Patents

Literature

42results about How to "Avoid tooth loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Agitating device for efficient sweet potato wine processing

InactiveCN107096422AStir wellImprove stirring efficiencyRotary stirring mixersTransportation and packagingReciprocating motionSlide plate

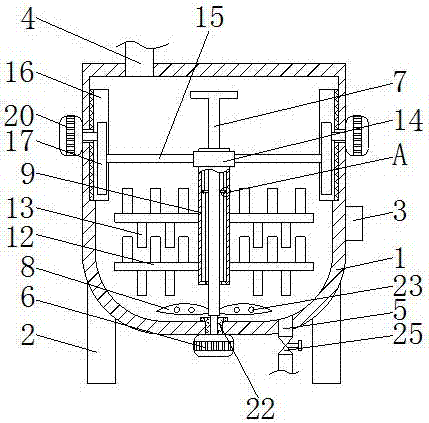

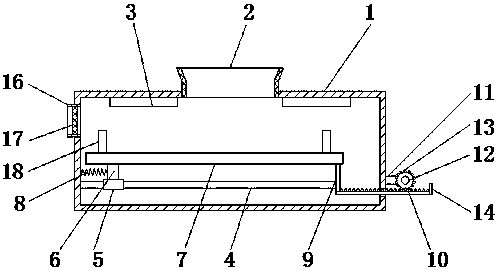

The invention discloses an agitating device for efficient sweet potato wine processing. The agitating device comprises a box body. Support legs are fixedly connected to both sides of the bottom of the box body. A controller is fixedly connected to the bottom of the right side of the box body. The left side of the top of the box body is communicated with a feeding pipe. The right side of the bottom of the box body between the support legs is communicated with a discharge pipe. The middle shaft at the bottom of the box body is fixedly connected to a motor. A rotation shaft of the motor extends into the inner cavity of the box body and is fixedly connected to a vertical rod. Stirring blades are fixedly connected to the bottom at two sides of the vertical rod. The surface of the vertical rod above the stirring blades is sleeved by a casing pipe. The sliding plate can move up and down and respectively drives a cross rod, a bearing, the casing pipe, a stirring rod and a stirring block to carry out vertical reciprocating motion so that the materials in the inner cavity are uniformly stirred and thus material stirring efficiency is improved and sweet potato wine production efficiency is improved.

Owner:耒阳市耒兴薯业发展有限公司

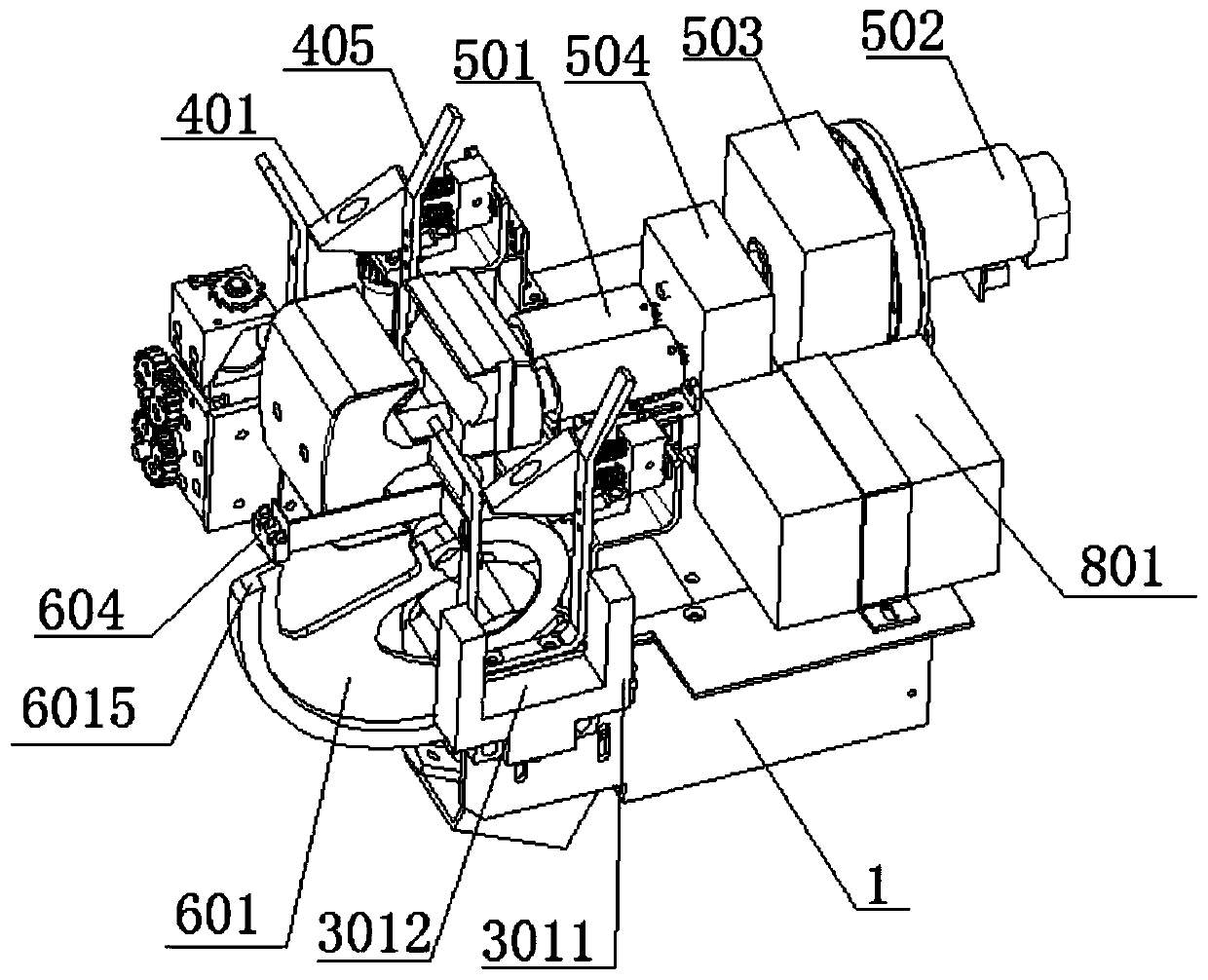

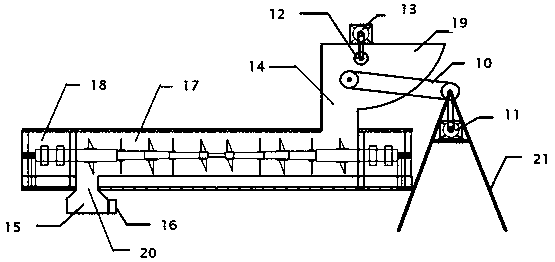

Special tool for 10KV circuit live-wire work robot drainage wire connecting work

ActiveCN110021898AAvoid clutterBeautiful lengthApparatus for cutting/splicing cablesApparatus for joining/termination cablesEngineeringElectrical and Electronics engineering

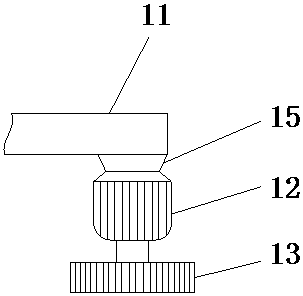

The invention discloses a special tool for 10KV circuit live-wire work robot drainage wire connecting work. The special tool comprises a cable stretch-in end and a cable stretch-out end, wherein a puncture cable clamp is positioned between the cable stretch-in end and the cable stretch-out end. The special tool comprises a substrate, and is characterized by comprising a drainage wire shearing mechanism installed on the substrate, wherein the drain wire shearing mechanism comprises an electric cutter; and the electric cutter is positioned at the cable stretch-out end. According to the special tool, robot live-wire wiring work can be realized, manual live-wire wiring work also can be realized, and the special tool has the function of shearing unnecessary drainage wires.

Owner:山东乐普韦尔自动化技术有限公司

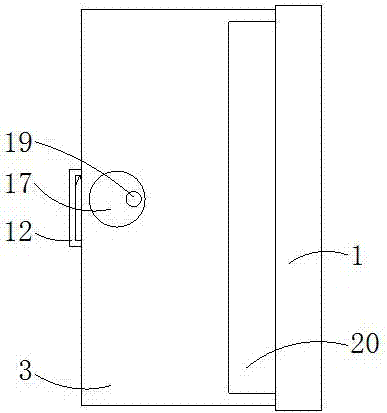

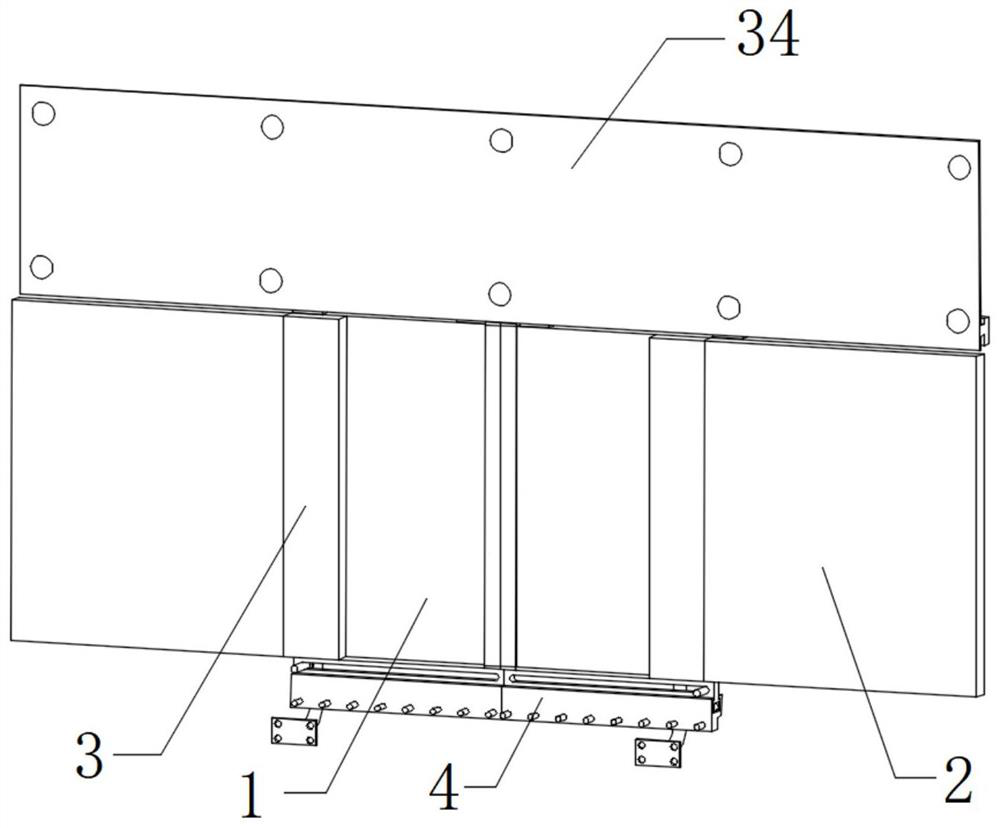

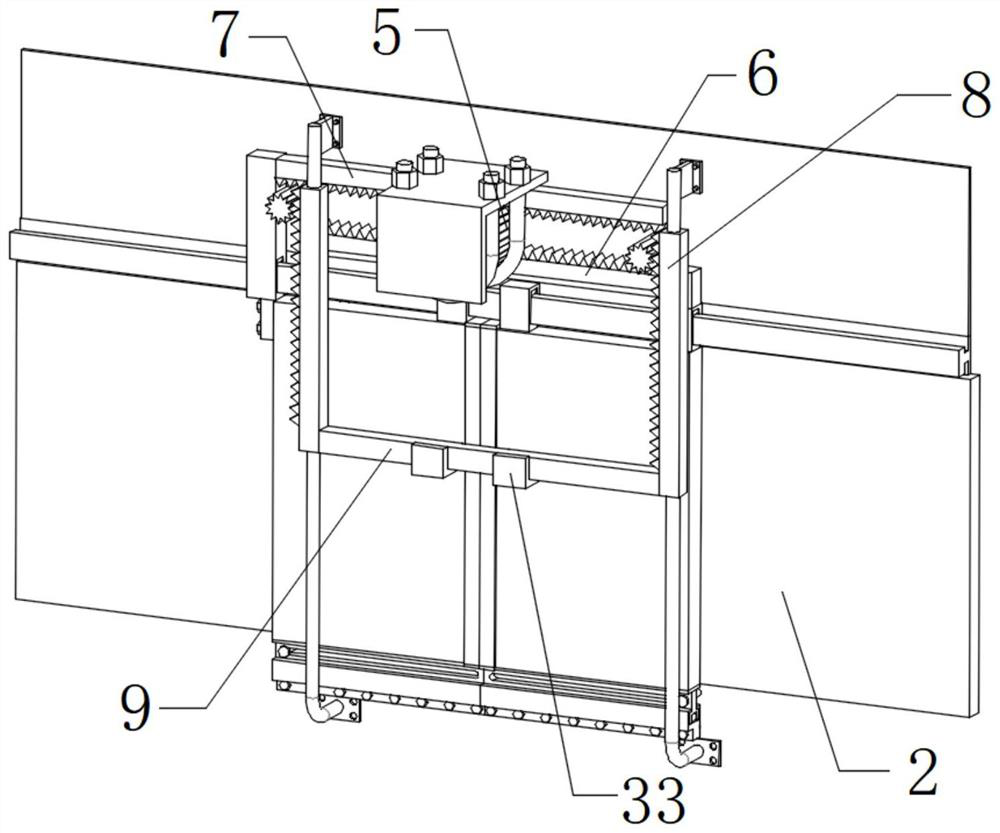

Publicity board adjustable in width

The invention discloses a publicity board with adjustable width, which comprises a base, the top of the base is fixedly connected with a vertical pipe, the top of the inner cavity of the vertical pipe is fixedly connected with a first motor, and the rotating shaft of the first motor is fixedly connected with There is a threaded rod, the top of the threaded rod is covered with a threaded pipe, the top of the threaded pipe extends to the outside of the vertical pipe, the top of the threaded pipe is fixedly connected with a fixing plate, and the top and bottom of the fixing plate are both A first chute is opened, movable plates are arranged on both sides of the inner cavity of the fixed plate, and the top and bottom of the movable plate are fixedly connected with a first slide bar, and the end of the first slide bar is far away from the movable plate Extends to the lumen of the first chute. The invention can make the rack move laterally, and the rack drives the movable plate to move laterally, so that the movable plate extends out of the inner cavity of the fixed plate, and information can be posted on the movable plate, which increases the publicity area of the publicity board and is convenient for people to use.

Owner:SUZHOU MOCHOU CULTURE TECH CO LTD

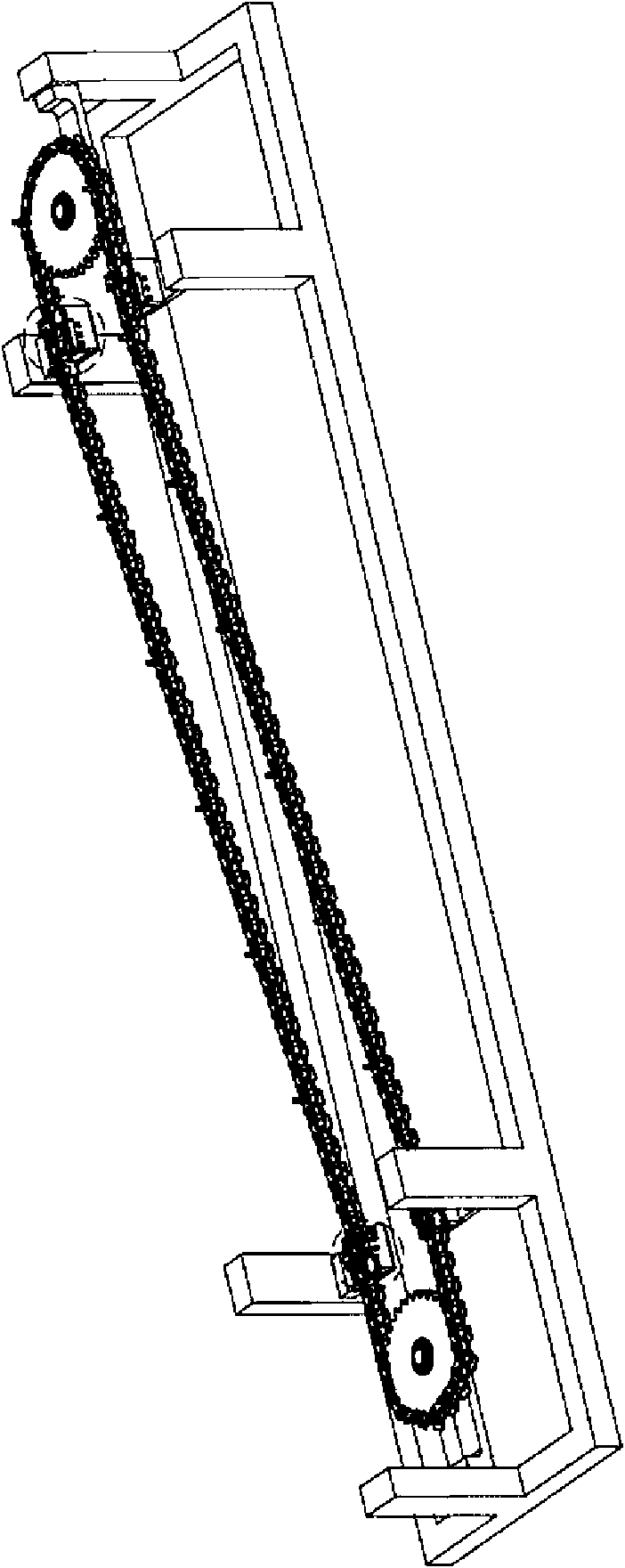

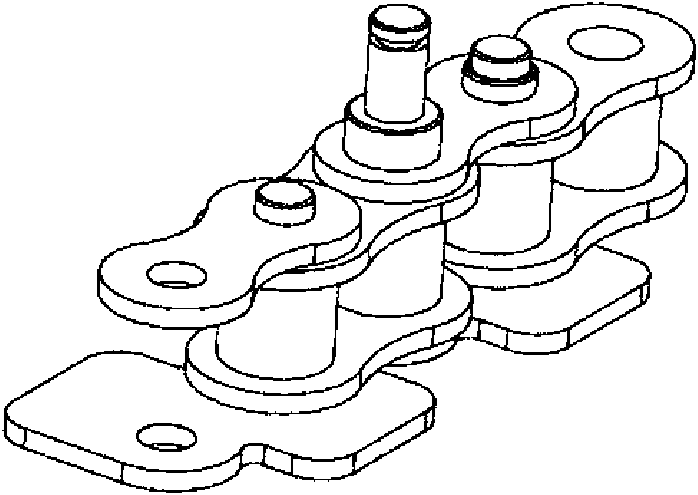

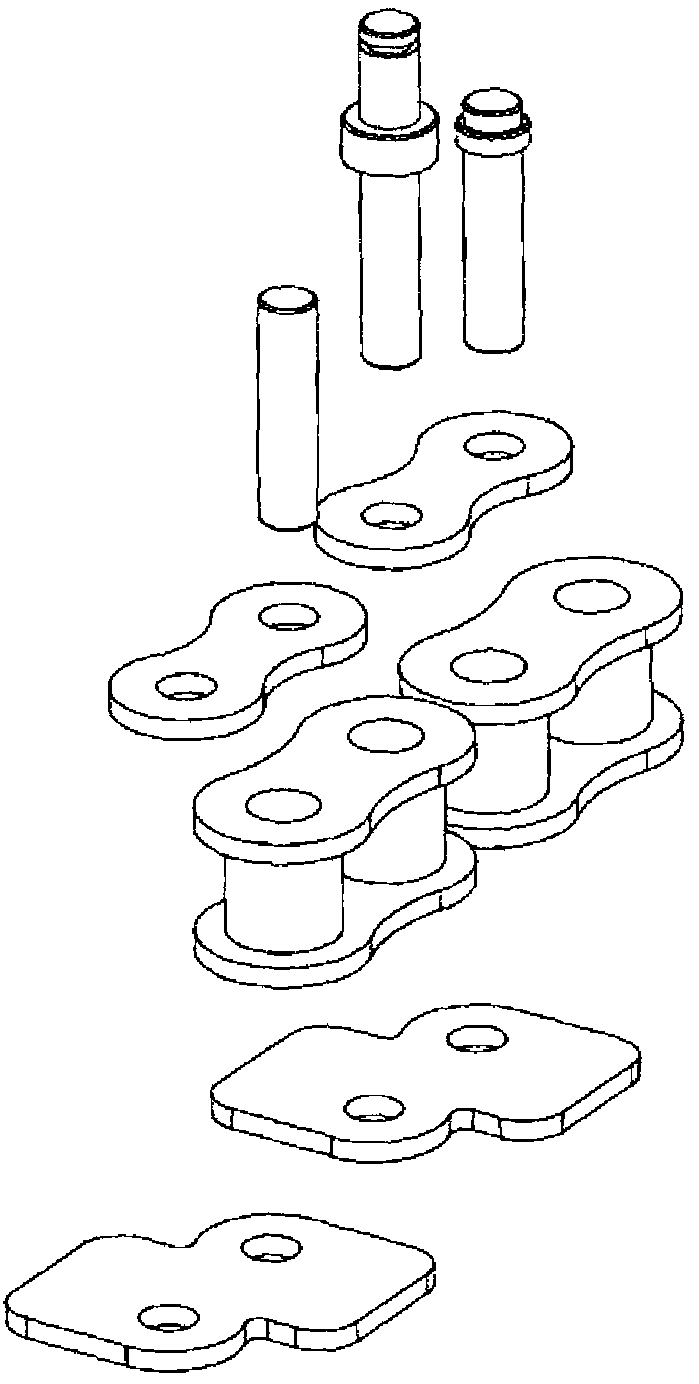

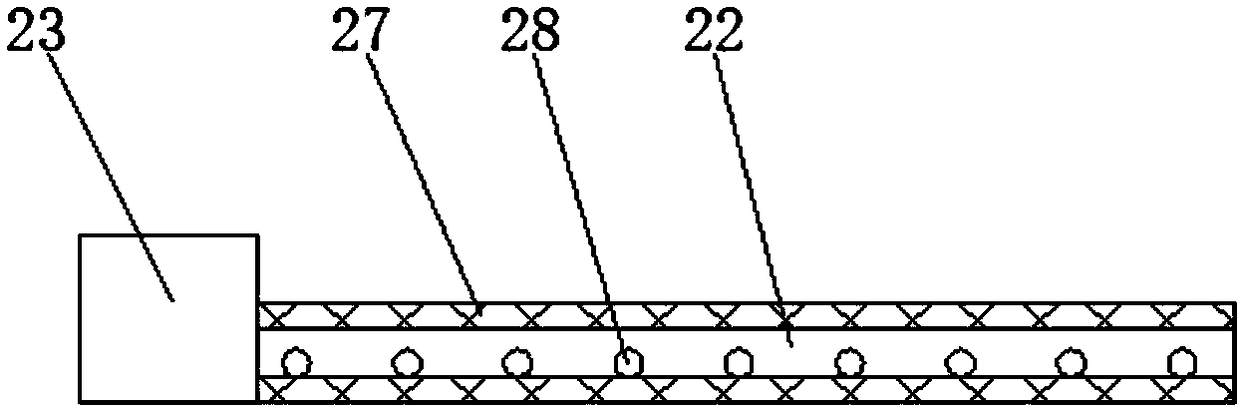

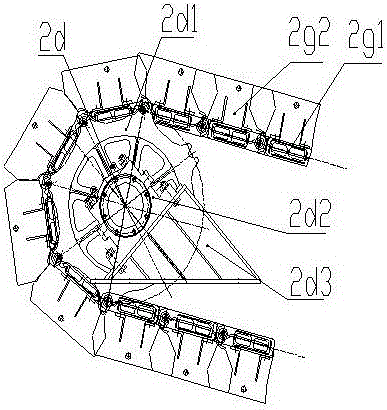

Conveying device

The invention discloses a conveying device, which comprises a conveying chain and two chain wheels, wherein the conveying chain is sleeved on the chain wheels and engaged with the chain wheel; the conveying chain comprises a plurality of link units and a plurality of connecting assemblies, every two link units are connected through a connecting assembly, and each link unit comprises an engaging groove; the chain wheel comprises a wheel body and a plurality of wheel teeth arranged on the periphery of the wheel body; the connecting assembly comprises a stop plate, and the stop plate is parallel to the wheel body of the chain wheel; the conveying device also comprises an adjusting mechanism, wherein the adjusting mechanism is arranged on the operation path of the conveying chain and adjacent to each side of the chain wheel, and the adjusting mechanism comprises a plurality of propping pieces arranged in parallel to the chain wheel; and when the conveying chain runs, the conveying chain is engaged with the chain wheel by the adjusting mechanism, and the stop plates are mutually propped against the plurality of propping pieces so that the wheel teeth and the engaging grooves are positioned on the same plane and aligned and engaged.

