Patents

Literature

45results about How to "Same tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

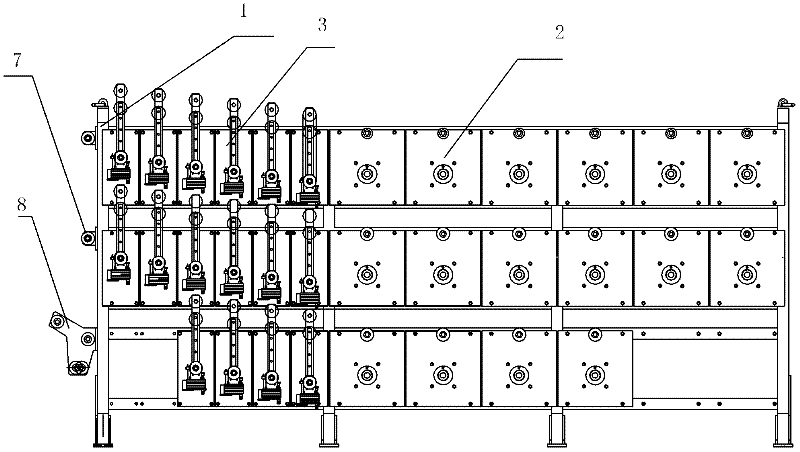

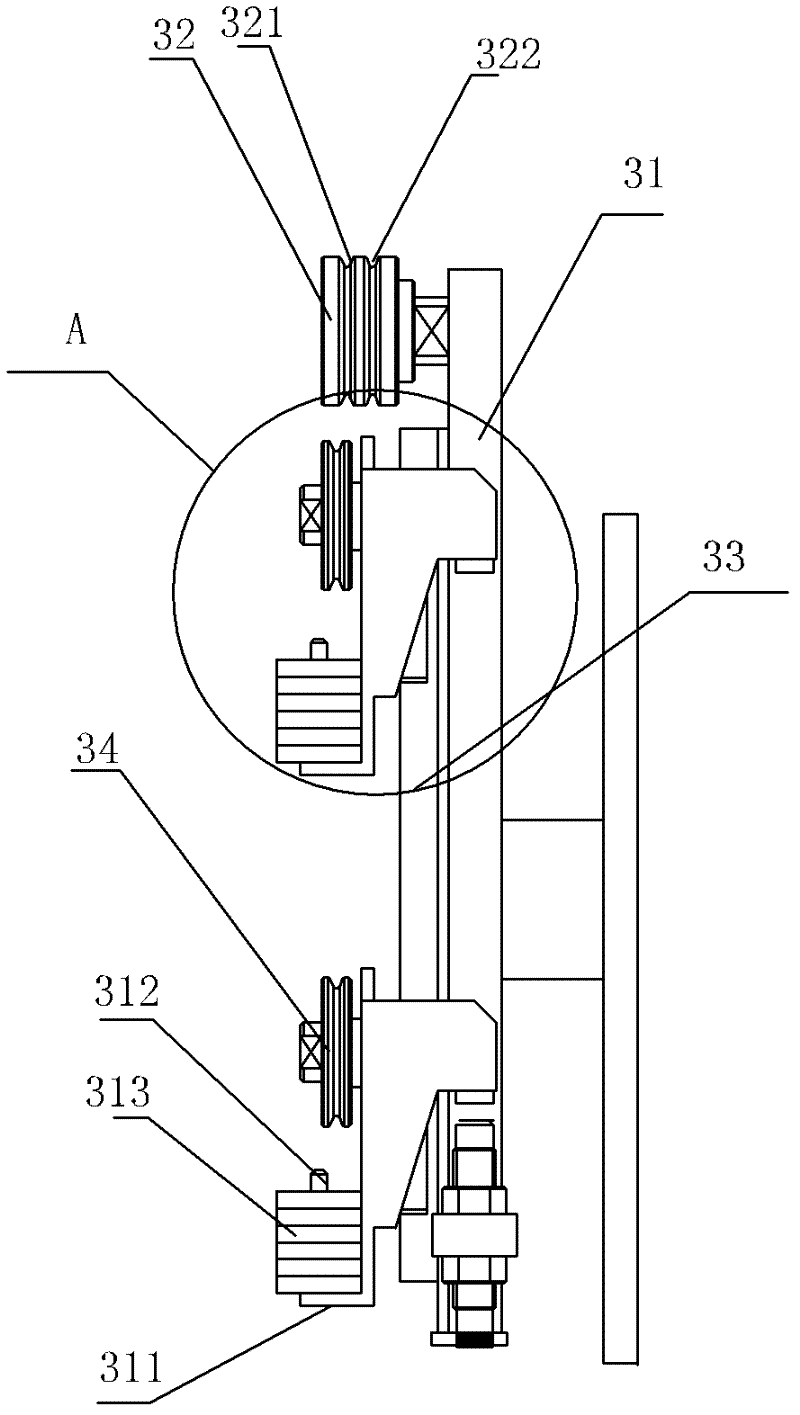

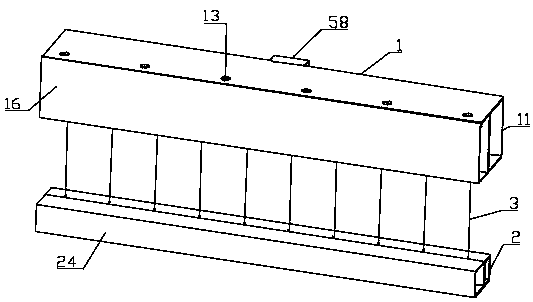

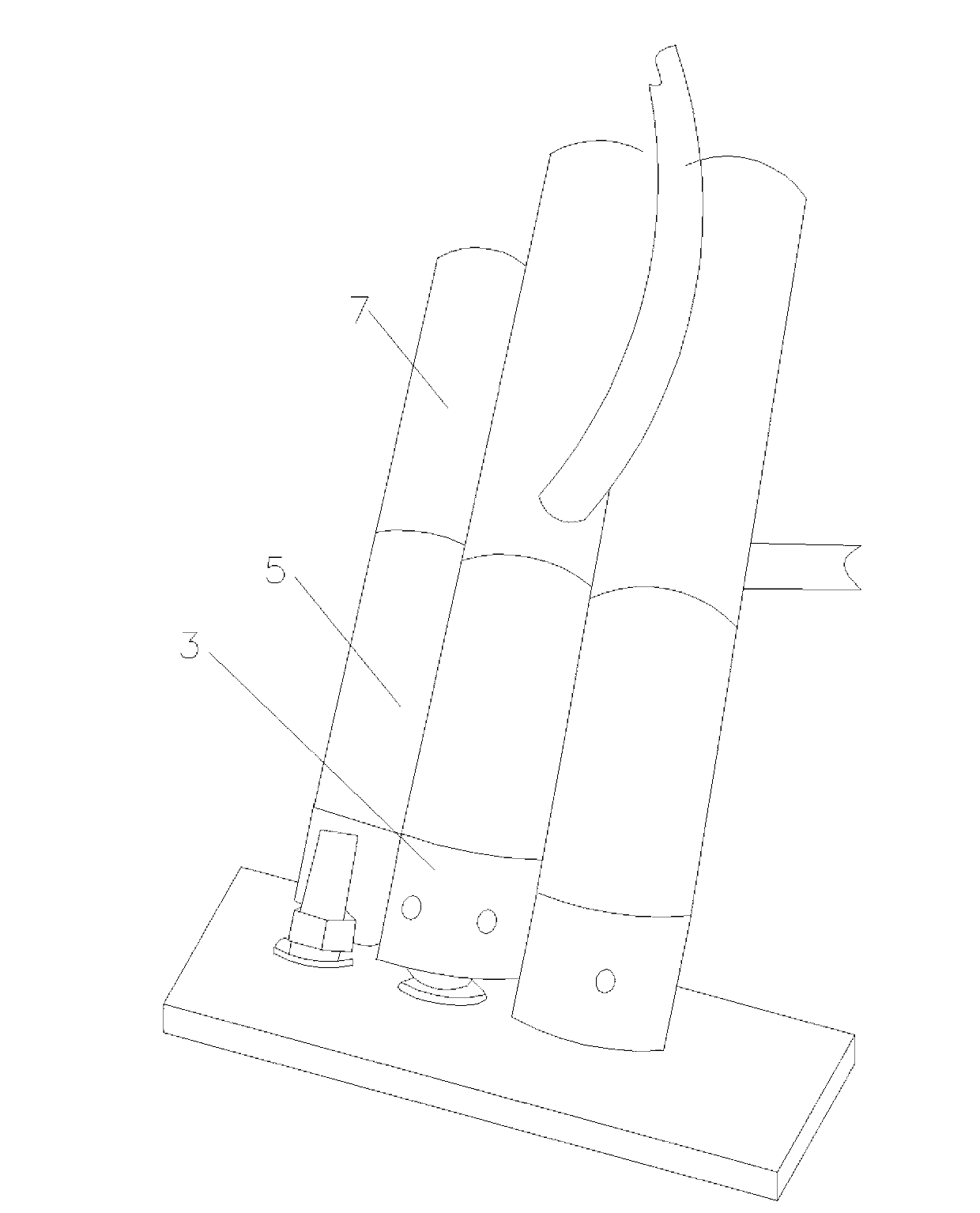

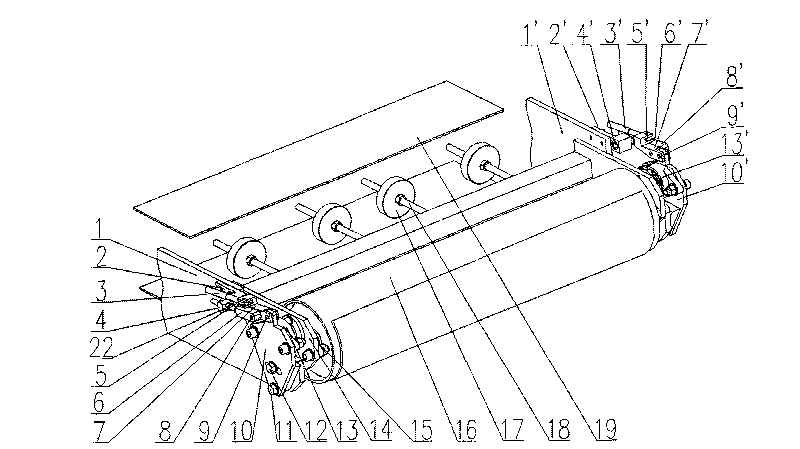

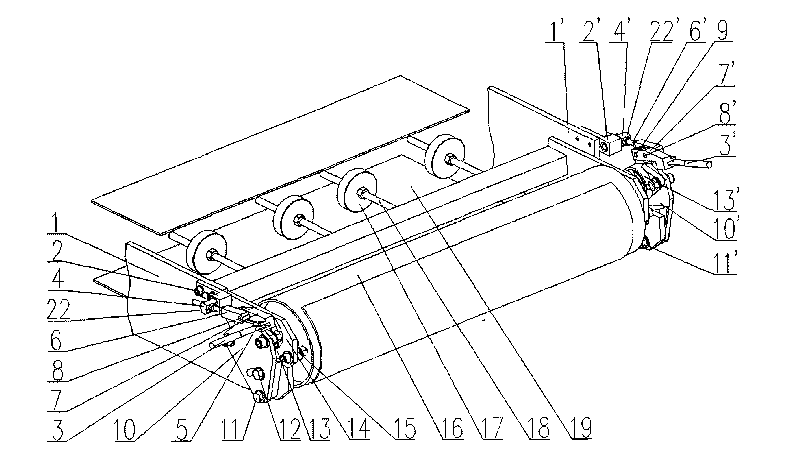

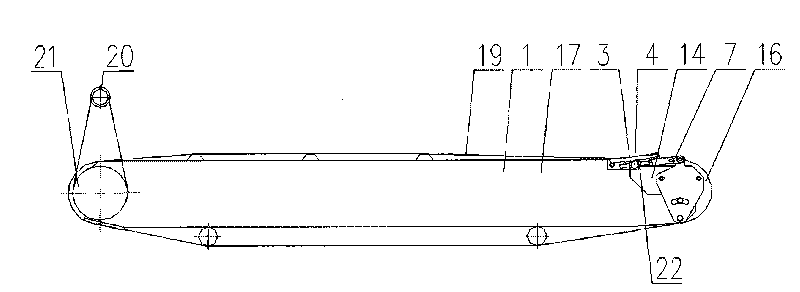

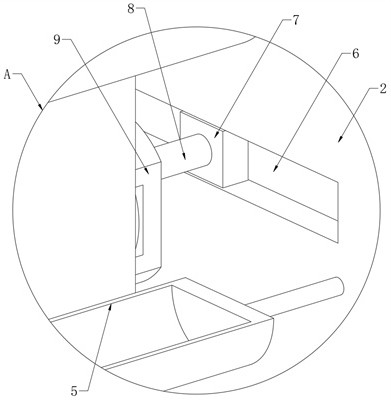

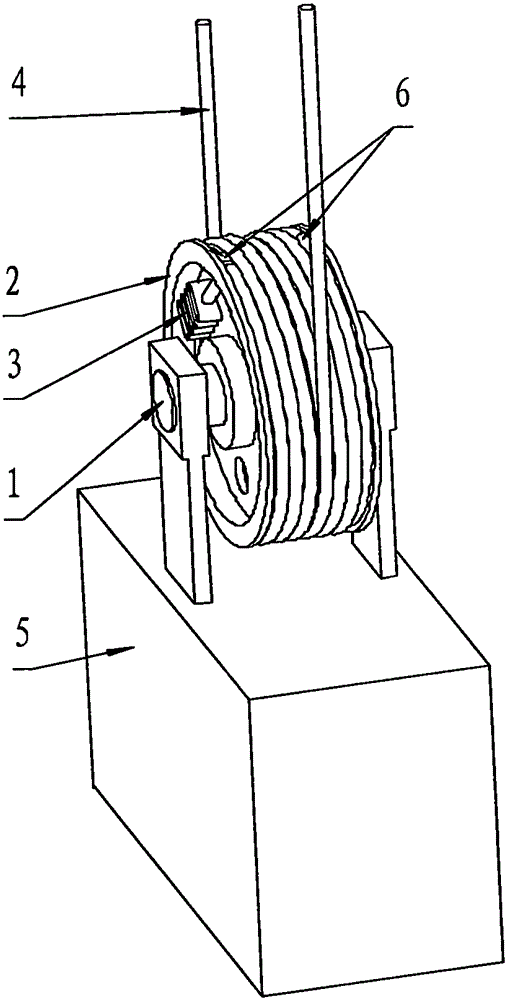

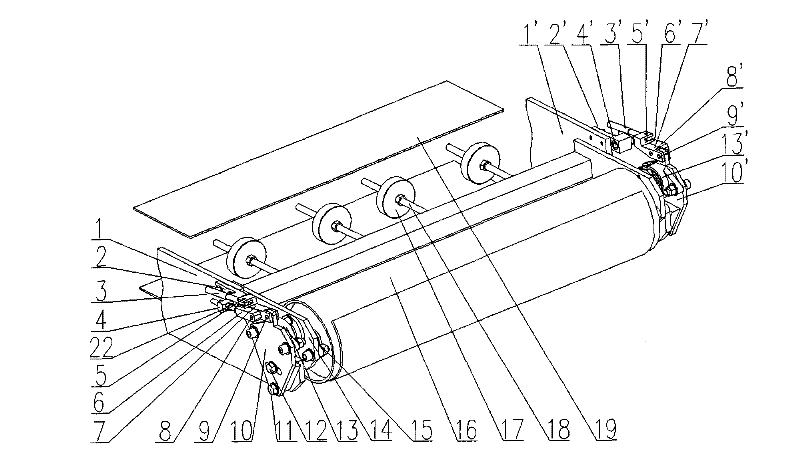

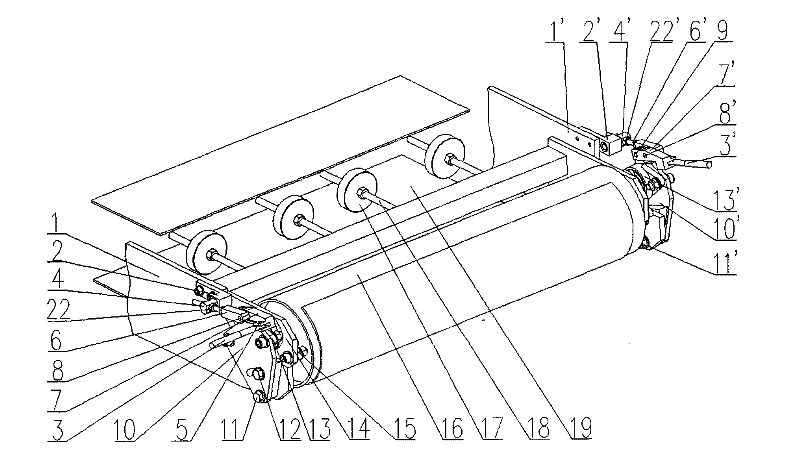

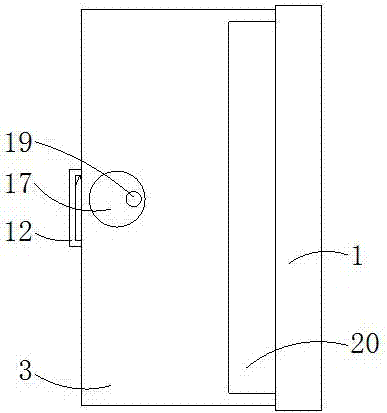

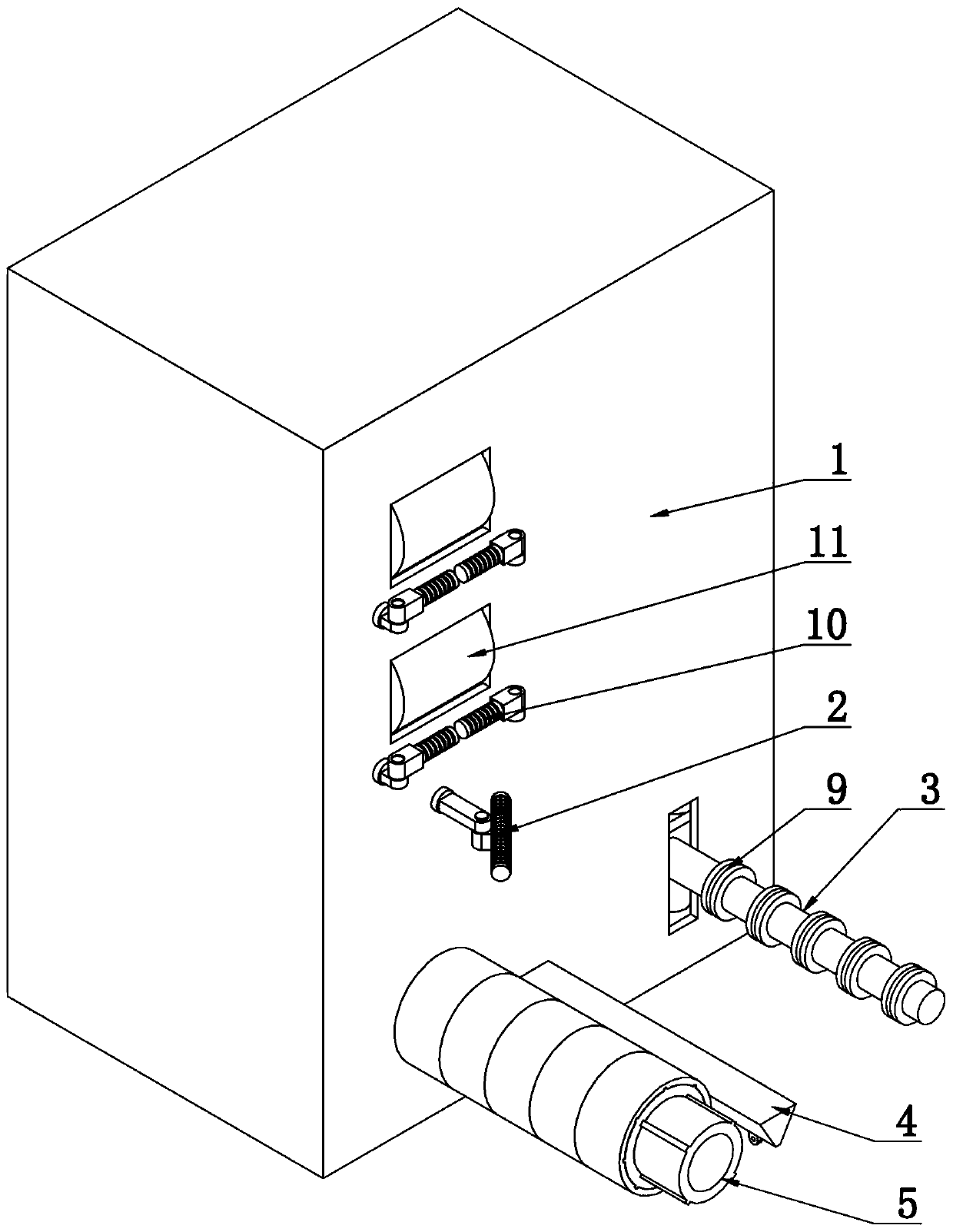

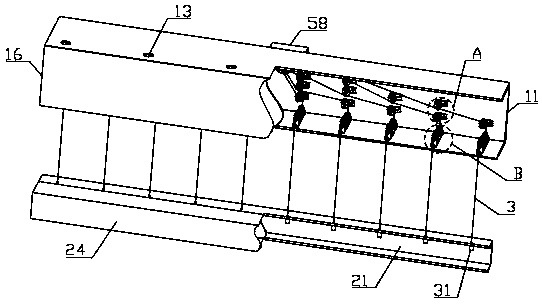

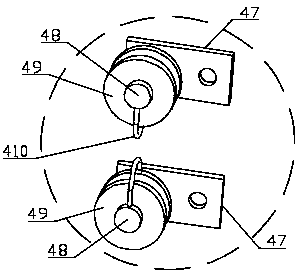

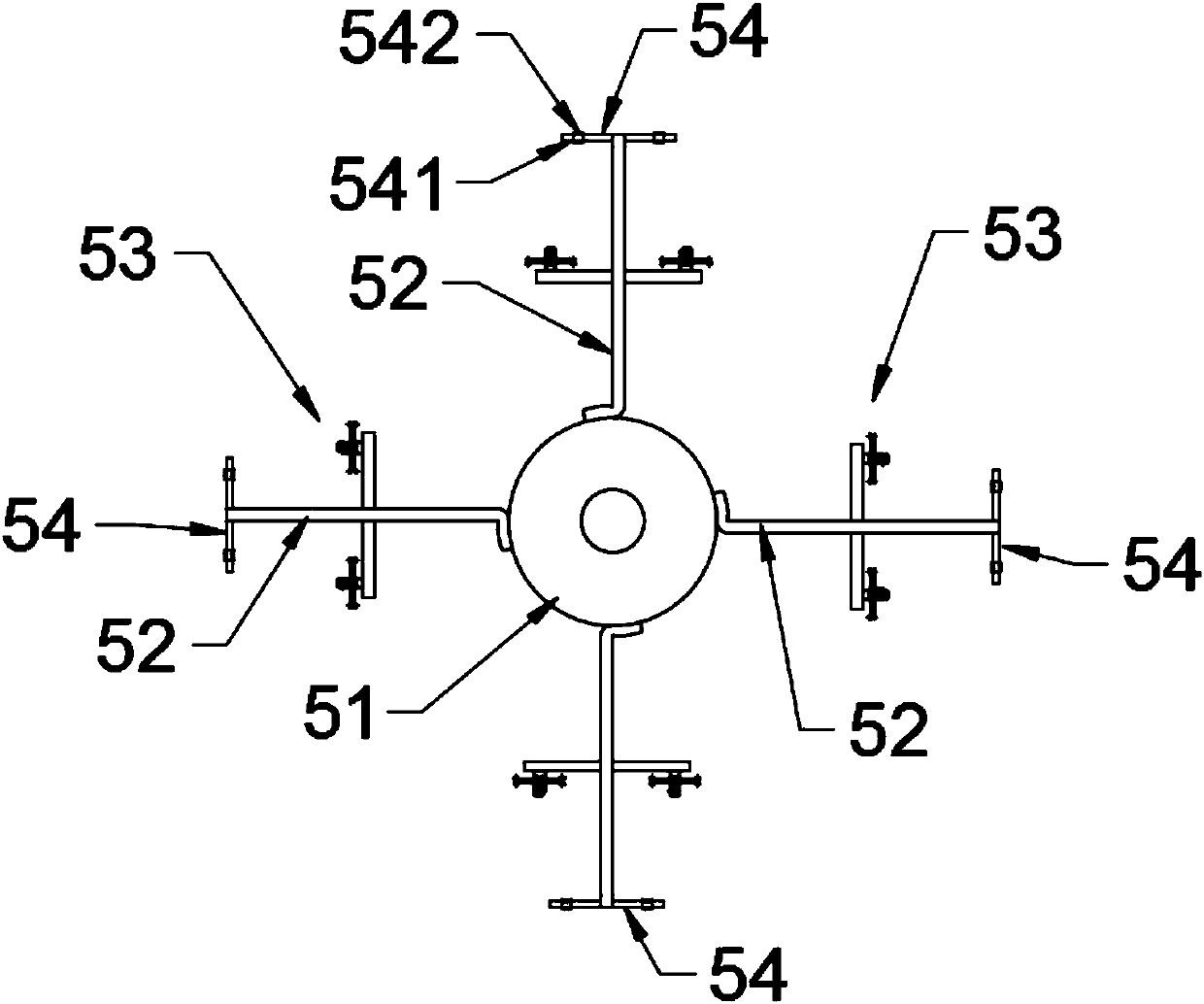

Paying-off mechanism of metal wire weaving machine

The invention discloses a paying-off mechanism of a metal wire weaving machine. The paying-off mechanism comprises a paying-off rack, wherein a plurality of paying-off devices and tension control devices are arranged on the paying-off rack; each paying-off device comprises a variable-frequency motor, a transmission shaft used for fixing a wire wheel, and a wire separating roller; the variable-frequency motor drives the wire wheel fixed to the transmission shaft to rotate; metal wires pass through the wire separating roller and are output; each tension control device comprises a fixing frame, a rotating wheel, a linear guide rail, a tension wheel and a displacement sensor; the rotating wheel is fixed at the upper end of the fixing frame; the linear guide rail is vertically arranged on the fixing frame; the tension wheel can move up and down along the linear guide rail; the metal wires output through the wire separating roller are downward after passing through the rotating wheel, then are upward after passing through the tension wheel, and are output after passing through the rotating wheel finally; when the displacement of the tension wheel changes, the displacement sensor detects the displacement change of the tension wheel and outputs an electric signal; and the displacement sensor is connected with the variable-frequency motor through a control circuit. The paying-off mechanism of the metal wire weaving machine has a simple structure, and can ensure that the speed and the tension of the metal wires which are output finally are the same.

