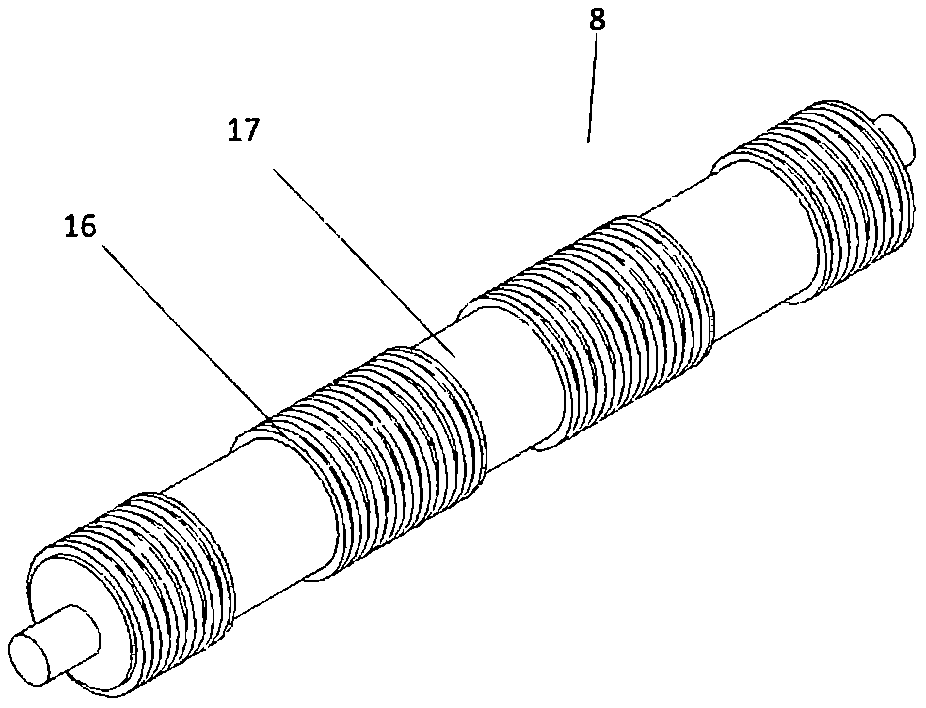

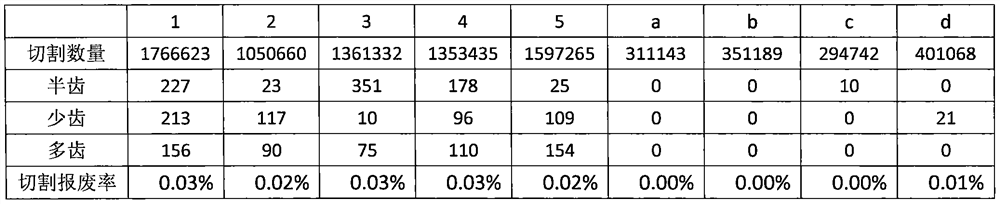

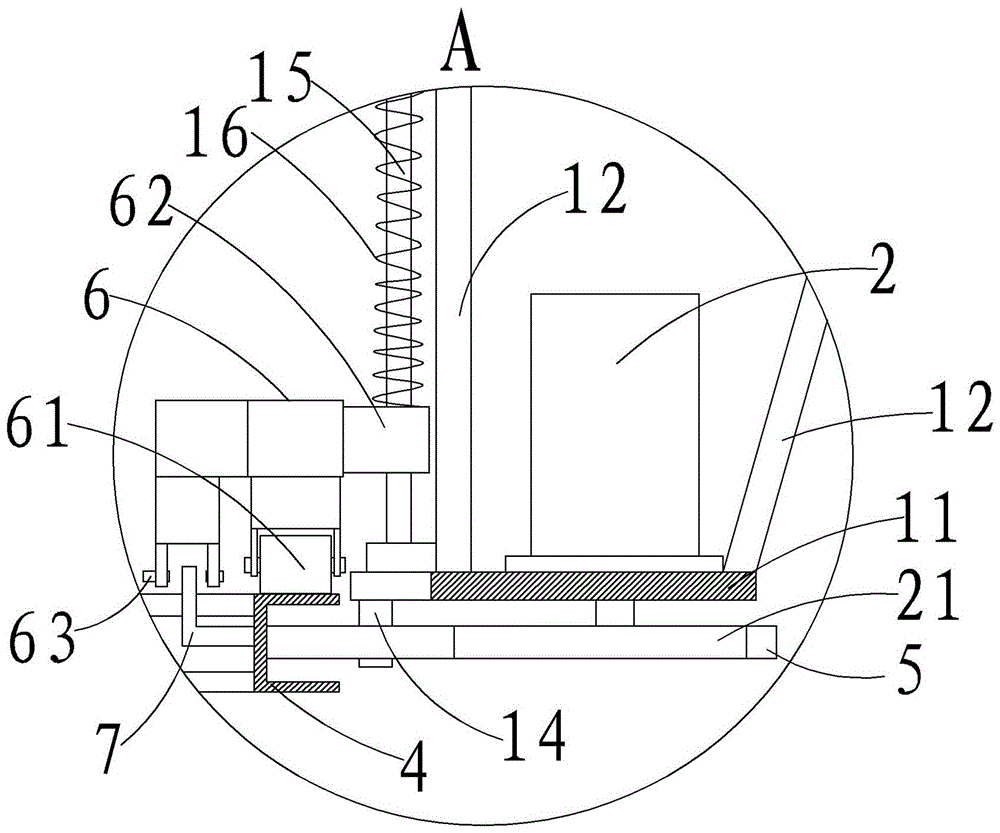

Multi-wedge-belt cutter

PendingCN111660374AReduce scrap rateAvoid tooth skippingMetal working apparatusStructural engineeringMechanical engineering

The invention provides a multi-wedge-belt cutter which comprises a fixed support, a support roller, a guide roller, a cutter, a tension roller, and a drive device and a tension device arranged on thefixed support. One end of the support roller is arranged on the fixed support; the guide roller, the tension roller and the support roller are arranged in parallel in the axial direction; the drive device is connected with the guide roller so as to drive the guide roller to move in the direction perpendicular to the axis of the support roller; the tension device is connected with one end of the tension roller so as to drive the tension roller to move in the direction perpendicular to the axis of the support roller; the tension roller can rotate relative to the tension device; and teeth segmentally distributed in the axis direction of the guide roller are arranged on the outer circumference face of the guide roller. The occurrence of the phenomenon of more wedges, less wedges or semi-wedgesduring multi-wedge-belt cutting is reduced.

Owner:GATES UNITTA POWER TRANSMISSION (SUZHOU) LIMITED

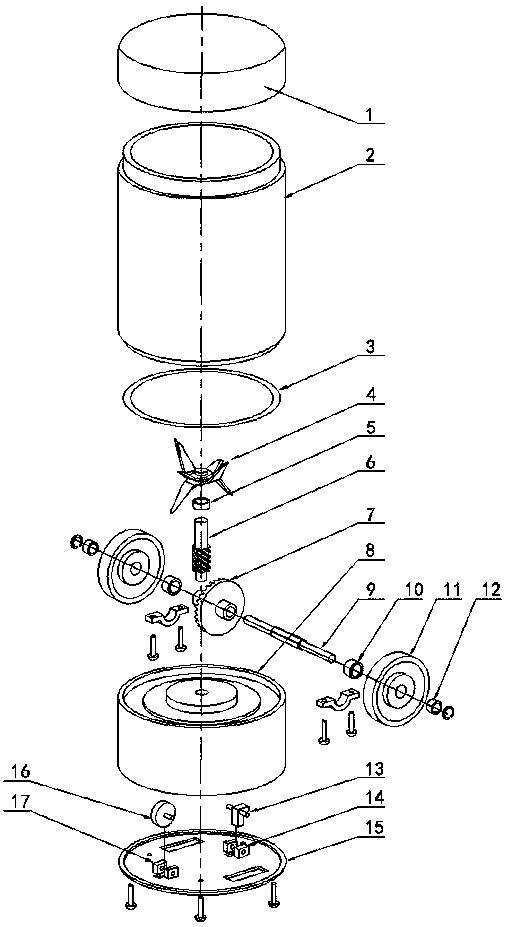

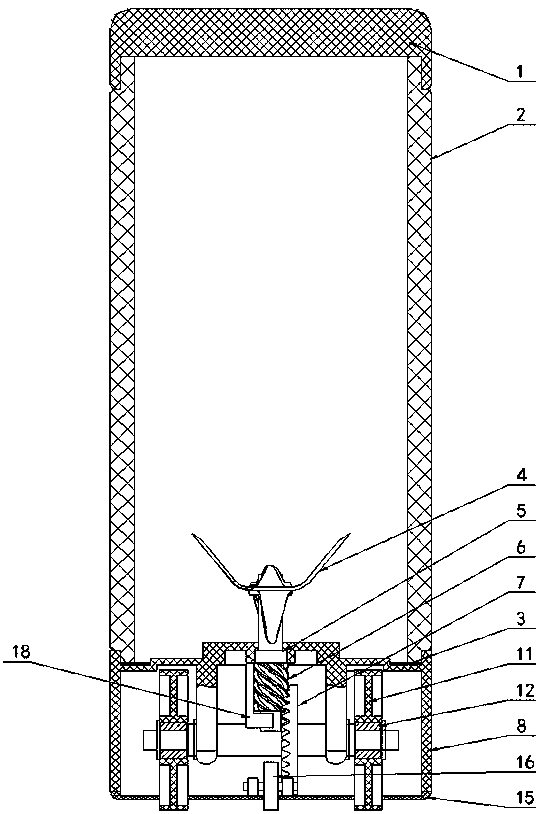

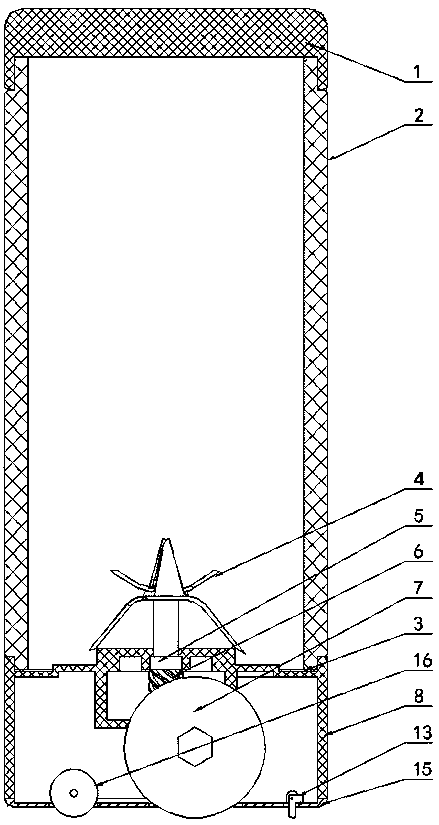

Rolling juicer cup

The creation of the invention discloses a rolling juicer cup comprising a cup lid (1), a cup body (2) and a cup holder (8). The rolling juicer cup is characterized in that the cup body (2) is removably fixed on cup holder (8); the cup holder (8) is provided with a rotatable worm shaft (6) fixed with a rotary cutter head (4); the rotary cutter head (4) is located in the cup body (2); the cup holder(8) is internally provided with a worm support seat (18) which is in semi-circular rotation fit with the worm shaft (6) and plays a supporting role; a worm gear (7) meshing with a worm of the worm shaft (6) is arranged on cup holder (8) which is located on the other side and opposite to the worm support seat (18); the worm support seat (18) cooperates with the worm gear (7) to guarantee force balance when the worm shaft (6) rotates; the worm gear (7) is provided with a wheel shaft (9) capable of rotating relative to the cup holder (8); both ends of the wheel shaft are correspondingly providedwith a left and a right wheel (11) that can rotate in one direction. With the above-mentioned structure, the rolling juicer cup has the such advantages as simple and reasonable structure, easy operation, quick juice extraction, high work efficiency and convenient collection and carrying.