Owner:JIANGSU JIAXUAN INTELLIGENT IND TECH CO LTD

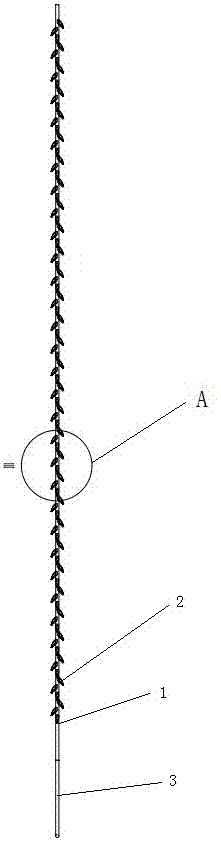

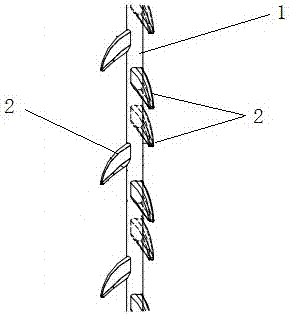

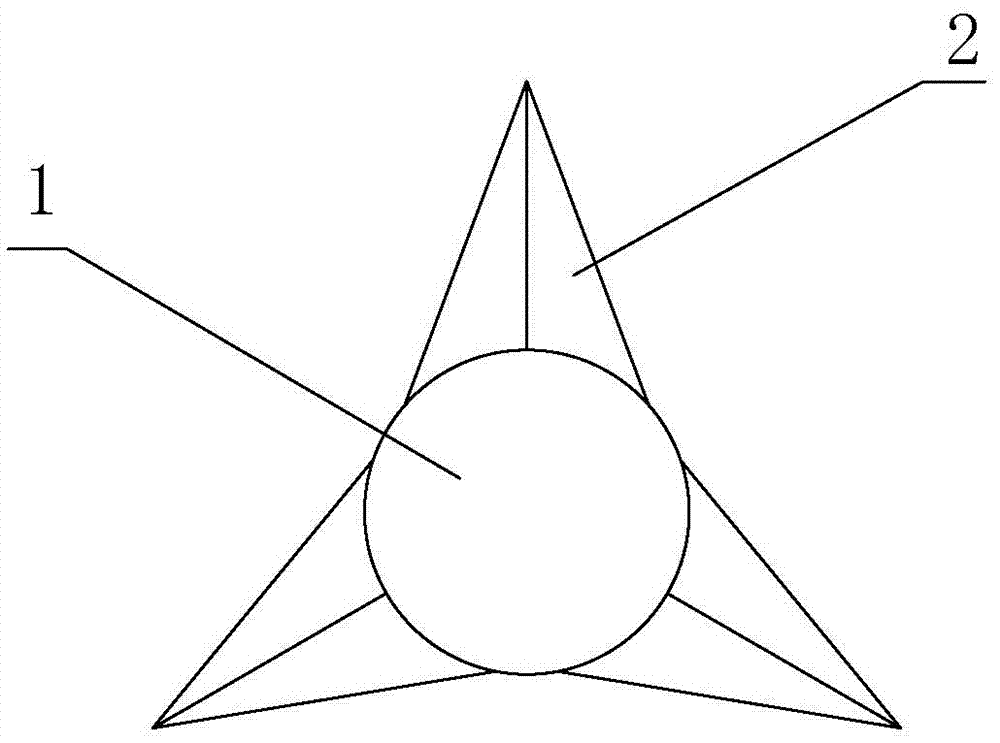

Cosmetic barb string

The invention discloses a cosmetic barb string. The cosmetic barb string is characterized by comprising a string body (1) made of PCL or PP or PLGA, the peripheral side wall of the string body (1) is provided with 3-5 rows of barbs (2), the string body (1) and the barbs (2) are integrally formed through the hot-pressing injection molding process, one barb in one row of barbs (2) and two adjacent barbs in the other two rows of barbs (2) are spirally distributed on the peripheral side wall of the string body (1), the two ends of the string body (1) are each provided with a smooth section without barbs, and the barb body of each barb (2) is a triangular prism, wherein the barb tips are bent in the same direction. In the use process of the cosmetic barb string, general anesthesia is not needed, the cosmetic barb string is implanted in the cortex of the human body through a minimally invasive incision, no scar is left, the effect is improved and is natural and lasting, and the cosmetic barb string is especially suitable for people who refuse surgery or can not undergo surgery but need cosmetology. The cosmetic barb string can be absorbed by the human body and gradually degraded and metabolized without residues, is safe to the human body and guarantees the safety without worries about future.

Owner:王月玲

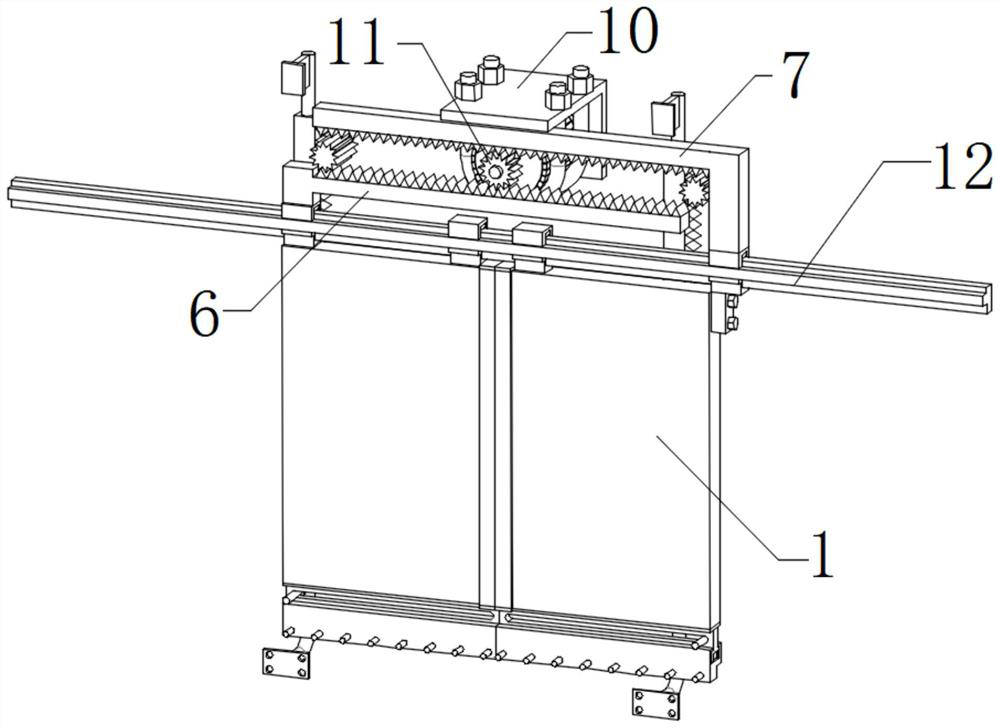

Horizontal double-shaft reverse differential efficient stirring device for soil remediation

InactiveCN110898704AWell mixedImprove mixing uniformityRotary stirring mixersTransportation and packagingSoil remediationEnvironmental engineering

The invention relates to a horizontal double-shaft reverse differential efficient stirring device for soil remediation. The device comprises an outer shell module, driving modules, stirring modules, afeeding module and a discharging module. The stirring modules and the driving modules are connected through chains, the stirring modules and the outer shell module are connected through bearings, andthe number of the driving modules and the number of the stirring modules are both two; the outer shell module comprises a stirring bin shell and driving bin shells, and the stirring bin shell and thedriving bin shells are separated through steel plates. According to the invention, the horizontal double-shaft reverse differential efficient stirring device for soil remediation inherits stirring capacity of the horizontal double-shaft stirring equipment, and on the basis of a double-shaft stirrer, a group of reverse stirring blades are added behind each group of forward propelling stirring blades, so that the stirring capacity of the horizontal double-shaft stirring equipment is improved, and the stirring capacity and stirring efficiency of the equipment are improved.

Owner:HEBEI YUHUAN ENVIRONMENTAL PROTECTION TECH CO LTD

Computer convenient for angle adjustment

InactiveCN107329531AAdjust the tilt angleEasy to adjust the tilt angleDigital data processing detailsArchitectural engineeringActive support

Owner:苏州艾虎数码科技有限公司

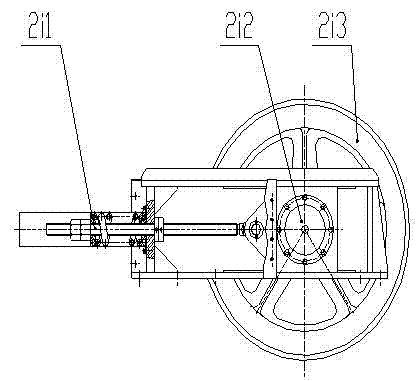

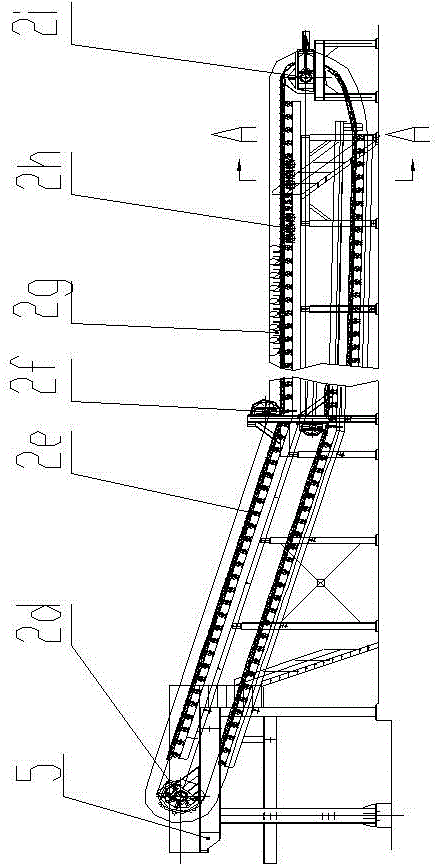

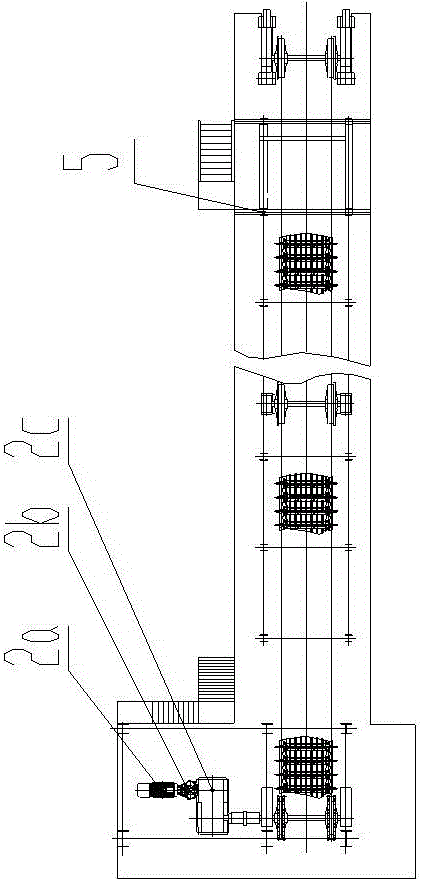

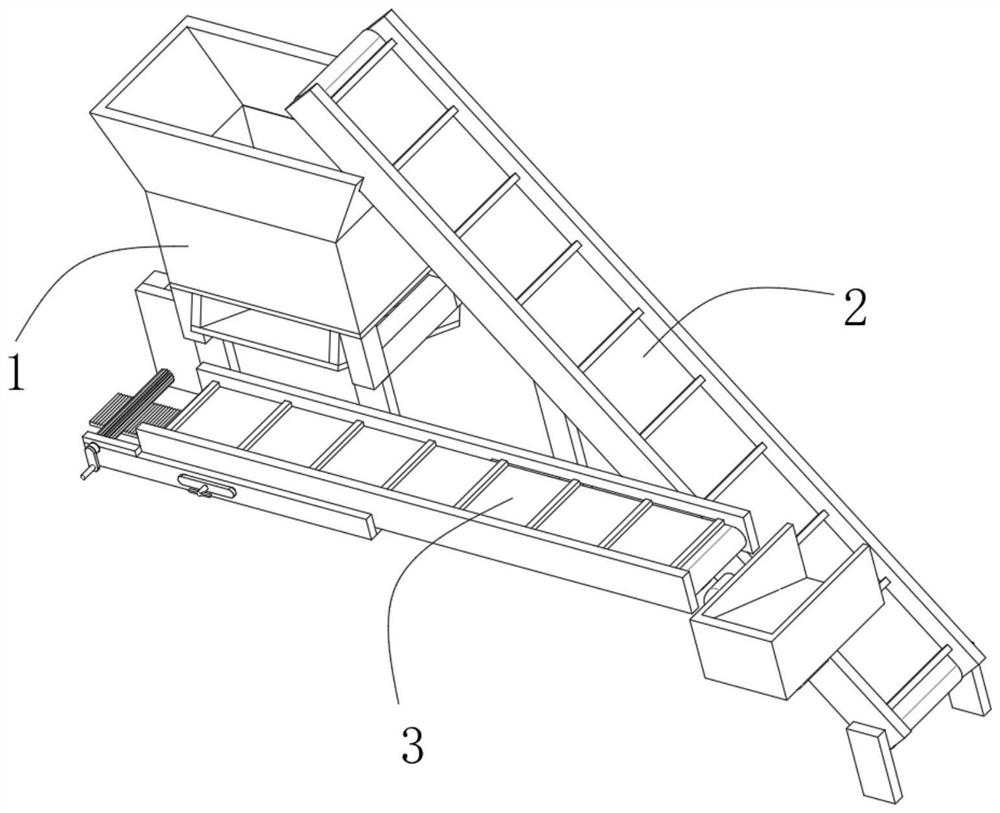

Long-service-life highly-efficient safe chain-belt pallet-type conveyor system

ActiveCN103204353AIncrease production capacityIncrease productivityConveyorsRollersEngineeringDelivery system

The invention discloses a long-service-life highly-efficient safe chain-belt pallet-type conveyor system which includes a chain-belt pallet-type conveyor, an automatic receiving two-way buffer diversion groove is arranged under the tail portion of the chain-belt pallet-type conveyor, an automatic two-way output diversion groove is arranged above the conveyor head, and a system frame connects the chain-belt pallet-type conveyor, the automatic receiving two-way buffer diversion groove and the automatic two-way output diversion groove into a whole. The long-service-life highly-efficient safe chain-belt pallet-type conveyor system is characterized by utilizing the automatic receiving two-way buffer diversion groove to divert iron blocks which are formed by an iron casting machine in a casting mode to a dumping ground or to the chain-belt pallet-type conveyor, and utilizing the automatic two-way output diversion groove to divert the iron blocks transported by the conveyor to different automobiles or trains to transport the iron blocks out of the producing field of the iron casting machine. According to the long-service-life highly-efficient safe chain-belt pallet-type conveyor system, the using effect and the safety performance of the conveying system of iron blocks, minerals or block-shaped materials are significantly improved, the service life is prolonged, and accidents of the chain-belt pallet-type conveyor due to the breakage of chain belts are prevented. The long-service-life highly-efficient safe chain-belt pallet-type conveyor system is safe and reliable and has high production capacity and production efficiency, and the production capacity can reach 300 to 500 tons per hour and 4000 to 10000 tons per day.

Owner:SHILIN LUOHE METALLURGY EQUIP

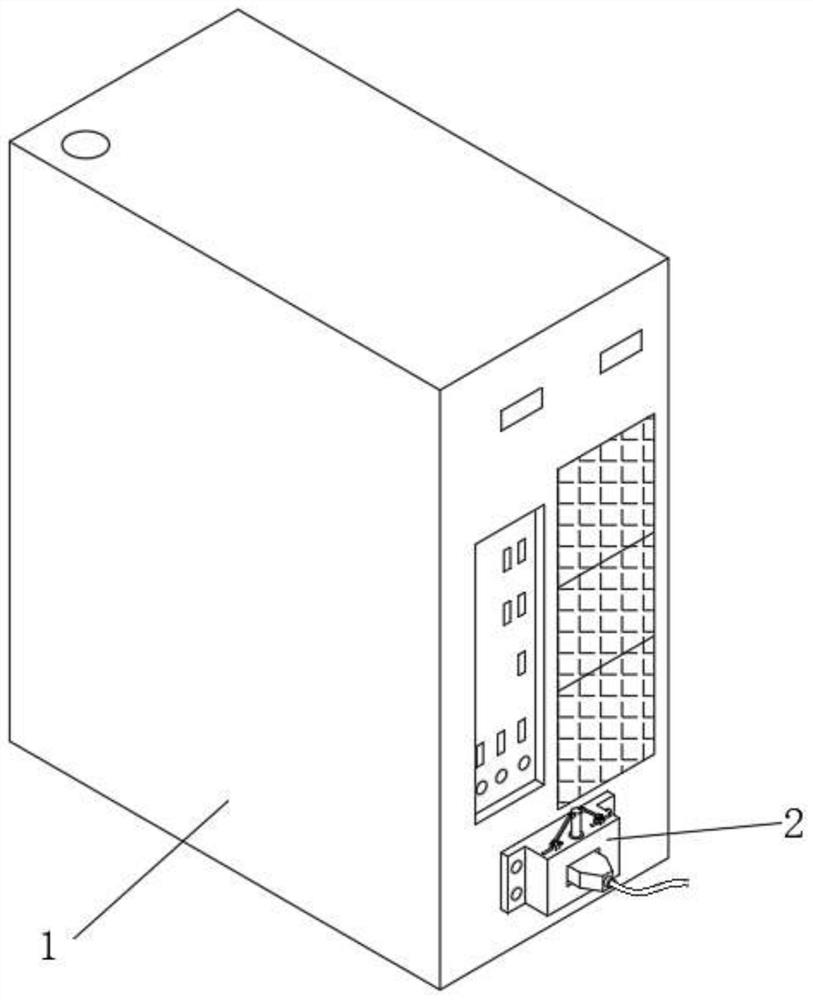

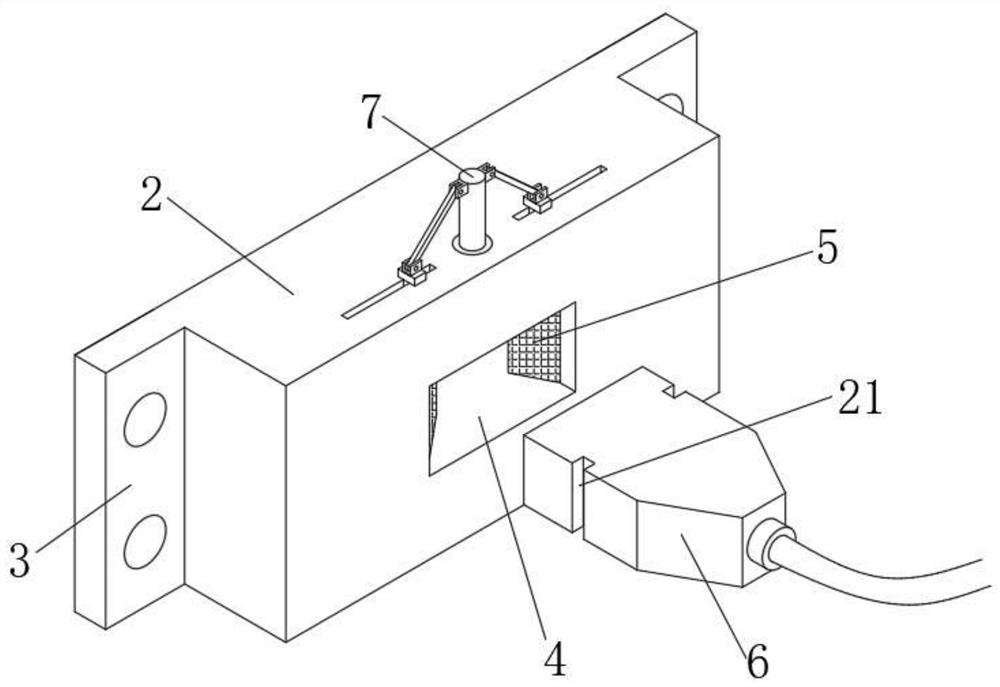

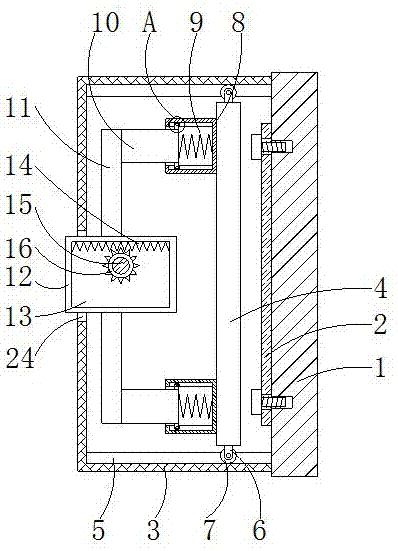

Protection device of computer power interface

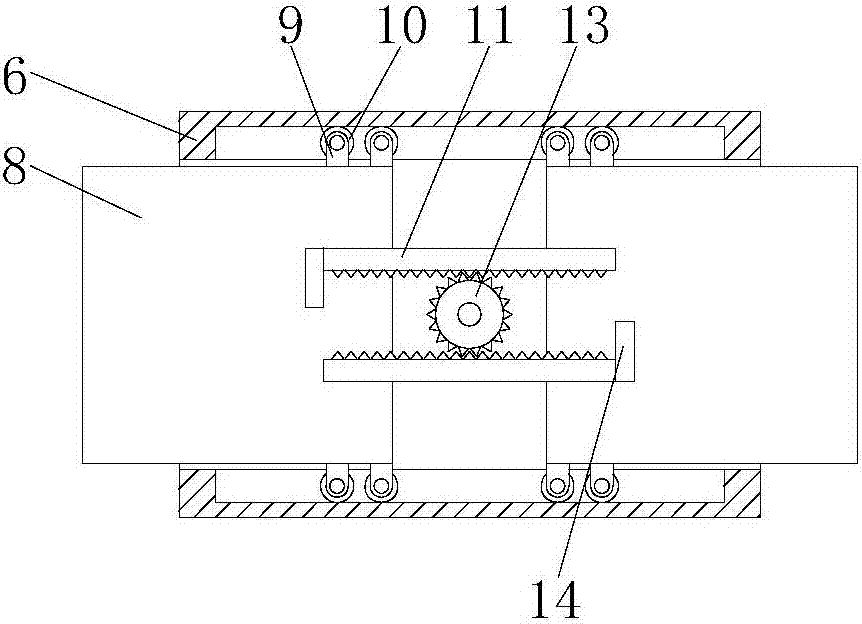

ActiveCN112072397AInhibit sheddingImprove dustproof effectVolume/mass flow measurementCouplings bases/casesGear wheelPhysics

The invention discloses a protection device for a computer power interface, and relates to the field of computers. According to the protection device for the computer power interface, a fixing base isfixedly connected to the back face of a case, an inserting groove is formed in the outer surface of the fixing base, triangular blocks are movably clamped to the two sides of the inner wall of the inserting groove, a power line plug is movably inserted into the inserting groove, and limiting grooves are formed in the two sides of the power line plug; the two sides of the power line plug are movably clamped with the triangular block, the upper surface of the fixing base is fixedly connected with an adjusting assembly, the two sides of the adjusting assembly are slidably connected to the uppersurface of the fixing base and fixedly connected with the triangular block, the side face of the triangular block is fixedly connected with a first rack, a gear is rotatably connected into the fixingbase, and the first rack is engaged with the gear. According to the protection device for the computer power interface, the power line plug is clamped and fixed in use, so that the power line plug isprevented from falling off from the power interface, and meanwhile, a dustproof effect on the power interface is achieved when the protection device is not used.

