Electric servo x-type robot welding gun

A technology of robotic welding tongs and electric servo, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of short service life of synchronous toothed belt, short service life of welding tongs, high price of welding tongs, etc. Achieve the effect of stable control, low production cost and remarkable application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

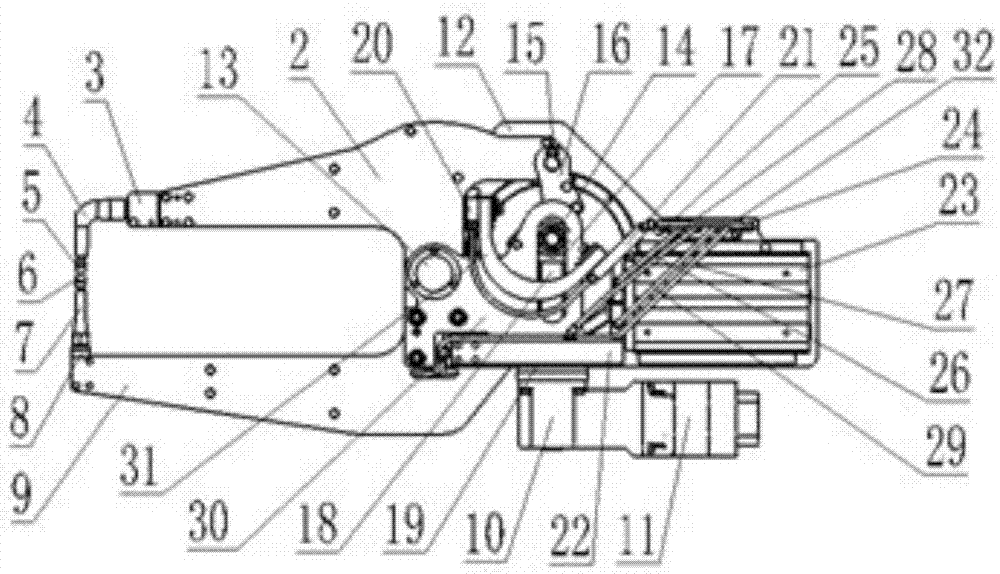

[0019] Below in conjunction with accompanying drawing and preferred embodiment, to the specific implementation mode, structure, feature according to the present invention are described as follows:

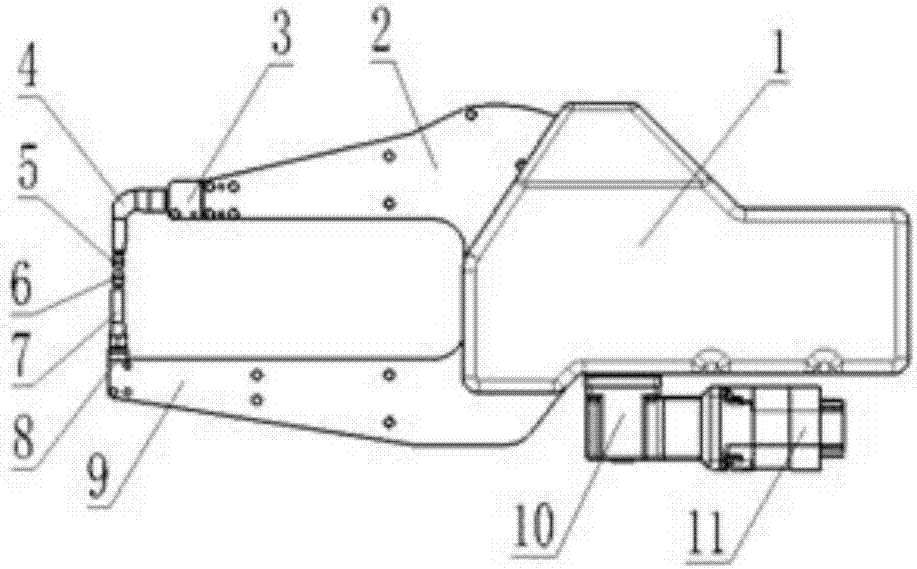

[0020] Such as figure 1 , figure 2 As shown, an electric servo X-type robot welding tongs includes a drive assembly, an upper electrode arm assembly, a lower electrode arm assembly, a water pipe assembly, a transformer assembly, a base plate 12 , an upper plate 30 and a shield 1 .

[0021] The drive assembly includes a servo motor 11, a reducer 10, a ball screw 18, a connecting rod 16, a shaft two 15, a deep groove ball bearing 14, a screw nut shaft 17 and a bearing housing 19; the servo motor 11 and the reducer 10 The reducer 10 is installed on the bearing seat 19, the ball screw 18 is connected with the reducer 10 through the bearing seat 19, and the other end of the ball screw 18 is installed with a screw female shaft 17, and the horizontal axes on both sides of the screw fema...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com