Compression roller drive mechanism of flying saw machine

A transmission mechanism, the technology of flying saw machine, which is applied to the attachment of sawing machine, sawing machine device, metal sawing equipment, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

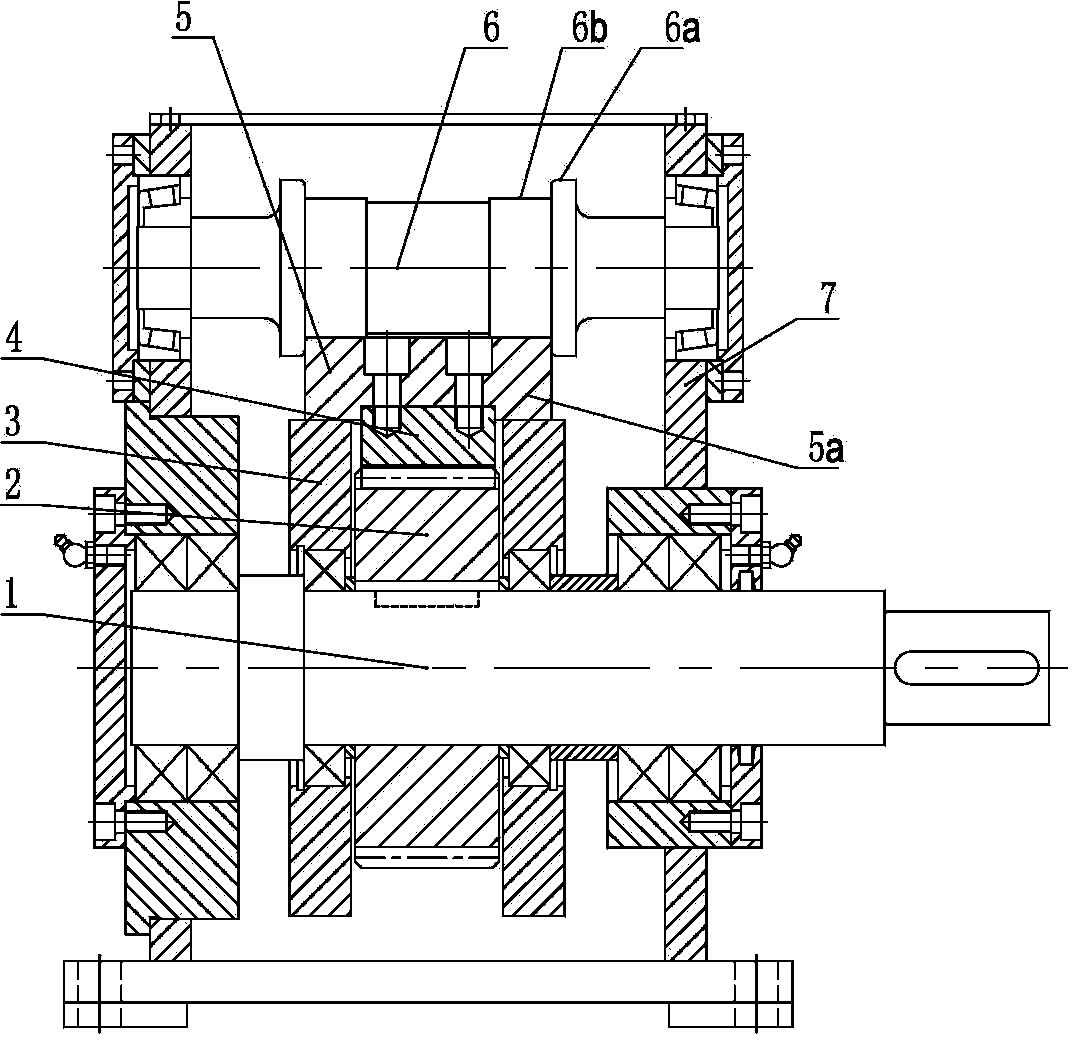

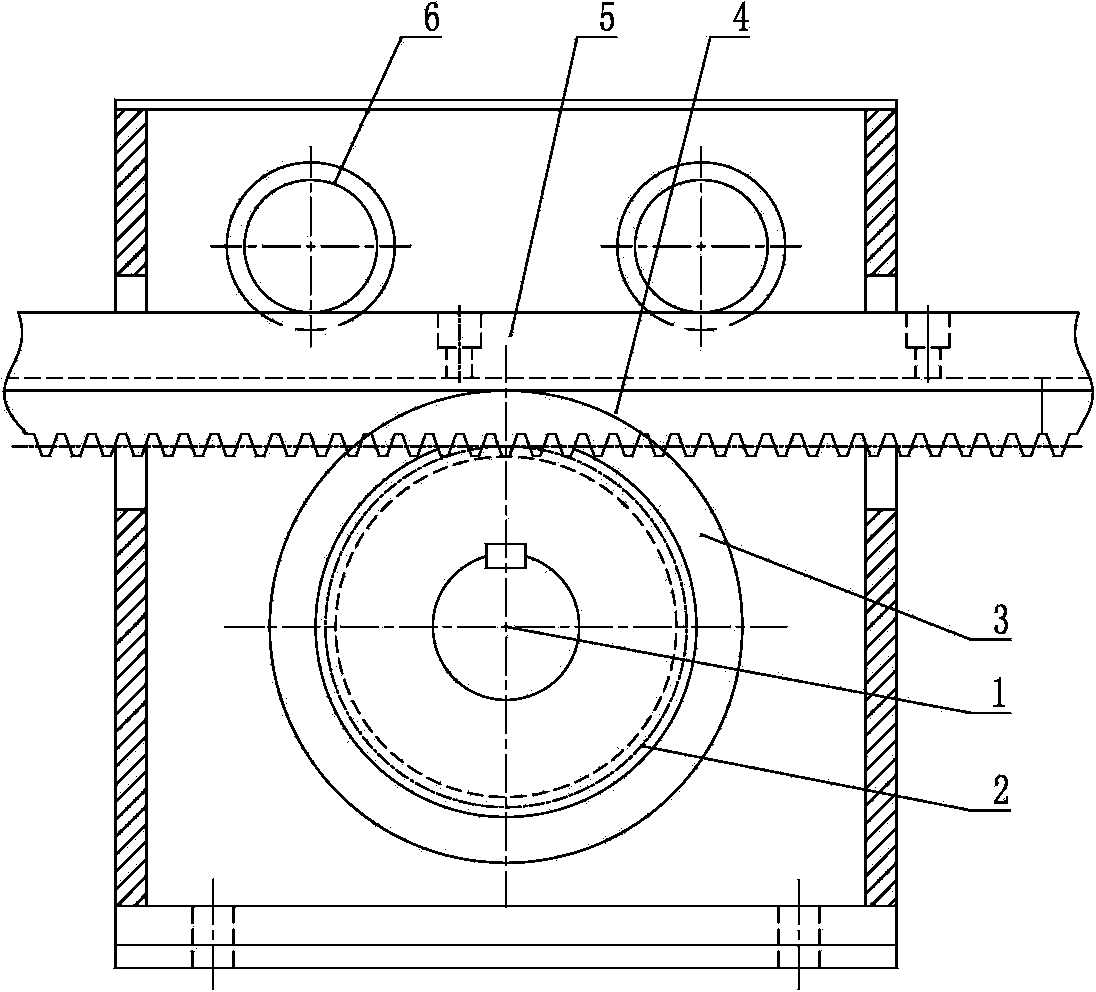

[0012] Such as Figure 1-2 As shown, it is a pressure roller transmission mechanism of a flying saw machine, which includes a gear 2 and a rack 4 that mesh with each other. The gear 2 is installed on the gear shaft 1, and the end of the gear shaft 1 is connected to the servo motor. The rack 4 and the The sports car of the flying saw machine is relatively fixed. When the rack 4 moves linearly, it can drive the sports car to move linearly. The device includes a frame 7, and the gear shaft 1 is rotatably arranged on the frame 7 through the bearing and the bearing seat. The gear shaft 1 is located on both sides of the gear 2 and is respectively rotatably provided with idlers 3, the idlers 3 can rotate relative to the gear shaft 1, and the two are supported and connected by bearings; the rack 4 is installed on the lower side of the rack seat 5, and the gear Both sides of the bar seat 5 are respectively provided with protruding parts 5a protruding from both sides of the rack, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com