Owner:GUANGDONG PEIZHENG COLLEGE

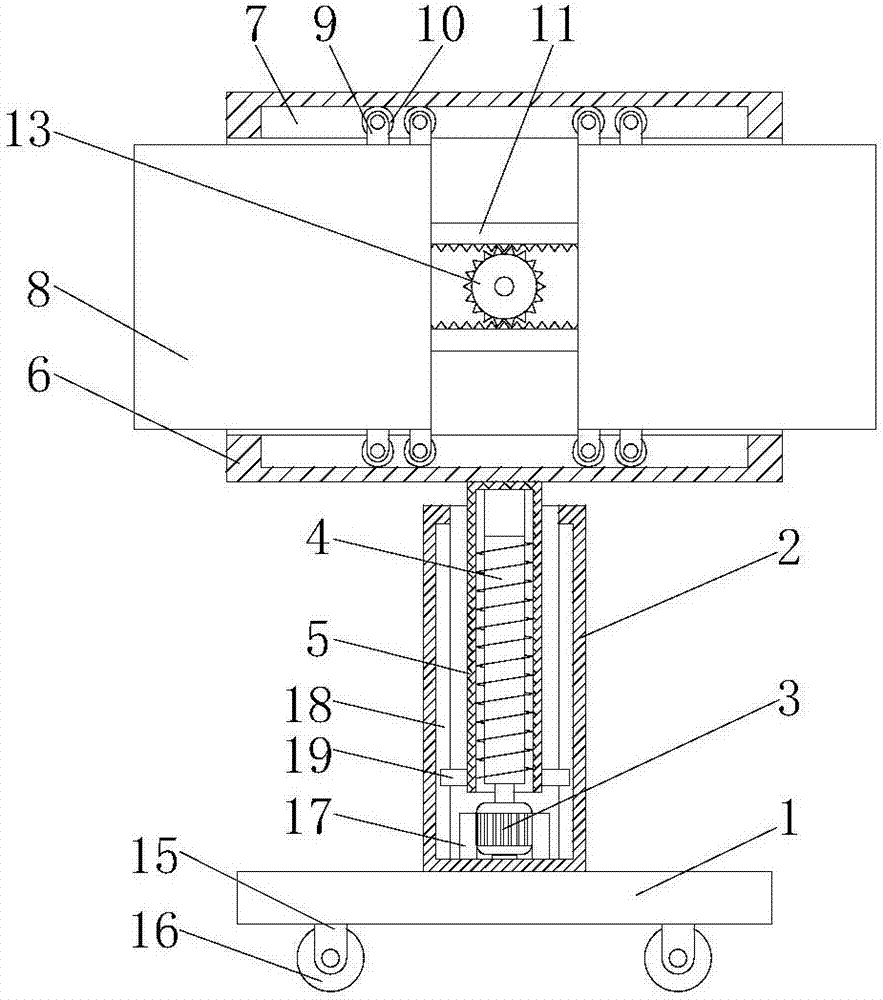

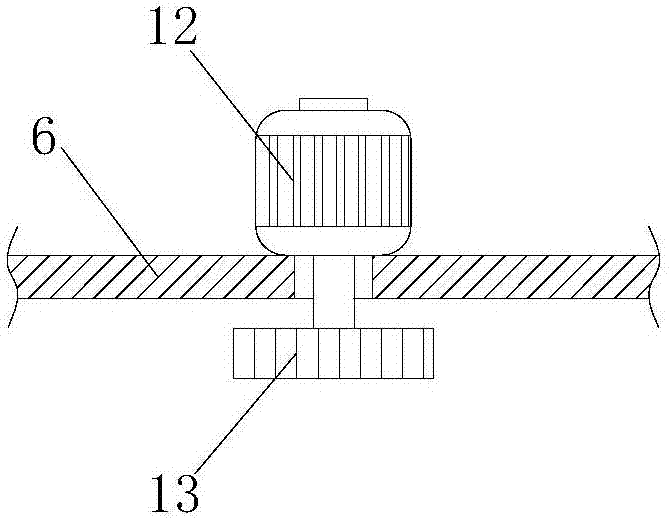

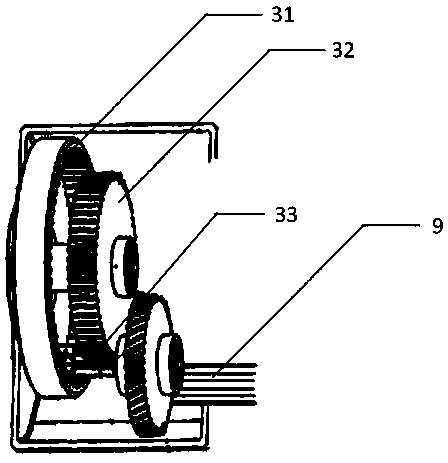

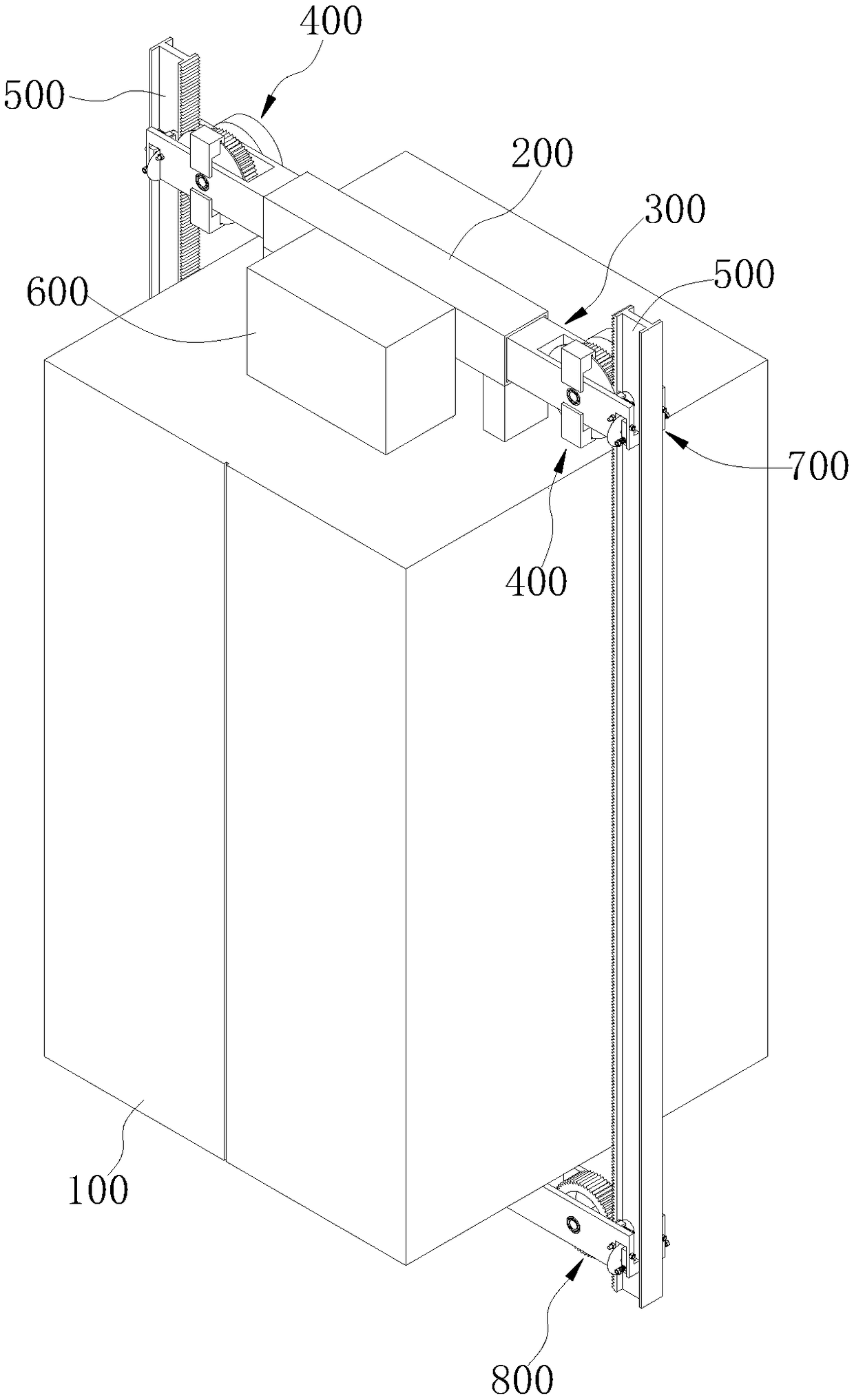

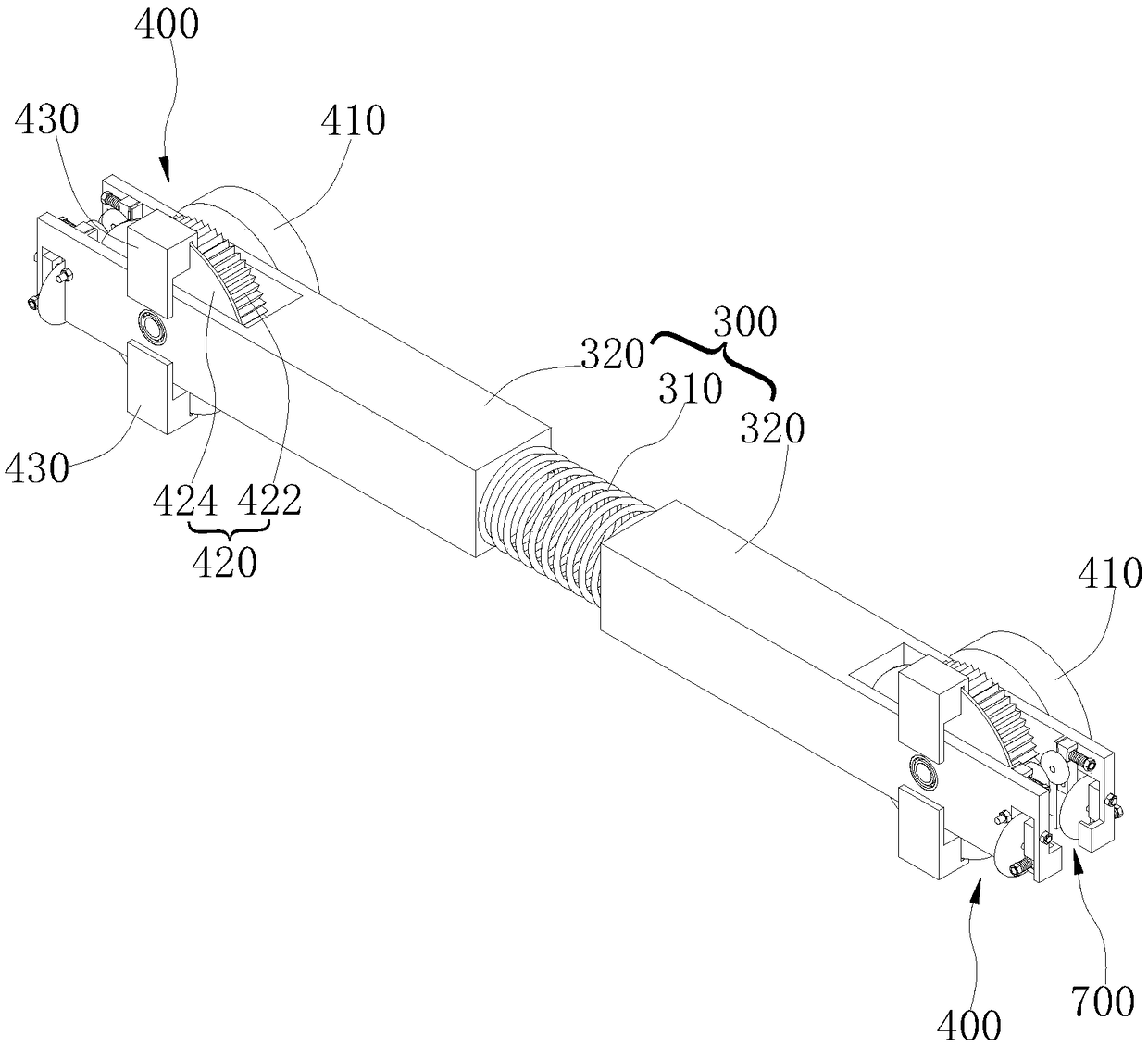

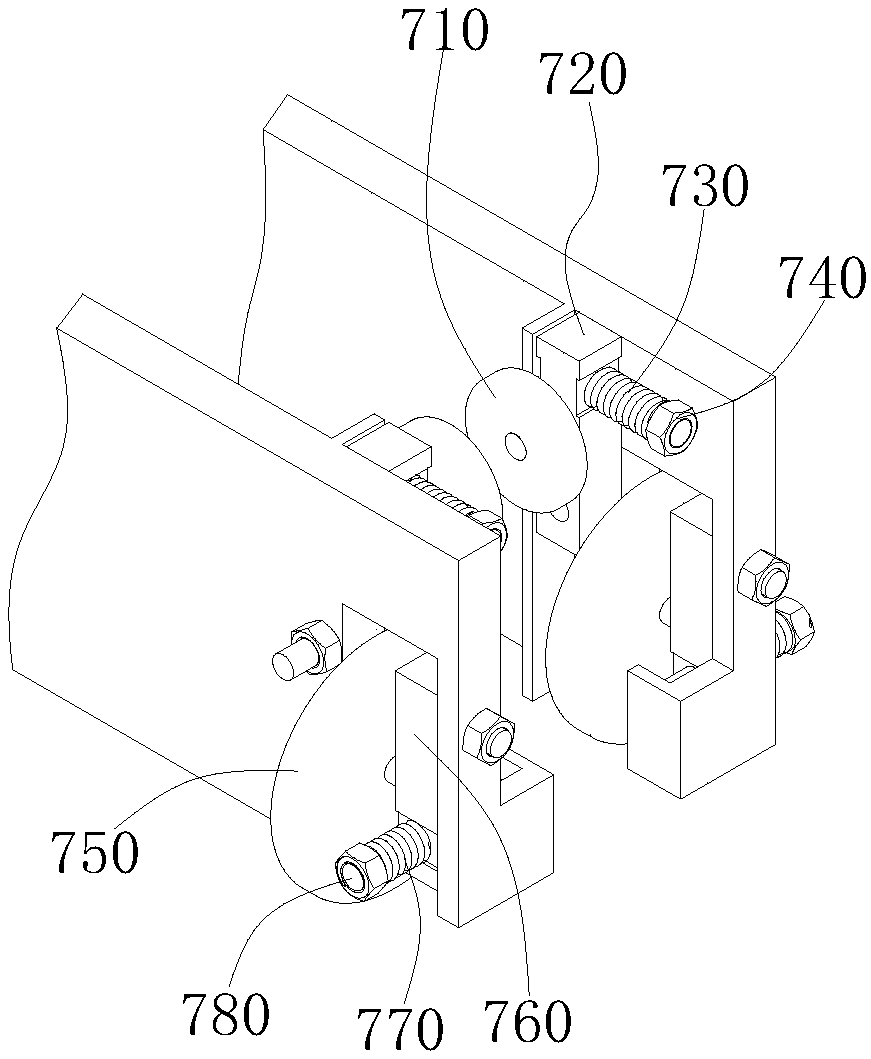

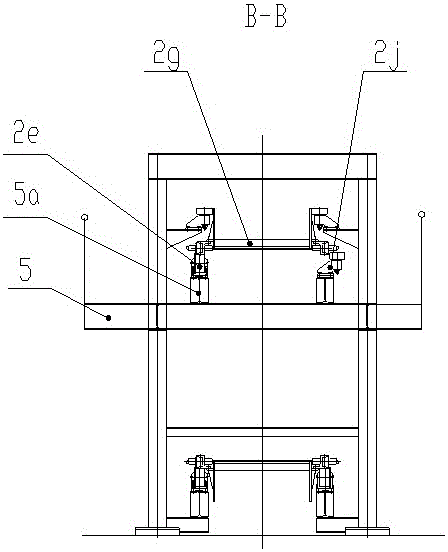

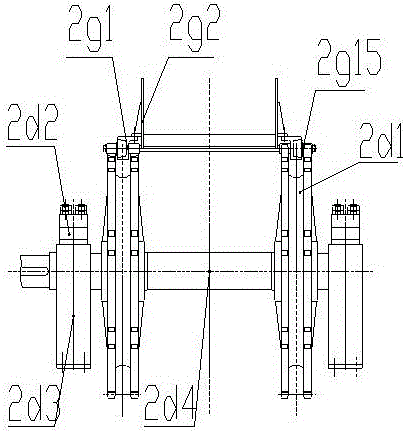

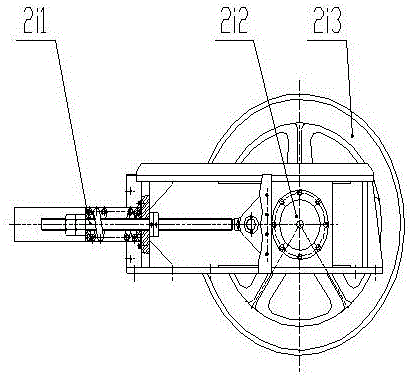

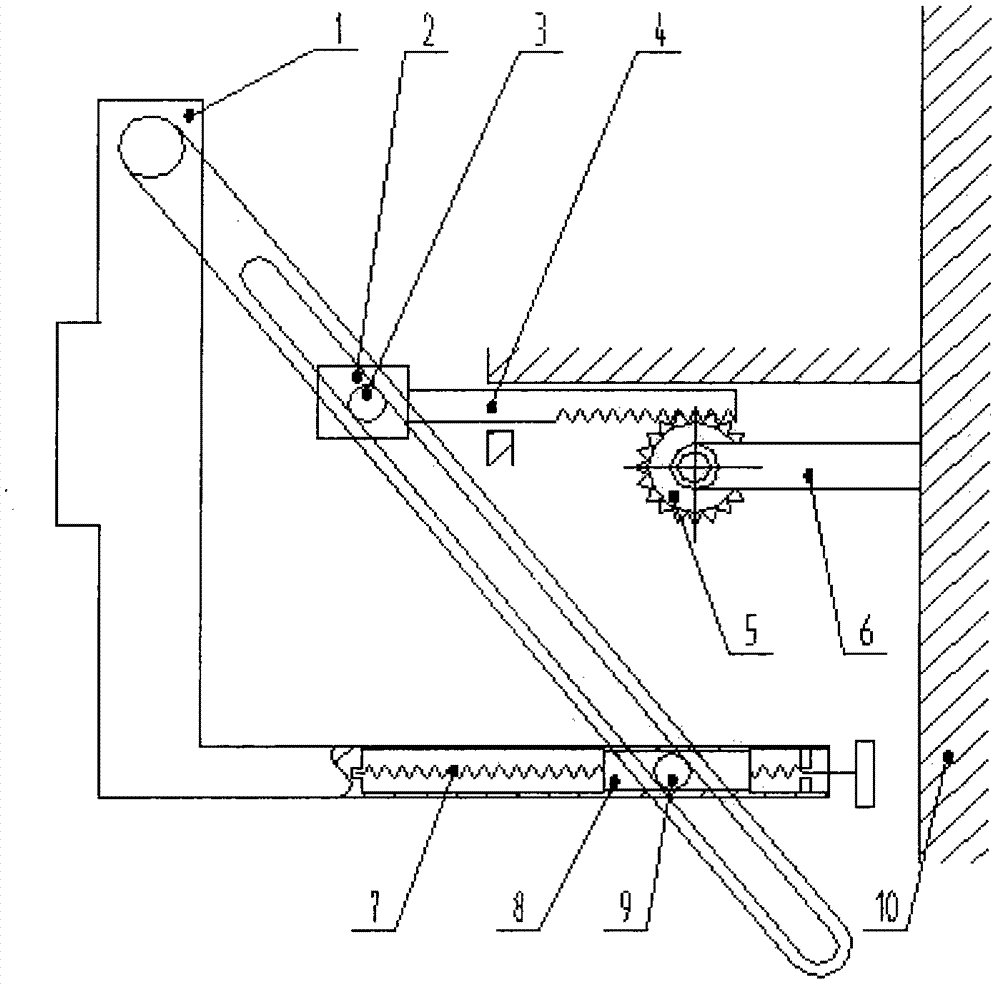

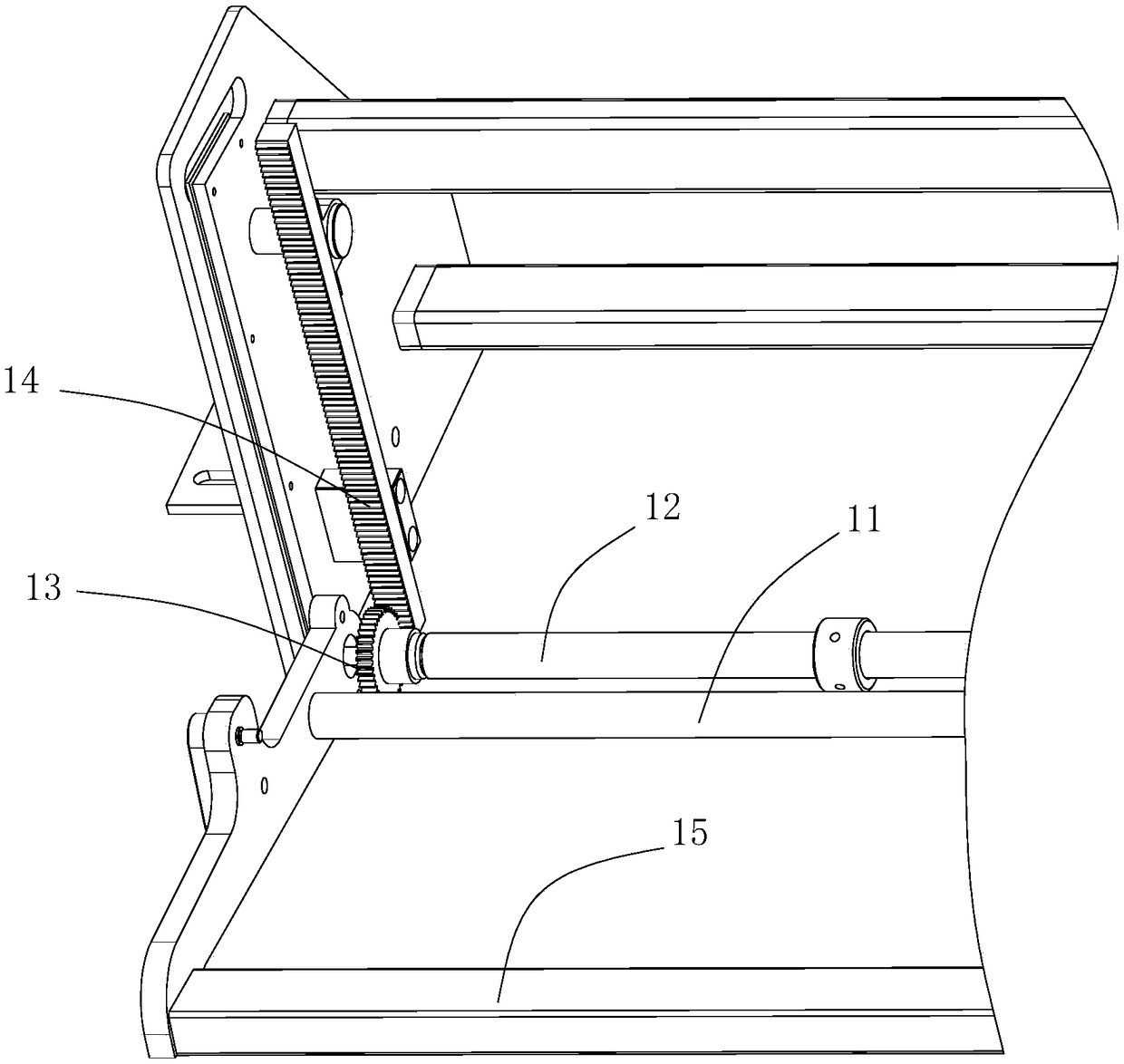

Gear self-driving elevator

ActiveCN109368440AEliminate potential safety hazardsFirmly connectedElevatorsBuilding liftsGear driveEngineering

The invention relates to a gear self-driving elevator. The gear self-driving elevator comprises a lift car, an elastic compensation mechanism, two gear driving devices and two toothed guide rails, wherein the top of the lift car is provided with a load bearing transverse beam, and the load bearing transverse beam is provided with a containing cavity of which the two ends are through; the elastic compensation mechanism is arranged in the containing cavity; the two gear driving devices are both connected with the elastic compensation mechanism and can go close to or go away from each other, andthe two gear driving devices are arranged at the two ends of the load bearing transverse beam correspondingly; and the two toothed guide rails are arranged on the two opposite sides of the lift car and are in engagement fit with the two gear driving devices in a one-to-one correspondence mode. The two gear driving devices can be pushed by the compensation capacity of the elastic compensation mechanism to move away from each other, accordingly, the two gear driving devices can be in engagement fit with the two toothed guide rails reliably always, the tooth disengagement problem is avoided, andthe lift car high-altitude falling potential safety hazard is eliminated.