Owner:NINGBO LONG WALL FLUID KINETIC SCI TECH

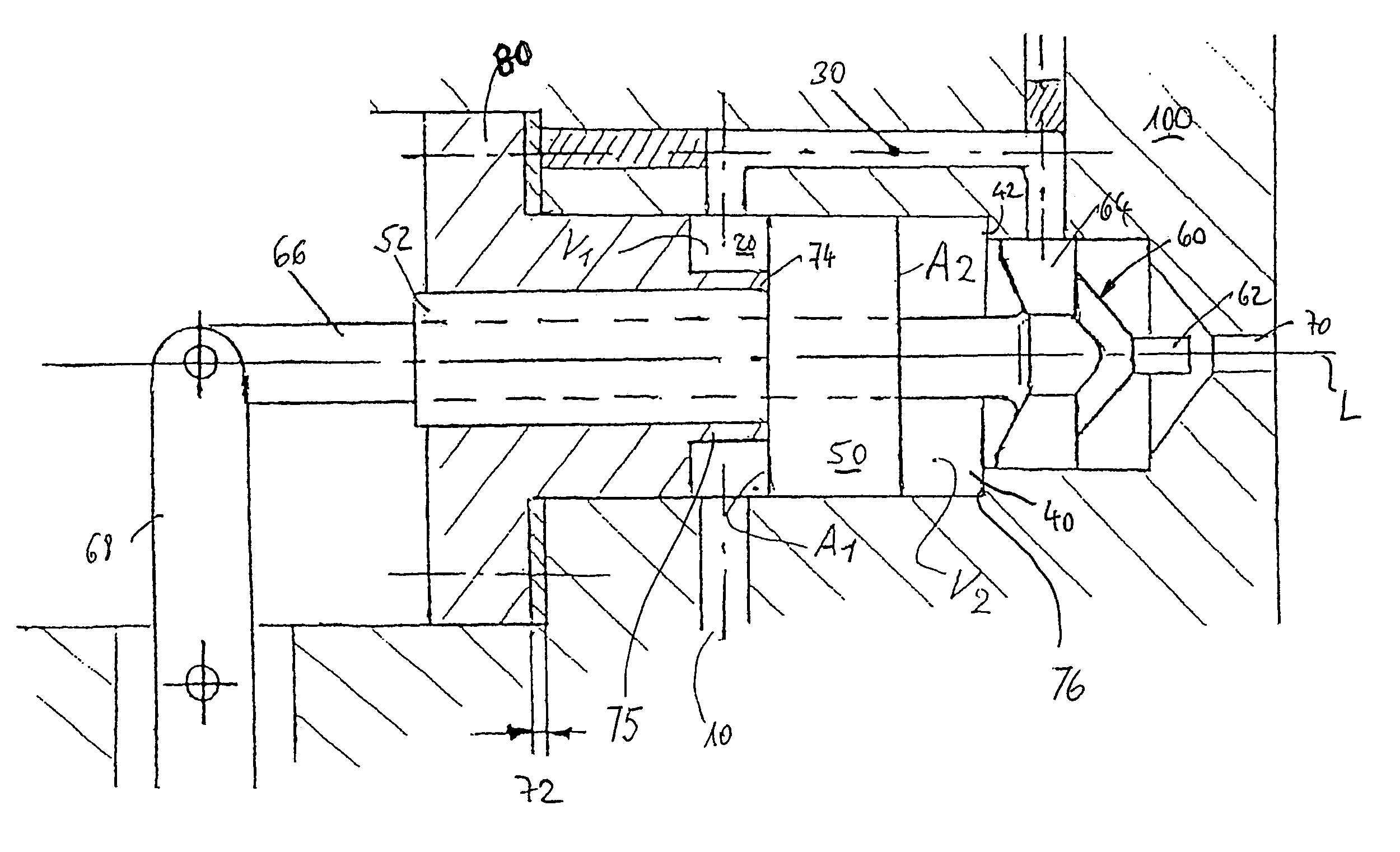

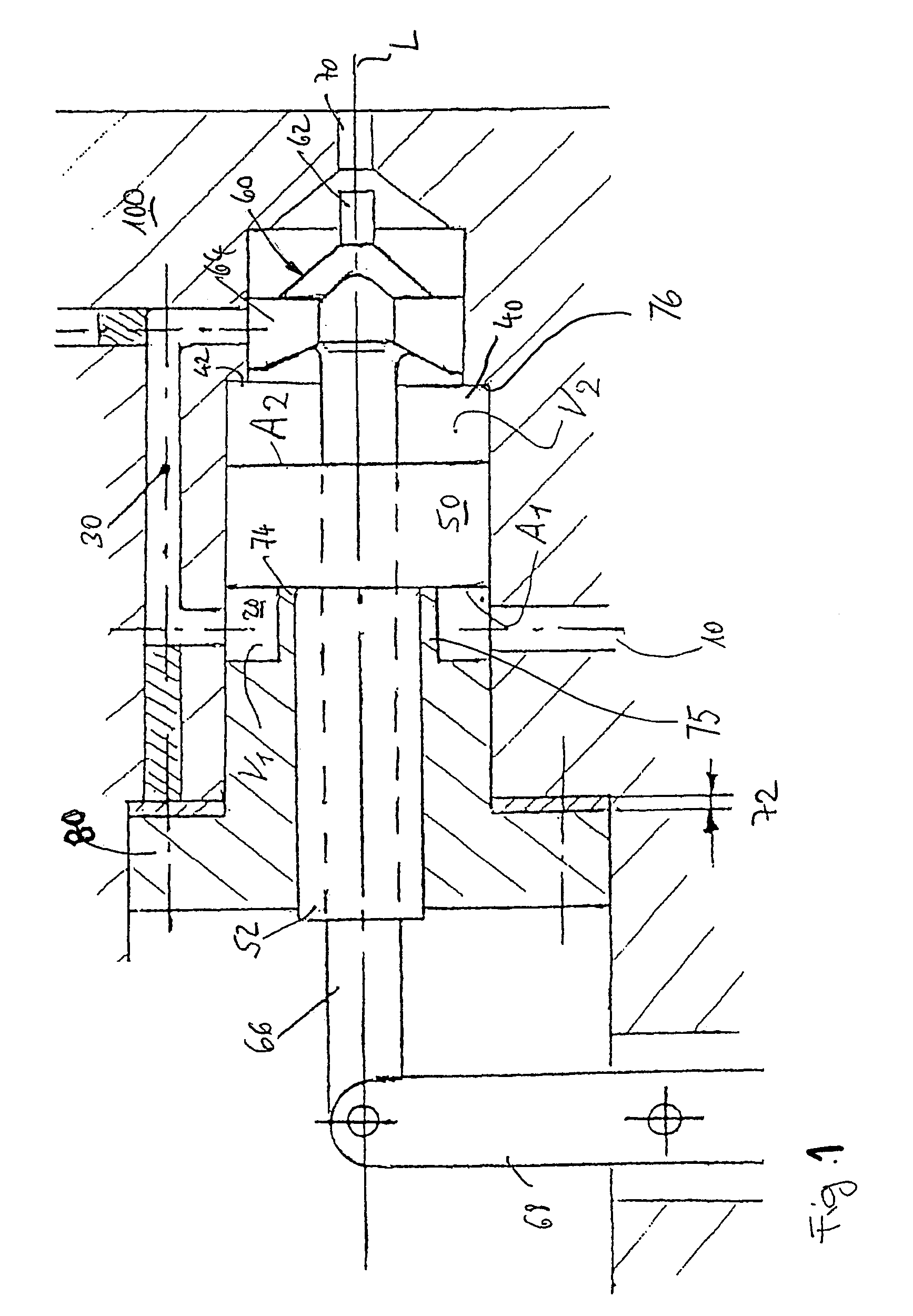

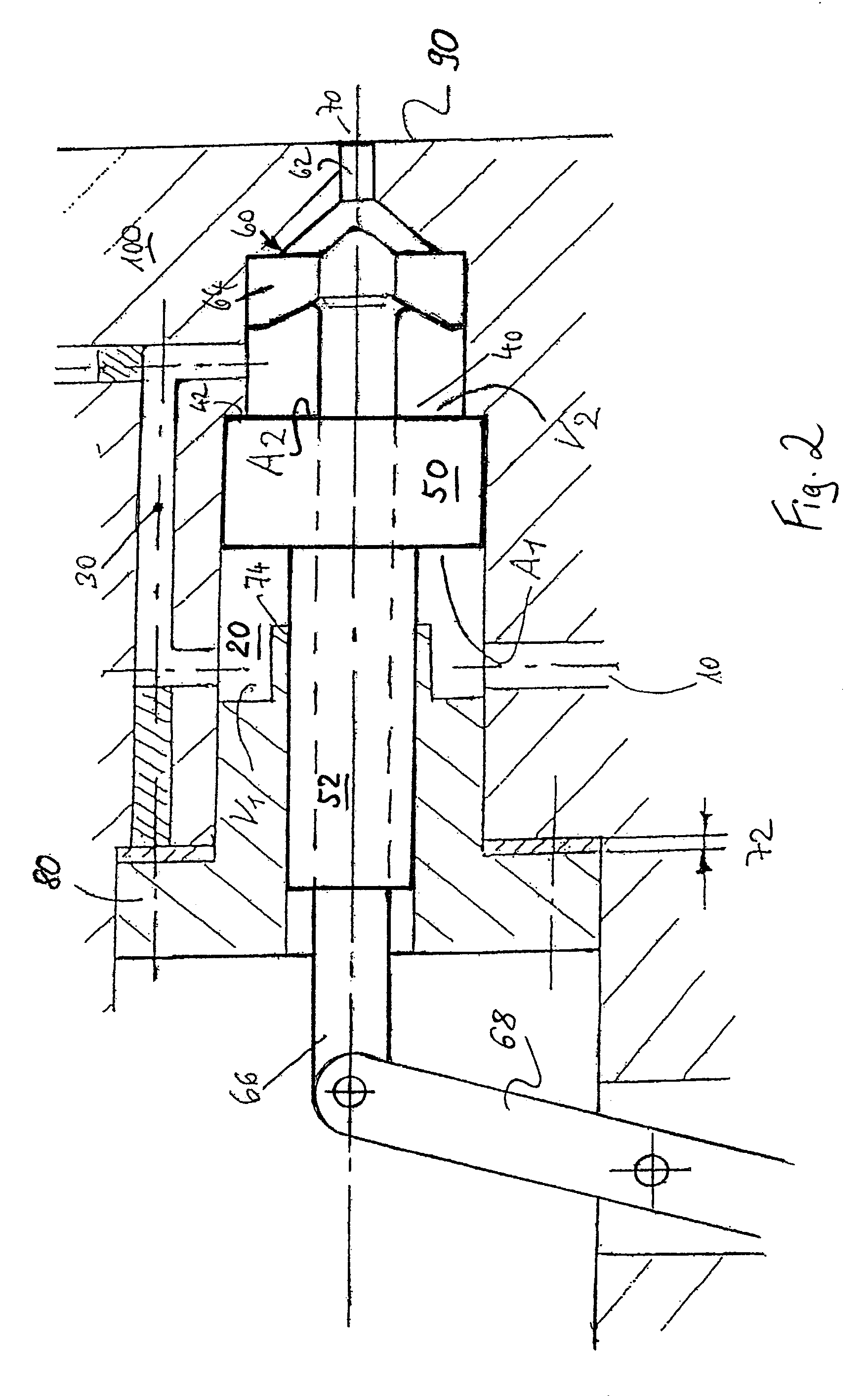

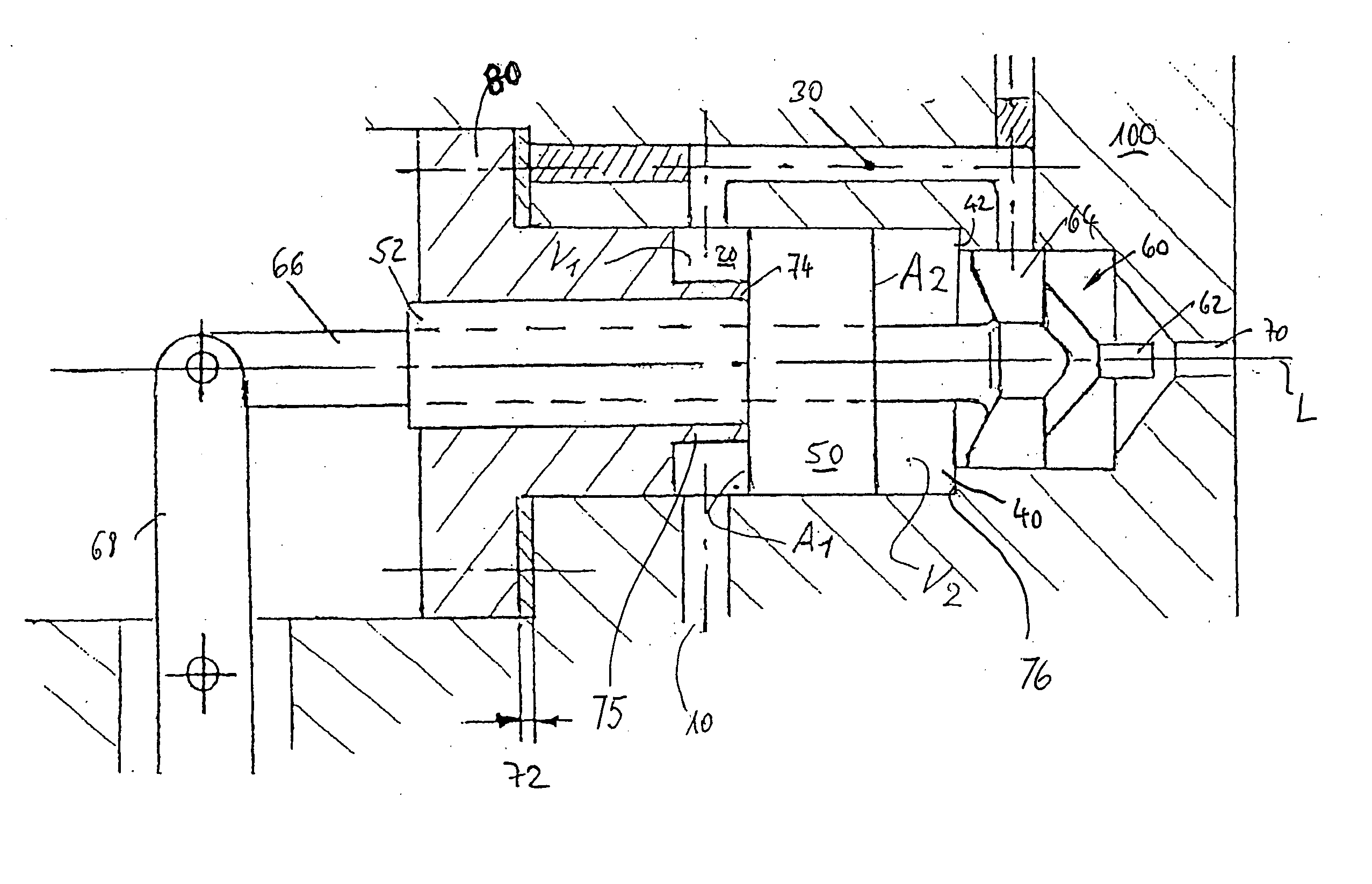

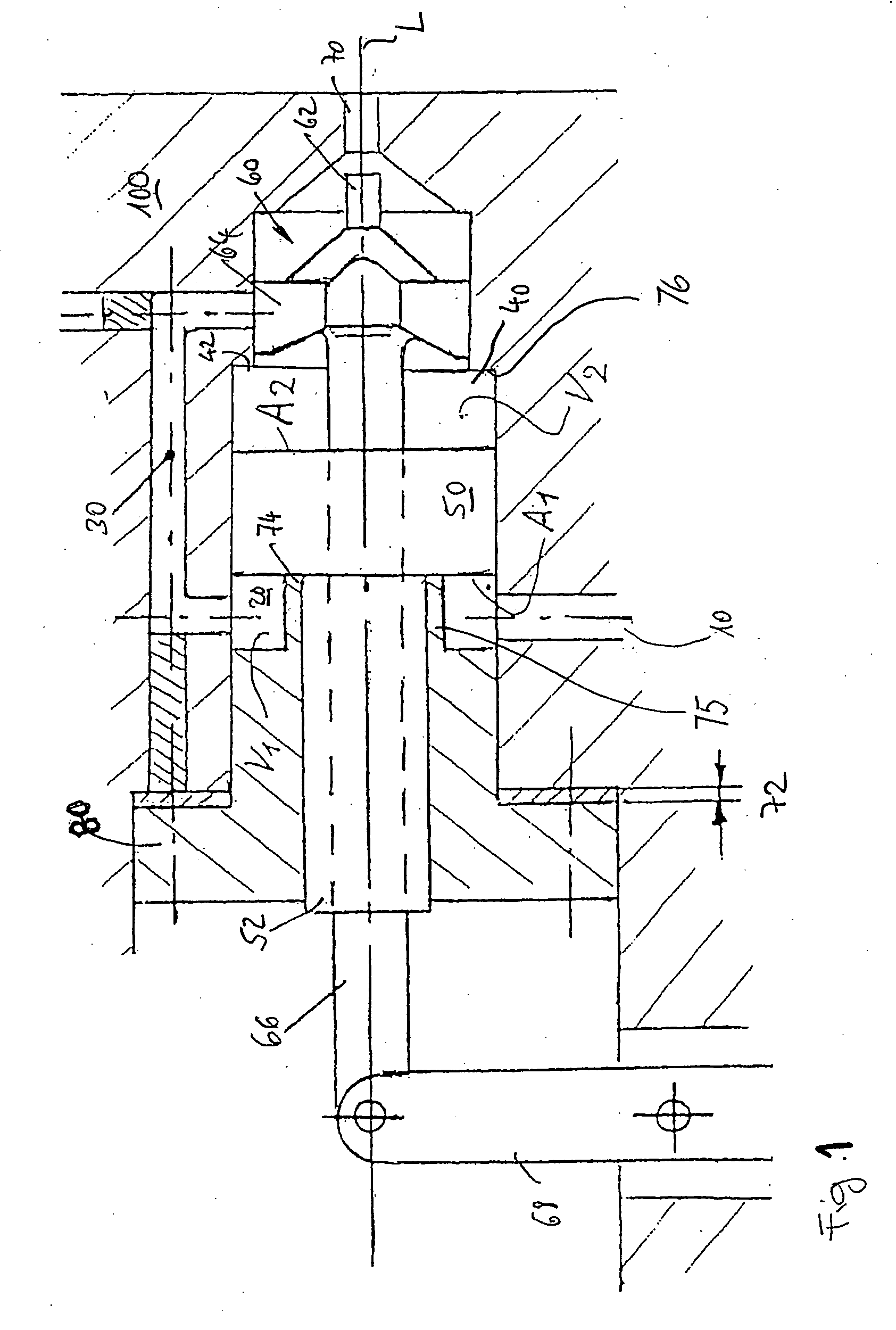

Metering device for an injection molding unit

InactiveUS7014454B2Positively affects the shot precisionSame tensionRecord carriersFood shapingAntechamberInjection molding machine

A metering device for an injection molding unit includes a base body having an antechamber in fluid communication with a feed channel for introduction of plastic material, and a metering chamber in fluid communication with a injection channel. The antechamber and the metering chamber are connectable with one another by a closeable passageway. Movably arranged in the base body between the antechamber and the metering chamber is a displacement member in the form of a piston to separate the antechamber and the metering chamber. The piston has a first end face which demarcates the antechamber and a second end face which demarcates the metering chamber, with the first end face defining an effective area which is smaller than an effective area of the second end face.

