Semiconductor detection taping process and system

A semiconductor and braiding technology, which is applied in the direction of transportation packaging, packaging, packaging protection, etc., can solve the problems that the defective rate of the carrier tape is difficult to reduce, and it is impossible to accurately identify whether the positive and negative electrodes of the material are placed correctly, so as to reduce the defective rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

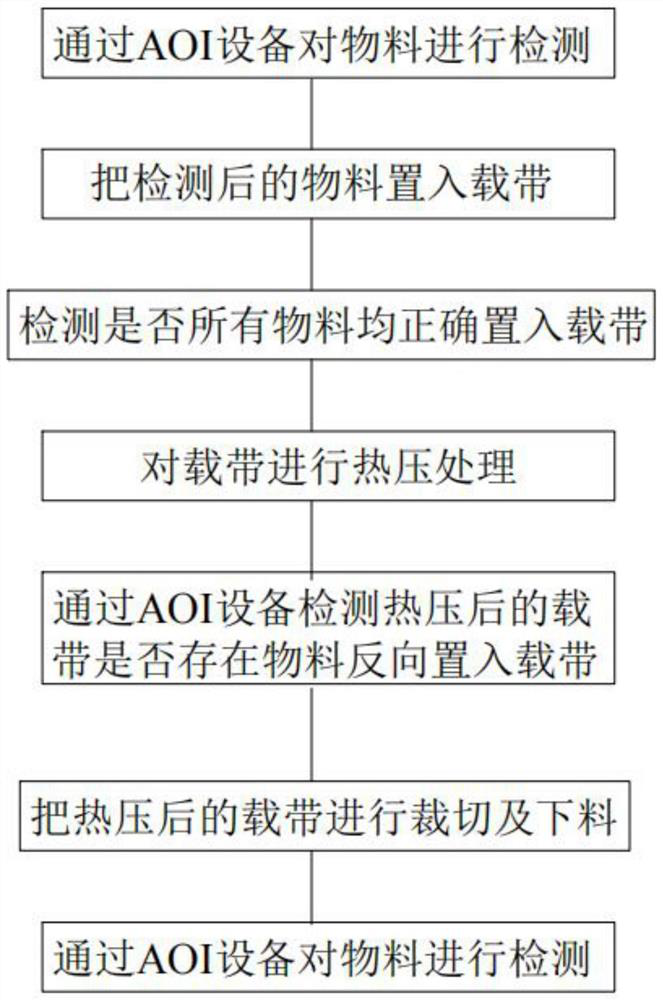

[0031] Such as figure 1 As shown, the present embodiment provides a semiconductor detection tape process, comprising the following steps:

[0032] A. Detect materials through AOI equipment;

[0033] B. Put the detected material into the carrier tape;

[0034] C. Carry out hot pressing treatment to the carrier tape;

[0035] D. Cut and unload the hot-pressed carrier tape.

[0036] Compared with the prior art that only detects whether the material can work normally, the present invention uses AOI equipment to detect the material, specifically to detect the appearance of the material, so as to identify whether the posture of the material is correct; in addition, the detection of the appearance of the material can also judge Whether there is wear and tear on the two power terminals of the material, so as to realize the detection of whether the material can be energized.

[0037] In summary, the use of AOI for detection also has the following advantages:

[0038] 1. The pixels...

Embodiment 2

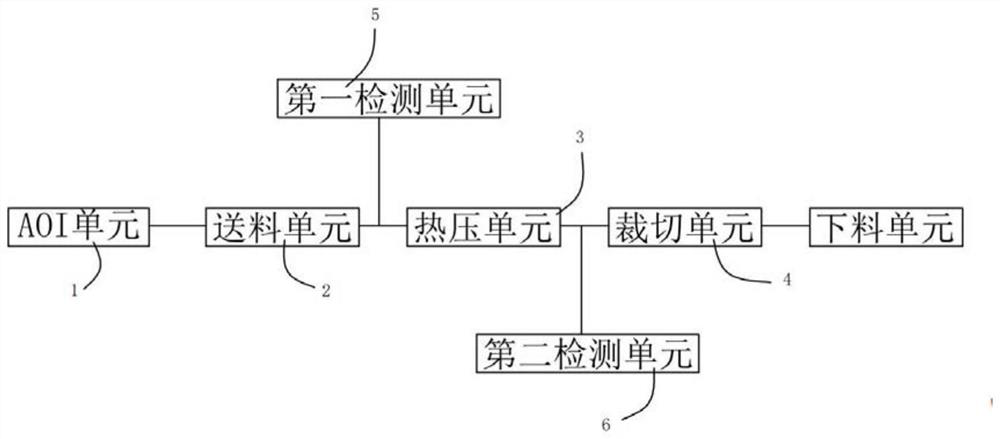

[0049] Such as figure 2 As shown, this embodiment provides a semiconductor detection tape system, including

[0050] AOI unit 1, used for visual inspection of materials;

[0051] The feeding unit 2 is used to put the detected material into the carrier tape;

[0052] The hot-pressing unit 3 is used for hot-pressing the carrier tape after placing the material;

[0053] The cutting unit 4 is used for cutting the hot-pressed carrier tape.

[0054] This embodiment can be used to implement the process described in Embodiment 1, that is, the AOI unit 1 is used to inspect the appearance of the material before braiding to detect whether its appearance is worn and whether its posture is accurate, and it can be judged according to the appearance that it can be reliably connected to electricity. And whether it is reversed, so that when the material is placed on the carrier tape, there will be no phenomenon of power failure or reversed connection, which improves the yield rate.

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com