Owner:HITACHI ELEVATOR CHINA

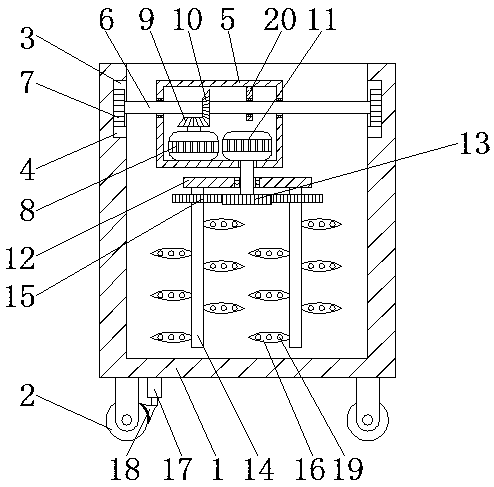

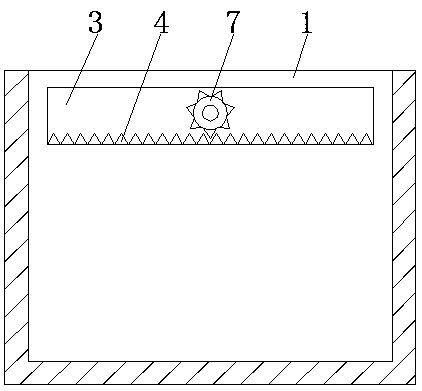

Stirring device for processing plastic products

InactiveCN108340502AImprove stirring efficiencyImprove processing efficiencyTransverse grooveProcess efficiency

The invention discloses a stirring device for processing plastic products. The stirring device comprises a box body. The two sides of the bottom of the box body are both movably connected with rollingwheels through supports. Transverse grooves are formed in the tops of the two sides of an inner cavity of the box body. The bottoms of inner cavities of the transverse grooves are fixedly connected with teeth. The inner cavity of the box body is provided with a movable box. A cross bar is arranged on an inner cavity of the movable box. The two ends of the cross bar both penetrate through the movable box and further extend to the inner cavities of the transverse grooves. The two ends of the cross bar are both sleeved with first spur gears. The first spur gears are engaged with a second spur gear. The left side of the bottom of the inner cavity of the movable box is fixedly connected with a first motor. By means of the stirring device for processing the plastic products, the movable box canbe moved transversely, the movable box drives a second motor, a transverse plate, vertical rods and stirring blades to move transversely, materials in the inner cavity of the box body can be fully stirred, more plastics can be stirred at a time, processing efficiency of the plastic products is improved and using by people is facilitated.

Owner:王光金

Food processing and drying apparatus

The invention discloses a food processing and drying apparatus. The food processing and drying apparatus comprises a machine frame; a material dropping tube is connected to a top of the machine frame;heaters are fixedly connected to both sides of a top of an inner cavity of the machine frame; a sliding rod is fixedly connected to a bottom of a left side of the inner cavity of the machine frame; asliding sleeve is connected to a surface of the sliding rod in a sliding way; a movable lever is fixedly connected to a top of the sliding sleeve; a placing plate is fixedly connected to a top of themovable lever; a spring is fixedly connected to a left side of the movable lever; and a left end of the spring is fixedly connected to the left side of the inner cavity of the machine frame. By arranging a motor, gears can be driven to rotate; by arranging the gears and a toothed plate, the toothed plate can be driven to move; and by arranging a connecting plate, the toothed plate moves so as todrive the placing plate to move via the connecting plate. And thus, the food processing and drying apparatus improves uniformity of food drying, and solves the problems of existing drying apparatuses,namely influence on processing effects caused by uneven drying during drying processes of the foods.

Owner:许昌锦荣食品有限公司

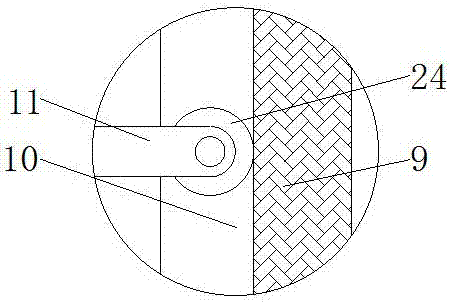

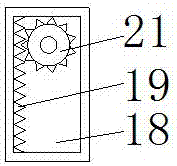

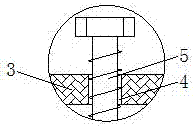

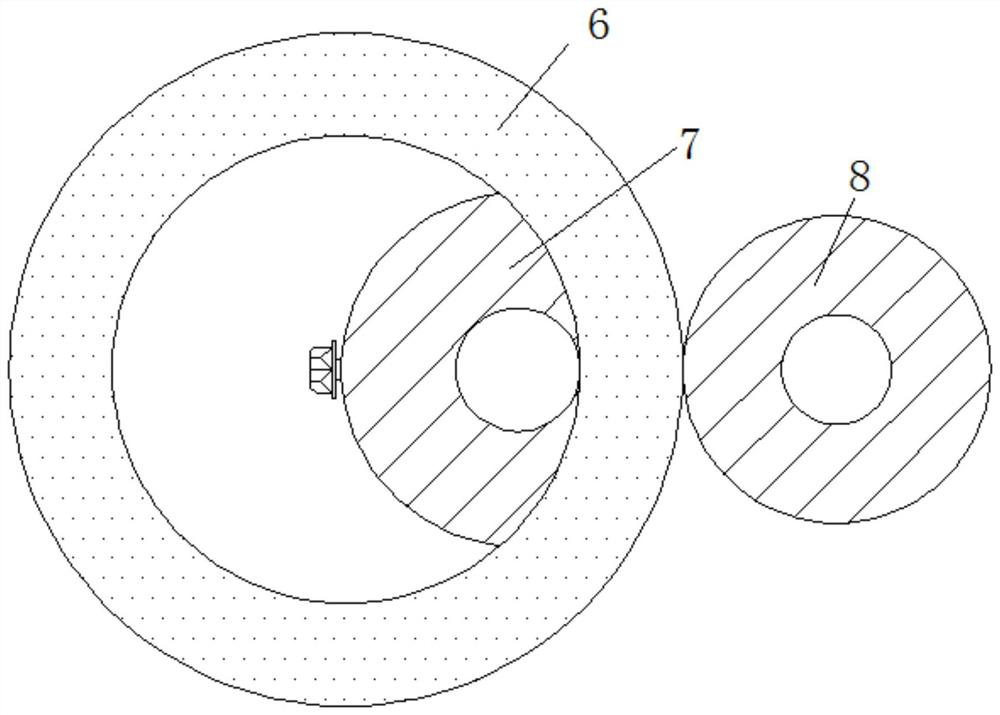

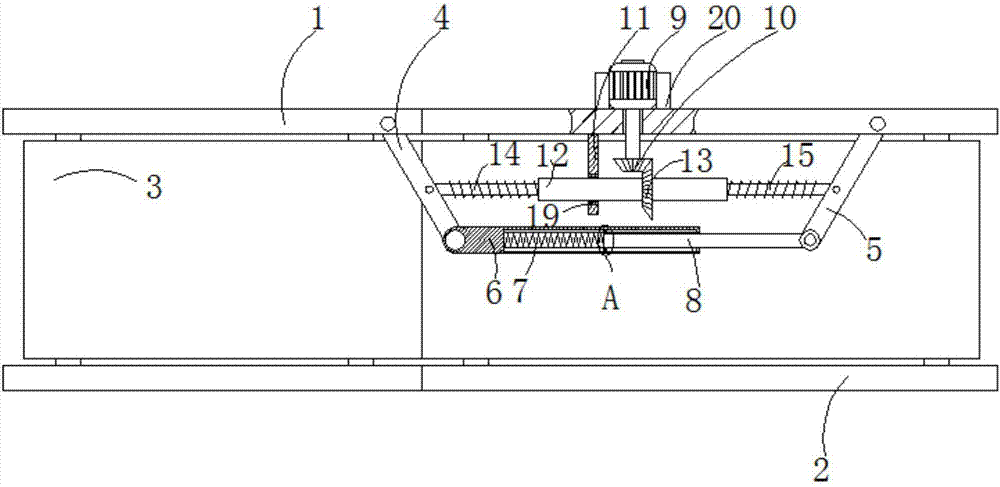

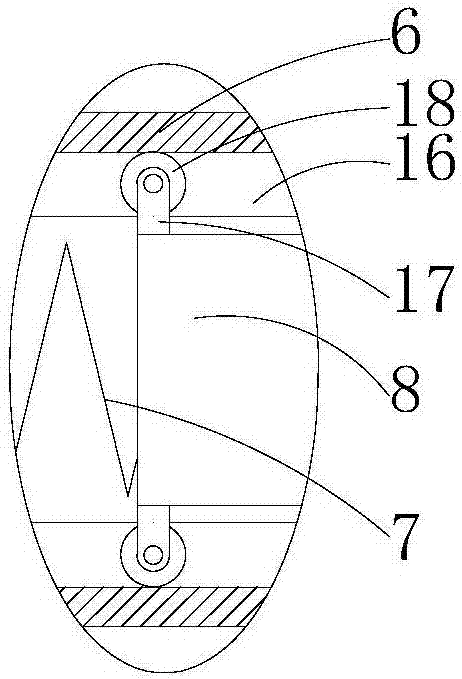

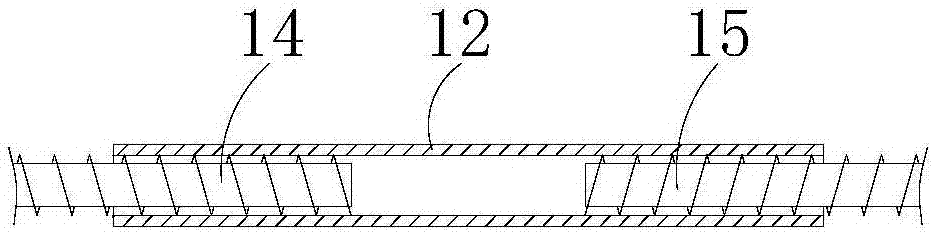

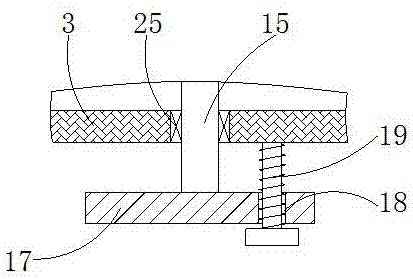

Thread roller device capable of avoiding thread lost caused by overhigh cutting speed

InactiveCN112548008AAvoid tooth lossCutting speed adjustmentMetal-working feeding devicesScrew-threads articlesEngineeringScrew thread

The invention relates to the technical field of thread rollers, and discloses a thread roller device capable of avoiding thread lost caused by overhigh cutting speed. The thread roller device comprises a knob and a conveying mechanism, wherein the bottom of the knob is fixedly connected with a threaded rod, the outer side of the threaded rod is in threaded connection with a sliding block, and theright side of the sliding block is fixedly connected with a baffle. According to the thread roller device capable of avoiding thread lost caused by the overhigh cutting speed, the knob is rotated, a circular ring moves up and down between a first conical shaft and a second conical shaft at the moment, the rotating speed between the second conical shaft and the first conical shaft is further changed, and then the rotating speed of a thread rolling cutter driven by a rotating shaft is also changed at the moment, so that the effect that the cutting speed can be adjusted according to different metal materials is achieved. When a rotary disc is rotated, a first connecting block and a second connecting block can drive a movable plate to periodically move up and down, and a stop lever can periodically release workpieces to be machined on the conveying mechanism, so that the effect of automatic feeding is achieved.

Owner:黄强

Bottled can conveying device

The invention discloses a conveying device for bottled and canned food, which comprises a horizontal conveying frame. An inclined conveying frame is arranged on the right side of the horizontal conveying frame. Conveyor belts are arranged inside the horizontal conveying frame and the inclined conveying frame. The surface of the conveying frame is movably connected with a first baffle through a rotating shaft, the surface of the inclined conveying frame is movably connected with a second baffle through a rotating shaft, and the end of the first baffle away from the horizontal conveying frame is movably connected with a cover plate through a rotating shaft , the left side of the sleeve plate inner cavity is fixedly connected with a spring. The first threaded rod of the present invention pushes the first baffle to move to adjust the inclination angle of the first baffle, and the second threaded rod pushes the second baffle to move to adjust the inclination angle of the second baffle, so that the first baffle and the second baffle The plate reaches an optimal inclination angle, which can make the cans be transferred smoothly, avoid the occurrence of the cans being poured out and piled up, and is convenient for people to use.

Owner:长兴天恩赐饮用水科技有限公司

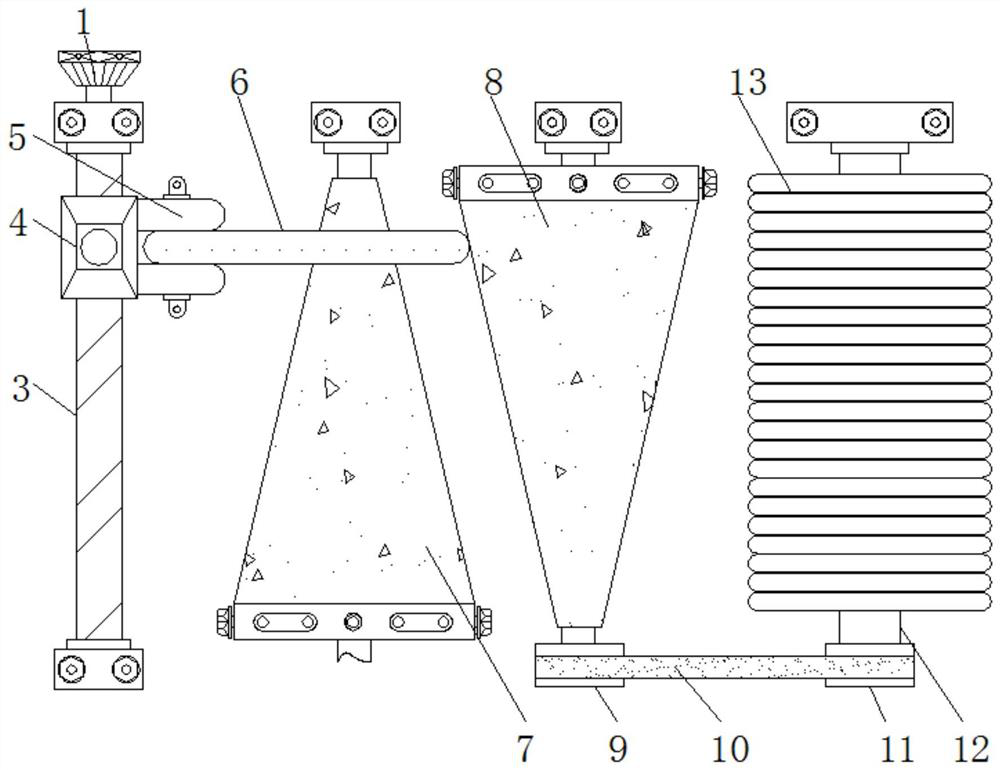

Investment casting composite pouring system

InactiveCN108380823AEasy to replaceChange sizeFoundry mouldsFoundry coresInvestment castingMaterials science

The invention discloses an investment casting composite pouring system. The investment casting composite pouring system comprises a transverse runner and a tie piece part; the transverse runner is located above the tie piece part, the left side of the transverse runner communicates with a left runner, and the right side of the transverse runner communicates with a right runner; the bottom of the left runner communicates with a first straight runner; the bottom of the transverse runner communicates with a second straight runner and a third straight runner from left to right in sequence; the right side of the right runner communicates with a fourth straight runner; the bottoms of the first straight runner, the second straight runner, the third straight runner and the fourth straight runner are fixedly connected with the top of the tie piece part; and the top of the transverse runner is provided with a round hole. According to the investment casting composite pouring system, by arrangingclamping plates, a feeding hopper can be clamped tightly, meanwhile, replacement of the feeding hopper is facilitated, feeding hoppers with different sizes can be replaced, the feeding amount can be changed, the feeding flow rate can be conveniently controlled by people, and accordingly, the pouring quality of a finished product is improved.

Owner:郑州郑飞锻铸有限责任公司

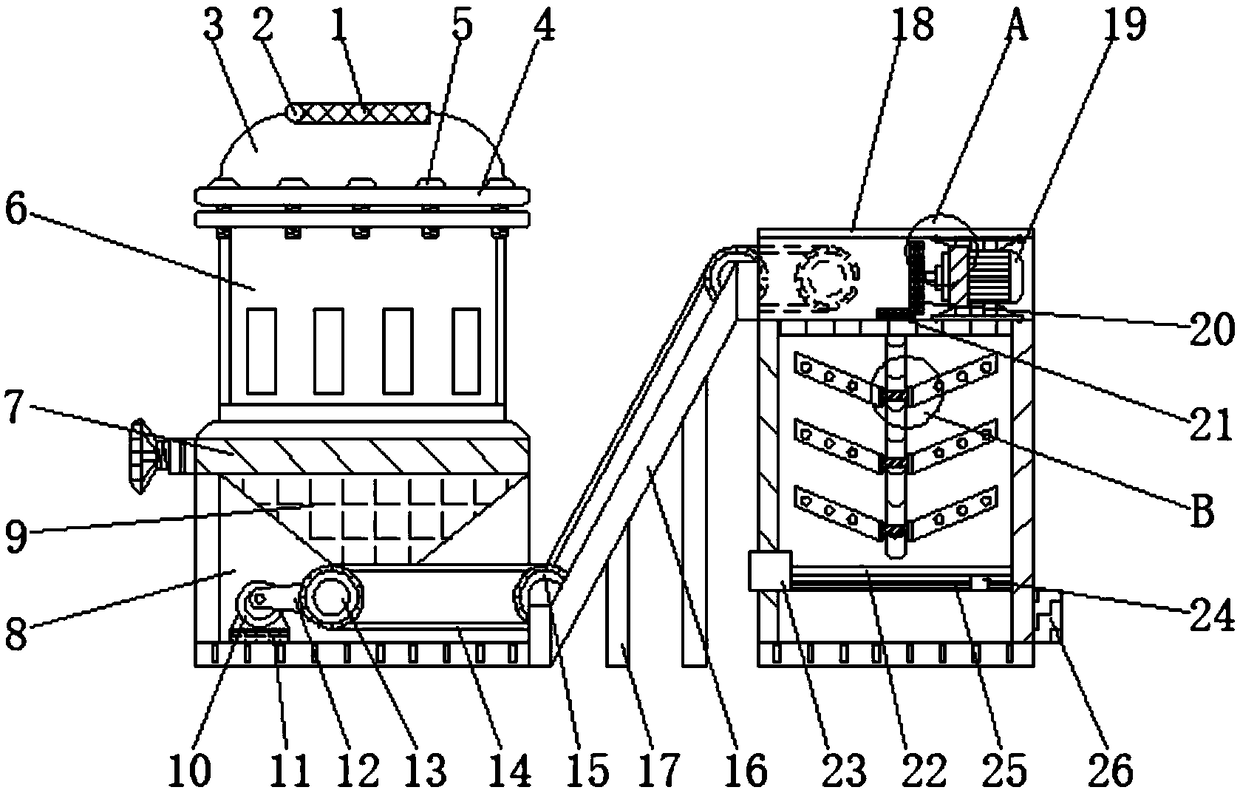

Fodder processing and feeding integrated device for livestock raising

InactiveCN108421460APrevent spoilageCausing deteriorationFeeding-stuffRotary stirring mixersFiltrationSlide plate

The invention discloses a fodder processing and feeding integrated device for livestock raising. A rotating shaft is connected to the left end of a sealing cover. A sliding plate valve is mounted on the lower side of a storage tank. A connection belt is connected to the right side of a first motor. A conveyor belt is arranged on the right side of a rotating wheel. A stop plate is fixed to the right side of an auxiliary rotating wheel. A stirring chamber is fixed to the right side of the stop plate. A turning gear is connected to the lower side of a gear. A slider is arranged on the surface ofthe right end of the stop plate. A discharge outlet is mounted on the lower right side of the stop plate. A filtration screen is connected to the surface of the top end of the stop plate. A fixing plate is arranged at the bottom end of a fixing base. A rubber pad is attached to the upper side of a second motor. A mounting plate is connected to the right side of a fixing block. The fodder processing and feeding integrated device has the advantages that through the sealing cover, the rotating shaft, a top cover, flanges, screws and the storage tank, feeding is facilitated, and materials in the storage tank can be protected and do not go bad easily.

Owner:金旭晨

Strip crease preventing device of high-precision barcode printer

The invention discloses a strip crease preventing device of a high-precision barcode printer. The device comprises a strip crease preventing base plate. The left side of the strip crease preventing base plate is fixedly connected with a hairbrush plate through screws. The left side of the strip crease preventing base plate is fixedly connected with a cover. The top and the bottom of the cover are respectively provided with a first chute. The inner chamber of the cover is provided with a strip crease preventing cover plate. The top and the bottom of the strip crease preventing cover plate are fixedly connected with a first slide rod. One end, which is far from the strip crease preventing cover plate, of the first slide rod extends into the inner chamber of the first chute. One end, which is in the inner chamber of the first chute, of the first slide bar is movably connected with a first roller through a rotating shaft. The strip crease preventing device of the high-precision barcode printer can make the strip crease preventing cover plate perform transverse movement for keeping the strip crease preventing cover plate in a vertical state always, thereby keeping the same tension between top of the right side of the strip crease preventing cover plate and a carbon strip, improving adjustment precision for the strip crease preventing cover plate, and improving quality of a finished product.

Owner:李琼兵

Special tool for 10kv line live work robot connection and drainage line operation

ActiveCN110021898BAvoid clutterBeautiful lengthApparatus for cutting/splicing cablesApparatus for joining/termination cablesStructural engineeringMechanical engineering

The invention discloses a special tool for 10KV circuit live-wire work robot drainage wire connecting work. The special tool comprises a cable stretch-in end and a cable stretch-out end, wherein a puncture cable clamp is positioned between the cable stretch-in end and the cable stretch-out end. The special tool comprises a substrate, and is characterized by comprising a drainage wire shearing mechanism installed on the substrate, wherein the drain wire shearing mechanism comprises an electric cutter; and the electric cutter is positioned at the cable stretch-out end. According to the special tool, robot live-wire wiring work can be realized, manual live-wire wiring work also can be realized, and the special tool has the function of shearing unnecessary drainage wires.