Owner:陈政

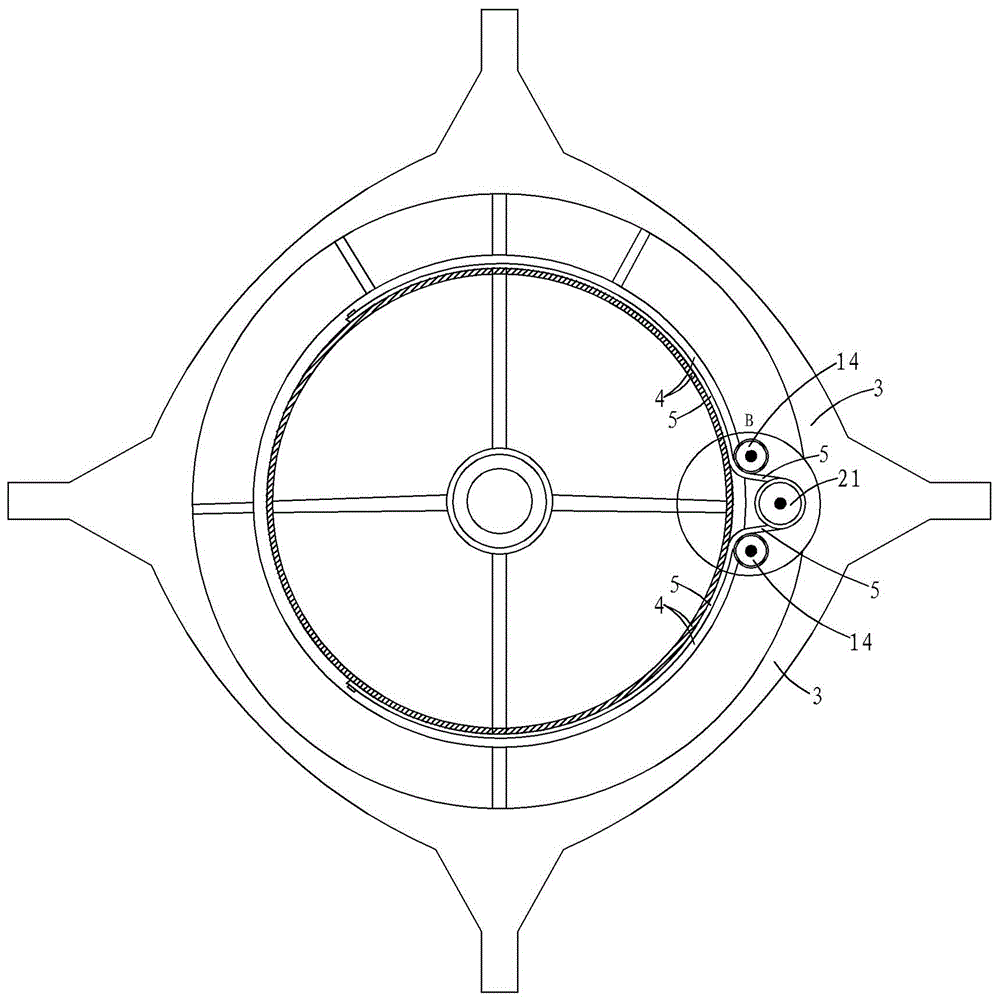

A comb-tooth type multi-directional displacement bridge expansion device

ActiveCN107558359BWill not skip teethAvoid tooth skippingBridge structural detailsWear resistantEngineering

The invention relates to the bridge dilatation joint technology field, and particularly relates to a comb-type multidirectional displacement bridge telescoping apparatus, wherein, each tooth of a fixed tooth plate is bolted to a fixed beam body; a slide tooth plate is shaft-connected to a slide beam body at the comb back far from the tooth through a rotating shaft apparatus; a gap is left betweena side beam and the slide tooth plate; the slide tooth plate is provided with an elastic straining device between the comb back close to the tooth and the slide beam body for restricting downward displacement of the slide tooth plate and the slide beam body. Compared with prior art, the downward displacement is solved through the relative movement of the slide tooth plate and the fixed beam body;a lower shaft rotates relatively little, which is solved by further compression of a spring; at the same time, the slide tooth plate is pressed on the fixed beam body surface through the spring, preventing jumping gear; furthermore, garbage is removed through a wear resistant-rod arranged under the slide tooth plate, preventing jumping gear caused by the garbage.

Owner:SHANGHAI EAGLE BRIDGE TECH

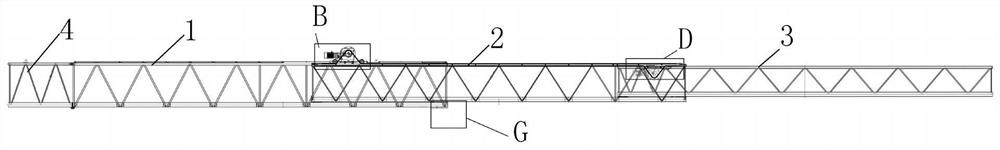

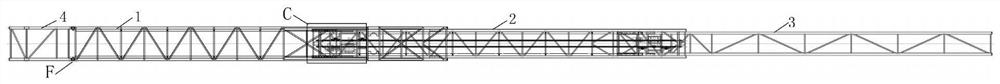

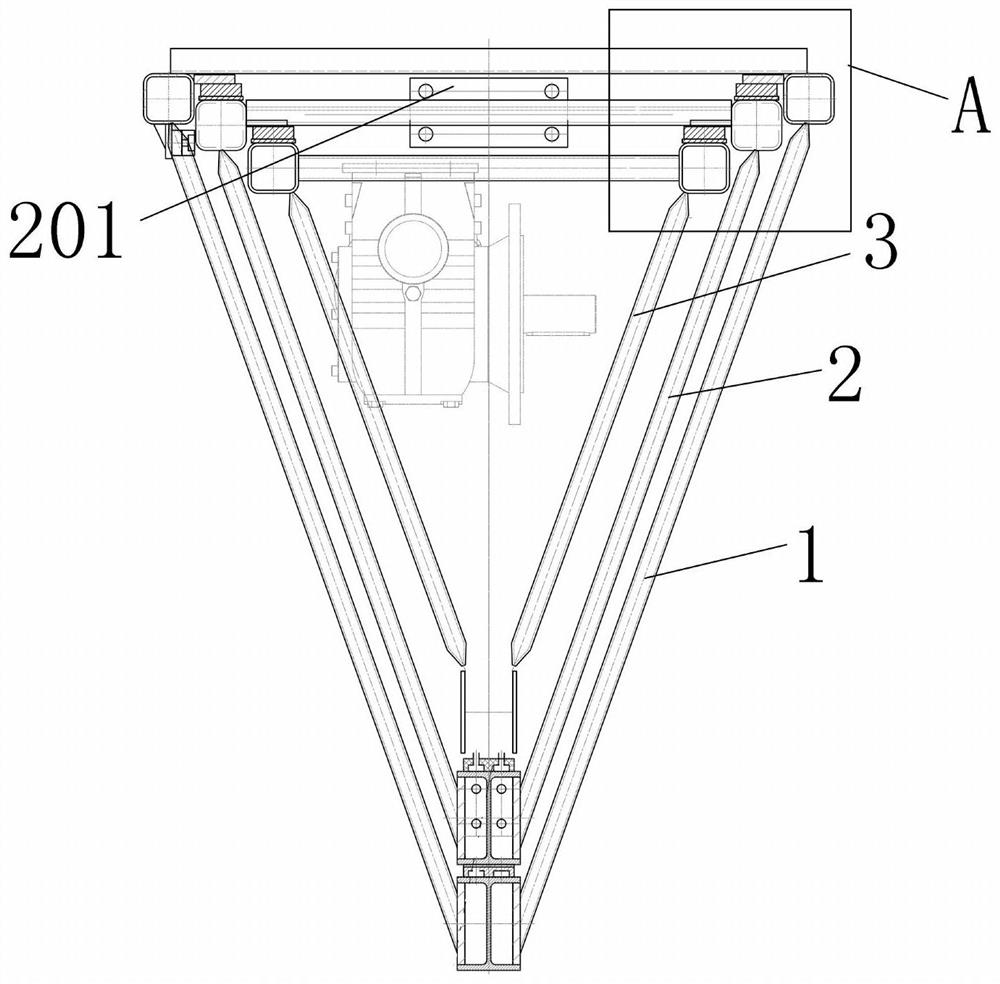

Crossing frame telescopic main arm and double-arm telescopic push type crossing frame

PendingCN111969483AAvoid tooth skippingBlocking time is controllableApparatus for overhead lines/cablesEngineeringComputer hardware