Owner:KRAUSS MAFFEI KUMSTSTOFFTECHNIK GMBH

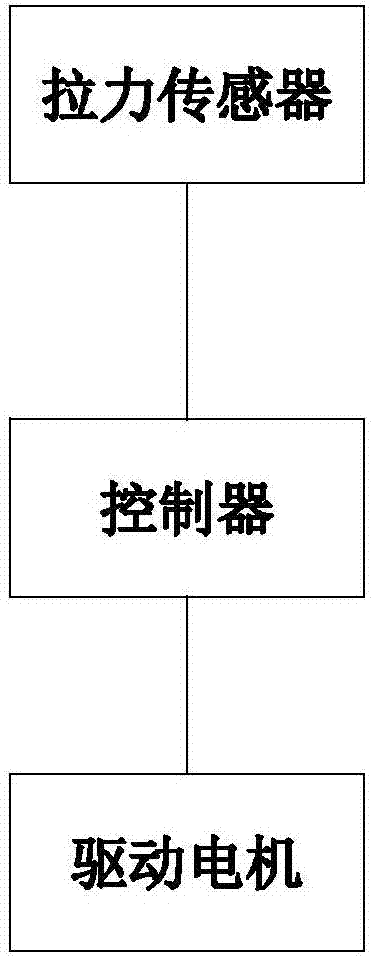

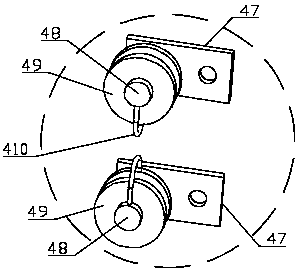

Intelligent line tightening device

PendingCN107453280AGuaranteed tensionGuarantee the size of the tensionApparatus for overhead lines/cablesElectricityPull force

An intelligent line tightening device relates to the power supply construction equipment field and is used to solve a problem that tension degrees of leads located at a same power transmission line during a line tightening process are different. The intelligent line tightening device comprises a pedestal and a controller. The pedestal is rotatably connected to at least three line wrapping wheels. A ratchet-and-pawl mechanism is arranged between each line wrapping wheel and the pedestal. Each line wrapping wheel corresponds to one driving motor. A working shaft of each driving motor and the line wrapping wheel corresponding to the driving motor are connected in a transmission mode. Each line wrapping wheel is wrapped with a tension rope. Each tension rope is connected to a pulling force sensor. Each pulling force sensor is connected to a connection rope used for connecting a lead. Each pulling force sensor is connected to the controller in a signal connection mode, and each driving motor is electrically connected to the controller respectively. The device has an advantage that the tension degrees of each phase of leads at the same power transmission line can be guaranteed to be consistent.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO YUNCHENG POWER SUPPLY CO

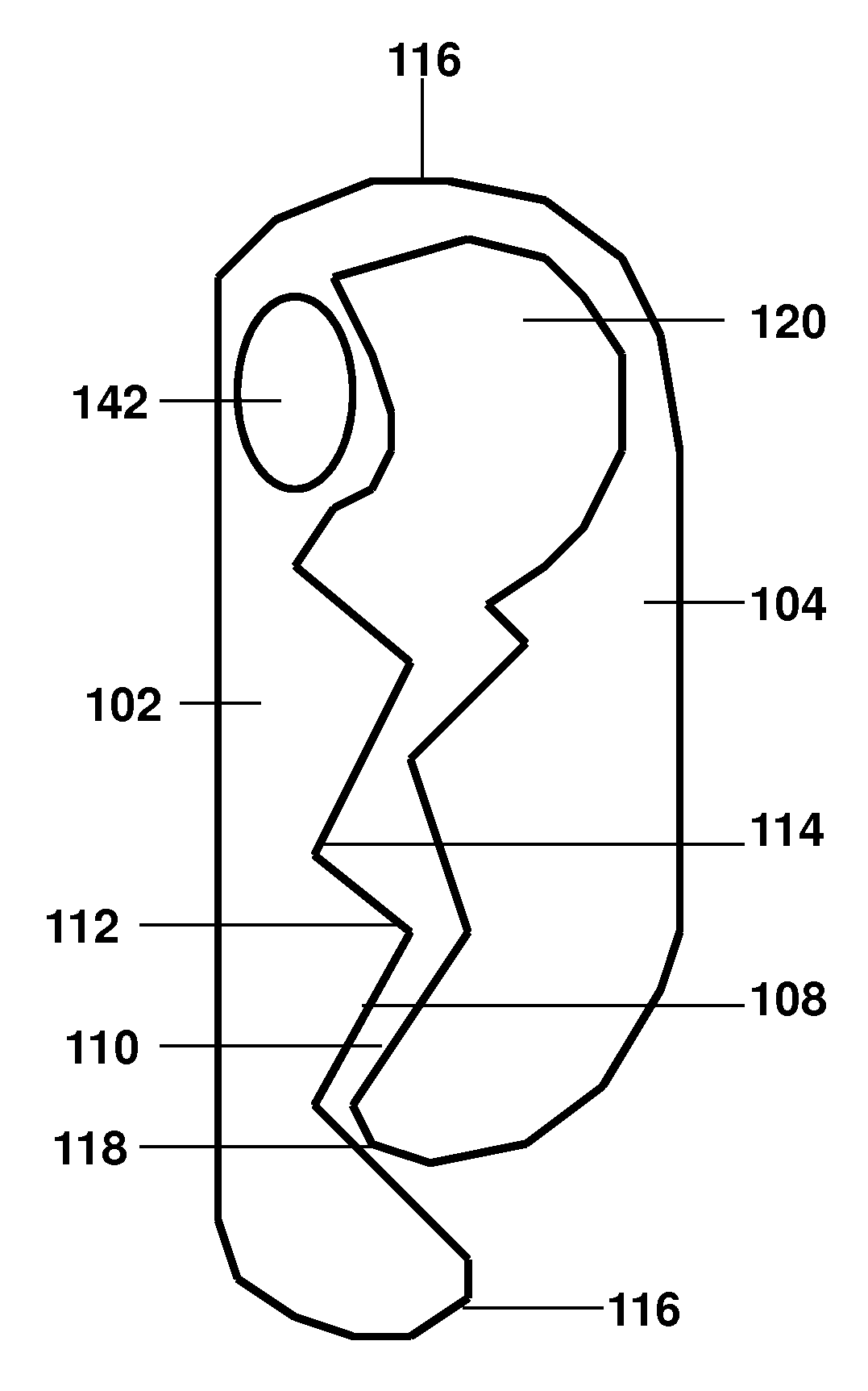

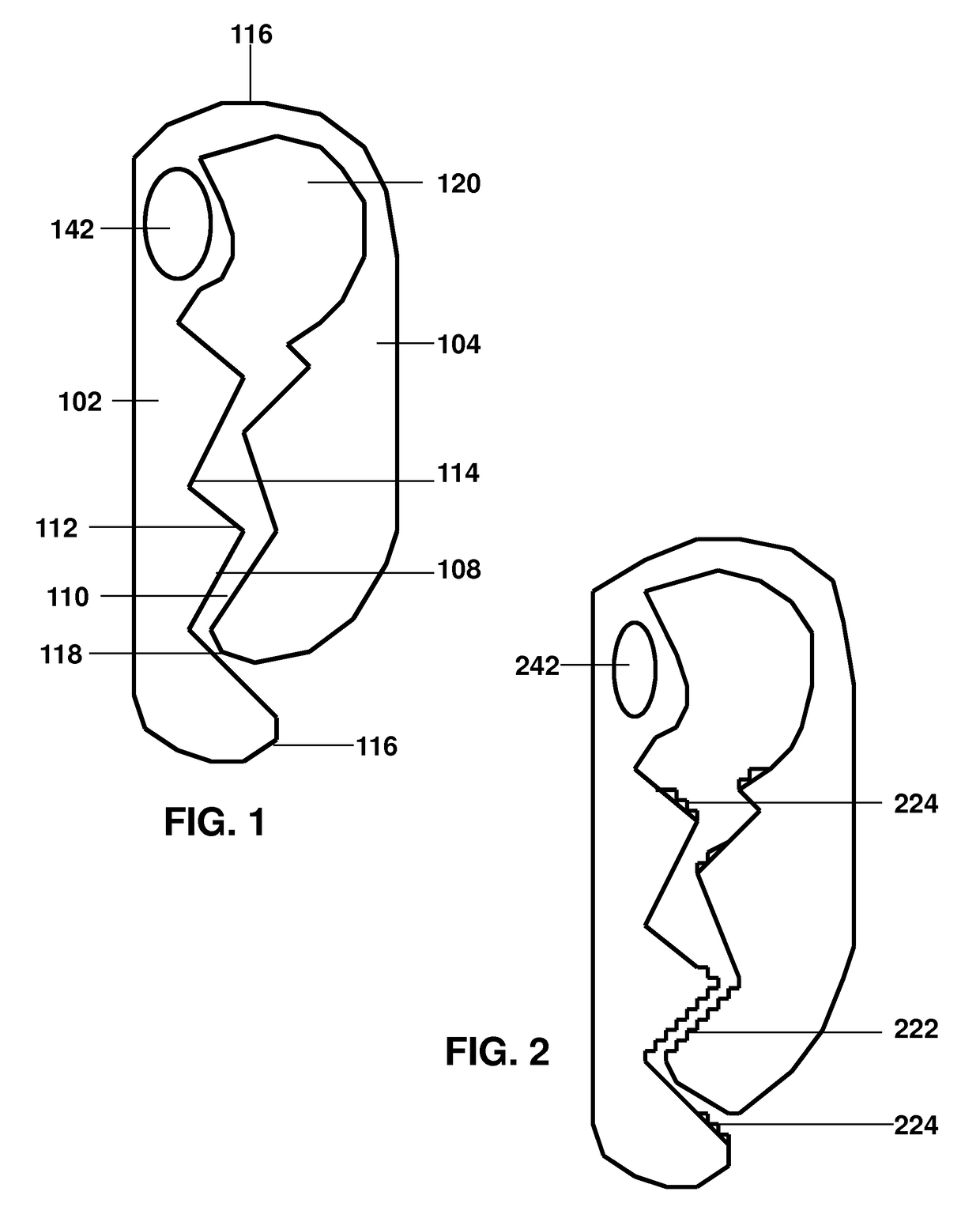

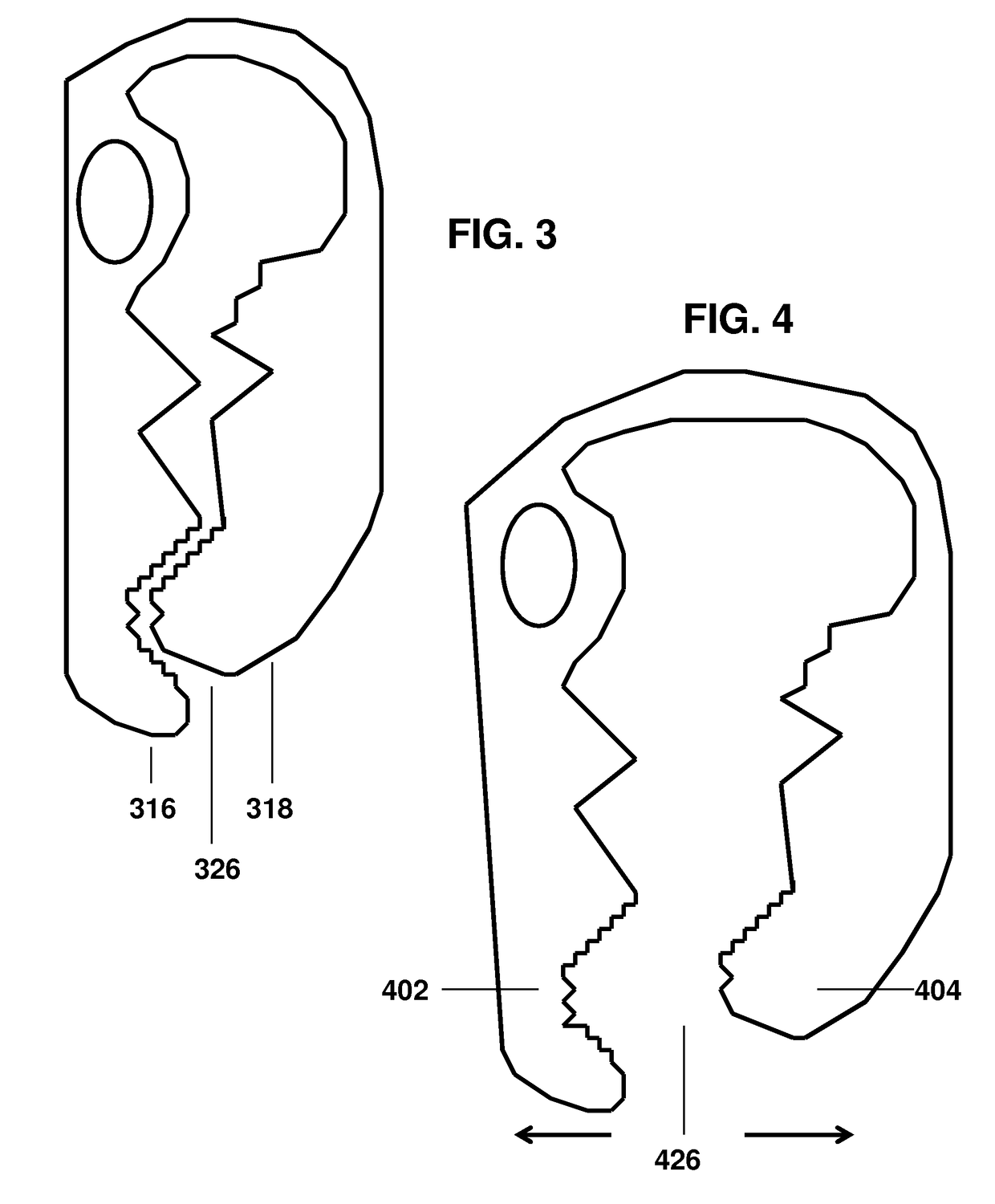

Spa Clip for Towels

InactiveUS20170303614A1Maintain tensionSame tensionGarment suspendersTextiles and paperEngineeringMechanical engineering

A clip element secures a towel or other cloth-like item around a person's body. The clip secures a cloth item that is wrapped around a user's body where one end of the cloth is flat against the wearer's skin and the other end of the cloth has been gathered and tucked behind the flat cloth and preventing separation of overlapping and tucked portions of the cloth item. Unlike previous clips where the clip exerts the pressure, the bulk from the cloth and the barrier that is the wearers torso, creates the leverage to hold the towel in place. The flexible bridge allows a user to pull out on the bottom front portion of the clip while catching the back portion of the clip behind the cloth on the wearer's torso to “thread” the cloth up to the top of the clip. Once the cloth knot (created from gathering one end of the towel and tucking it behind the flat part of the towel against the wearer's skin) is at the top rounded portion of the internal clip the cloth is being held by the pressure that is created by the clips fullness.