Owner:山东乐普韦尔自动化技术有限公司

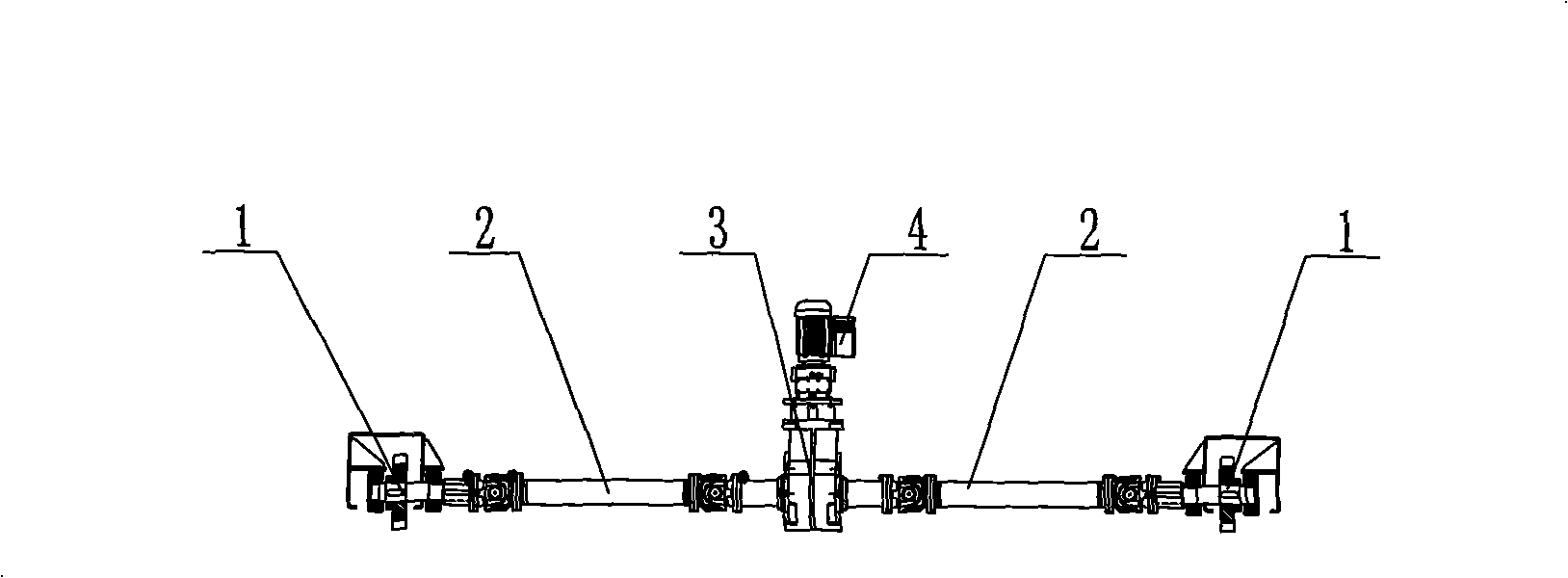

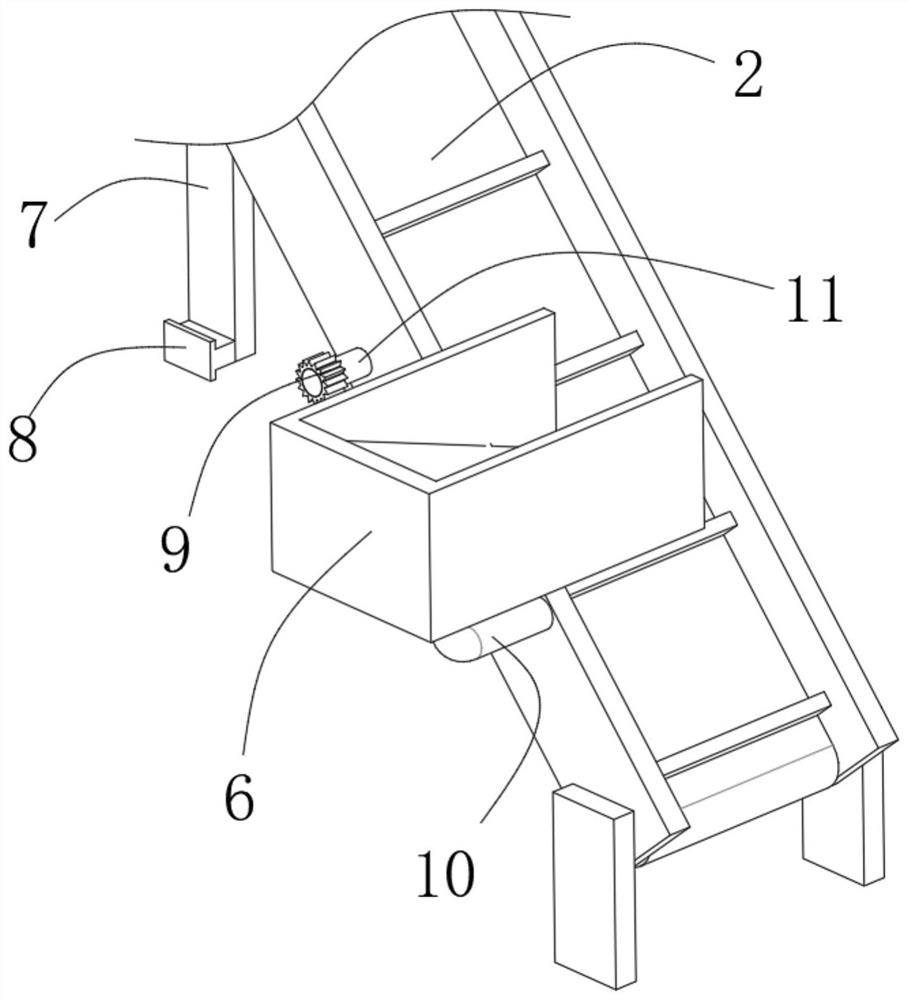

Walking transmission mechanism of powdered coke scraper

The invention provides a walking transmission mechanism of a fine coke scraping machine, which completes the transmission process mechanically, thus having high efficiency, high stability and high precision. The walking transmission mechanism comprises a stop motor, which is connected with a double-output reducer. The invention is characterized in that two output shafts of the double-output reducer are respectively connected horizontally with gears by a universal coupling.

Owner:无锡雪浪输送机械有限公司

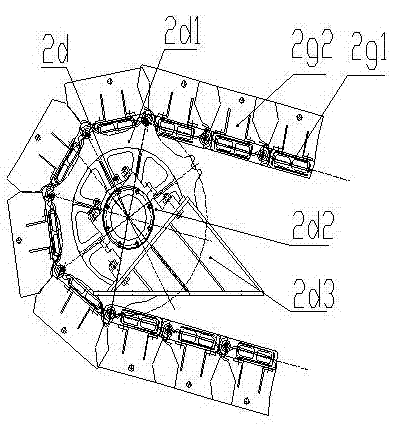

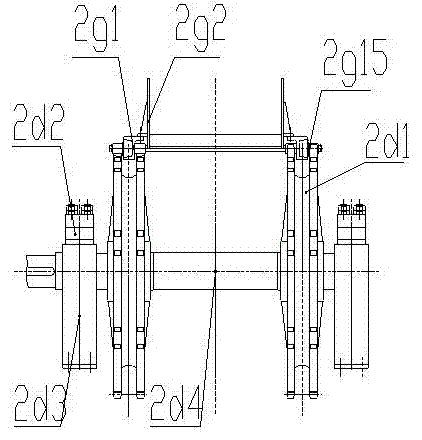

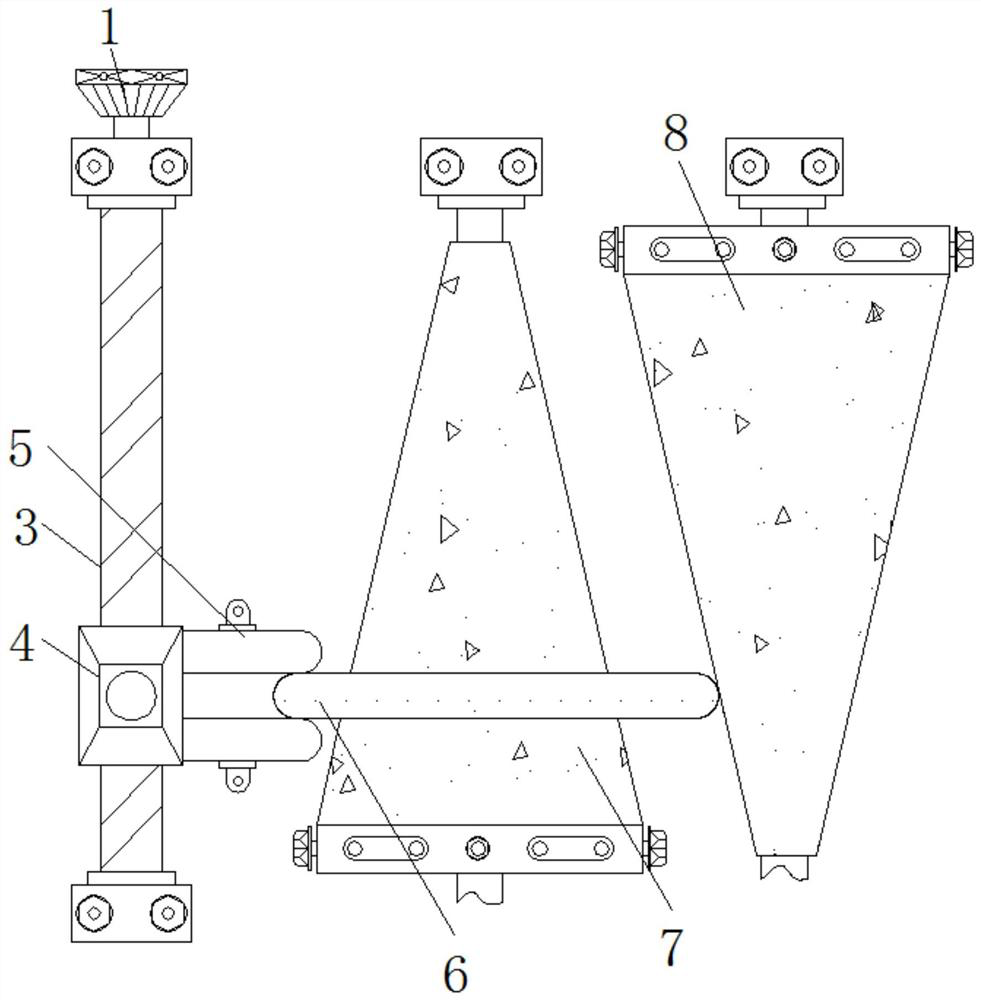

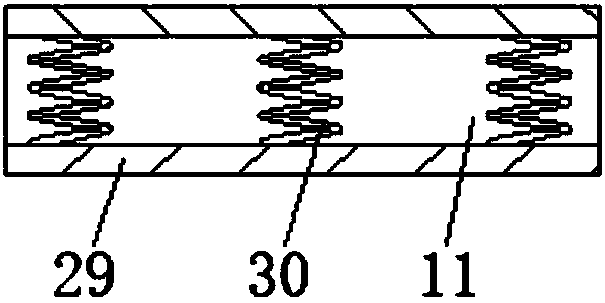

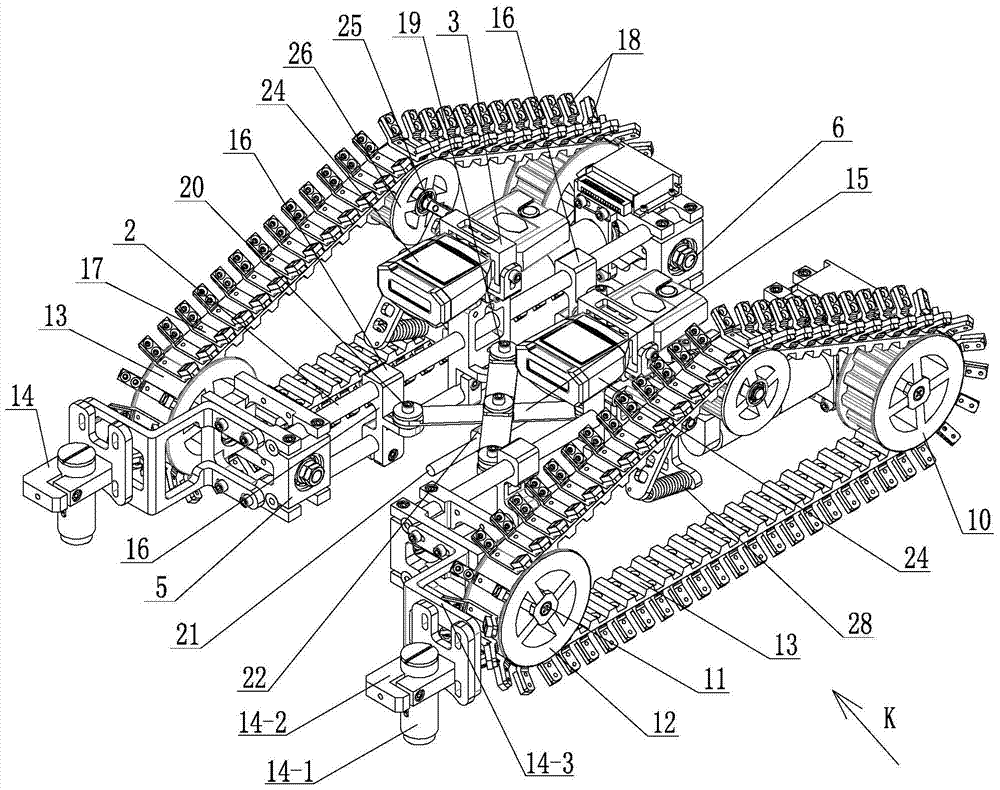

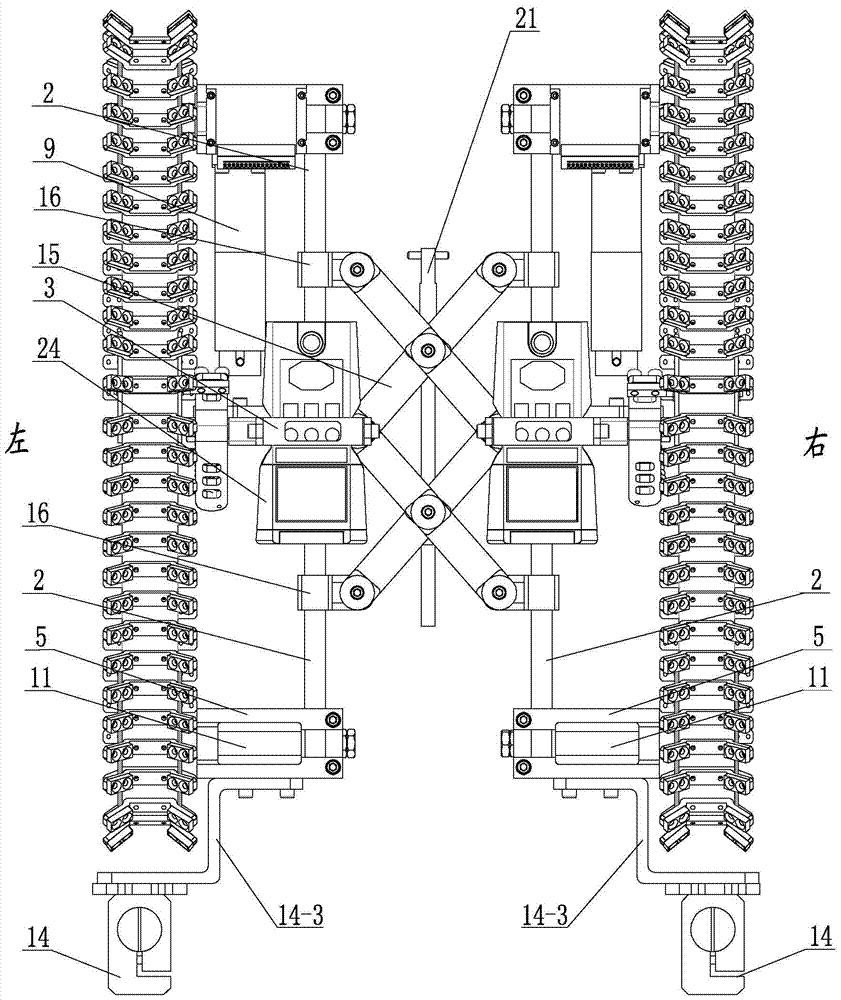

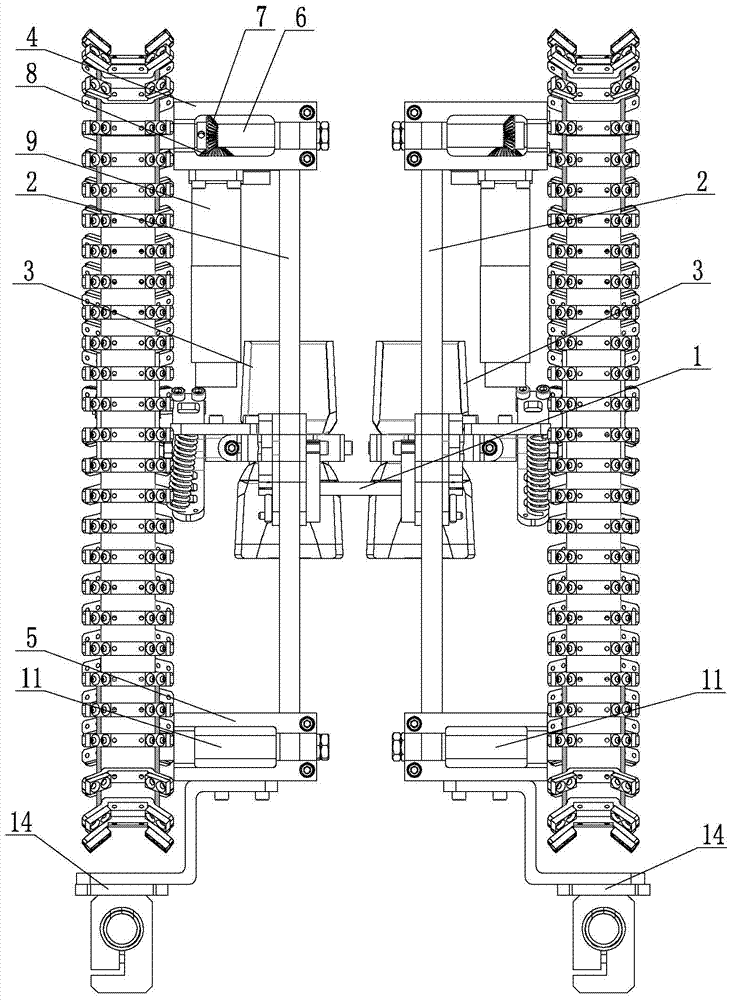

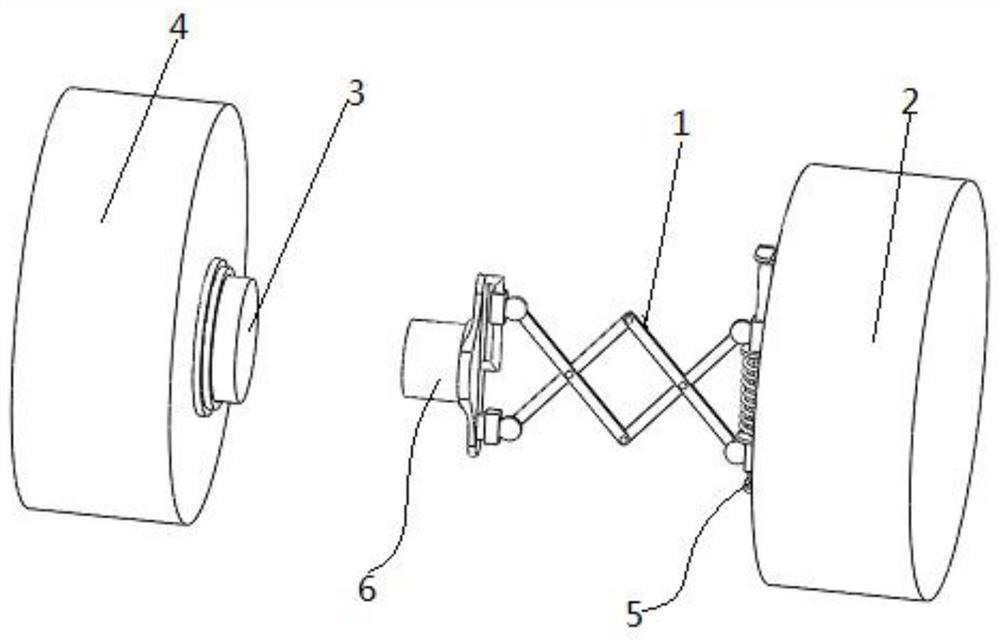

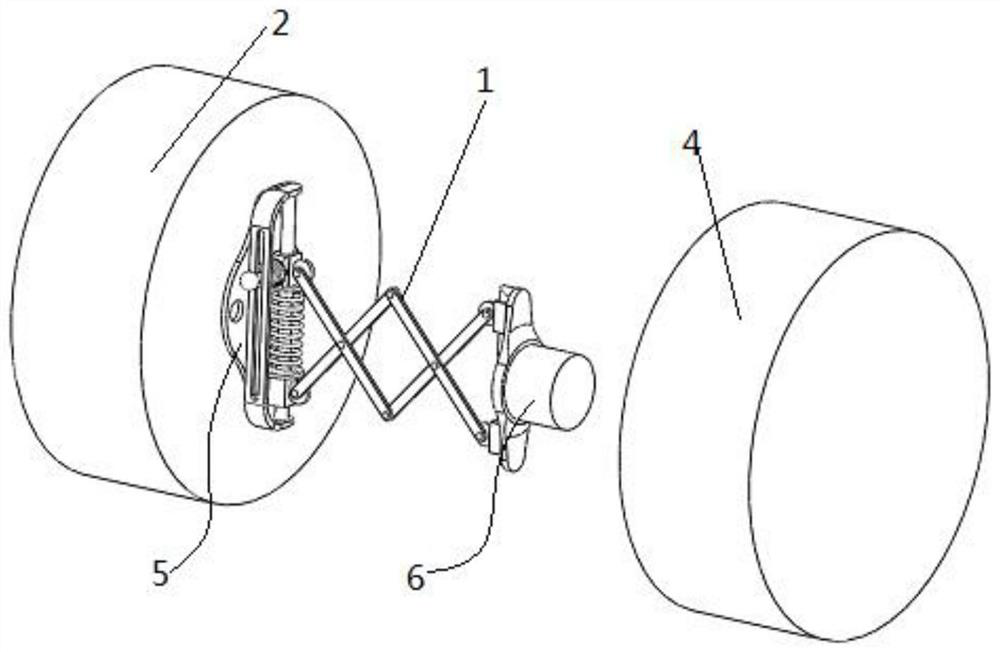

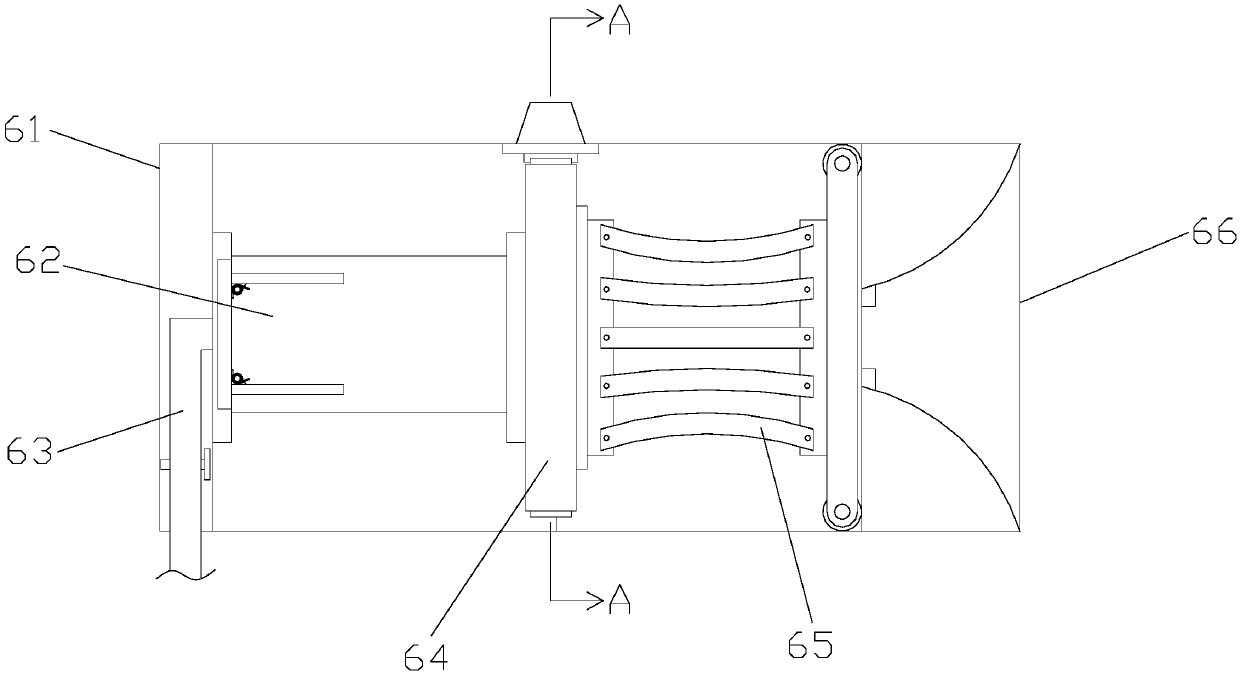

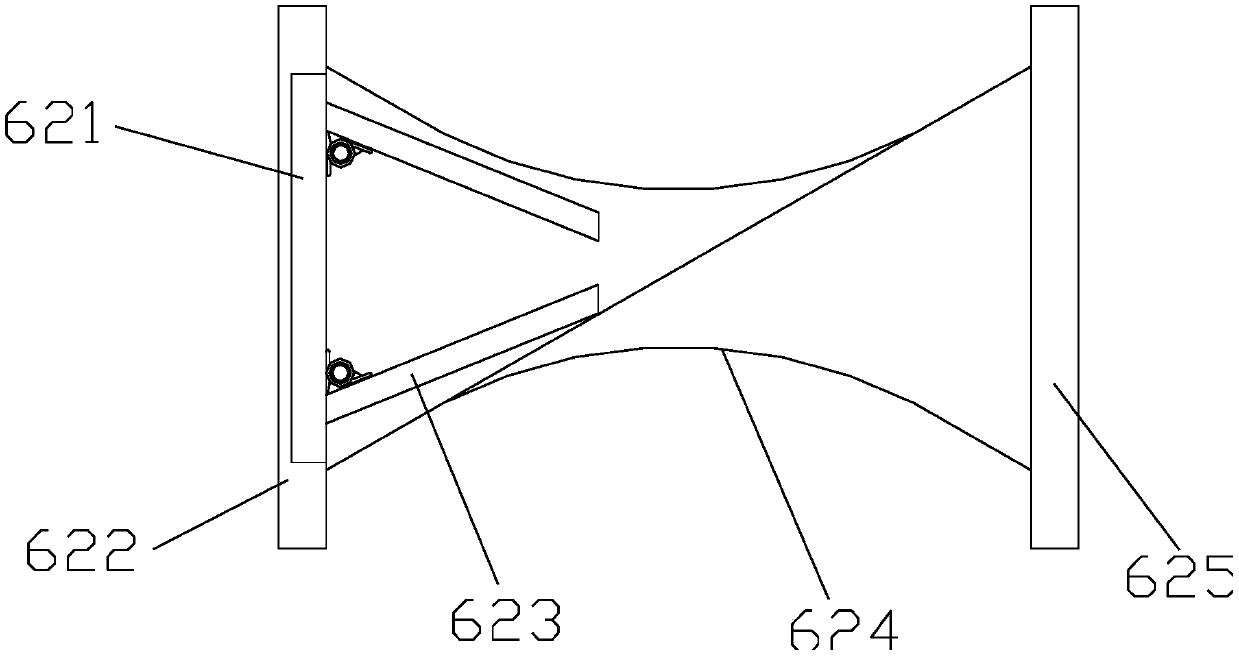

A wall-climbing robot with V-shaped permanent magnet chain pieces buffered by elastic steel sheets

ActiveCN105383581BPlay a buffer roleFlexible climbingUsing subsonic/sonic/ultrasonic vibration meansEndless track vehiclesDrive wheelFixed frame

A wall climbing robot with V-shaped permanent magnet chain sheets buffered by elastic steel sheets solves the problem that an existing water-cooled water robot is not flexible in movement and climbing. Every two adjacent elastic steel sheets are arranged in a crossing mode. Two crossed elastic steel sheet assemblies are arranged vertically. The two elastic steel sheets in the middle of the left side are hinged to a main frame body on the left side through a first pin. The two elastic steel sheets in the middle of the right side are hinged to the main frame body on the right side through a first pin. The upper elastic steel sheet and the lower elastic steel sheet on the left side are hinged to corresponding fixing pieces through second pins respectively. The upper elastic steel sheet and the lower elastic steel sheet on the right side are hinged to corresponding fixing pieces through second pins respectively. Each fixing piece is fixedly arranged on a corresponding connecting rod. Each driven wheel fixing frame is fixedly provided with a probe supporting mechanism. Each trapezoid synchronous belt is evenly provided with a plurality of V-shaped supports. The V-shaped openings of the V-shaped supports are right opposite to the length direction of the trapezoid synchronous belts. A magnet is arranged on the inner wall of each V-shaped sheet of each V-shaped support. The wall climbing robot is used for detecting the water-cooled wall.