Owner:浙江省建设工程机械集团有限公司

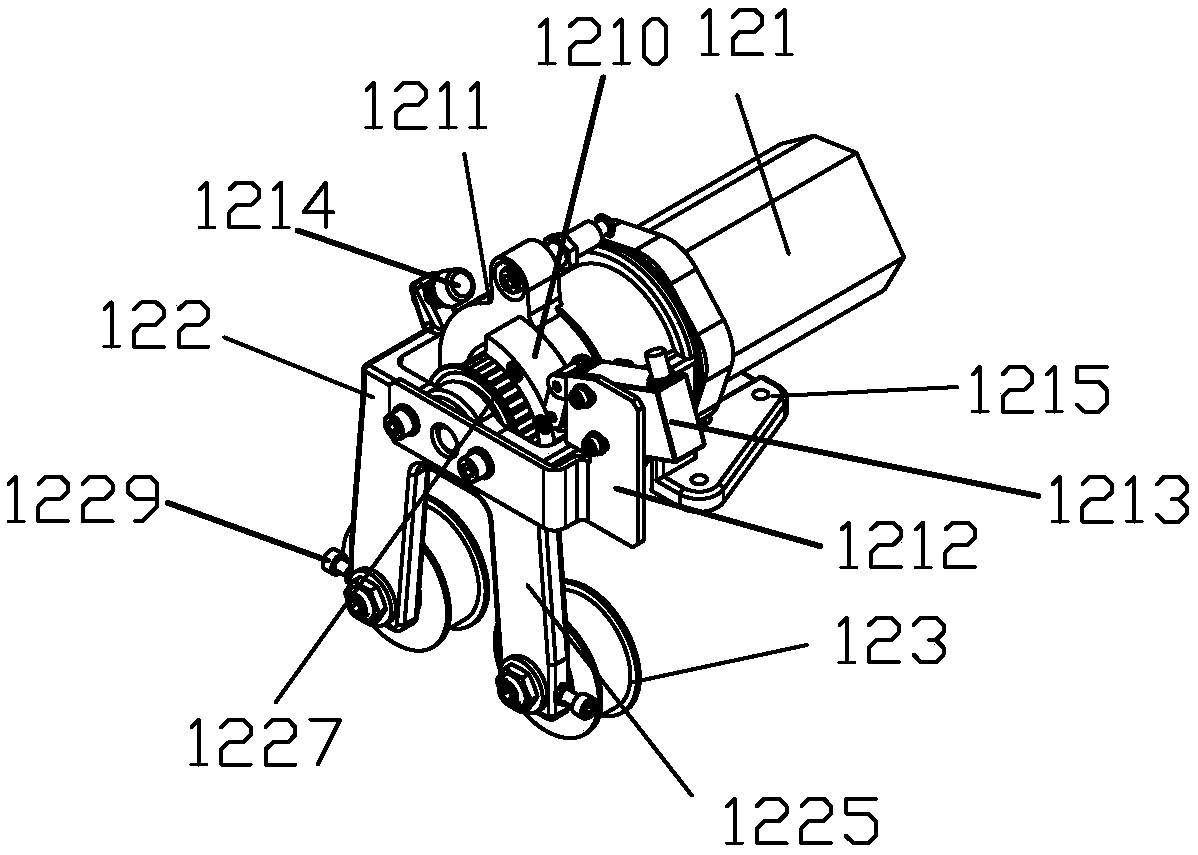

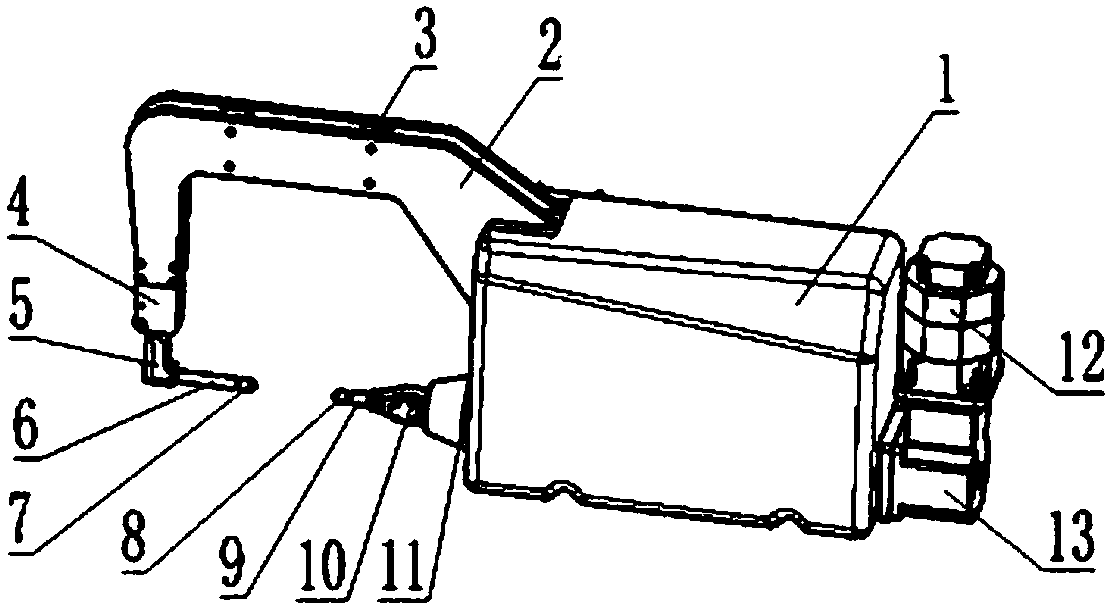

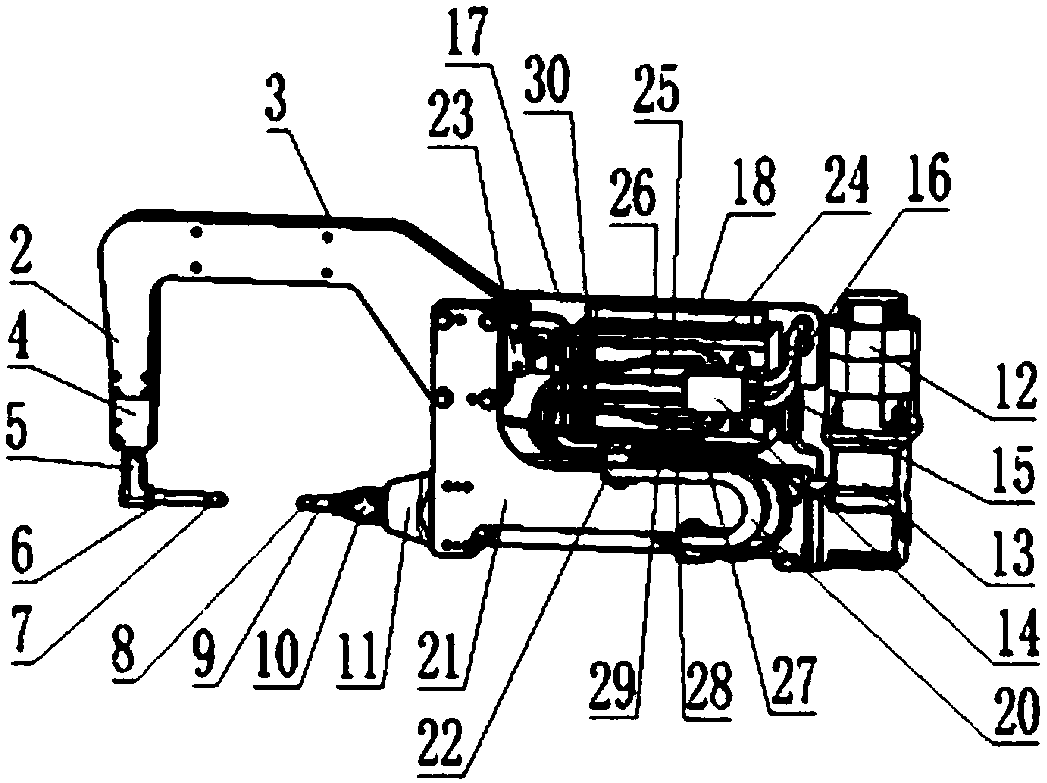

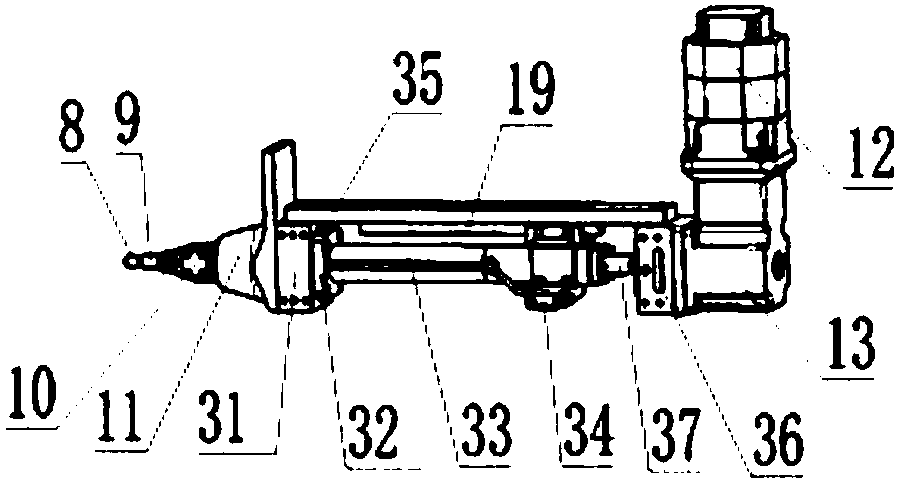

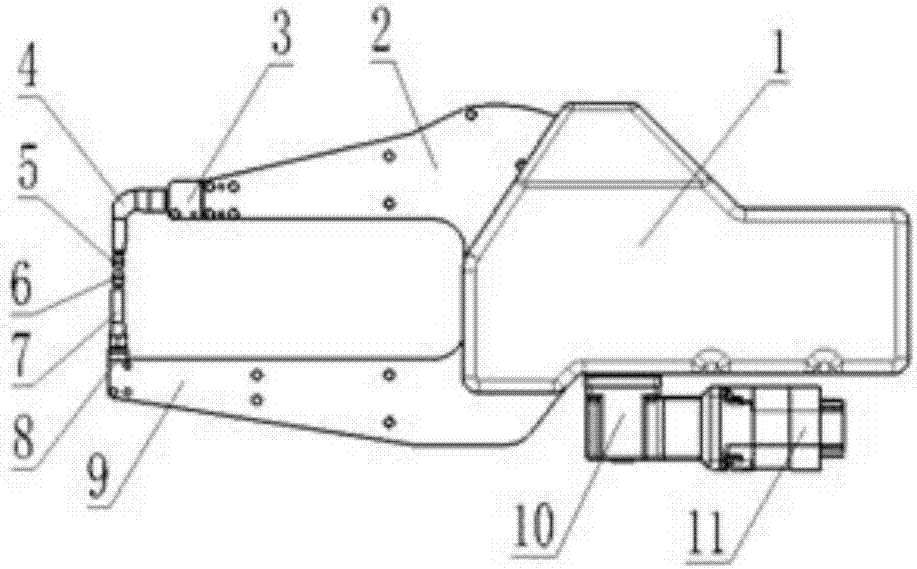

Electric servo c-type robot welding gun

The invention relates to an electric servo C-shaped robot welding clamp. The electric servo C-shaped robot welding clamp comprises a driving module, a protective cover, a substrate, an upper plate, a fixed electrode arm module, a movable electrode arm module, a water pipe module and a transformer module. The driving module includes a servo motor and a speed reducer; the fixed electrode arm module includes a welding clamp arm connecting bracket, an aluminum alloy welding clamp arm, a copper connecting block, a copper welding clamp arm, a fixed electrode rod and a fixed electrode cap; and the movable electrode arm module includes a movable electrode arm, a movable electrode rod, a movable electrode arm cover, a movable electrode cap, a linear guide rail, a plummer linear bearing, a ball screw and a push rod. The water pipe module includes a distributor, a water inlet pipe, a water return pipe, a fixed electrode arm water return pipe, a movable electrode arm water return pipe, a transformer water return pipe, a fixed electrode arm water inlet pipe, a transformer water inlet pipe, a movable electrode arm water inlet pipe and a water pipe mounting bracket; and the transformer module includes a transformer, a copper bar 1, a copper bar 2, a copper bar 3 and a soft copper bar. The electric servo C-shaped robot welding clamp adopts a modular servo technology, and is precise in control.