Owner:MCMAHON SHERRE

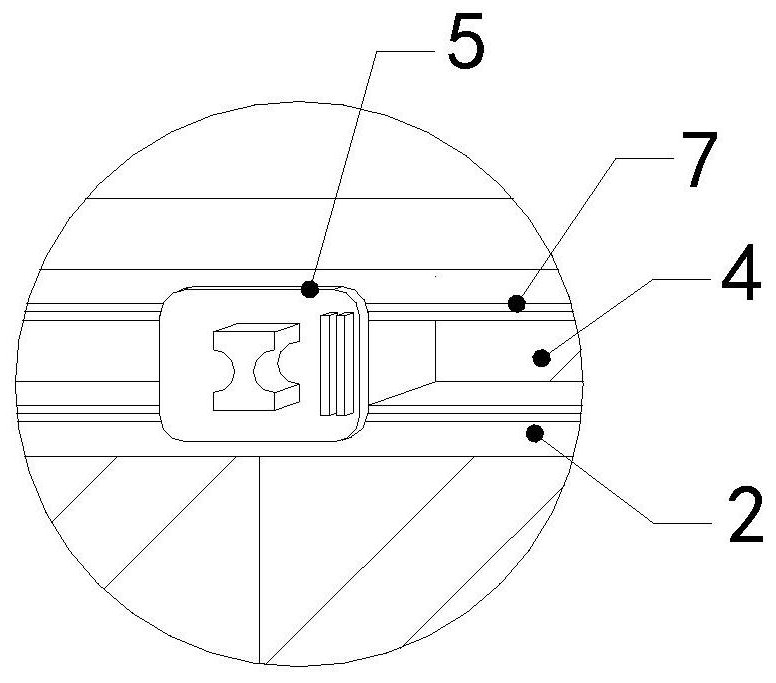

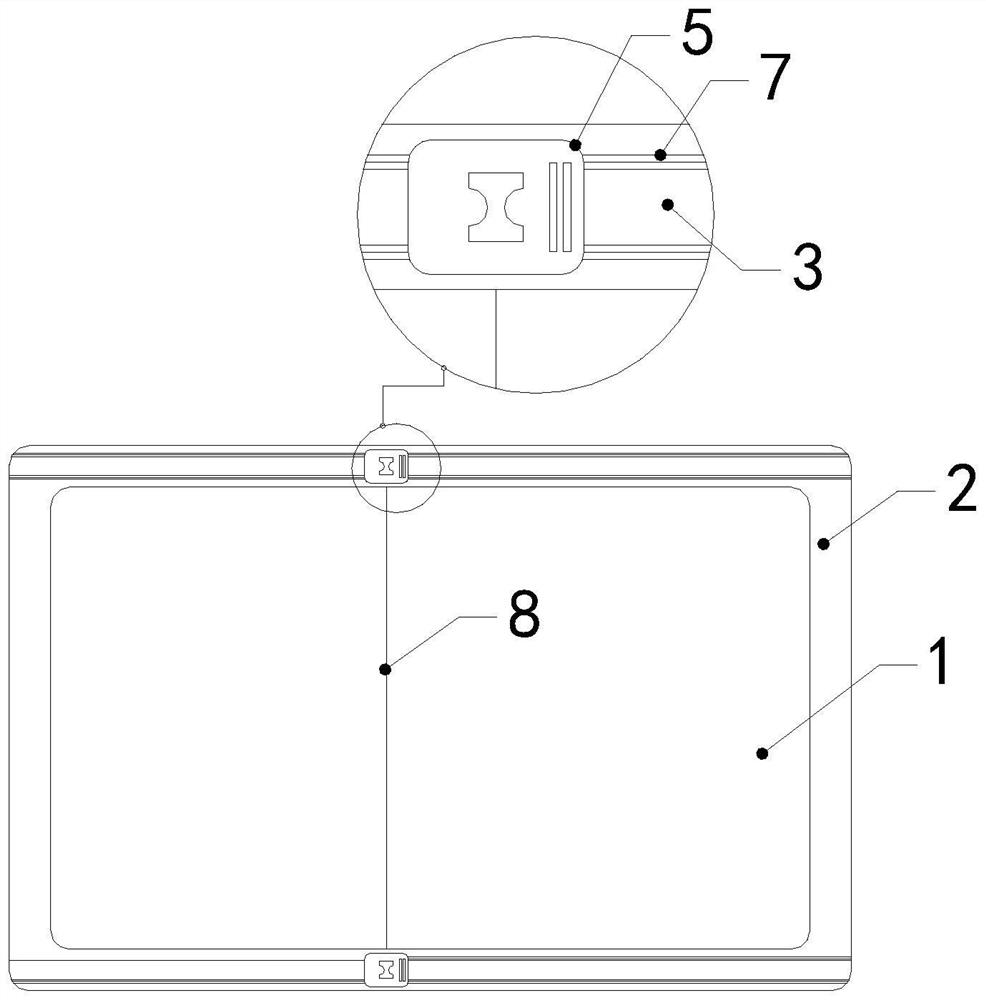

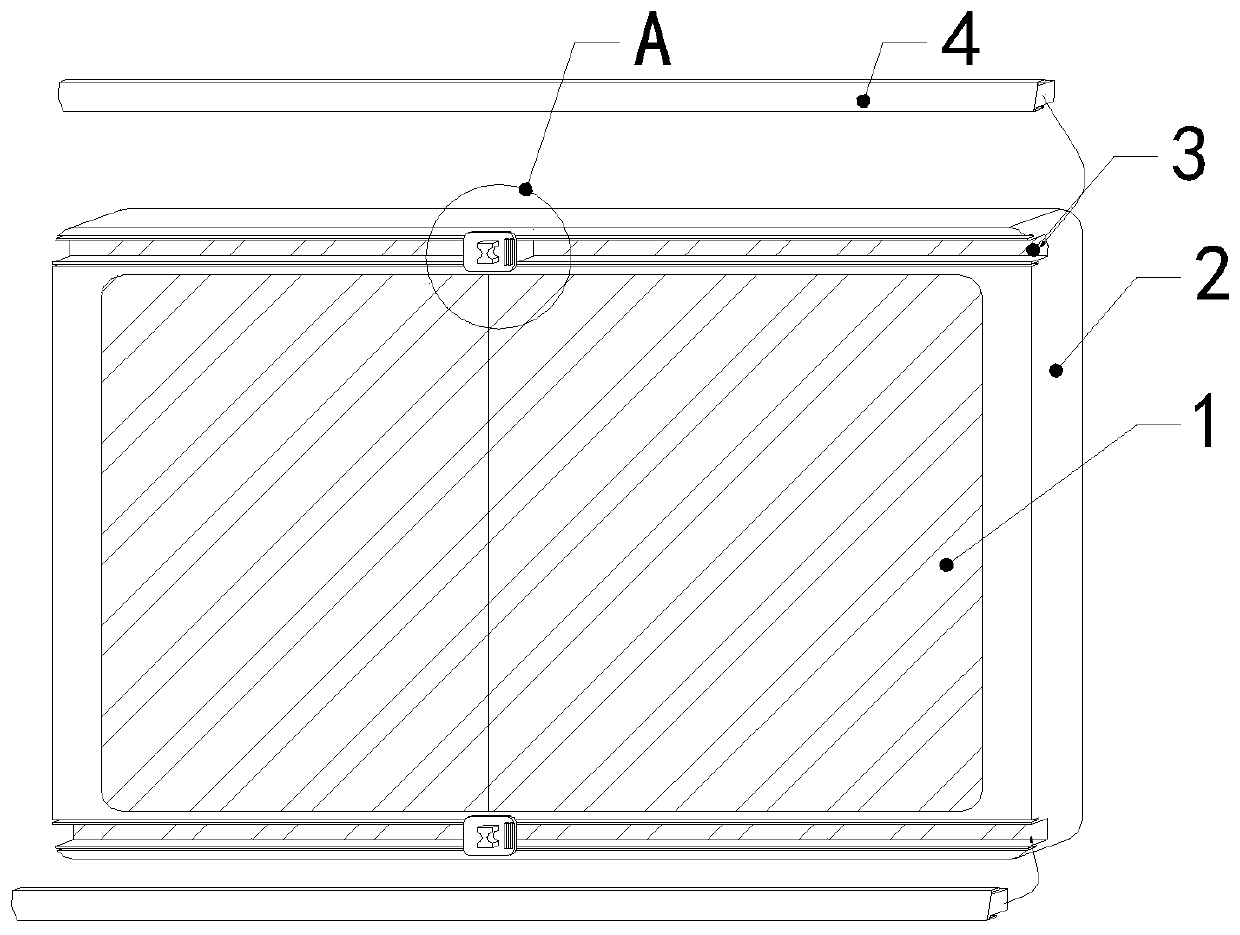

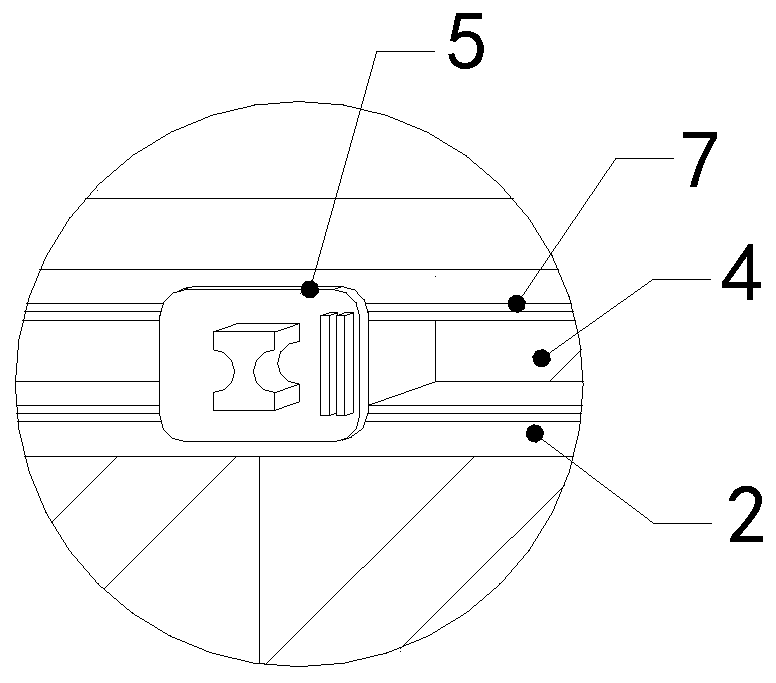

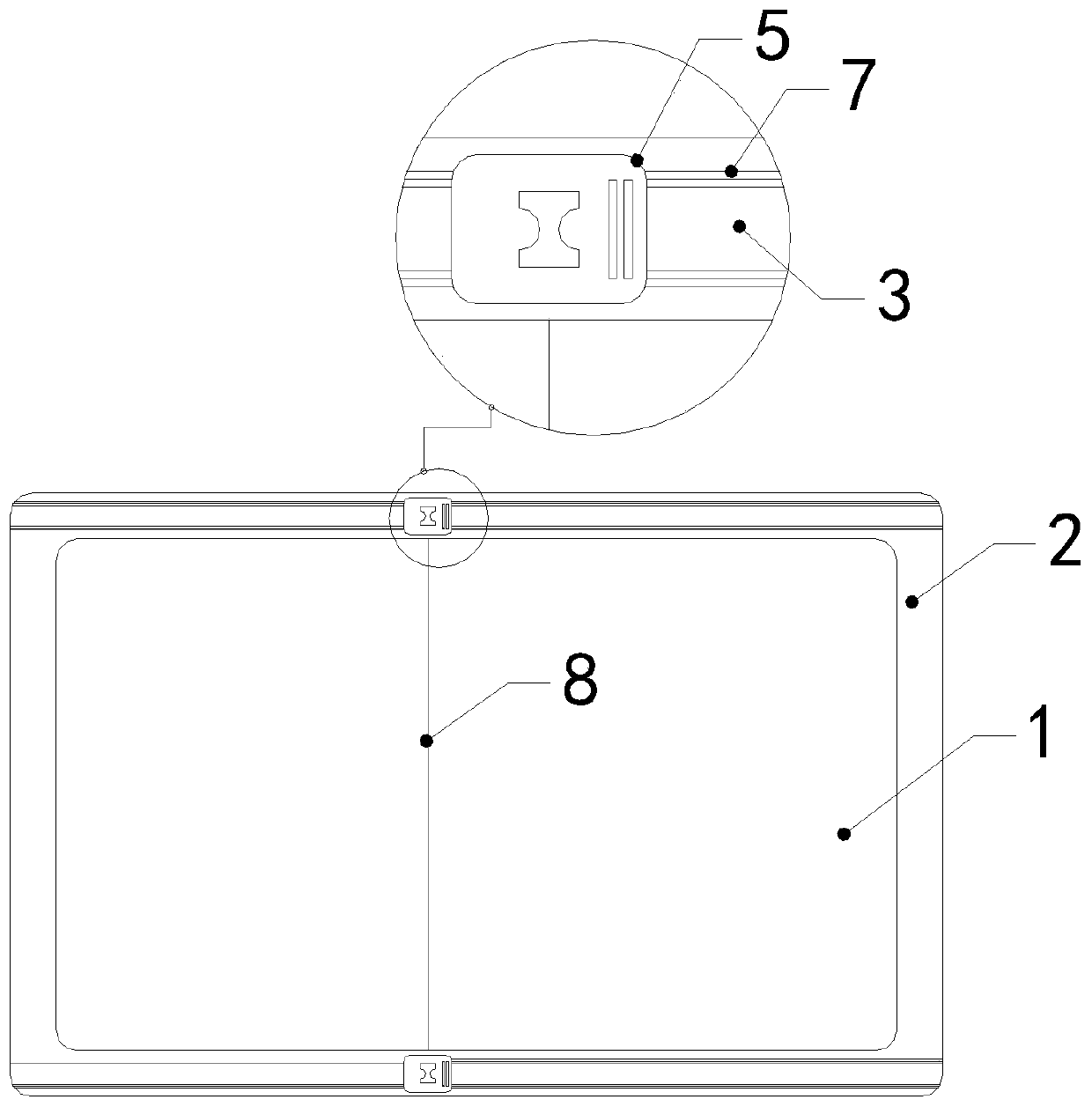

Invisible anti-theft net

Owner:永春县产品质量检验所福建省香产品质量检验中心国家燃香类产品质量监督检验中心福建

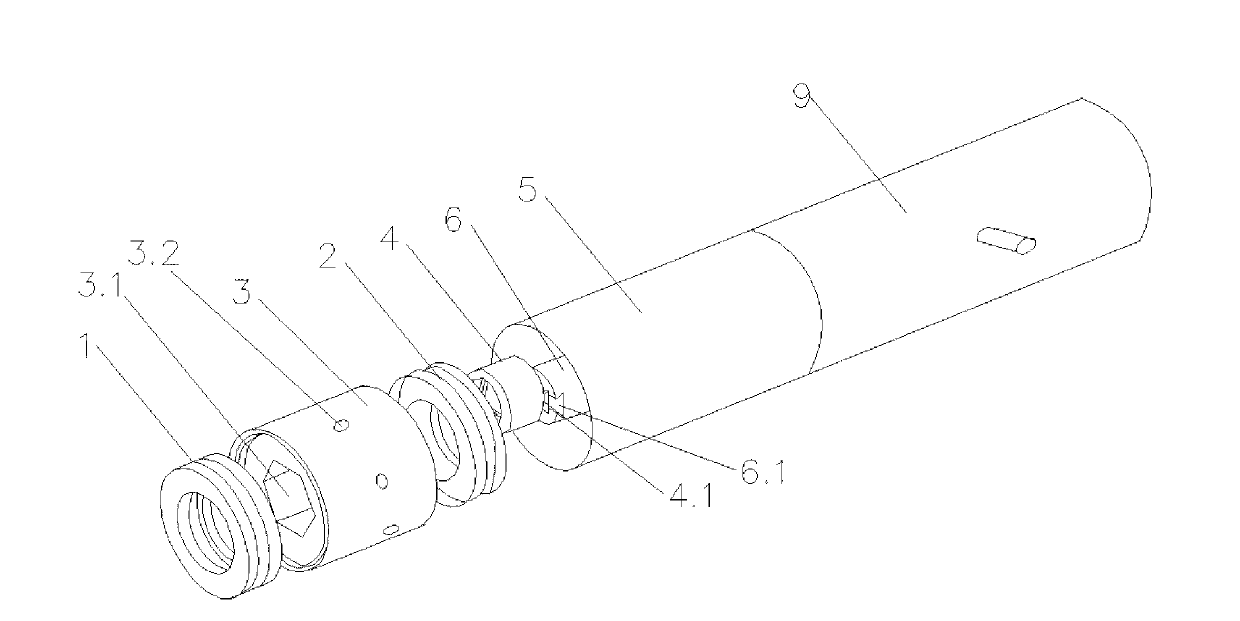

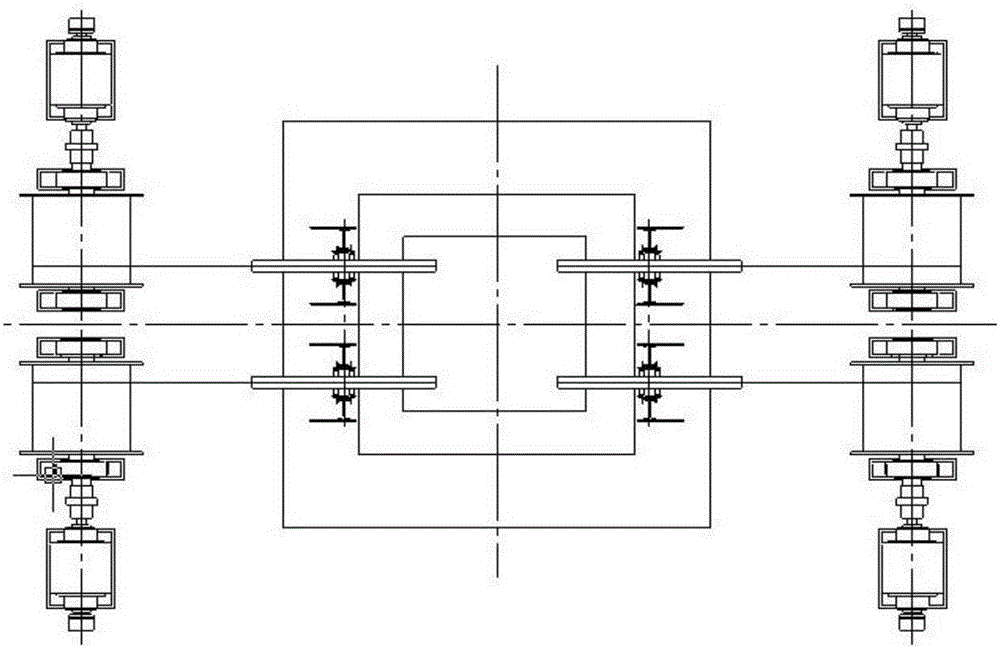

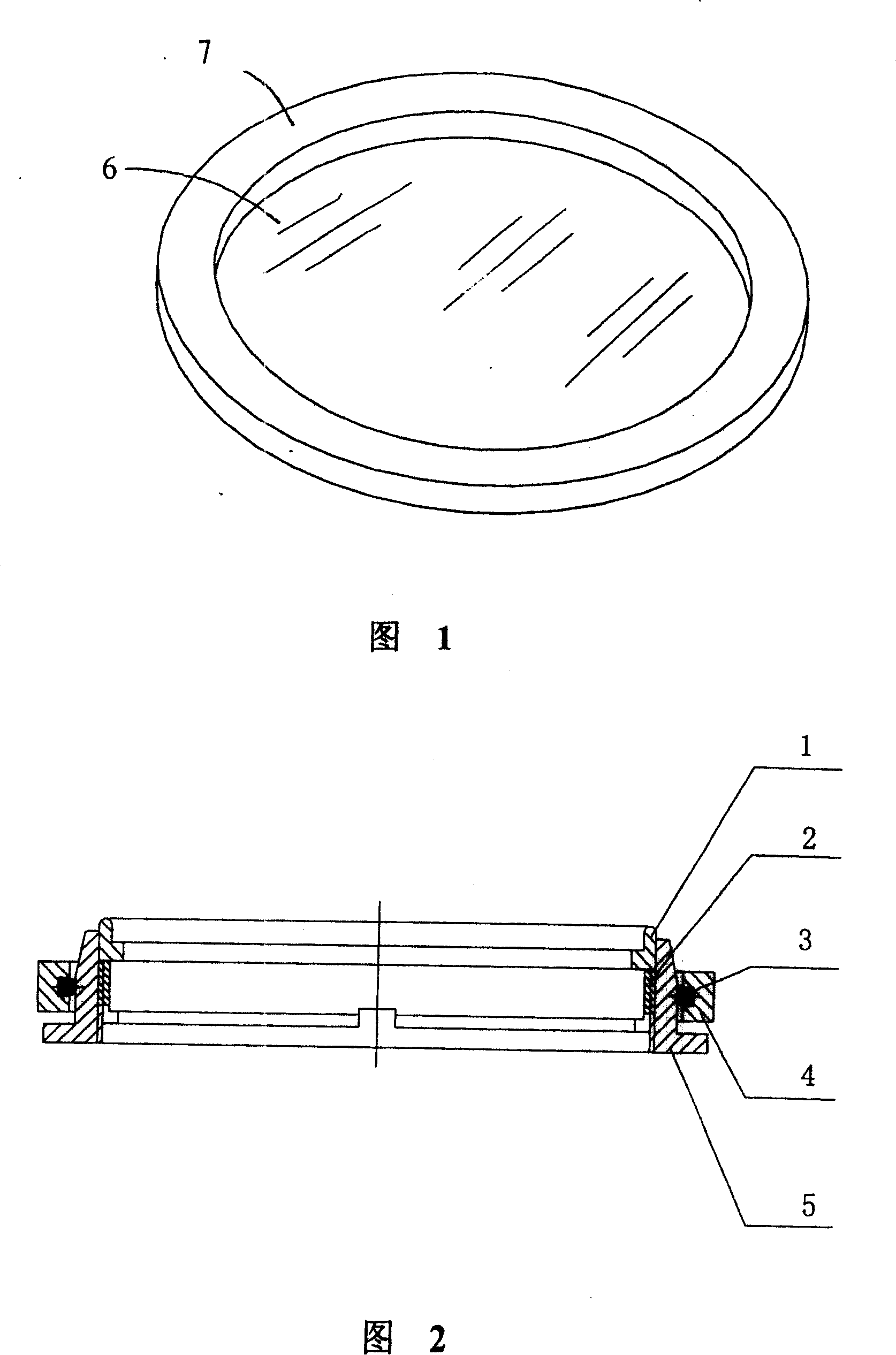

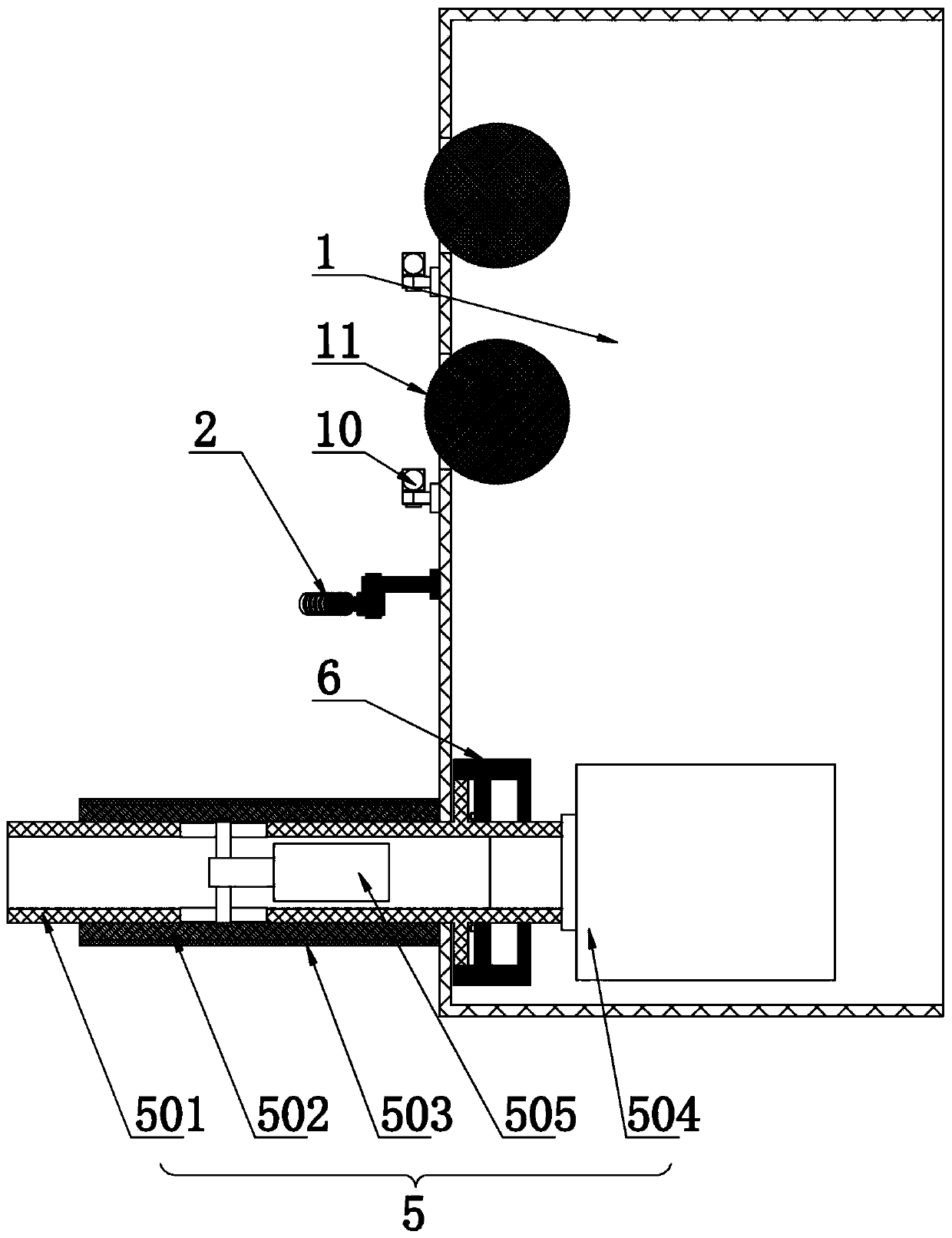

Steel wire tensile force equalizer for lift car

InactiveCN103121613AGuaranteed stabilityEliminate potential safety hazardsElevatorsPull forceBall bearing

The invention discloses a steel wire tensile force equalizer for a lift car and multi-group steel wire tensile force equalizer devices can produce the same tensile force. Each group of a steel wire tensile force equalizer device comprises a first single direction thrust ball bearing(1), a second single direction thrust ball bearing(2), a nut sleeve(3), a connector(4), an adapter sleeve(5) and a straight line telescoping mechanism provided with a telescopic link(6), wherein one end of the telescopic link(6) is connected with an end of the connector(4), the telescopic link(6) is arranged in the adapter sleeve(5), a threaded hole is formed in the other end of the connector(4), a through-hole(3.1) is formed in the nut sleeve(3), a plurality of radial direction through-hole(3.2) are arranged on the nut sleeve(3). The steel wire tensile force equalizer for the lift car enables tensile force of every steel wire to be the same so that the lift car is stressed evenly, guarantees the operational stability of the lift car and eliminates the potential safety hazard of the lift.

Owner:李宝良

Metering device for an injection molding unit

InactiveUS20050053692A1Narrow articleAccurate weighingRecord carriersFood shapingAntechamberInjection moulding

A metering device for an injection molding unit includes a base body having an antechamber in fluid communication with a feed channel for introduction of plastic material, and a metering chamber in fluid communication with a injection channel. The antechamber and the metering chamber are connectable with one another by a closeable passageway. Movably arranged in the base body between the antechamber and the metering chamber is a displacement member in the form of a piston to separate the antechamber and the metering chamber. The piston has a first end face which demarcates the antechamber and a second end face which demarcates the metering chamber, with the first end face defining an effective area which is smaller than an effective area of the second end face.