Owner:HARBIN KENENG CLADDING TECH

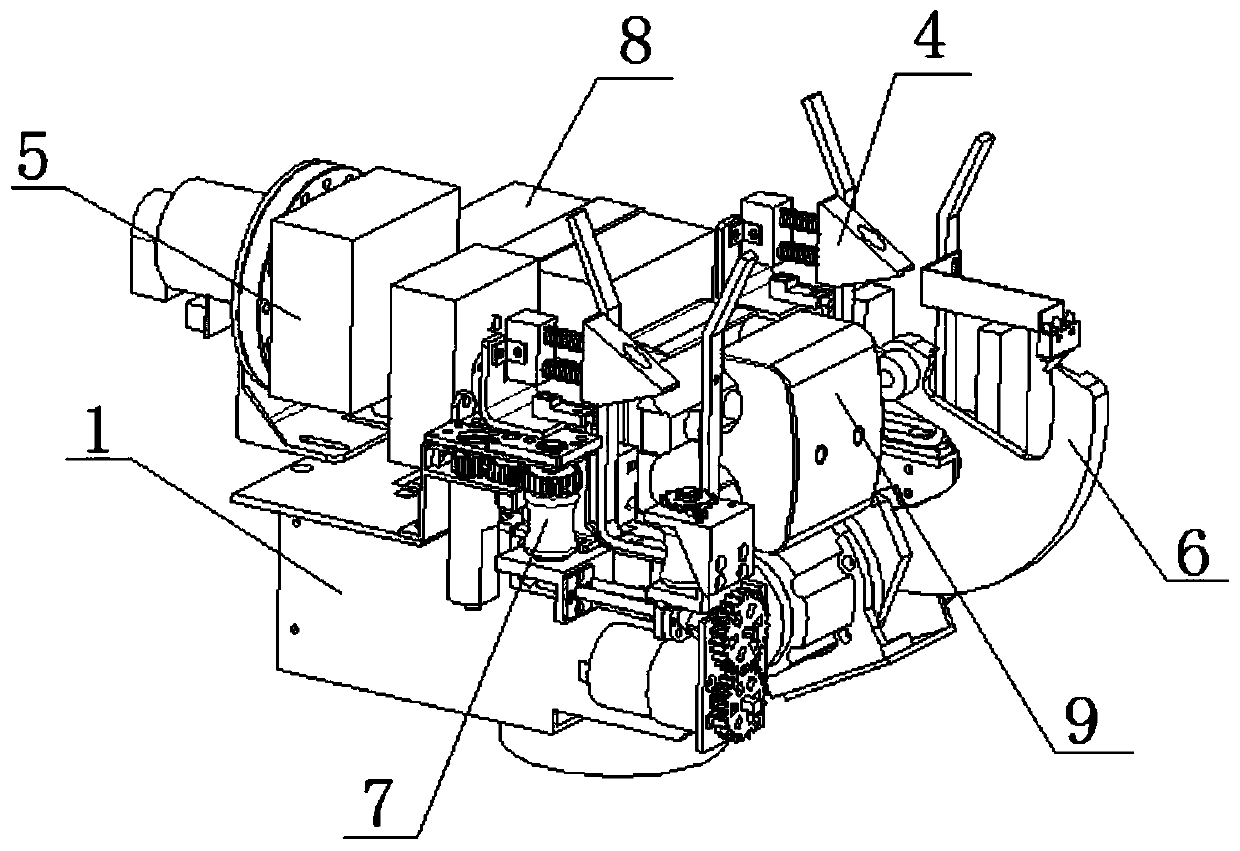

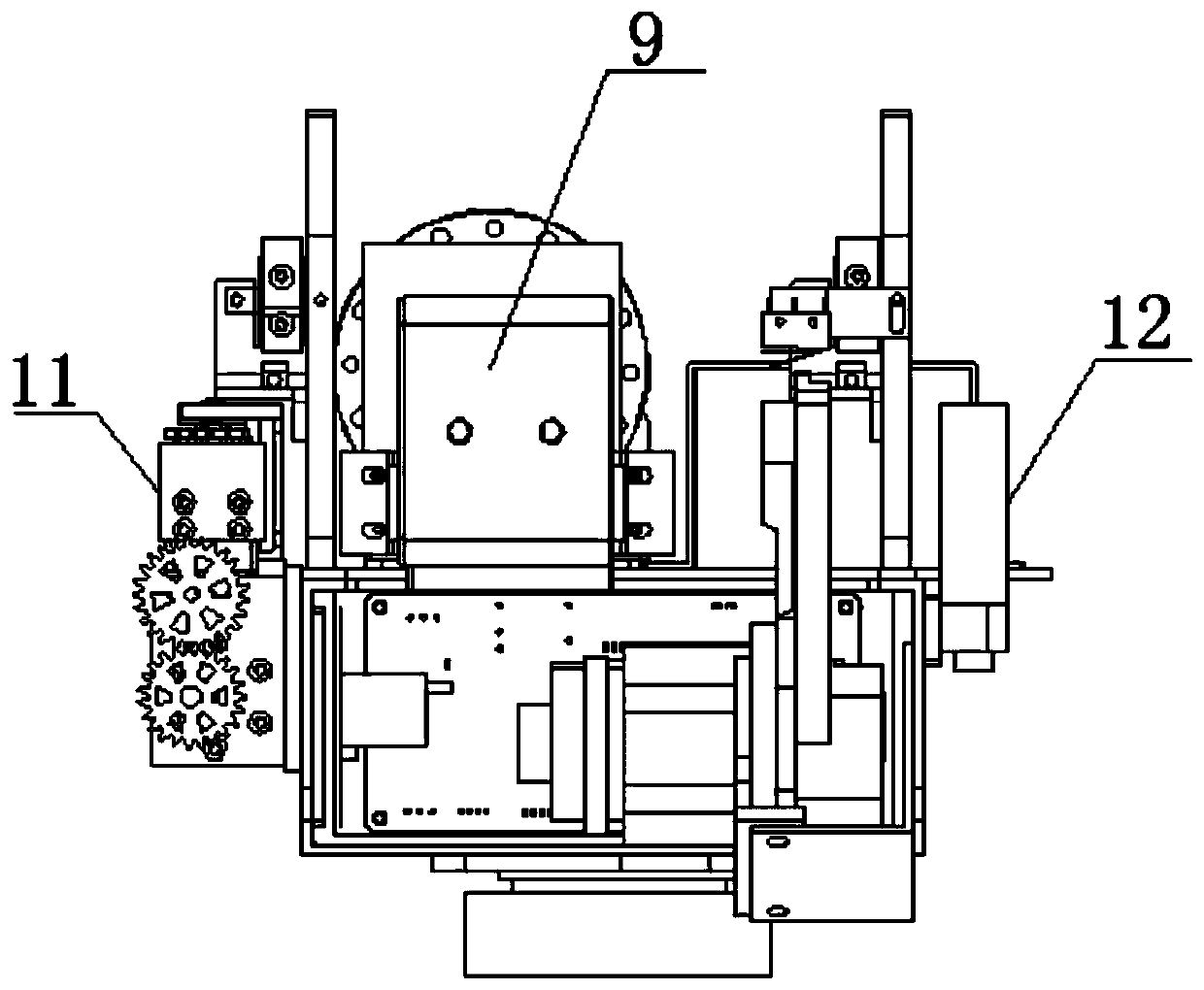

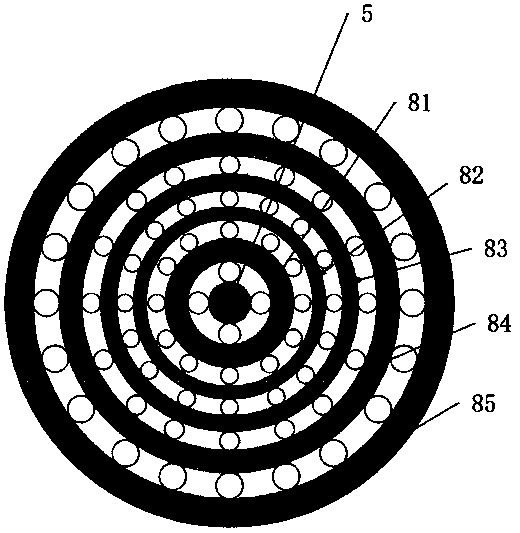

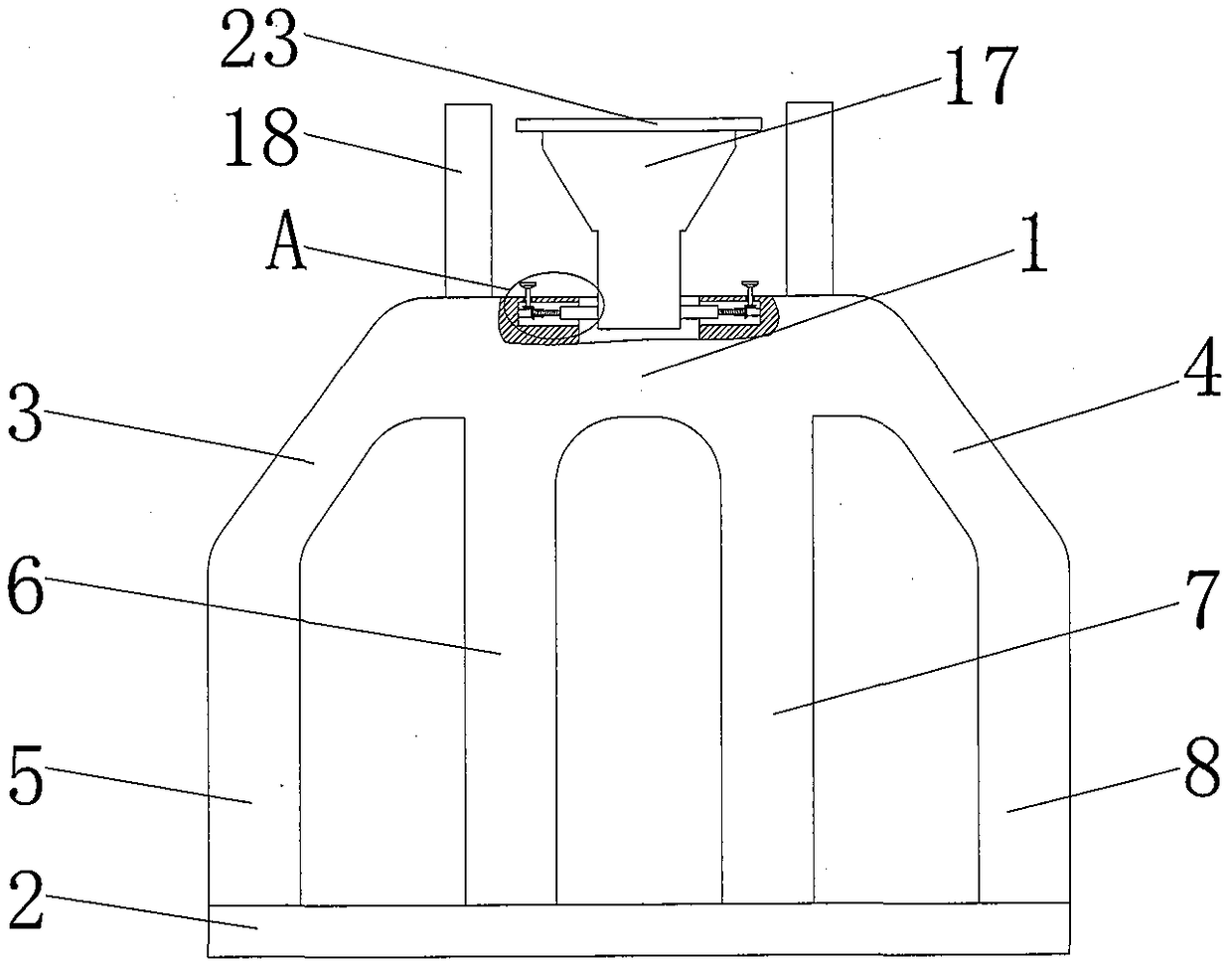

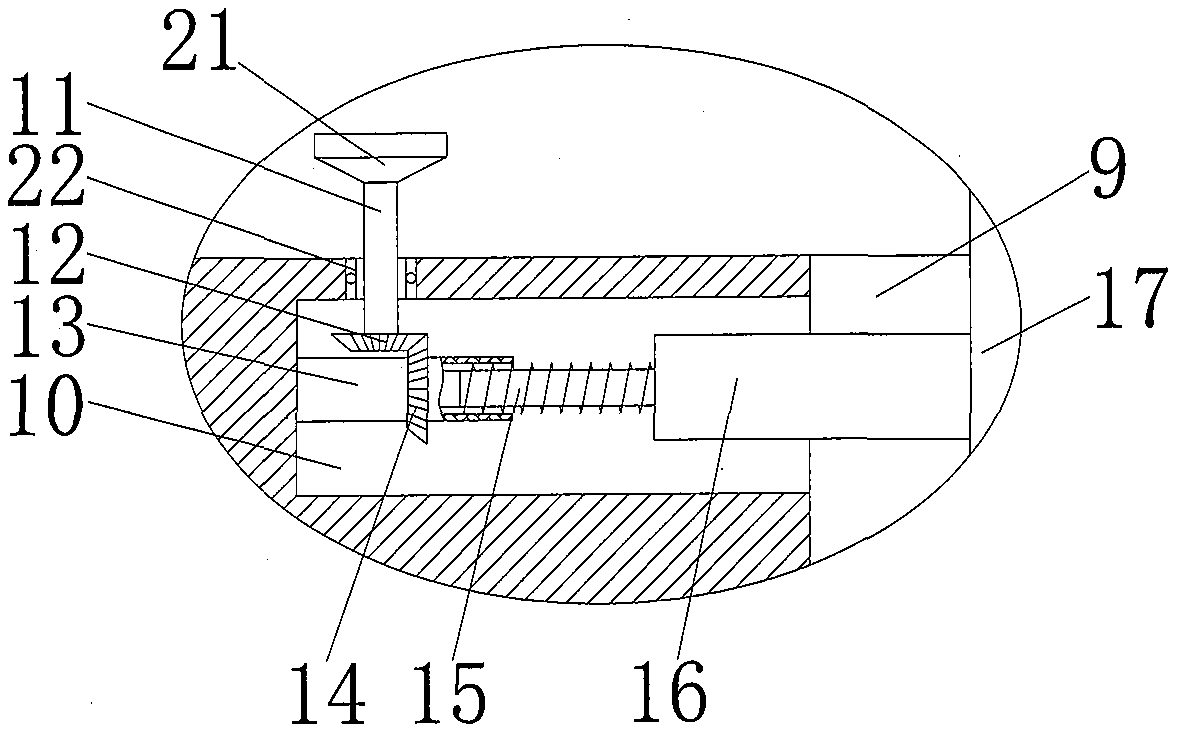

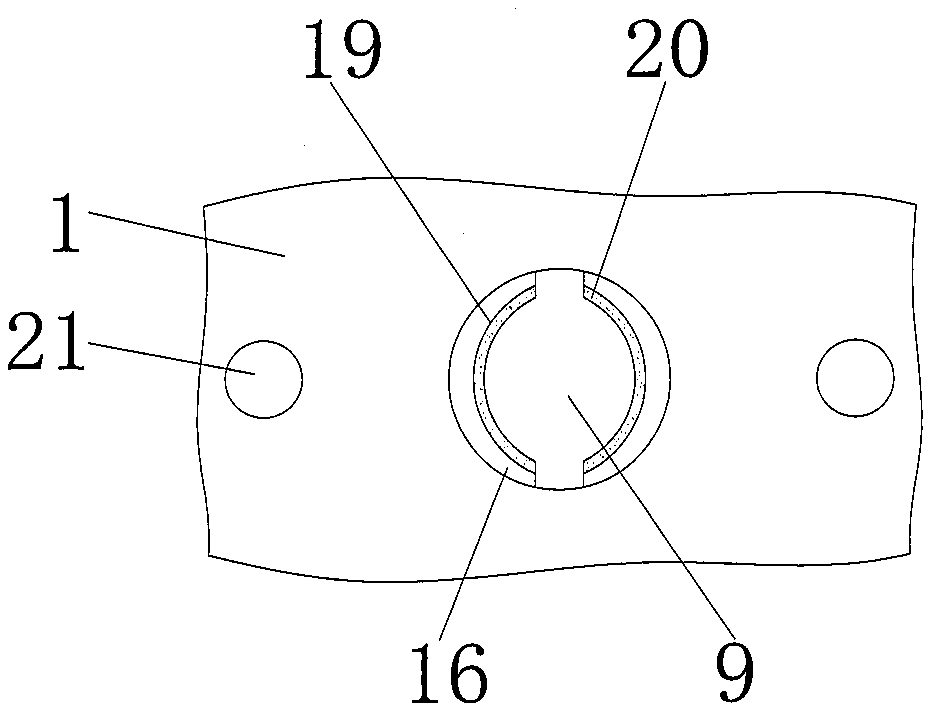

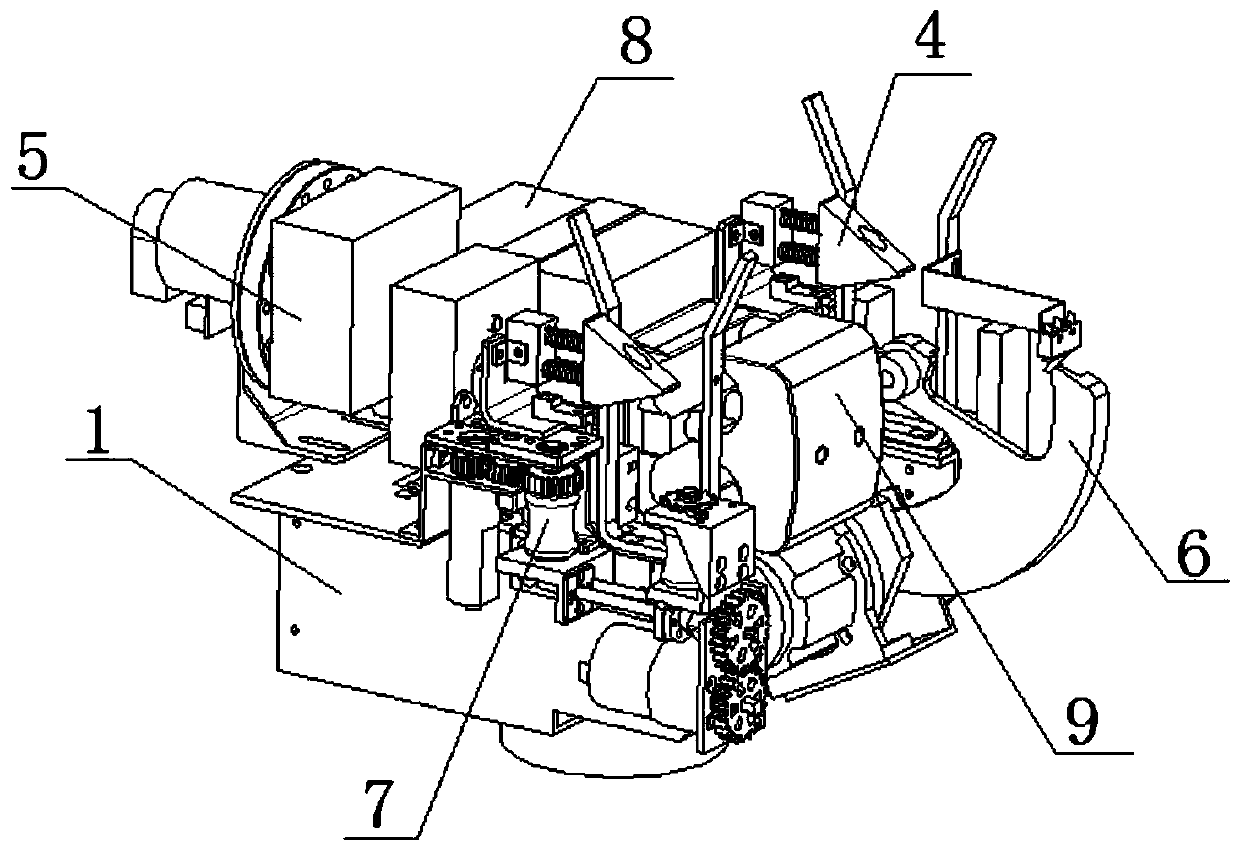

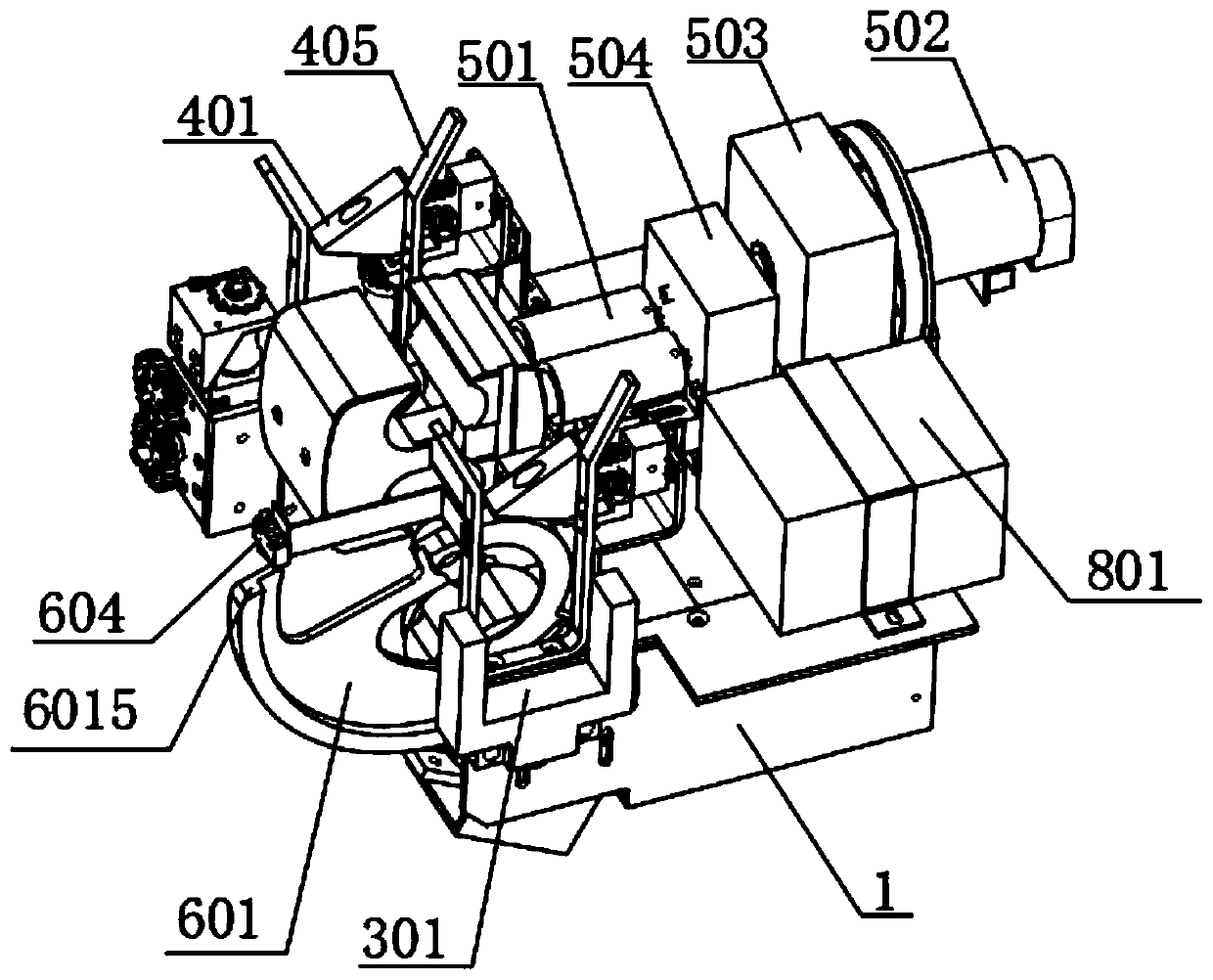

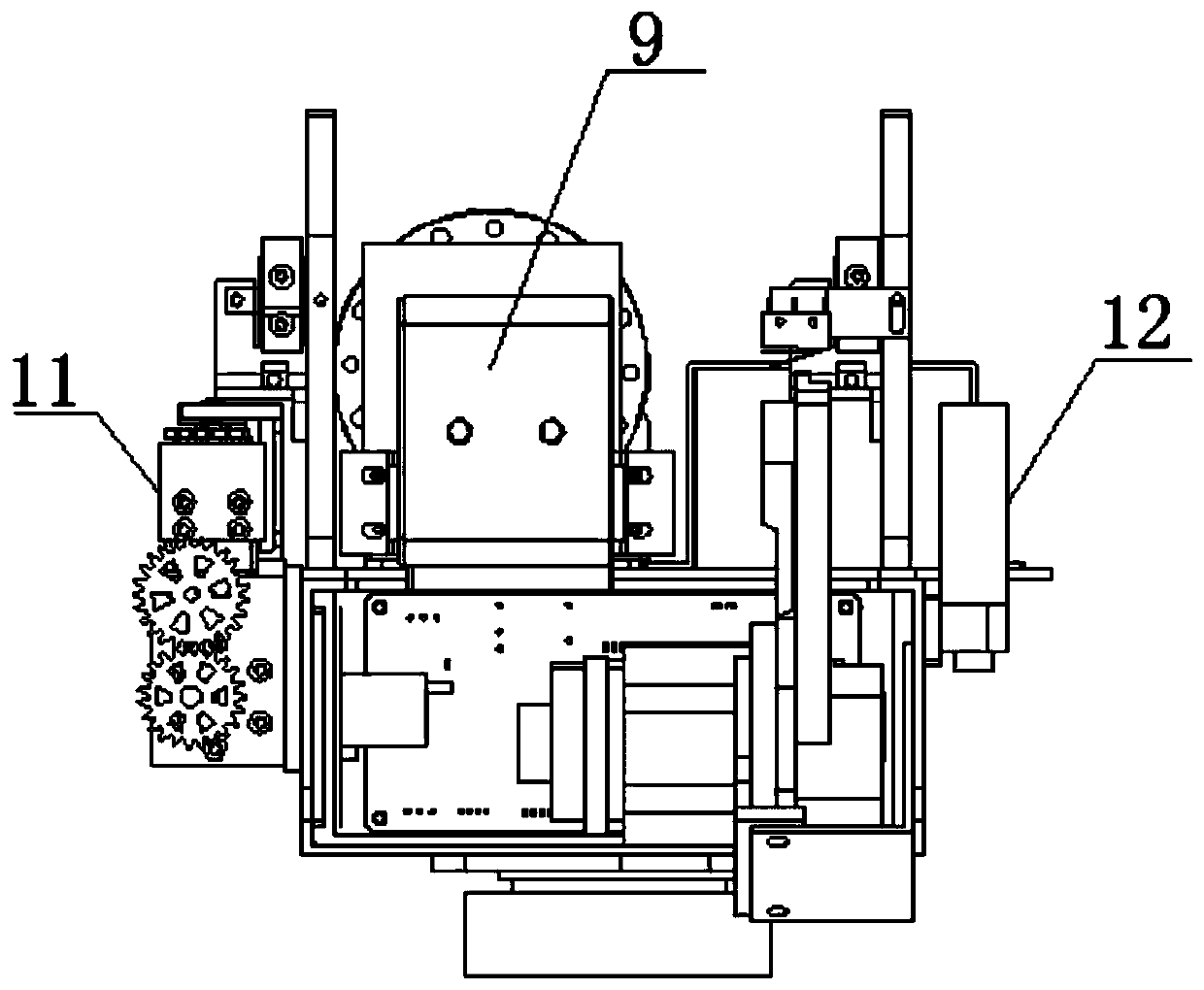

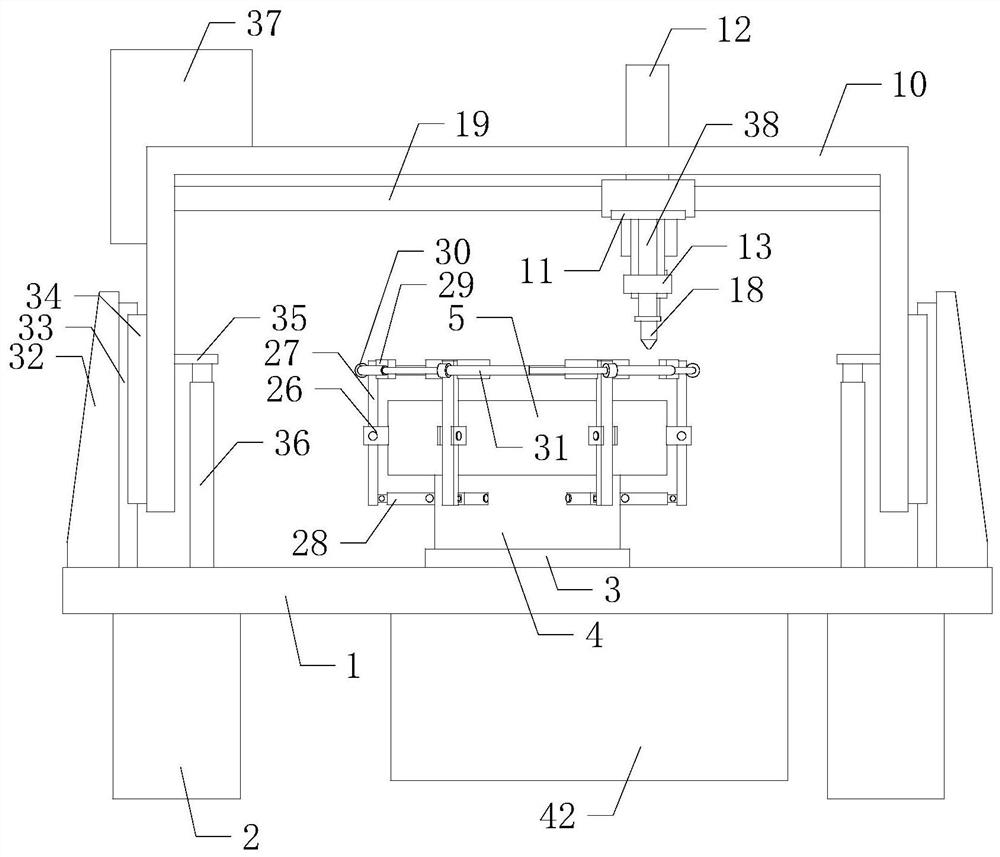

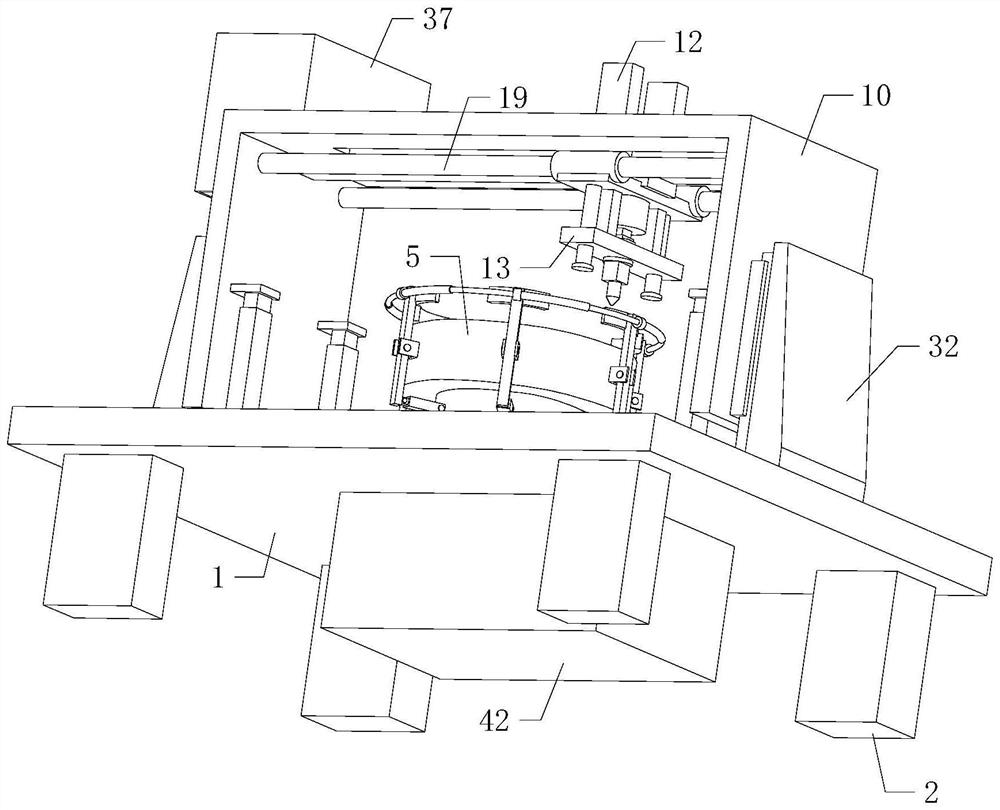

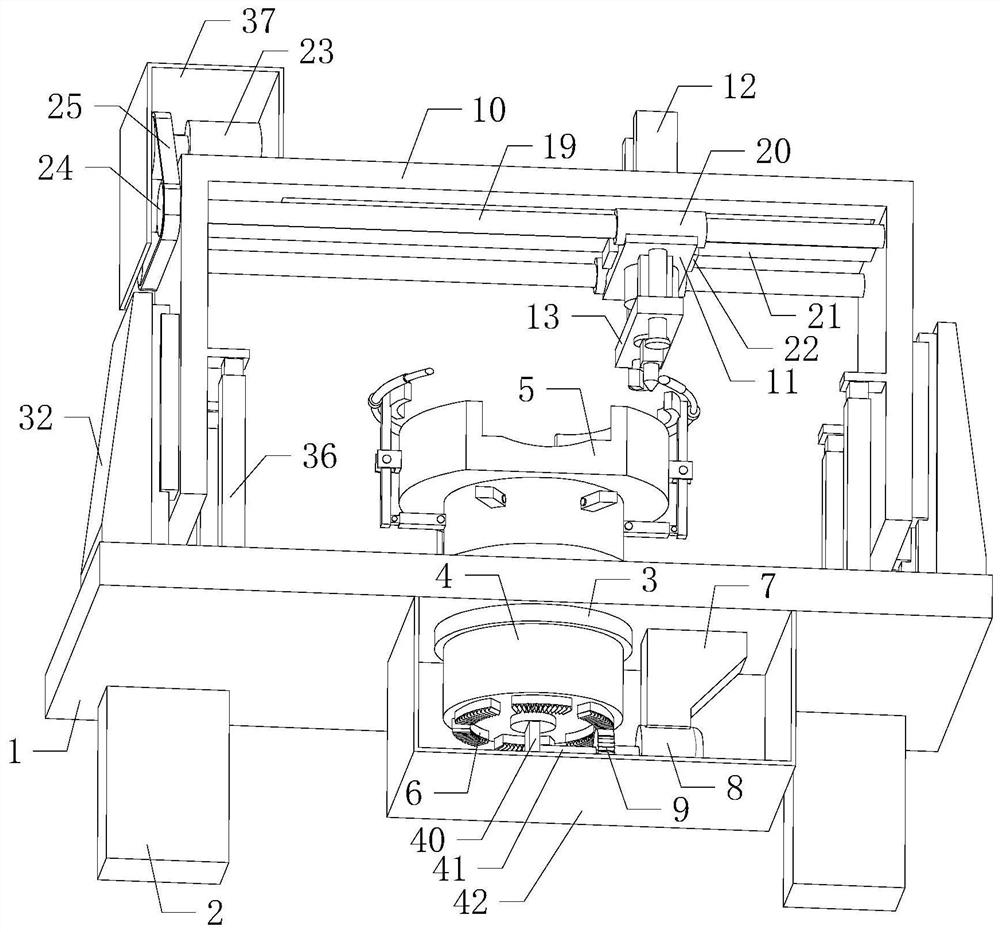

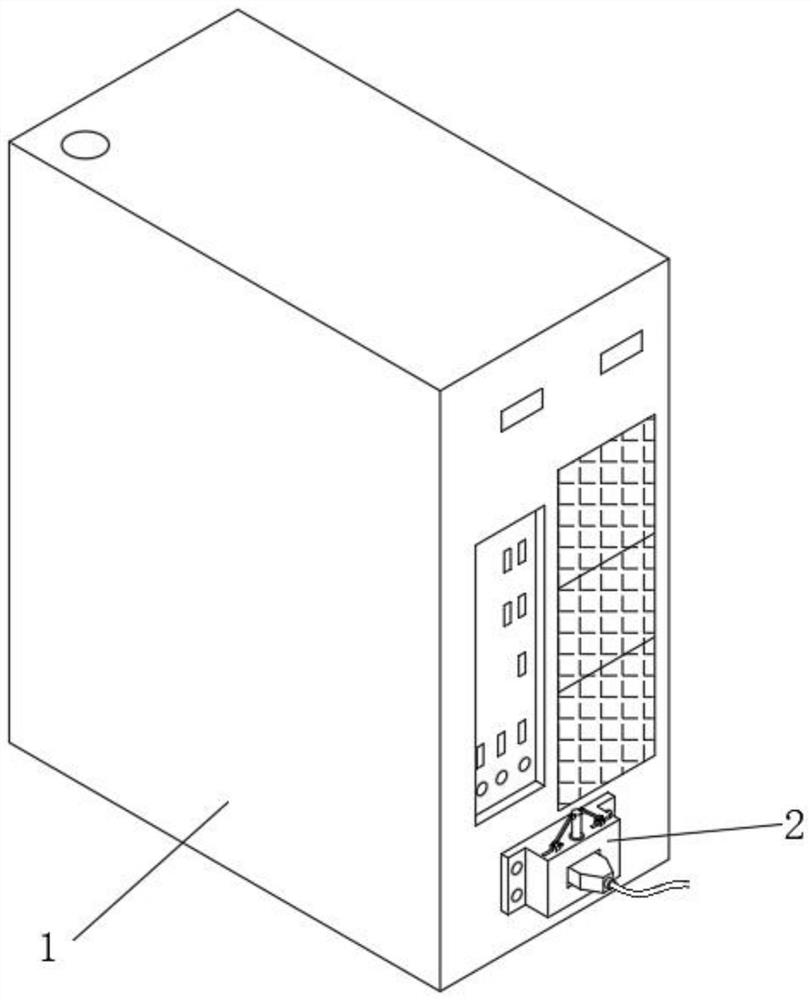

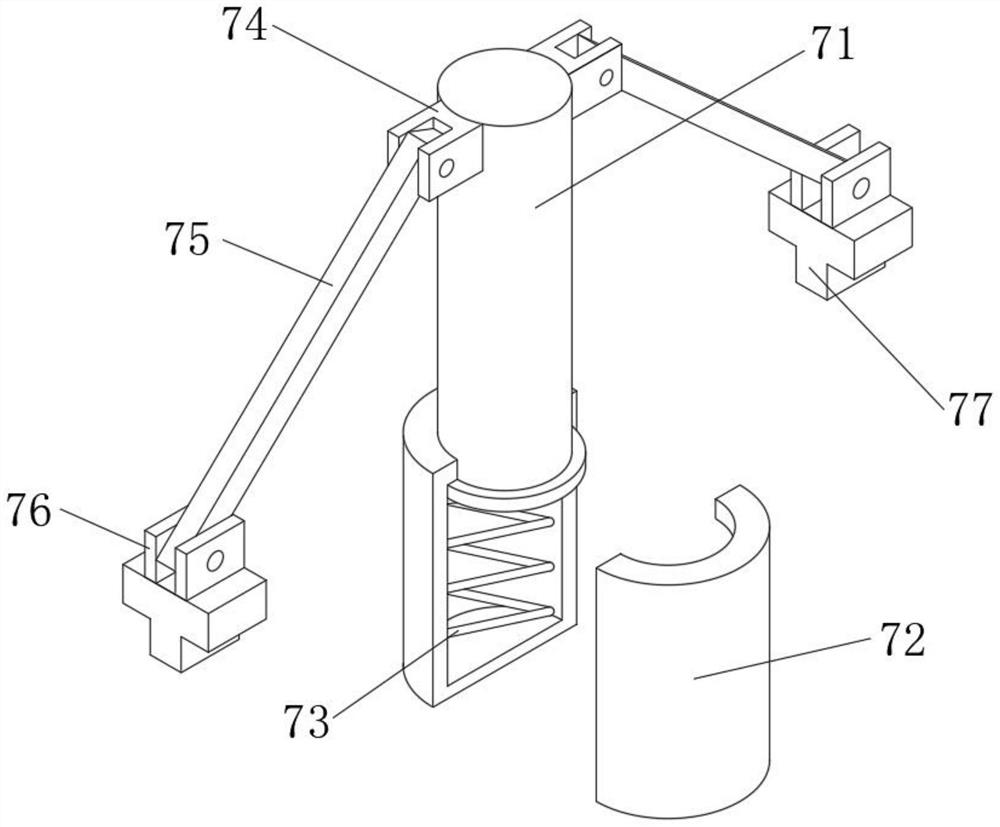

Automatic tapping equipment for fixing holes of vehicle-mounted air filter

ActiveCN112388018AStable supportAvoid tooth lossFeeding apparatusDriving apparatusIn vehicleDrill hole

The invention relates to the technical field of mechanical equipment, in particular to automatic tapping equipment for fixing holes of a vehicle-mounted air filter. According to the automatic tappingequipment, the vacancy distribution uniformity and the position accuracy can be conveniently improved by automatically drilling the vehicle-mounted air filter, deviation of drilling vacancies can be prevented from influencing product installation, the stability of the equipment is improved, the tapping quality is effectively improved, meanwhile, the tapping mode is effectively simplified, the physical strength and time during manual operation are saved, the working efficiency is improved, and the practicability and reliability are improved. The automatic tapping equipment comprises a workbench, four sets of supporting legs, a fixing sleeve, a rotating shaft and an annular groove plate, wherein the four sets of supporting legs are arranged at the bottom of the workbench; the fixing sleeve is arranged in the middle of the workbench; the upper side and the lower side of the fixing sleeve extend out of the workbench; and the bottom of the rotating shaft penetrates through the fixing sleeveand extends to the position below the fixing sleeve.

Owner:山东艾泰克环保科技股份有限公司

Protection device for computer power interface

ActiveCN112072397BInhibit sheddingImprove dustproof effectVolume/mass flow measurementCouplings bases/casesGear wheelControl theory