Owner:TIANJIN FUZHEN IND EQUIP

Timing cover of engine

The invention discloses a timing cover of an engine, comprising a cover body (8), wherein the cover body (8) is provided with an engine oil collecting groove and a crankshaft hole (7); the periphery of the crankshaft hole (7) is provided with an oil seal installing step (3) for installing an oil seal; the cover body (8) is provided with a slippage baffle (4); and the timing cover body (8) of the engine is provided with a sound-absorbing coating (5), and the timing cover of the engine is punched and molded by steel plates and is used for a timing chain driving engine and a timing belt driving engine. In the timing cover of the engine, the structure is compact, the strength is higher, the noise of the engine can be effectively reduced, the processing cost can be saved, multiple functions are achieved, the engine configuration is more reasonable and more compact, the volume is small, the weight is light, and the comport of the whole vehicle can be effectively improved.

Owner:CHERY AUTOMOBILE CO LTD

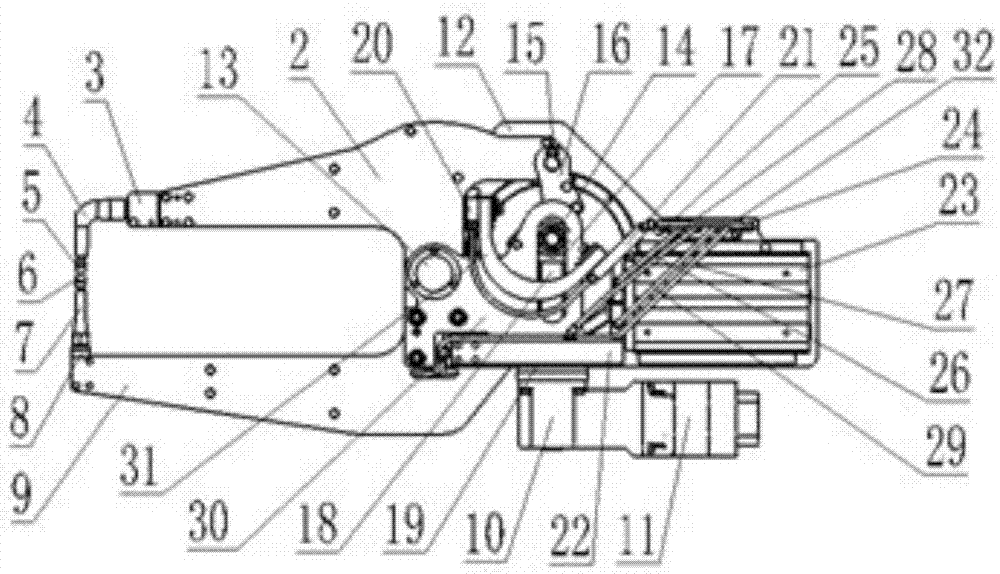

Electric servo x-type robot welding gun

ActiveCN106271282BReduce weightLow costWelding/cutting auxillary devicesAuxillary welding devicesTransformerEngineering

The invention relates to a pair of electric servo X type robot soldering pliers, comprising a driving component, a protecting cover, a base plate, an upper plate, an upper electrode arm component, a lower electrode arm component, a water pipe component and a transformer component, wherein the driving component comprises a servo motor, a speed reducer, a ball screw and a connecting rod; the upper electrode arm component comprises an upper arm, an upper arm connecting block, an upper arm electrode rod and an upper arm electrode cap; the lower electrode arm component comprises a lower arm, a lower arm connecting block, a lower arm electrode rod and a lower arm electrode cap; the water pipe component comprises a distributor, an upper arm water inlet pipe, an upper arm water return pipe, a lower arm water inlet pipe, a lower arm water return pipe, a transformer water inlet pipe and a transformer water return pipe; and the transformer component comprises a transformer, a first copper bar, a second copper bar, a third copper bar and a soft copper bar. The modular design is adopted for the soldering pliers, so that the mounting and debugging are more convenient; and the servo technique is adopted, so that the control is accurate, the performance is reliable, the design is reasonable, and the service life is longer.

Owner:TIANJIN FUZHEN IND EQUIP

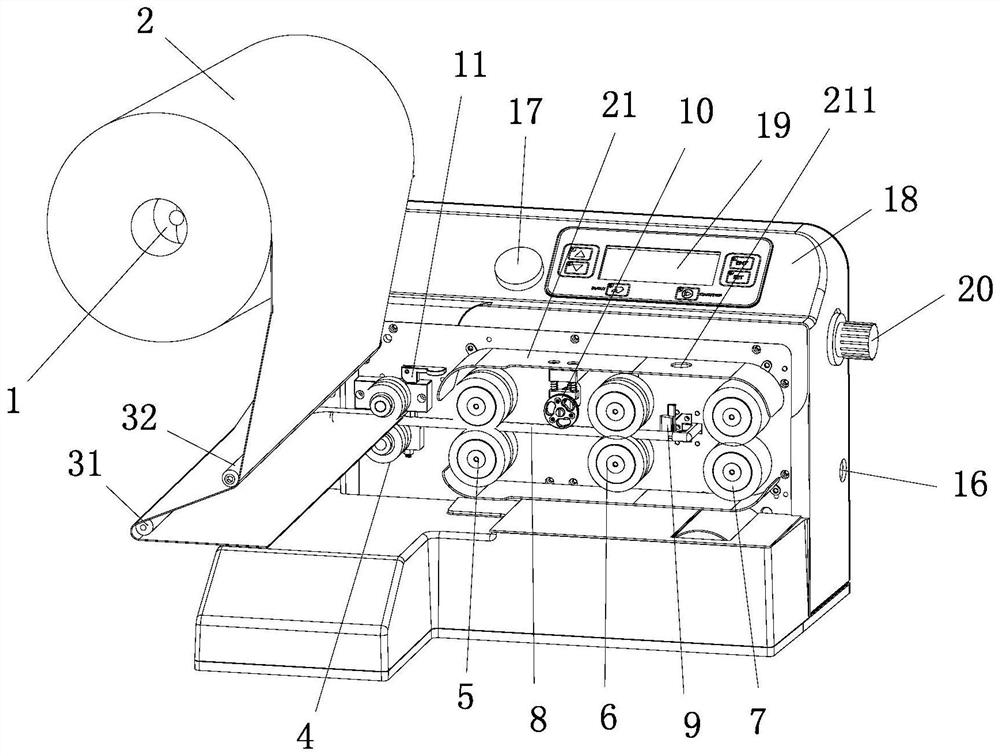

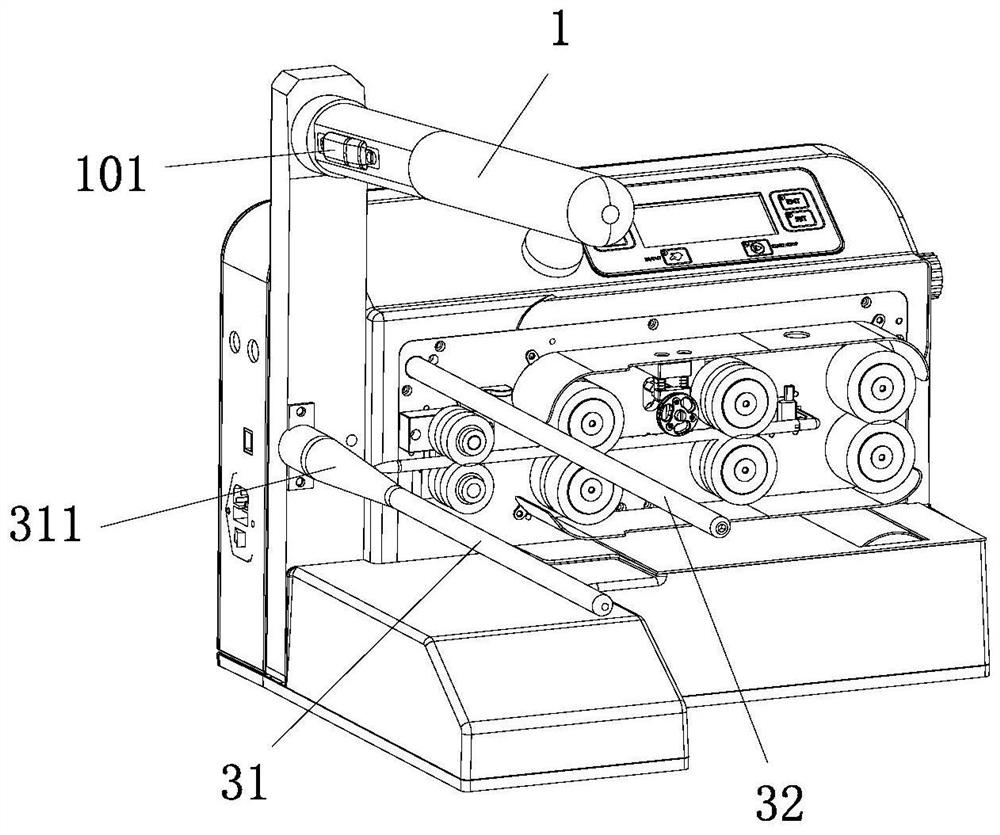

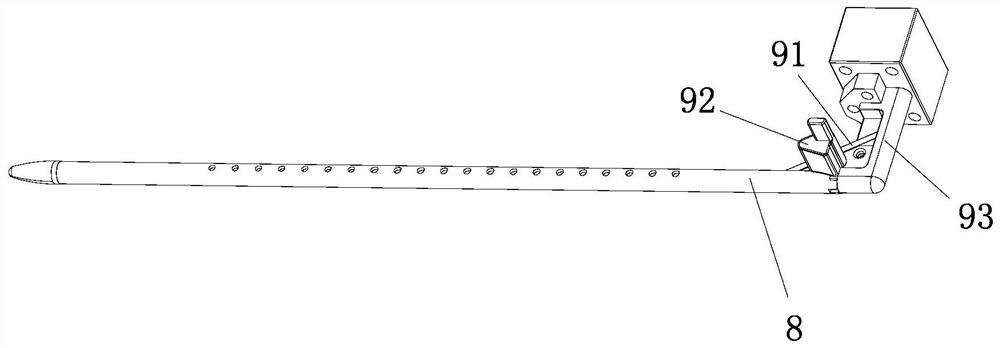

an inflator

ActiveCN110127419BFully inflatedWill not explodePaper/cardboard articlesContainers to prevent mechanical damageStructural engineeringMechanical engineering

