Intelligent control system and control method for scraper conveyer

An intelligent control system, technology of scraper conveyor, applied in the direction of conveyor control device, transportation and packaging, conveyor objects, etc., can solve the problems of poor adaptability, etc., and achieve the effect of motor energy saving, avoiding blockage failure, and appropriate size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

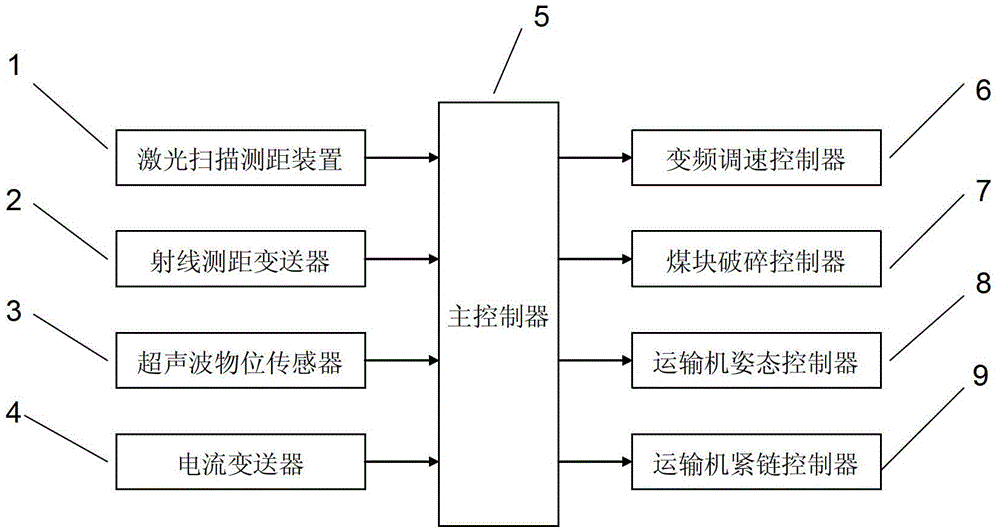

[0018] Embodiment: The intelligent control system of the scraper conveyor of the present invention mainly includes a laser scanning ranging device 1, a ray ranging transmitter 2, an ultrasonic level sensor 3, a current transmitter 4, a main controller 5, and a frequency conversion speed regulation Controller 6, coal block crushing controller 7, conveyor attitude controller 8 and conveyor tight chain controller 9. The laser scanning ranging device 1, the ray ranging transmitter 2, the ultrasonic level sensor 3 and the current transmitter 4 transmit the detection signal to the main controller 5 through wireless communication, and the main controller 5 controls the The command is sent to the frequency conversion speed regulation controller 6, the coal block crushing controller 7, the conveyor attitude controller 8 and the conveyor chain tightening controller 9.

[0019] The laser scanning distance measuring device 1 is installed on the upper roof of the scraper conveyor, and scan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com