The invention discloses a protection device for a computer power supply interface, and relates to the field of computers. The protection device for the power interface of the computer, the back of the chassis is fixedly connected with a fixing seat, the outer surface of the fixing seat is provided with a slot, the inner wall of the slot is movably connected with triangular blocks, and the interior of the slot is movably connected with a power supply There are limit slots on both sides of the power cord plug, the two sides of the power cord plug are movably connected with the triangular block, the upper surface of the fixed seat is fixedly connected with an adjustment component, and the two sides of the adjustment component are slidably connected to the fixed seat. The upper surface is fixedly connected with the triangular block, the side surface of the triangular block is fixedly connected with a first rack, the inside of the fixed seat is rotatably connected with a gear, and the first rack is meshed with the gear. The protection device for the power interface of the computer is used to clamp and fix the power cord plug to prevent the power cord plug from falling off from the power supply interface, and at the same time, the power supply interface is protected from dust when not in use.

Owner:GUANGDONG PEIZHENG COLLEGE

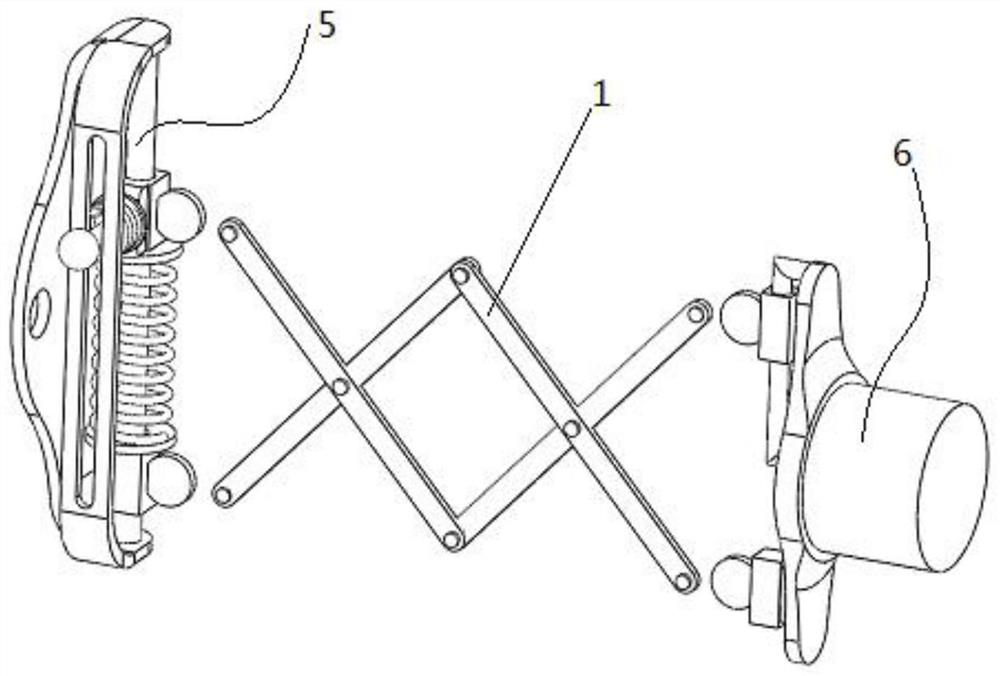

Anti-collision device for moving part

ActiveCN113418128AStretch length compressionStretched length Compressed shortenedEngineering emergency devicesBrake typesMoving partsEngineering

The invention discloses an anti-collision device for a moving part. When the anti-collision device is used, a braking distance stretching arm, a braking distance adjusting base assembly and a braking switch triggering assembly form a set of complete braking stretching arm unit; and the stretching length of the braking distance stretching arm represents the braking distance between a first movement mechanism component and a second movement mechanism component, the braking distance between the components in actual use is adjusted by adjusting the stretching length of the braking distance stretching arm, when the first movement mechanism component and the second movement mechanism component interfere with each other and get close to each other, the braking switch triggering assembly makes contact with an emergency stop and emergency brake switch on the second movement mechanism component at the first time, emergency braking is achieved through triggering of the emergency stop and emergency brake switch, and through the compression of braking stretching arm unit length, the situation that when the first movement mechanism component and the second movement mechanism component continuously get close to each other, the braking distance stretching arm, the braking switch triggering assembly and the braking distance adjusting base assembly are extruded and damaged is avoided.