The invention discloses an inflator, and relates to the field of packaging equipment. The inflator comprises an inflating pipe and a pressing wheel assembly, a first roller assembly and a second rolling wheel assembly which are arranged in sequence along the axial direction of the inflating pipe; the surface of the part, between the pressing wheel assembly and the second rolling wheel assembly, ofthe inflating pipe is provided with rows of inflating holes in the axial direction, the inflating pipe is divided into a first inflating section and a second inflating section, and the aperture of the inflating holes of the first inflating section is smaller than the aperture of the inflating holes of the second inflating section; and an inflating channel of a rolling film penetrates through theinflating pipe, the pressing wheel assembly, the first rolling wheel assembly and the second rolling wheel assembly are used for pressing and closing the inflating channel of the rolling film, the first inflating section is used for pre-inflating the rolling film, and the second inflating section is used for inflating the pre-inflated rolling film to be full. The first inflating section opens a valve of a film rolling air column, the second inflating section provides air flow with smaller pressure to fill the air column, the inflating mode of the two sections of inflating holes is adopted, sothat inflating of the rolling film is more full and cannot be exploded, in this way, the inflating efficiency is improved.

Owner:XIAMEN AMESON NEW MATERIAL INC

Comb-type multidirectional displacement bridge telescoping apparatus

ActiveCN107558359AWill not skip teethAvoid tooth skippingBridge structural detailsWear resistantEngineering

The invention relates to the bridge dilatation joint technology field, and particularly relates to a comb-type multidirectional displacement bridge telescoping apparatus, wherein, each tooth of a fixed tooth plate is bolted to a fixed beam body; a slide tooth plate is shaft-connected to a slide beam body at the comb back far from the tooth through a rotating shaft apparatus; a gap is left betweena side beam and the slide tooth plate; the slide tooth plate is provided with an elastic straining device between the comb back close to the tooth and the slide beam body for restricting downward displacement of the slide tooth plate and the slide beam body. Compared with prior art, the downward displacement is solved through the relative movement of the slide tooth plate and the fixed beam body;a lower shaft rotates relatively little, which is solved by further compression of a spring; at the same time, the slide tooth plate is pressed on the fixed beam body surface through the spring, preventing jumping gear; furthermore, garbage is removed through a wear resistant-rod arranged under the slide tooth plate, preventing jumping gear caused by the garbage.

Owner:SHANGHAI EAGLE BRIDGE TECH

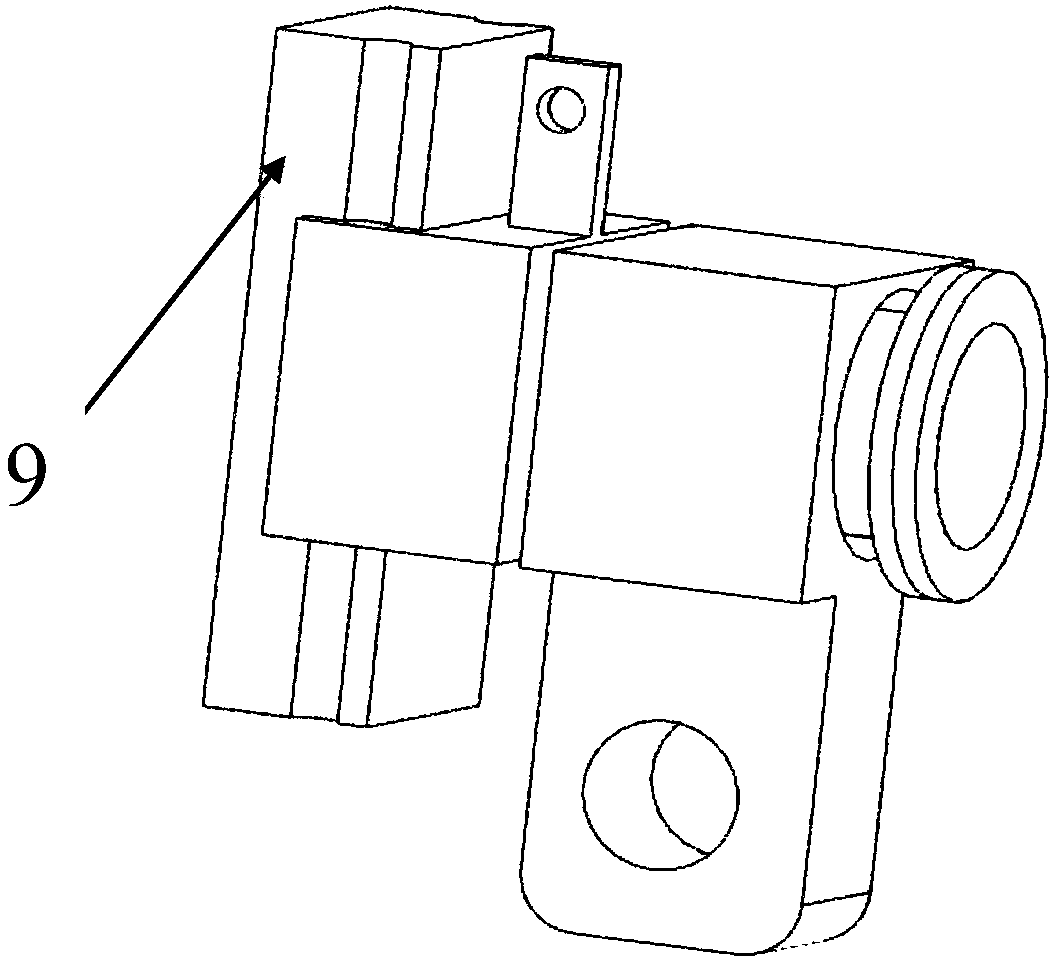

Compression roller drive mechanism of flying saw machine

InactiveCN103433556ALimited beatingReduce wearMetal sawing devicesMetal sawing accessoriesGear wheelEngineering

The invention discloses a compression roller drive mechanism of a flying saw machine in the flying saw machine field. The compression roller drive mechanism comprises a gear and a rack, wherein the gear and the rack are mutually meshed, the gear is installed on a gear shaft, the end of the gear shaft is in transmission connection with a servo motor, the rack is relatively fixed to a band mill of the flying saw machine, the gear shaft is rotatably arranged on a machine frame, and the positions, locating on the two sides of the gear, of the gear shaft are respectively and rotatably provided with a carrier roller; the rack is installed on the lower side of a rack base, the two sides of the rack base are respectively provided with a protruding portion which protrudes out of the two sides of the rack, the lower side of each protruding portion is correspondingly supported on each carrier roller, a compression roller is further arranged on the machine frame and arranged on the upper surface of the rack base in a matched mode, and the axis of the compression roller is parallel to that of the gear shaft. According to the compression roller drive mechanism, a proper gap is formed between the gear and the rack, so that transmission accuracy is guaranteed, and abrasion between the gear and the rack is reduced; due to the fact that the compression roller limits bouncing of the rack from above the rack, a gear and rack action line is prevented from being moved outwards. The compression roller drive mechanism is applied to the flying saw machine, and has the effect of improving the movement accuracy of the flying saw machine.