Owner:KRAUSS MAFFEI KUMSTSTOFFTECHNIK GMBH

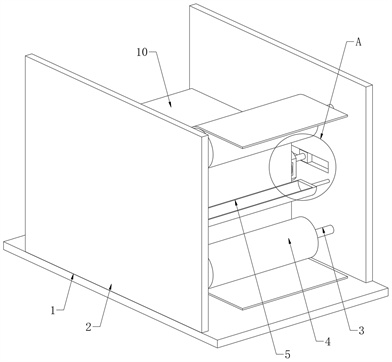

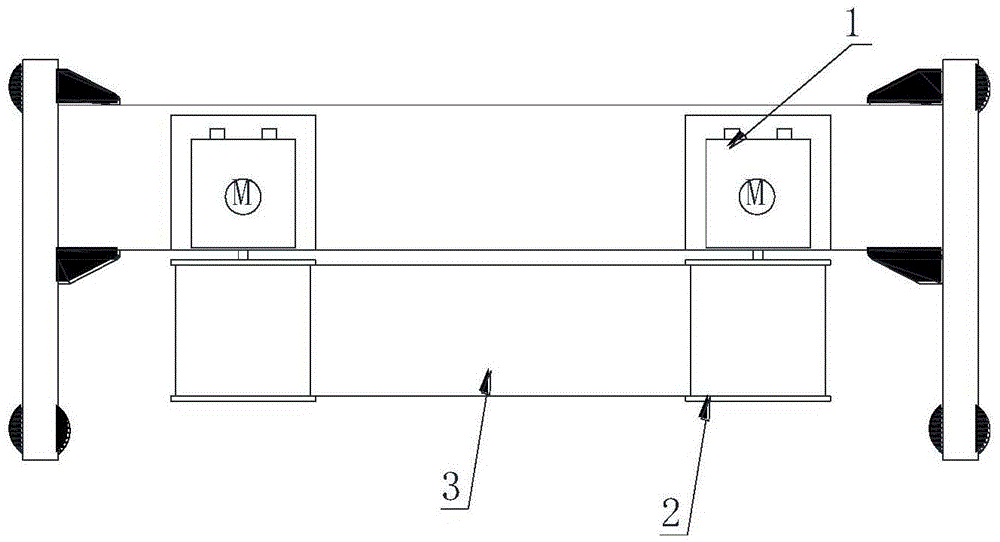

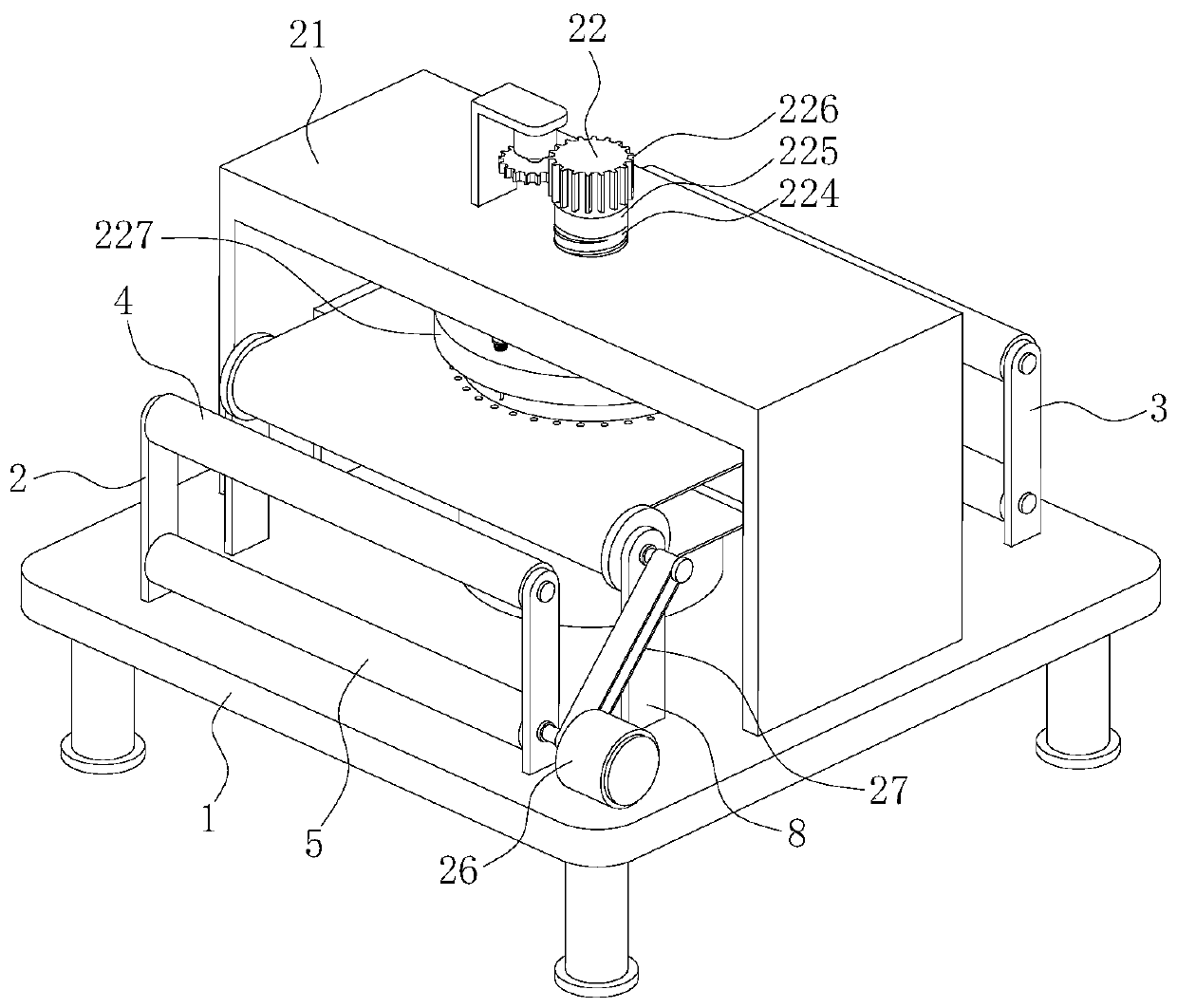

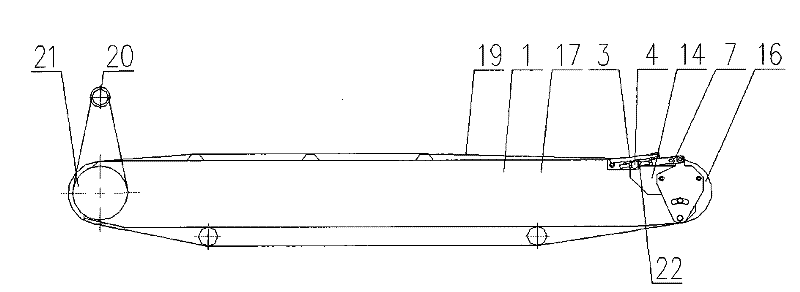

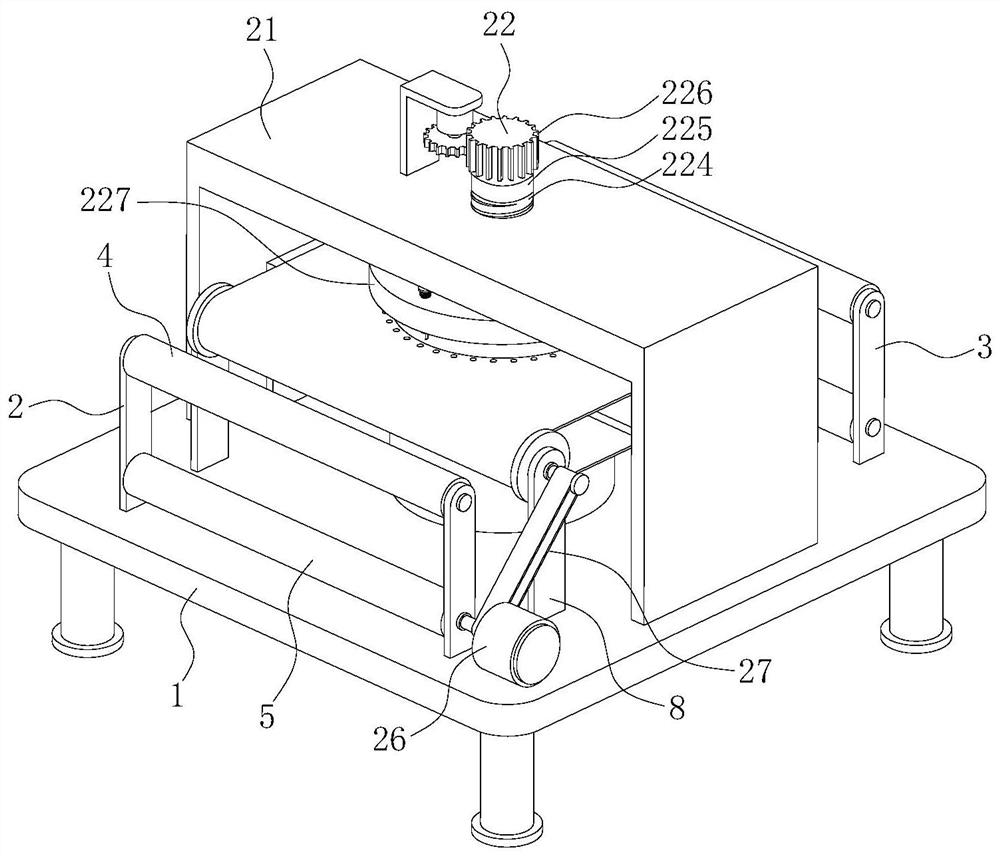

Electronic belt scale nutation type belt tensioning device

ActiveCN101726347AGuaranteed to workSimplify workWeighing apparatus detailsWeighing apparatus for continuous material flowFuselageWrench

The invention relates to an electronic belt scale nutation type belt tensioning device which comprises a tensioning framework, main body lateral plates and a link mechanism, wherein the tensioning framework is spanned over both ends of a driven roller of an electronic belt scale and is positioned between an upper belt and a lower belt, the main body lateral plates are symmetrically arranged at the two outer sides of the tensioning framework, the link mechanism is installed on the main body lateral plates, the link mechanism is formed by sequentially connecting pedestals, first connecting rods, second connecting rods and nutation plates, the pedestals are fixed on the main body lateral plates, the first connecting rods are articulated with the pedestals through first rotating shafts, the second connecting rods are articulated with the first connecting rods through second rotating shafts, and the nutation plates are respectively articulated with the second connecting rods through third rotating shafts and articulated with the main body lateral plates through fourth rotating shafts; fastening bolts are arranged on the nutation plates; wrenches are installed on the second connecting rods; and the nutation plates are also connected with the tensioning framework through first bearings, and the tensioning framework is connected with a central shaft of the driven roller through a second bearing. The electronic belt scale nutation type belt tensioning device has light structure and can rapidly realize the tensioning or relaxation of belts with labor saving, and the size of tensioning force can be accurately regulated in real time.

Owner:云南昆船电子设备有限公司

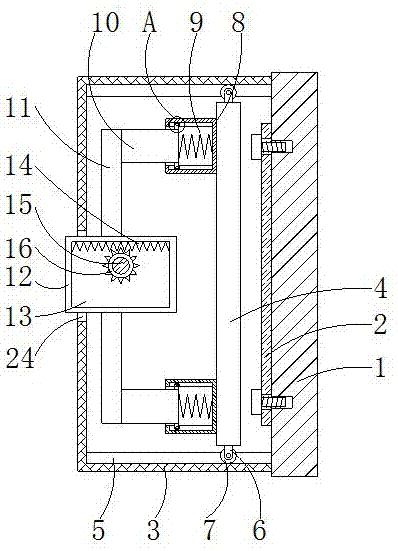

Tension detection device for textile fabric production

The invention discloses a tension detection device for textile fabric production, which comprises a base plate, two vertical plates are symmetrically, vertically and fixedly connected to the upper end surface of the base plate, a fixed block is horizontally and fixedly connected between the two vertical plates, an abutting block is slidably arranged between the two vertical plates through a limiting mechanism, a detection mechanism matched with the abutting block is arranged in the fixed block, a transmission mechanism matched with the abutting block is arranged between the two vertical plates, and a cooling mechanism is arranged in the abutting block. When the tension detection device works, no matter whether cloth becomes loose or too tensioned, the tensioning state of the cloth can be adjusted in time, and the tensioning force borne by the cloth is always the same, so that yarn breakage of the cloth can be avoided, the cloth can be prevented from deviating, and meanwhile, cold air can be blown to the cloth in a pulse mode, so that the cloth can be cooled and cleaned, and the use effect is good.

