Product feeding equipment for self propelled car steering knuckle full-automatic press-fitting line

A steering knuckle, fully automatic technology, used in metal processing equipment, manufacturing tools, vehicle parts, etc., can solve problems such as insufficient stability and inconvenient steering knuckle transmission, and achieve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

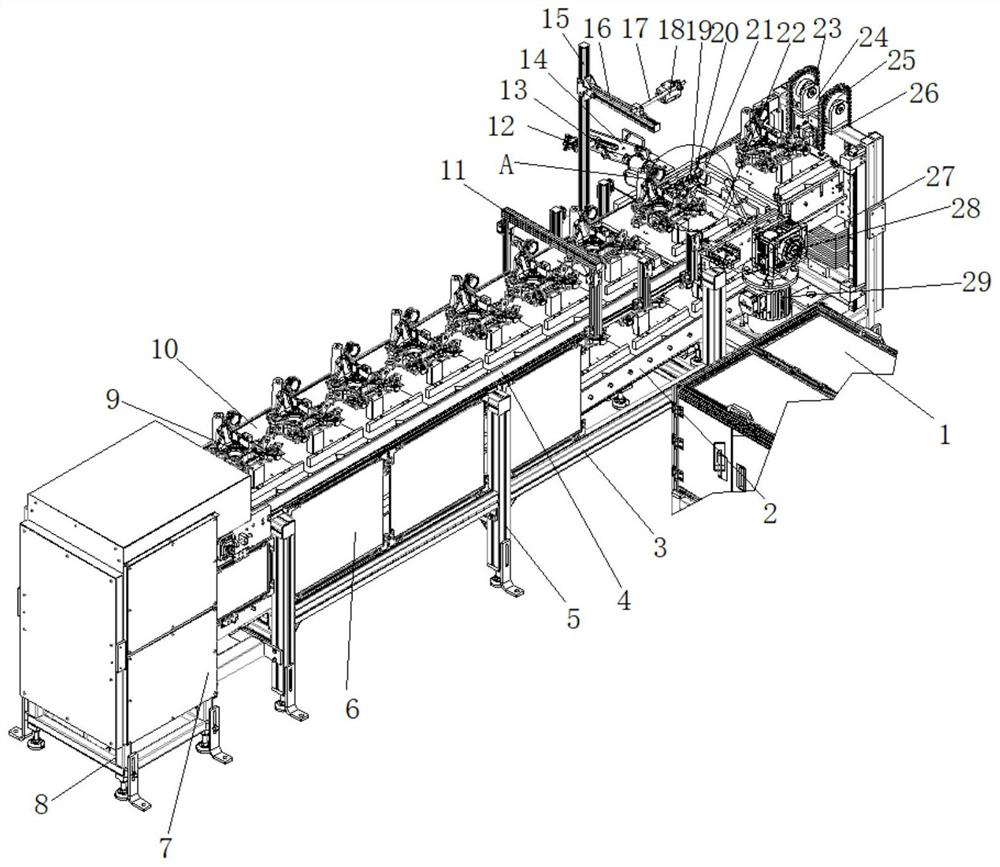

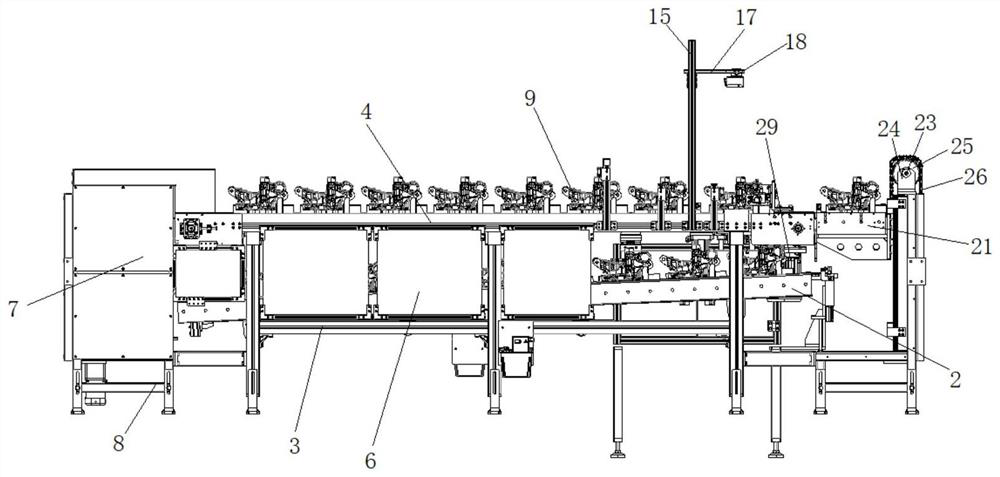

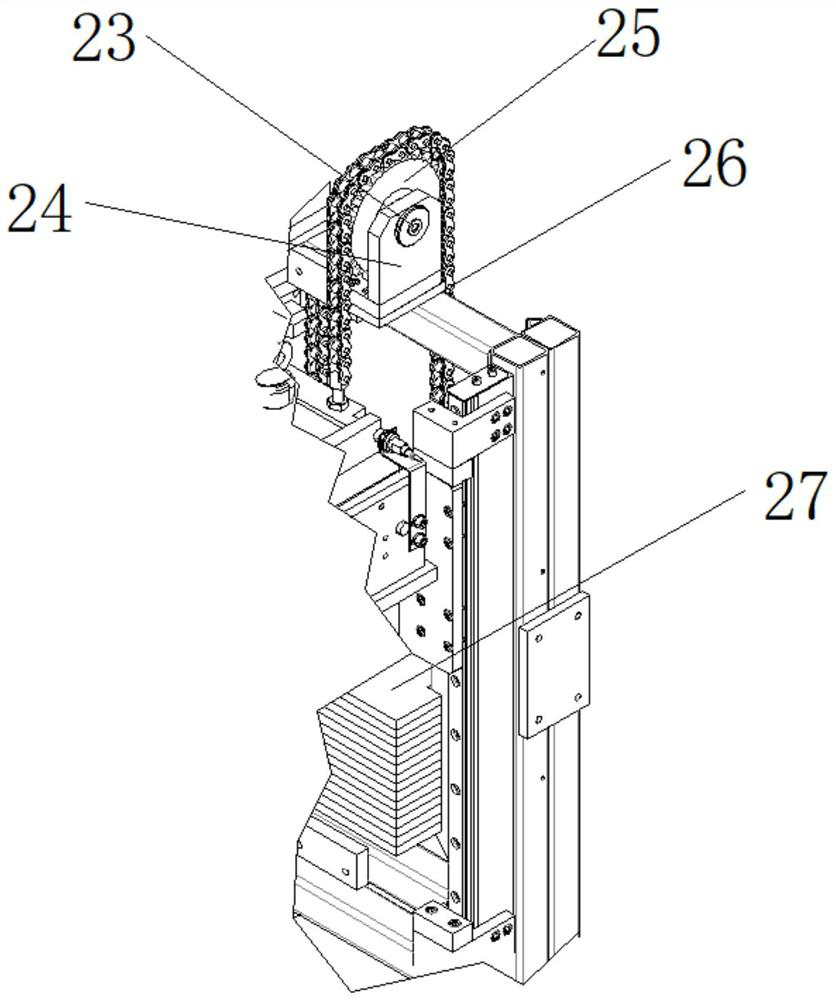

[0026] Example 1: See Figure 1-4 , a kind of product feeding equipment for the automatic press-fitting line of the steering knuckle of an automatic car, comprising a power distribution control box 1, a first support frame 3 is arranged on one side of the power distribution control box 1, and a first support frame 3 is installed on one end of the first support frame 3 Baffle plate 6, support seat 5 is installed between the first support frame 3, a fixed frame 8 is installed on one side of the first support frame 3, the top of the first support frame 3 other side is fixedly installed with a fixed seat 24, the fixed frame The top of 8 is equipped with a fixed cover 7, the top of the first support frame 3 is equipped with a second support frame 15, and the second support frame 4 is arranged between the first support frame 3;

[0027] The bottom end of the second fixed mount 4 is provided with the first fixed mount 2, and the bottom end of the second fixed mount 4 one end is fixed...

Embodiment 2