Owner:江苏省南扬机械制造有限公司

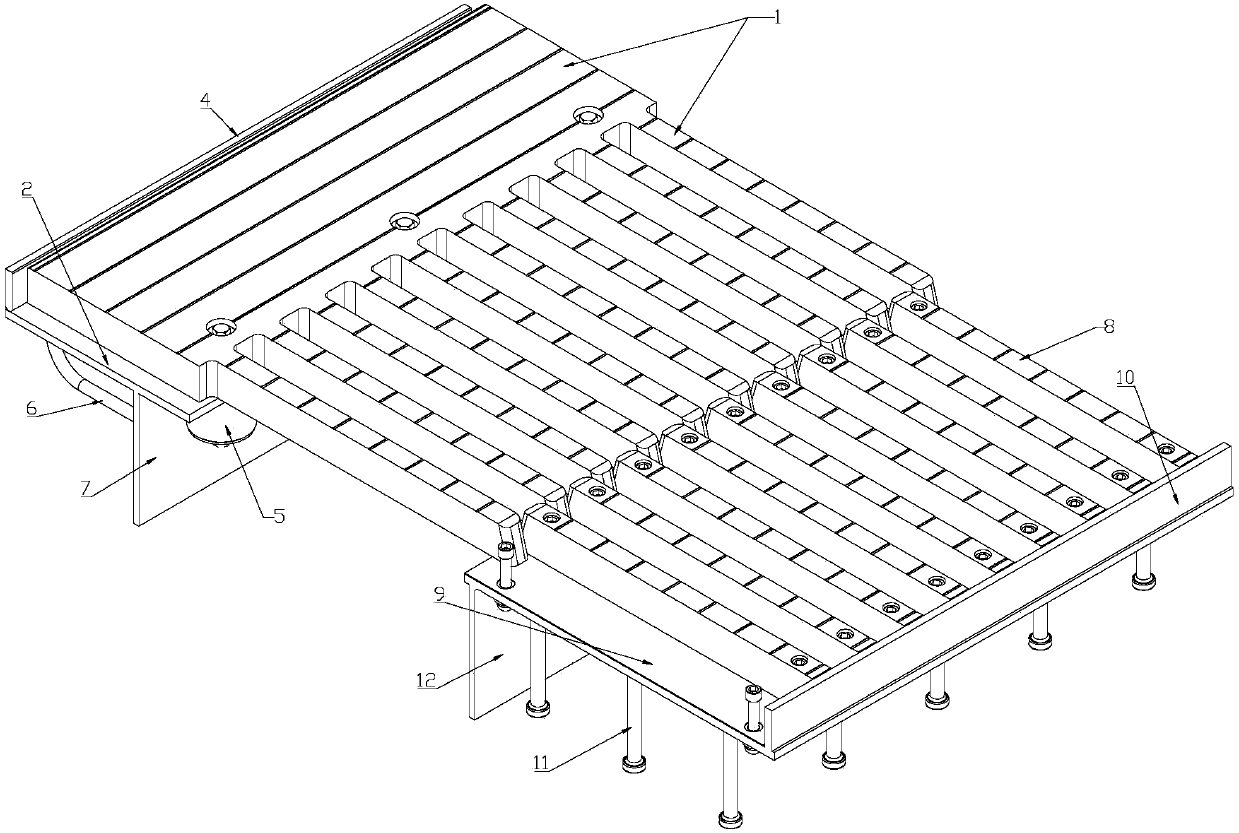

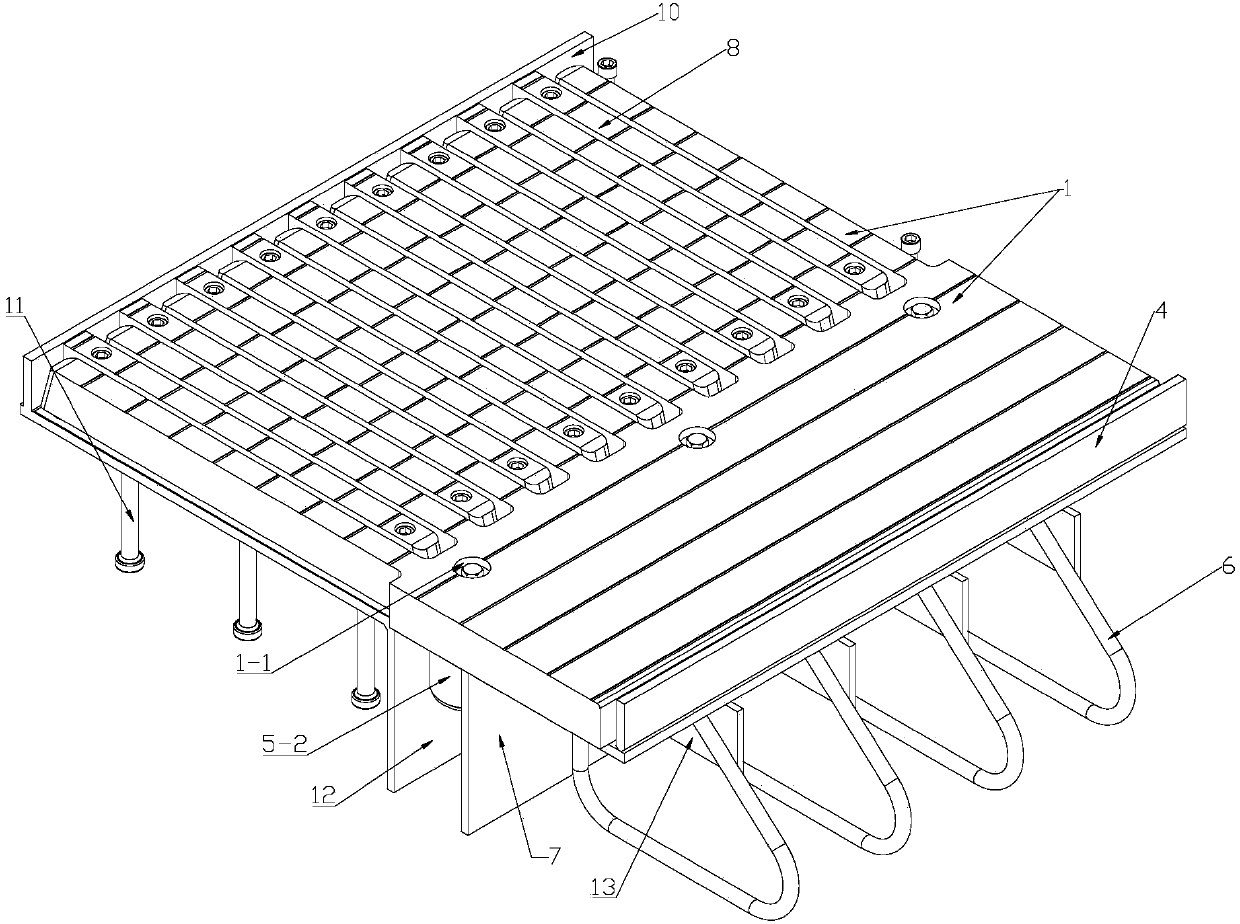

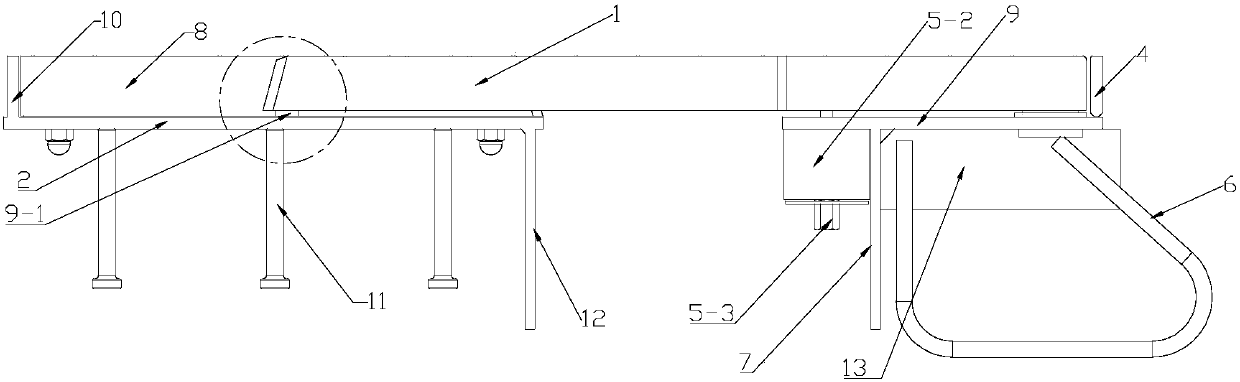

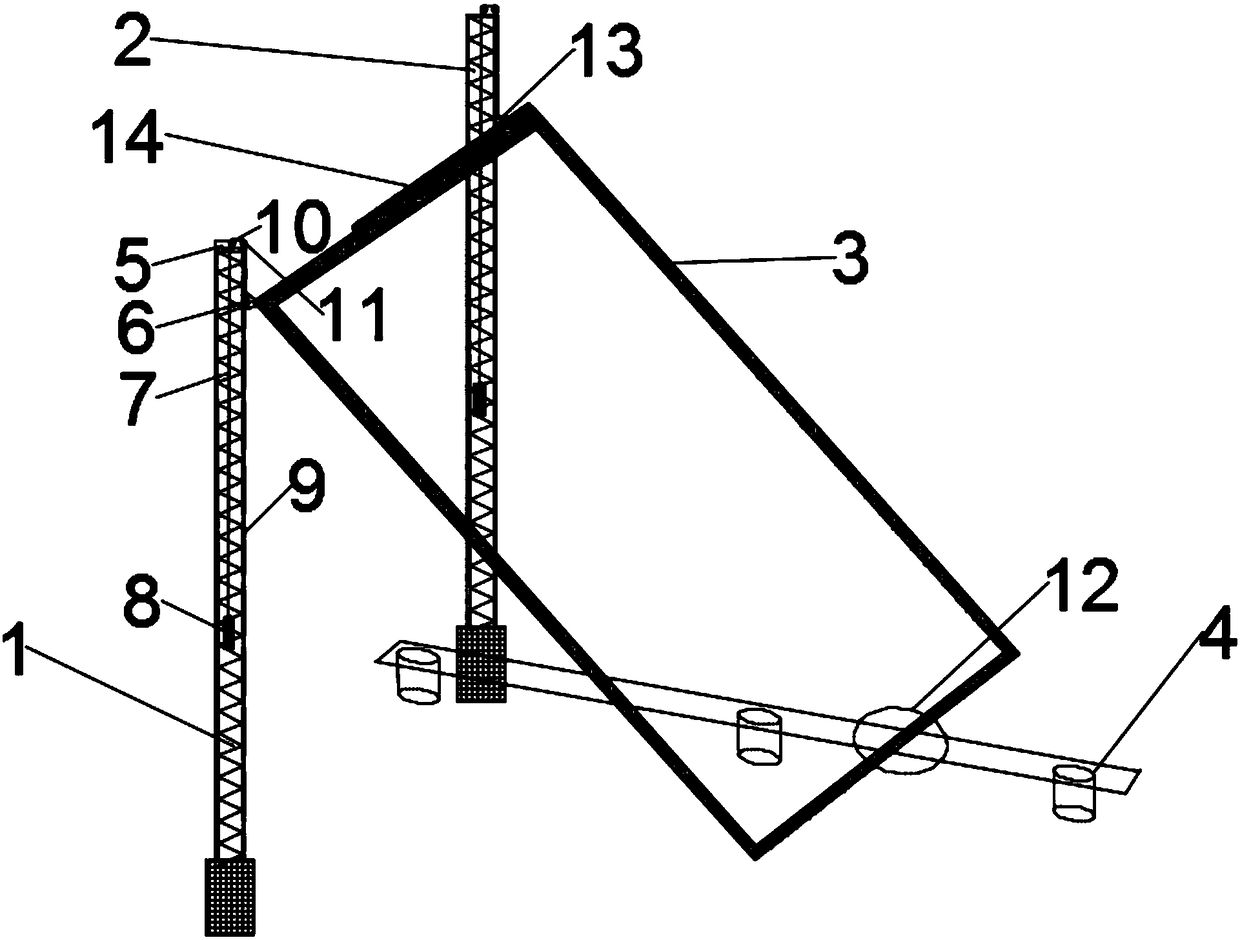

Double-mast-type tracking photovoltaic support

InactiveCN108306605AReduce motor loadIncrease pressurePhotovoltaic supportsSolar heating energyIntermediate pointEngineering

The invention discloses a double-mast-type tracking photovoltaic support. The support is characterized by comprising linear guide rails, a horizontal guide rail, first and second slide blocks, a support plate of a photovoltaic panel, and left and right head masts vertical to the horizontal plane, each head mast is provided with a hoisting mechanism, the linear guide rails are arranged in the axialedges of the left and right head masts respectively, the first and second slide blocks are connected with the linear guide rails of the left and right head masts respectively, one end of the supportplate of the photovoltaic panel is provided with a cylindrical slideway, the slideway is positioned in the end portion of one side of the support plate of the photovoltaic panel and is parallel with the side, the first slide block is connected with a fixed corner of the support plate of the photovoltaic panel, the second slide block is connected with the slideway, and a horizontal slide block on the horizontal guide rail is connected with the intermediate point of a side opposite to the slide block connecting side of the support plate of the photovoltaic panel. The angle of the support plate of the photovoltaic panel can be adjusted by controlling relative positions of three points, and the defect that a bi-axial tracking photovoltaic support is not strong enough to support the large-areasupport plate of the photovoltaic panel in the prior art can be overcome.