Owner:彩虹(合肥)液晶玻璃有限公司

A long-life, high-efficiency, and safe chain-belt pallet conveyor

ActiveCN103057903BIncrease production capacityIncrease productivityConveyorsRollersDrive wheelSprocket

Owner:SHILIN LUOHE METALLURGY EQUIP

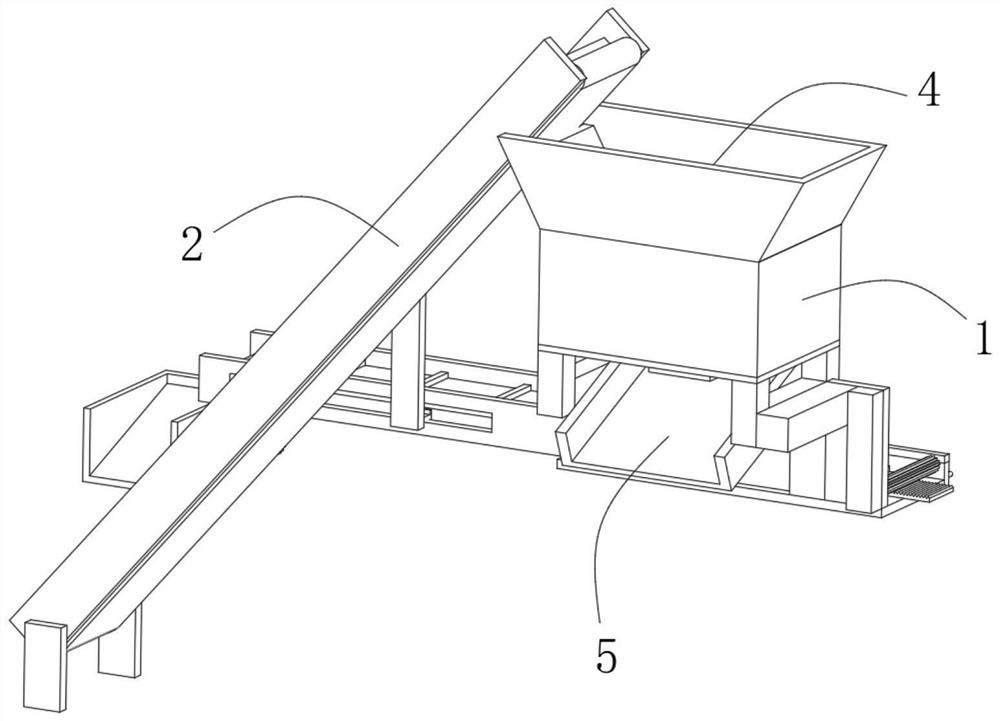

Lithium battery recycling equipment with disassembling function

PendingCN113764764AReduce harmReduce energy consumptionWaste accumulators reclaimingBattery recyclingCrankStructural engineering

The invention discloses lithium battery recycling equipment with the disassembling function, and relates to the field of lithium battery recycling. According to the lithium battery recycling equipment with the disassembling function, a first conveying belt and a second conveying belt are arranged on the side face of a first-stage crushing bin, an inclined hopper is fixedly installed on the outer surface of the first conveying belt, the tail end of the second conveying belt right faces the position over the inclined hopper, and a rotary material guide plate is arranged at the bottom of the first-stage crushing bin; the second conveying belt is arranged at the tail end of the rotary material guide plate; a crank is fixedly installed on the side face of the driving rotating rod, the outer surface of the driving rotating rod is fixedly sleeved with a third gear, the third gear is in transmission connection with the second conveying belt, the end of the driving rotating rod is in transmission connection with a transmission rod, and the transmission rod is in transmission connection with the rotary material guide plate. According to the lithium battery recycling equipment with the disassembling function, a crank is rotated, so that a first conveying belt drives a second conveying belt to move. Meanwhile, a rotary material guide plate is turned over.

Owner:ZHEJIANG COLLEGE OF ZHEJIANG UNIV OF TECHOLOGY

A chain-belt pallet conveyor system

ActiveCN103204353BIncrease production capacityIncrease productivityConveyorsRollersEngineeringDelivery system

Owner:SHILIN LUOHE METALLURGY EQUIP

Rail transit platform screen door safety protection equipment and method thereof

ActiveCN114312852ASituations to Avoid CasualtiesCasualtiesRailway componentsRailway transportGear wheelRail transit

The invention discloses rail transit platform screen door safety protection equipment and a method thereof, and relates to the field of rail transit. According to the rail transit shielding door safety protection equipment and the method thereof, a servo motor is fixedly installed above shielding door bodies, a driving gear is installed at the output end of the servo motor, and a first driving rack and a second driving rack are arranged at the tops of the two shielding door bodies; the first driving rack and the second driving rack are engaged with the two sides of the driving gear correspondingly, the bottom ends of the two sets of transmission racks are fixedly connected with protective stop levers, and the protective stop levers are movably clamped in L-shaped clamping bases on the outer surface of the shielding door body; the first driving rack and the second driving rack are in transmission connection with the two transmission racks through the two transmission gears correspondingly. According to the rail transit platform screen door safety protection equipment and the method thereof, the protection stop lever moves up and down to protect the platform screen door body in the opening and closing process of the platform screen door.

Owner:GUANGZHOU VOCATIONAL COLLEGE OF TECH & BUSINESS

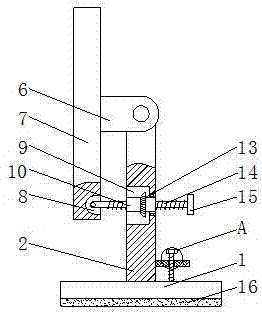

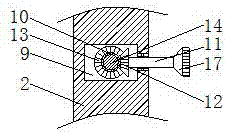

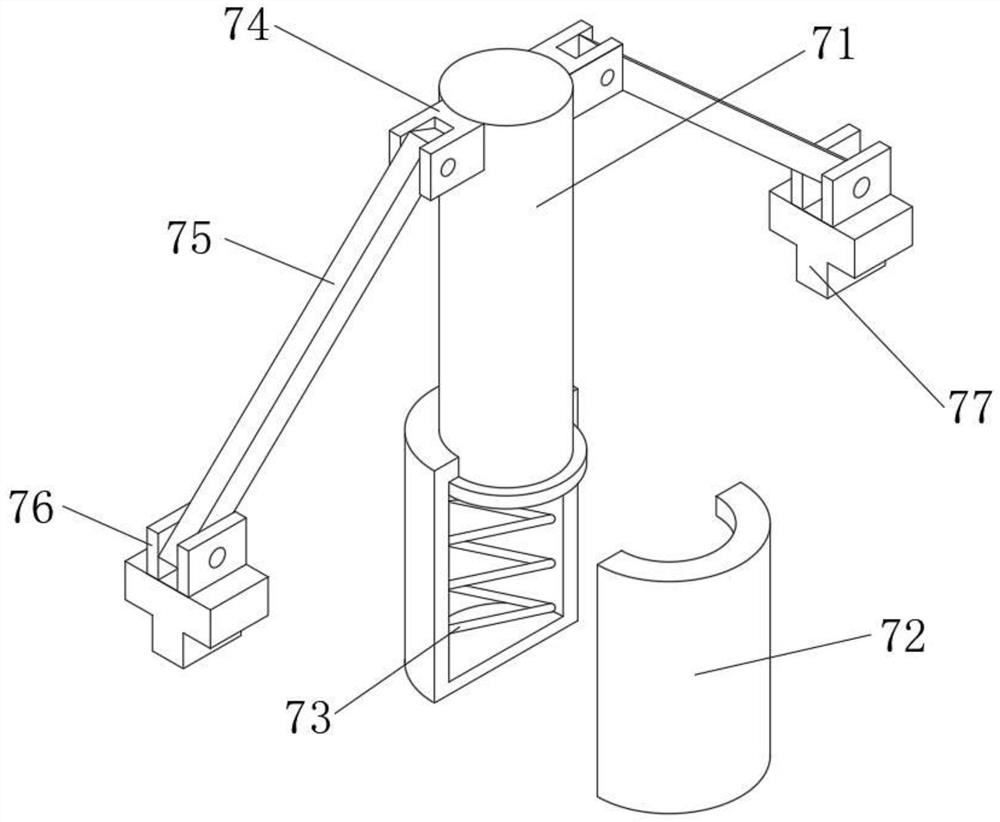

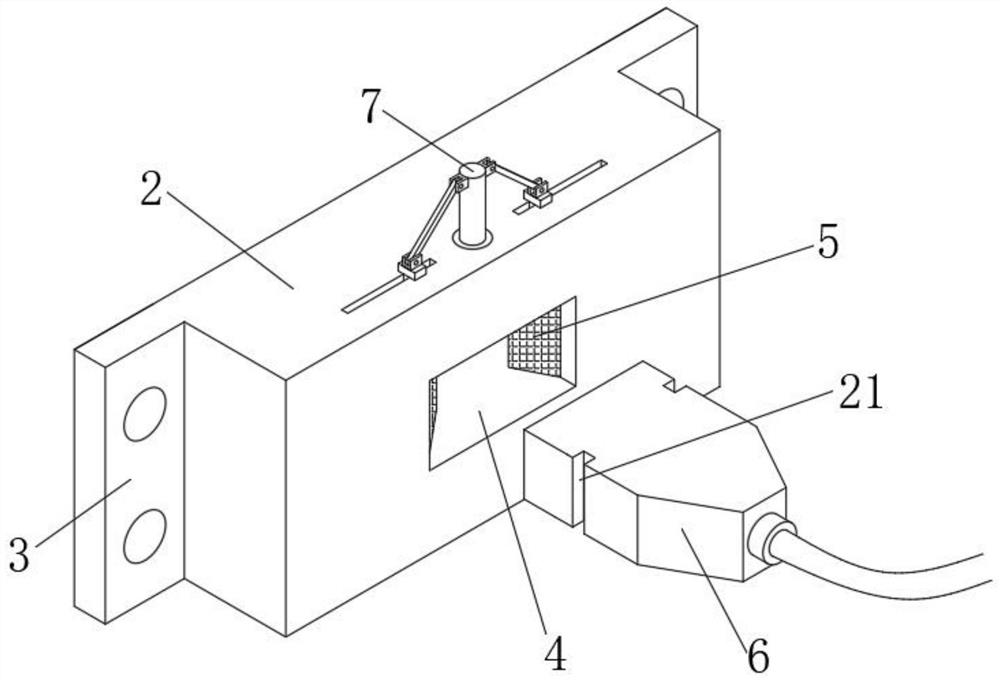

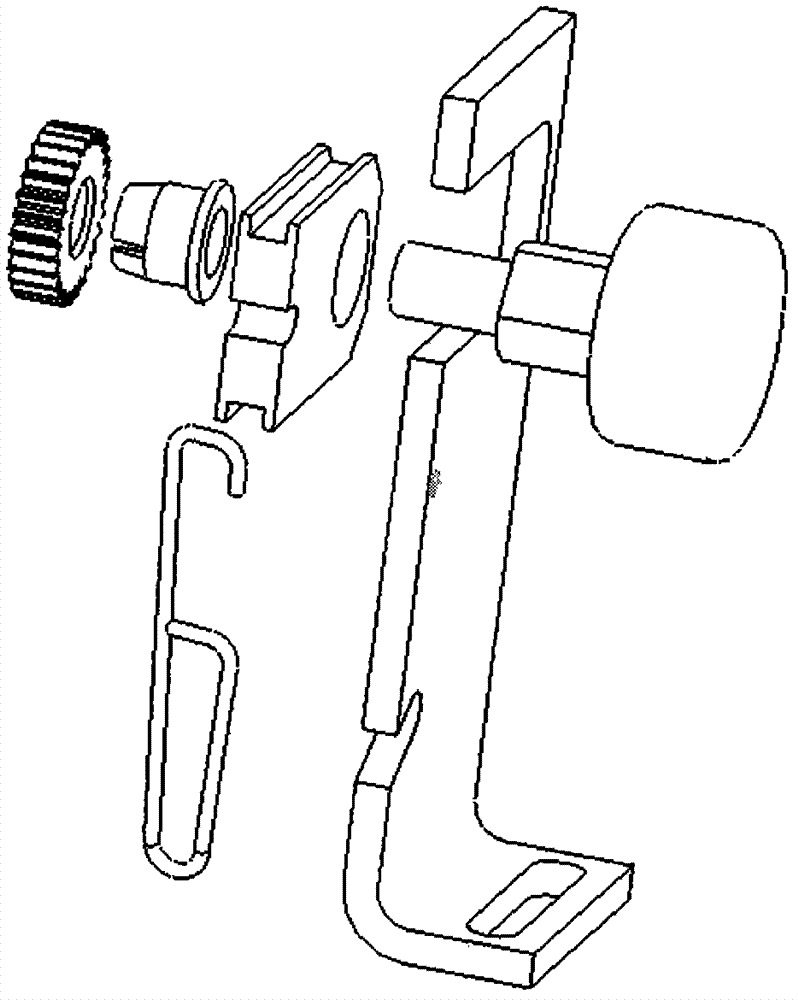

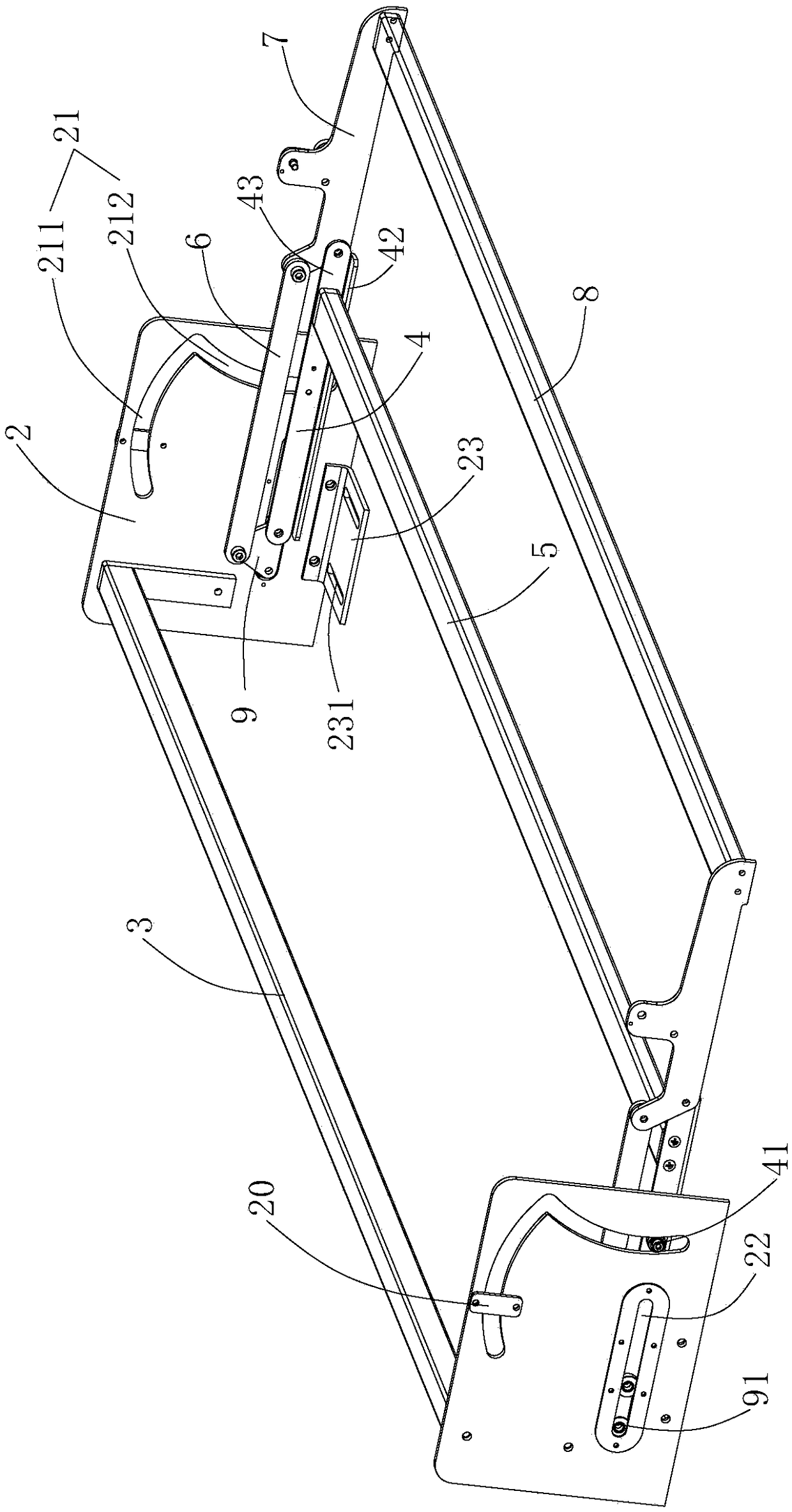

Adjustable precise position sensor

ActiveCN102168992BLow costCost controlConverting sensor output mechanicallyEngineeringPosition sensor

The invention relates to an electric operating mechanism used for industrial automation control instruments, particularly relates to an adjustable precise position sensor which comprises a right-angle frame (1), a feedback rod (2) and a fixing base (10), wherein a screw rod pair is arranged on one end of the right-angle frame (1); a screw nut (8) of the screw rod pair is fixedly connected to an adjustable pin shaft (9); the feedback rod (2) is provided with a sliding slot along the length direction; one end of the feedback rod (2) is connected to one end of the right-angle frame (1); the feedback rod (2) is sleeved on the adjustable pin shaft (9) through the sliding slot; a potentiometer fixing plate (6) is fixed on the fixing base (10); a potentiometer is fixed on the potentiometer fixing plate (6); and a feedback gear (5) is sleeved on the potentiometer. The adjustable precise position sensor can be used for replacing the original feedback parts. Meanwhile, by using the adjustable precise position sensor, the gear dropping phenomenon under the conditions of faults, installing, debugging and the like is avoided.

Owner:WUZHONG INSTR

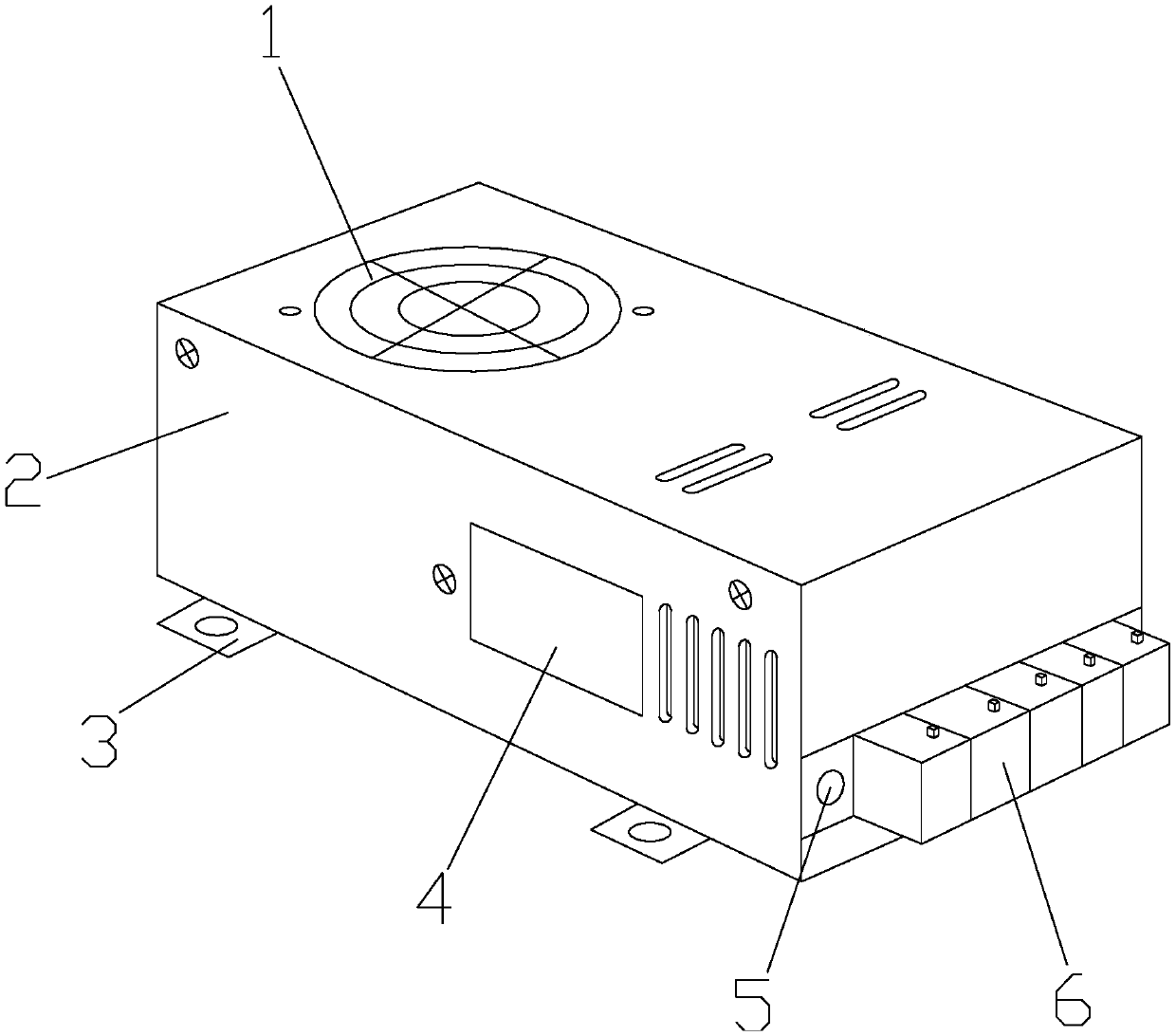

Spring-fixed switching power supply transformer for electrical teaching

ActiveCN109545520AImprove conductivityGuaranteed to be conductiveTransformers/inductances coils/windings/connectionsElectricityTransformer

The invention discloses a spring-fixed switching power supply transformer for electrical teaching. The transformer comprises a cooling fan, a transformer casing, a casing fixing block, a product nameplate, a power indicator lamp, and a wire connector. According to the transformer, a copper wire stranding structure, a driving structure and a wire fixing device cooperate with one another, when a power wire needs to be mounted on the transformer, the driving structure enables the wire fixing device to fix a copper wire, so that the power wire can be fixed in place without repeatedly screwing a bolt, thereby shortening the wiring time of a practice worker and improving the wiring efficiency during the training process. Further, the copper wire stranding structure strands the copper wire and then delivers the current so as to ensure that each copper wire can conduct electricity and improve the electrical conductivity of the wire.

Owner:LEBIAN ELECTRIC CO LTD

Cloth pressing frame and using method thereof

PendingCN109132653AAvoid tooth lossAvoid wear and tear defectsUnfolding thin materialsWebs handlingMechanical engineeringGear transmission

The invention provides a cloth pressing frame and a using method thereof. The cloth pressing frame includes blocking plates, second connecting rods, a pulling rod, third connecting rods, connecting plates and a pressing rod. The blocking plates are vertically installed on a worktable at intervals, irregularly-shaped holes are formed in the blocking plates, the irregularly-shaped holes comprises first irregularly-shaped sections and second irregularly-shaped sections, the first irregularly-shaped sections are arcs with downward centers, the highest points of the arcs are located in the middlesof the irregularly-shaped sections, and the second irregularly-shaped sections extend downward from one ends of the first irregularly-shaped sections; the second connecting rods and the third connecting rods are rotatably connected to the inner sides of the blocking plates through connecting pieces correspondingly, and arranged parallel to the blocking plates; and the outer sides of the second connecting rods are provided with rollers which are matched with the irregularly-shaped holes, long waist-shaped holes is formed in the blocking plates, sliding blocks are installed on the back face of the connecting pieces, and the sliding blocks are installed in the long-shaped waist holes. The cloth pressing frame and the using method thereof has the advantages that gear transmission is changed into a roller and connecting rod mechanism, the noise of the pressing rod during moving up and falling is greatly lowered, the defects that gear transmission is prone to being subjected to tooth dropping and abrasion are avoided, and meanwhile use is labor-saving and convenient.

Owner:HEFEI AORUI DIGITAL CONTROL SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com