A chain-belt drive system

A chain belt drive and chain belt technology, applied in the field of chain belt drive system, can solve the problems affecting the normal operation and use of roller moving slat conveyor equipment, and achieve the effect of avoiding tooth loss and ensuring synchronization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

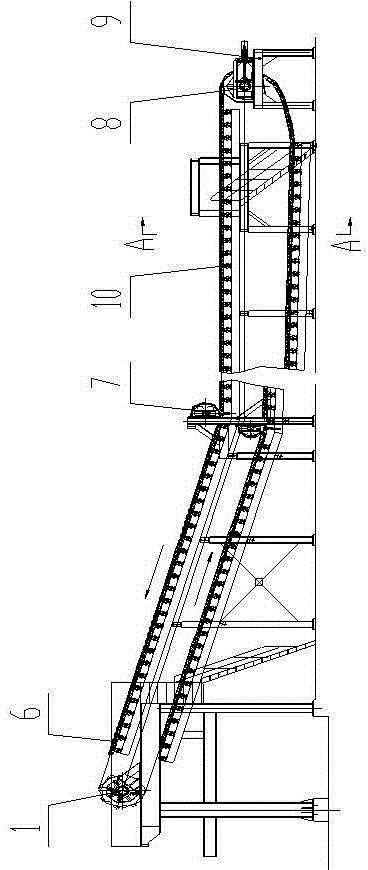

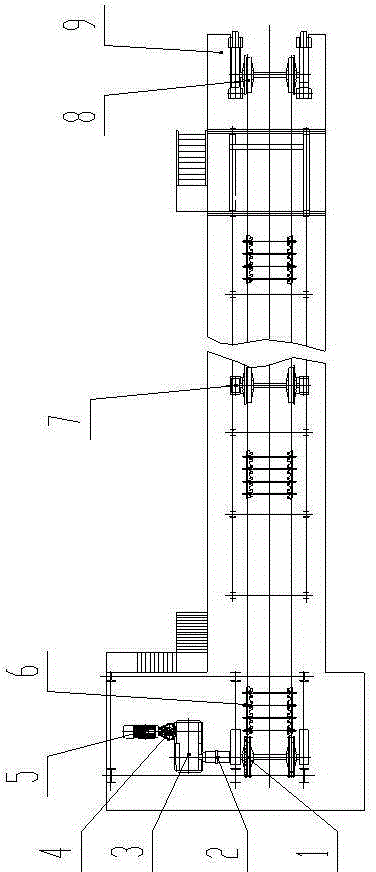

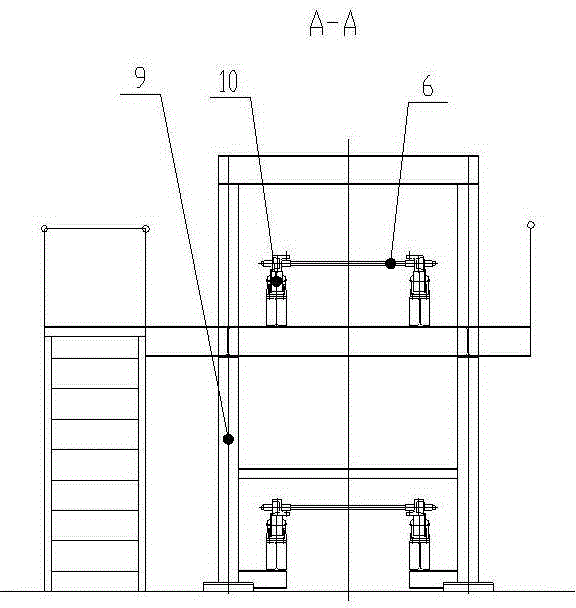

[0041] Such as figure 1 , figure 2 , image 3 As shown, the chain-belt transmission system of the chain-belt tray conveyor is shown. The chain-belt transmission system includes: a driving device, a driving sprocket 1, a chain belt 6, a guide wheel 7, and a driven wheel 8.

[0042] The driving device includes a motor 5, a hydraulic coupling 4, and a reducer 3. The motor 5 and the reducer 3 are connected through the hydraulic coupling 4. The hydraulic coupling 4 can prevent equipment from being damaged due to overloading. The motor 5 drives the reducer 3 through the hydraulic coupling, and connects the driving sprocket 1 through the coupling 2. The driving sprocket 1 drives the driven wheel 8 to run through the chain belt 6. At the turning position of the chain belt 6, in order to prevent the running chain Belt 6 jumps and guide wheel 7 is set. The chain belt 6 is supported by rollers 10 mounted on the equipment stand 9 .

[0043] Such as Figure 4 , Figure 5 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com