Owner:扬中市传盛支吊架有限公司

Rotating locating device adopting rotating support for rotating platform

The invention relates to a rotating locating device adopting rotating support for a rotating platform. The rotating locating device comprises a driving frame arranged at the bottom of the rotating platform, a driving motor arranged on the driving frame, a locating frame arranged on one side of the driving frame and a grooved rail arranged on a lifting platform, wherein the grooved rail is located on the lower side of the locating frame, corresponds to the position of a driving end of the driving motor, is an arc-shaped track, corresponds to the movement path of the driving frame, and adopts a U-shaped groove body with an opening opposite to the circle center. With adoption of the technical scheme, driving connection of the rotating platform and the lifting platform is transferred to the edge of the rotating platform, therefore, internal stress of mechanical driving can be changed effectively, a low-power driving motor can be assembled, a driving motor with high rotating speed and low torque can be also mounted, rapid response of the rotating platform can be realized, small-stress driving is realized, a locating point can be close to the parking space, and an action to reach the parking space is accurately controlled.

Owner:王景保

Structure for preventing gear slippage in optical disk drive

InactiveCN100343912CAvoid deflectionDoesn't change the weight muchTrack finding/aligningDisposition/mounting of headsEngineeringScrew thread

Owner:QUANTA STORAGE INC

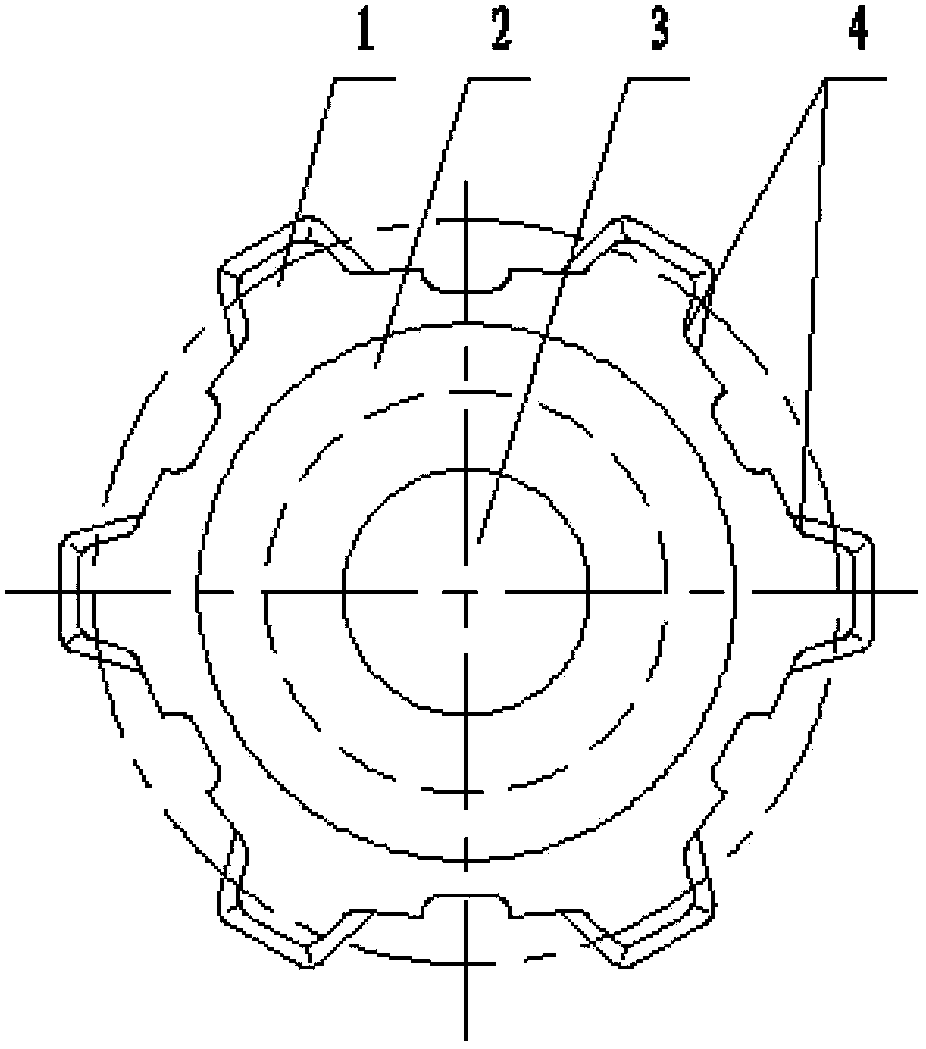

Timing chain wheel chamber shell

InactiveCN105545519AAvoid tooth skippingReduce maintenance costsCasingsValve arrangementsAutomotive engineeringSprocket

The invention discloses a technology of an engine timing system, and relates to a timing chain wheel shell. The timing chain wheel shell comprises a chain wheel cover cap, connecting holes are formed in the edge of the chain wheel cover cap, an intake camshaft groove and an exhaust camshaft groove are formed in the top of the chain wheel cover cap, and are respectively formed in the outside and the inside of the chain wheel cover cap respectively; semicircular rubber plugs are filled in the intake camshaft groove and the exhaust camshaft groove; an air phase commutation guide wheel is arranged between the grooves; a chain guiding groove is formed in a part, which is close to the exhaust camshaft groove, of the inner side of the chain wheel cover cap; and a crankshaft chain wheel is further arranged on the chain wheel cover cap, and is connected with a volute guiding groove. by the chain guiding groove and the volute guiding groove, chain teeth skipping caused by the reason of excessive fluctuation of tension of a timing chain system and the like is prevented, and repairing cost is saved; and during phase commutation, only the semicircular rubber plugs need to be taken down, and the time and labor are saved.

Owner:四川华威兄弟科技有限公司

Eccentric shaft drive mechanism and variable compression ratio mechanism

ActiveCN110966088BAchieve compression ratioSimple structureEngine controllersMachines/enginesClassical mechanicsCylinder block

The present invention provides an eccentric shaft drive mechanism and a variable compression ratio mechanism. The eccentric shaft drive mechanism of the present invention is used to receive the driving of the crankshaft to drive the eccentric shaft to rotate, and it includes a follower that is rotatably fitted on one end of the eccentric shaft. The transmission part sleeved on the eccentric shaft on the outer side of the follower, and the control part fixed on the engine block carrying the eccentric shaft, also includes the transmission connection part arranged on the transmission part and the follower, and the follower Connected with the crankshaft, the transmission part and the eccentric shaft rotate synchronously, and the transmission part can be driven by the control mechanism to be connected or disconnected from the follower, so that the rotation of the crankshaft can drive the eccentric shaft to rotate. The eccentric shaft drive mechanism of the present invention drives the rotation of the eccentric shaft by the rotation of the crankshaft, so that the angle of the eccentric shaft can be changed to achieve the compression ratio of the engine, and the drive mechanism is directly driven by the crankshaft to rotate the eccentric shaft without an external power device. The structure is simple, easy to arrange, and has good practicability.