[0030] Embodiment 2: One end of the first support frame 3 is installed and fixed with a first installation frame 14, and one side of the first installation frame 14 is installed and fixed with a hydraulic cylinder 12, and one end of the hydraulic cylinder 12 is fixedly connected with a telescopic rod 13, and the telescopic rod 13 One end of which is fixed with a rotary positioning device 30;

[0031] A detection module 11 is arranged between the tops of the second fixed frame 4, and the detection module 11 is mounted on the top of the second fixed frame 4 in a gantry type;

[0032] Specifically, such as figure 1 with Figure 4As shown, the detection module 11 is installed on the top of the second fixed frame 4, because the detection module 11 is a gantry type, through the cooperation with the CCD visual detector 18, in the process of the steering knuckle 9 being transmitted, it is convenient to remove the unidentified The steering knuckle 9 that meets the posture requirement...

Embodiment 3

[0033] Embodiment 3: The support seat 5 stands on the ground, and the bottom of one end of the support seat 5 is fixedly connected to the ground through an "L"-shaped angle steel sheet;

[0034] Specifically, such as figure 1 with figure 2 As shown, the "L"-shaped angle steel sheet at the bottom of the support base 5 can facilitate the fixed connection of the support base 5 to the ground, so that the support base 5 and the first support frame 3 can be more stable on the ground.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com