Owner:GREAT WALL MOTOR CO LTD

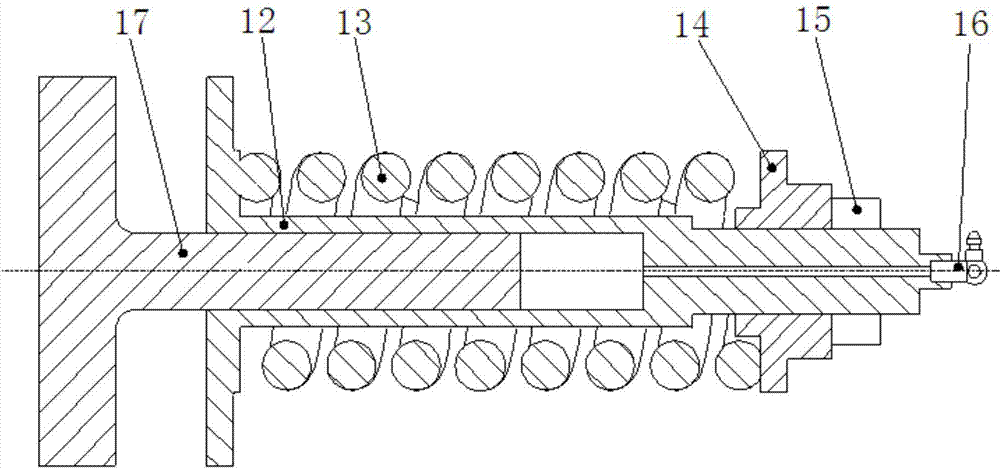

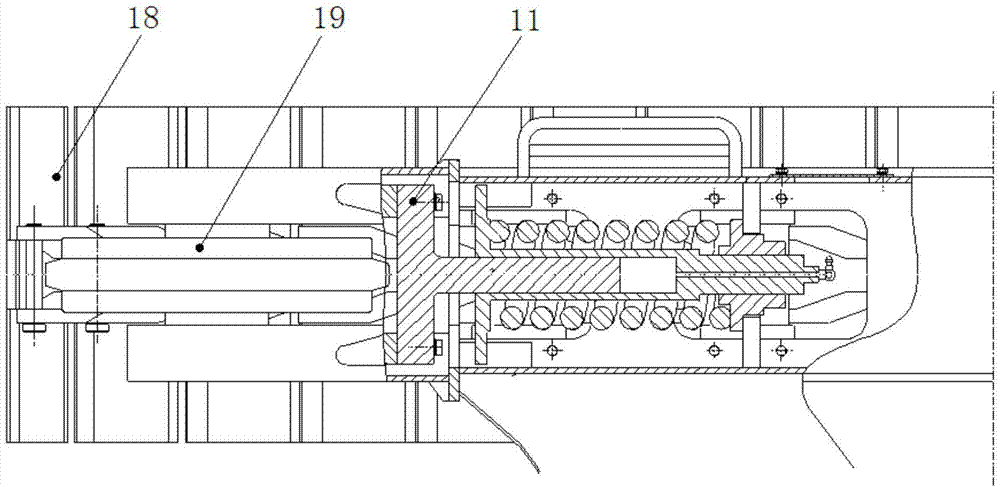

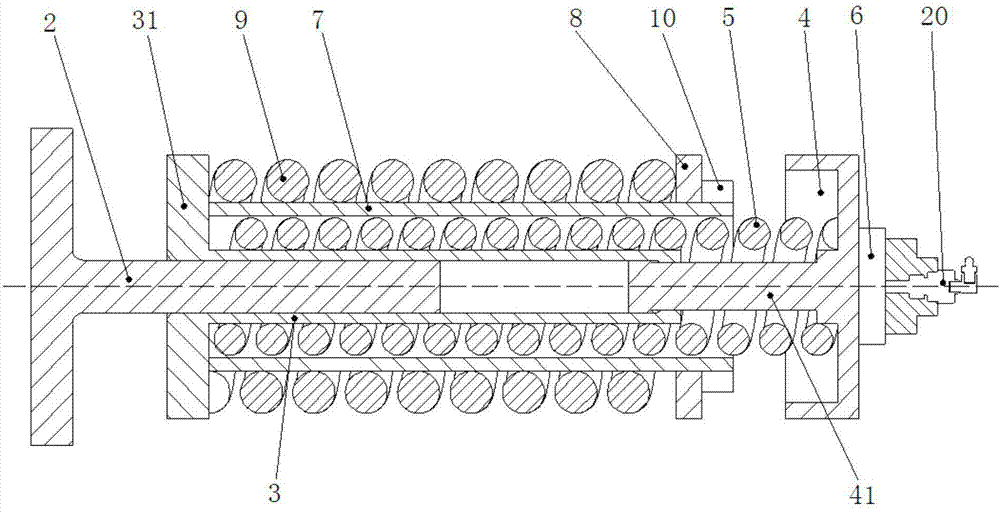

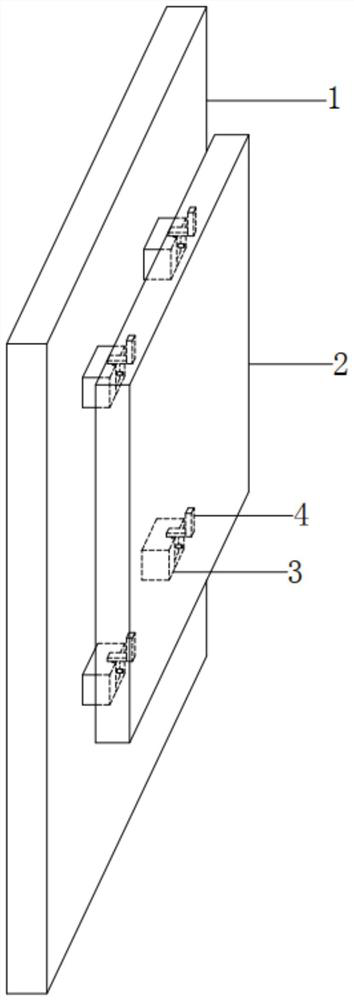

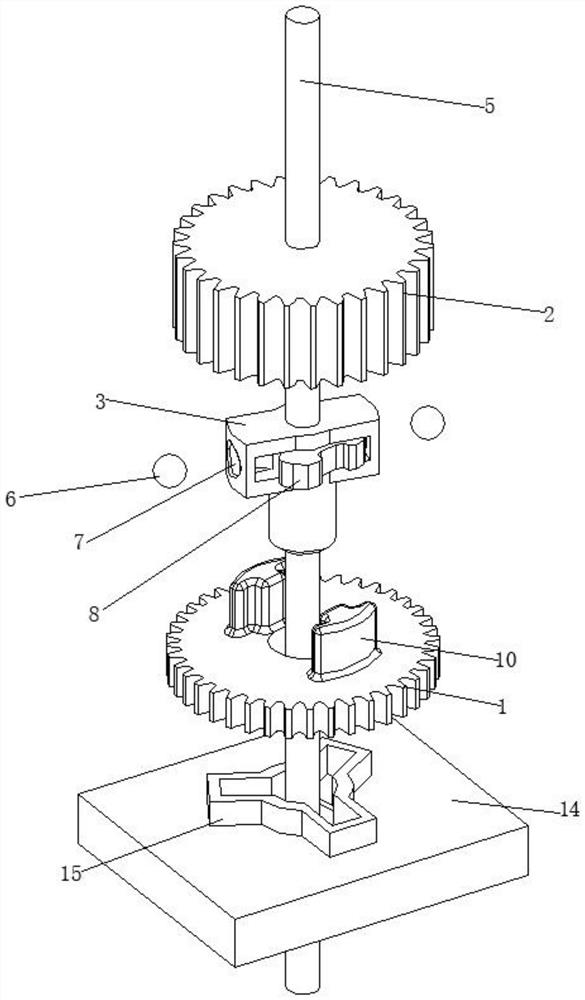

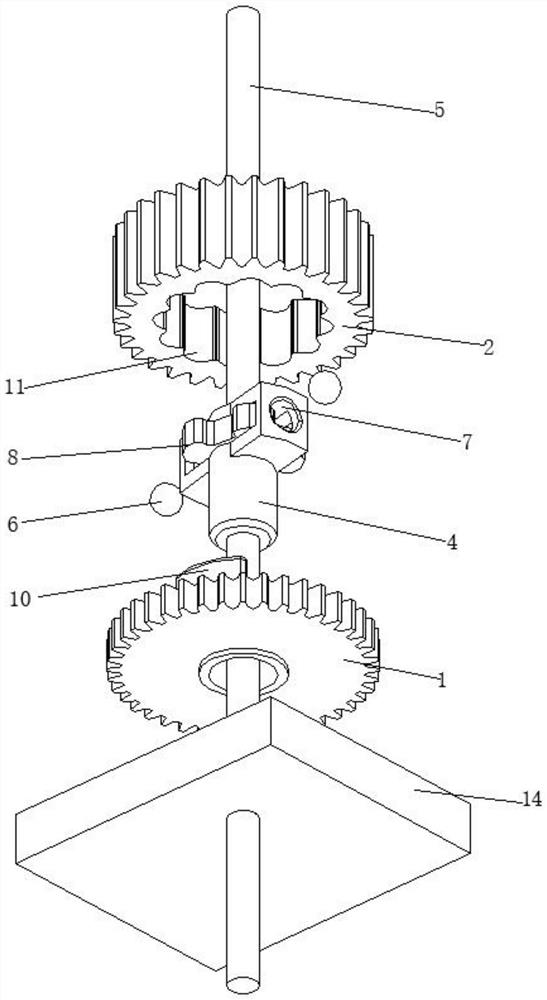

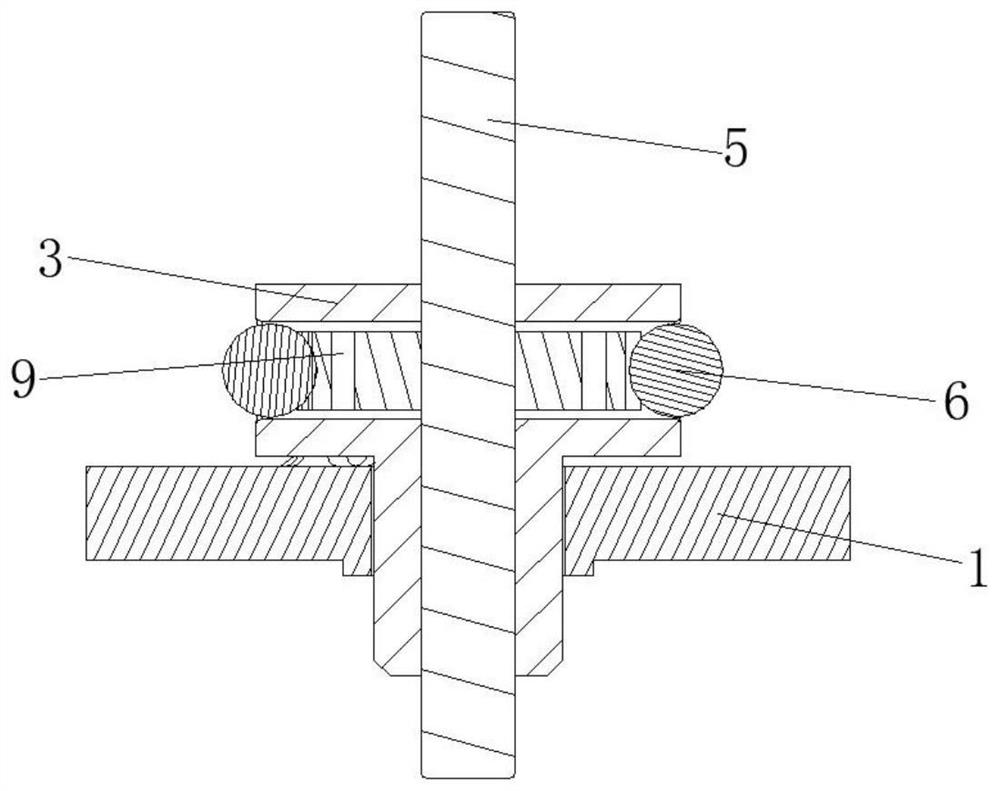

Ball clutch structure

PendingCN114483811AIngenious structureHigh clutch structure efficiencyMan-operated mechanismMagnetically actuated clutchesGear wheelDrive shaft

A ball clutch structure belongs to the field of movable closing device structures for door and window openings and is characterized in that a ball sleeve penetrates through the middle of a power input gear, a transmission shaft extends from the bottom of the ball sleeve, a rotating shaft penetrates through the middle of the ball sleeve, one end of the rotating shaft penetrates through the transmission shaft, and the other end of the rotating shaft penetrates through a power output gear; a ball is arranged on the inner side of the power input gear, a shifting piece is arranged on the inner side of the power input gear, and when the power input gear rotates, the shifting piece is driven to shift the ball to move so that the ball can be matched with the clamping groove, and the power output gear is driven to rotate. When the power input gear stops rotating, the ball is reset through the sliding groove and the magnetic attraction column, at the moment, the power output gear can rotate freely, manual opening is achieved, and the clutch structure is high in efficiency and capable of achieving complete clutch and effectively avoiding gear skipping.

Owner:瑞智轩科技(佛山)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com