Owner:南通腾霞纺织品有限公司

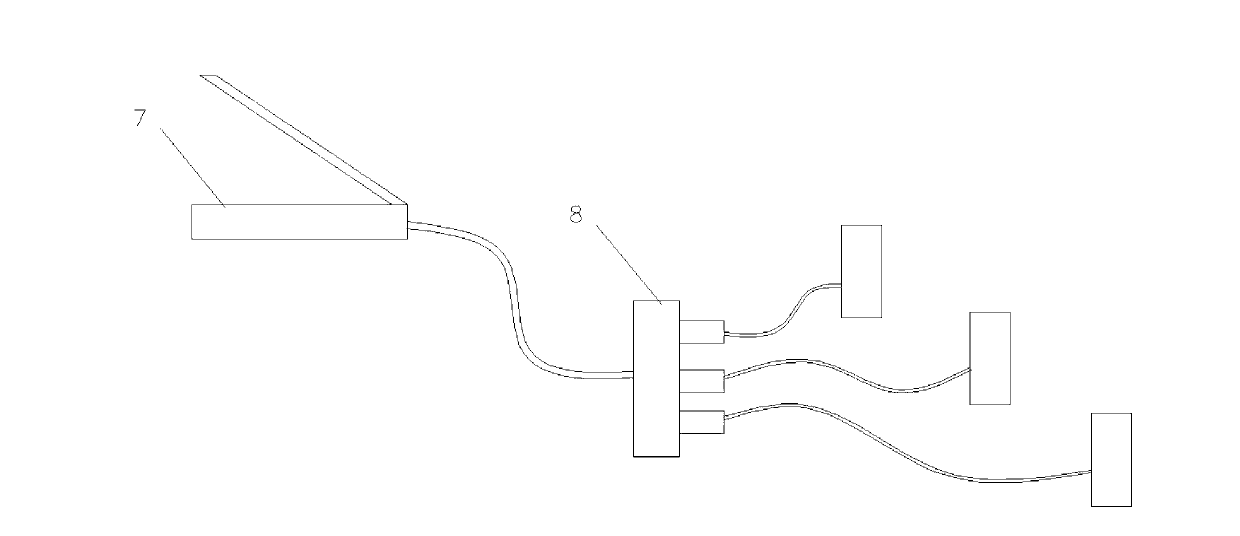

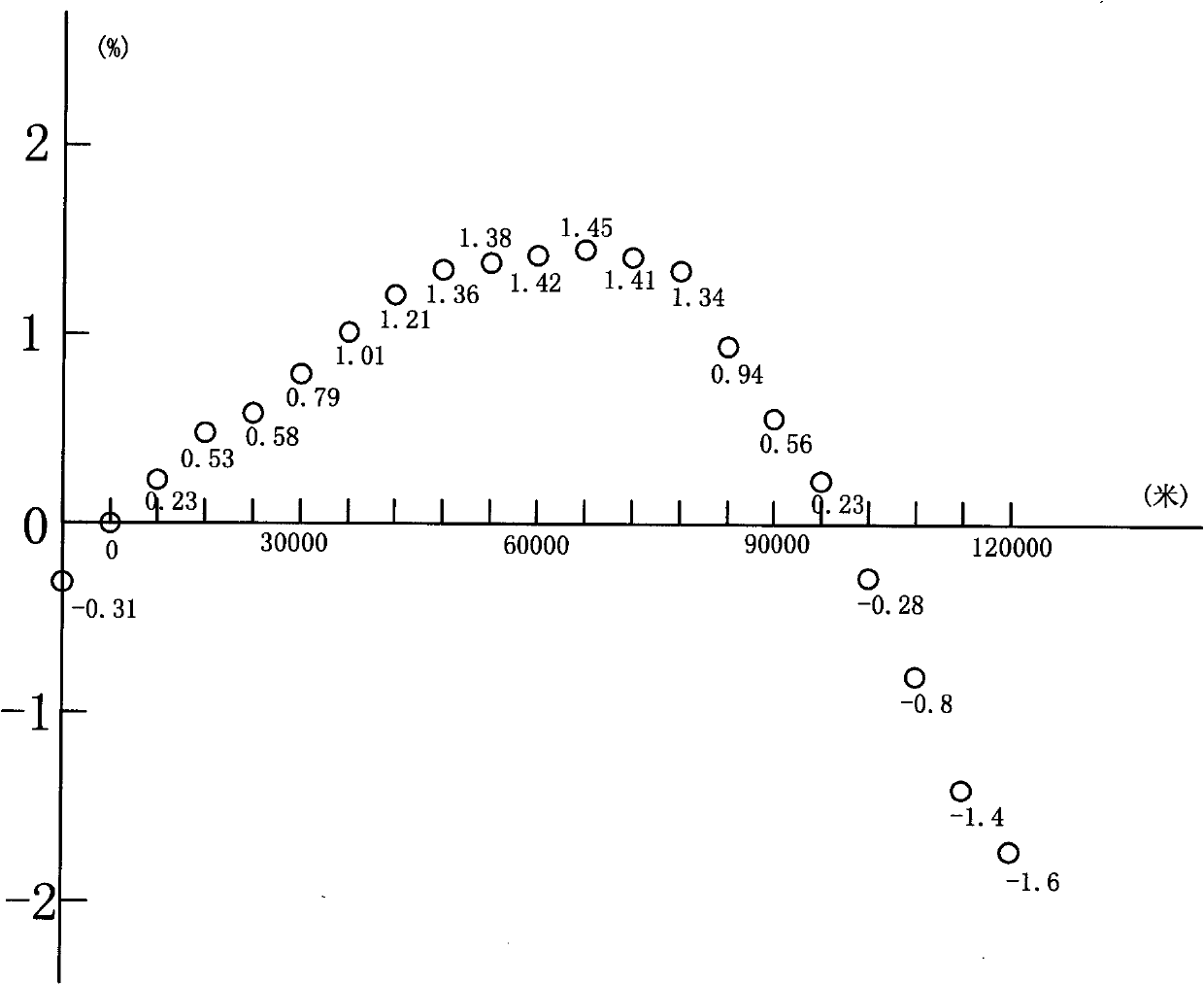

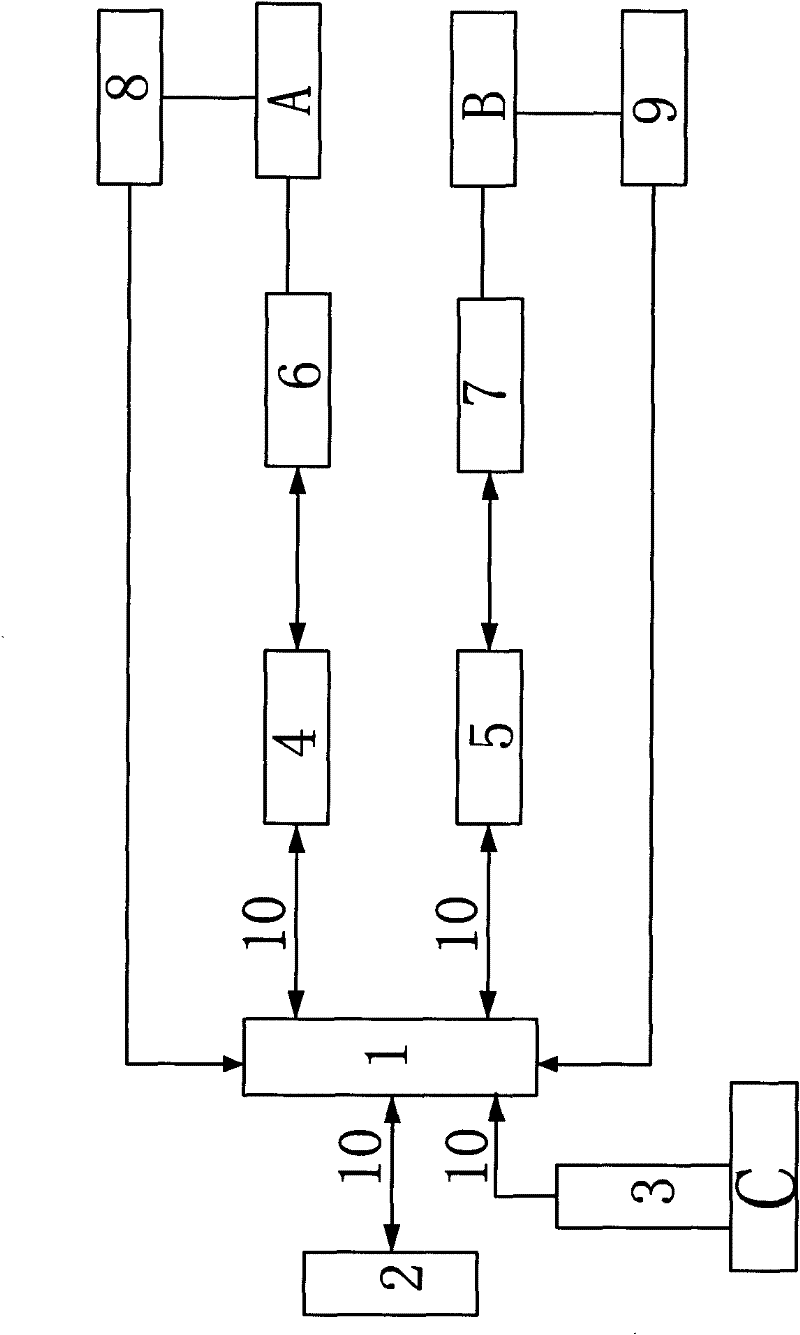

Method for compensating tension of elastane yarns of vertical elastane yarn warping machine

InactiveCN101906687ASame tensionThe specifications of the winding head are the sameWarping machinesOther manufacturing equipments/toolsHuman–machine interfaceMathematical model

The invention provides a method for compensating tension of elastane yarns of a vertical elastane yarn warping machine. In the method, the total length of the elastane yarns and the preset linear velocity of a creel roller are inputted through an human-machine interface; a programmable controller divides the current elastane yarn into 20 equal parts in accordance with the total length according to the setting of the human-machine interface so as to obtain 21 points; tension values of the 21 points are detected by a yarn tension detecting device, and the final tension values of the 21 points are saved by the programmable controller, and a compensation curve is drawn; the length of the current elastane yarn is detected by an encoder, and the programmable controller calculates a compensation value of the elastane yarn corresponding to the current length according to a mathematical model; and the programmable controller can calculate the linear velocity of the creel roller of the current length according to the compensation value of the elastane yarn corresponding to the current length, which is calculated in the step d, and regulates the linear velocity of the creel roller so as to regulate the tension of the elastane yarn. The method can ensure stable warping quality for the elastane yarn under a condition of large variation of temperature and humidity.

Owner:CHANGZHOU DIBA TEXTILE MACHINERY

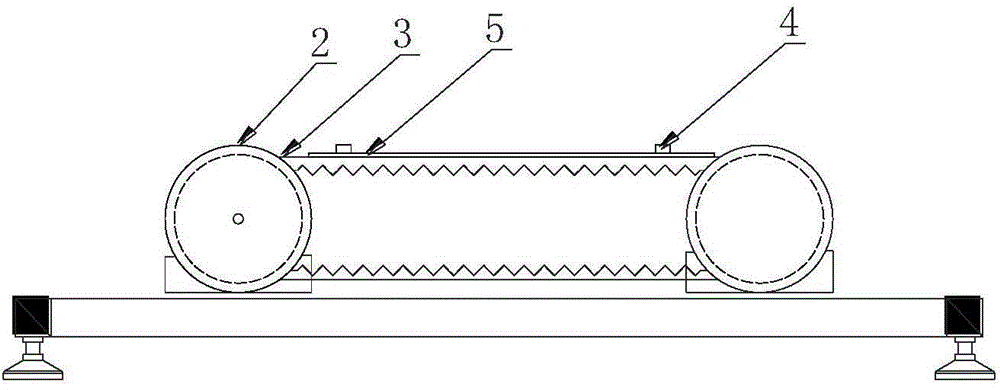

Cloth strip transmission device

InactiveCN104370136AGuaranteed uptimeSame tensionFunction indicatorsInvestigating moving sheetsMagnetic mediaMetallic materials

The invention discloses a cloth strip transmission device which comprises a stepping motor, a support and a controller controlling the stepping motor. The output shaft of the stepping motor is provided with a belt wheel, the outer edge of the belt wheel is provided with teeth, and the belt wheel is in transmission connection with the other belt wheel through a synchronous belt. Tooth patterns matched with tooth patterns of the belt wheels are arranged on the inner side of the synchronous belt, and flexible magnetic materials are arranged in the synchronous belt. The upper surface of the synchronous belt in horizontal, a tested cloth strip is horizontally placed on the upper surface of the synchronous belt, a plurality of magnetic metal materials or magnetic bodies are arranged on the cloth strip, and the synchronous belt and the belt wheels are installed on the support. The cloth strip transmission device has the advantages that the device is only provided with the two belt wheels, the motor and the synchronous belt, so that the structure is simple; in addition, the cloth strip is tightly attached to the surface of the conveying belt, metal matter or magnetic media are embedded in the conveying belt, the magnetic bodies or magnets are placed on the surface of the cloth strip for achieving the attachment between the cloth strip and the conveying belt, the tension of the cloth strip is the same all the time, and the operation of the cloth strip is stable; images of the head part and the tail part of the cloth strip can be collected.

Owner:JIANGNAN UNIV

Compensation method for steel wire rope synchronous compensation wheel of multi-rope winding type elevator

The invention discloses a compensation method for a steel wire rope synchronous compensation wheel of a multi-rope winding type elevator. When the steel wire rope synchronous compensation wheel of the multi-rope winding type elevator is used for lifting a container, under the condition that the stress of one steel wire rope is slightly larger due to the fact that the steel wire rope becomes shorter, the stress of the other steel wire rope becomes smaller due to the fact that the steel wire rope becomes longer, and according to a wheel body and a wheel shaft, the wheel body rotates towards the steel wire rope with the length becoming larger and the stress becoming smaller through the lever principle, so that the stresses of the two steel wire ropes are balanced. The tension force of the steel wire ropes of the multi-rope winding type elevator can be balanced flexibly and conveniently, and compensation of asynchronization is achieved; compared with a hydraulic tension balancing system for the multi-rope winding type elevator, the weight is reduced, and the adjustment capacity is higher; the compensation wheel rotates around a mandrel by means of the lever principle, the tension of the steel wire ropes on the two sides can be the same through compensation, and a mechanism is safe and reliable.

Owner:LUOYANG MINING MACHINERY ENG DESIGN & RES INST

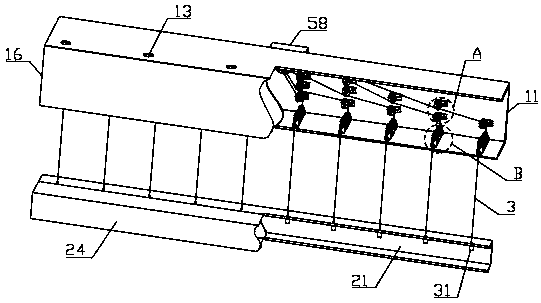

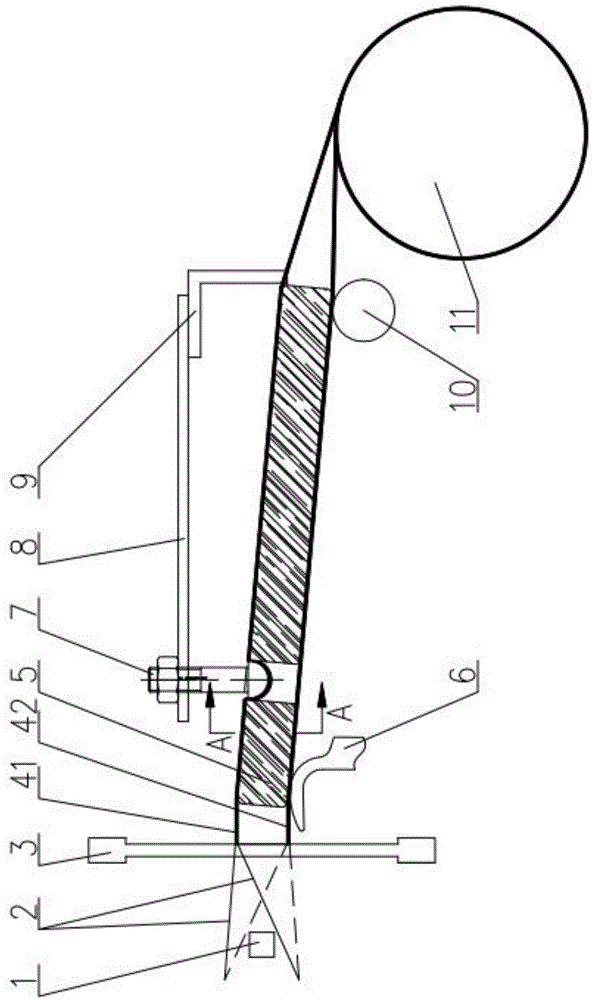

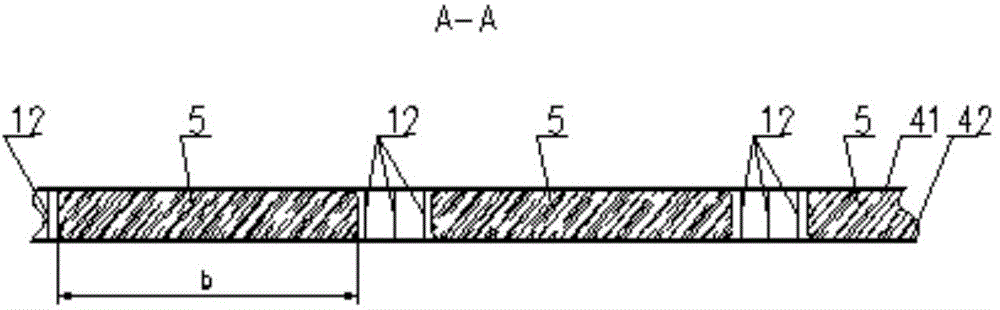

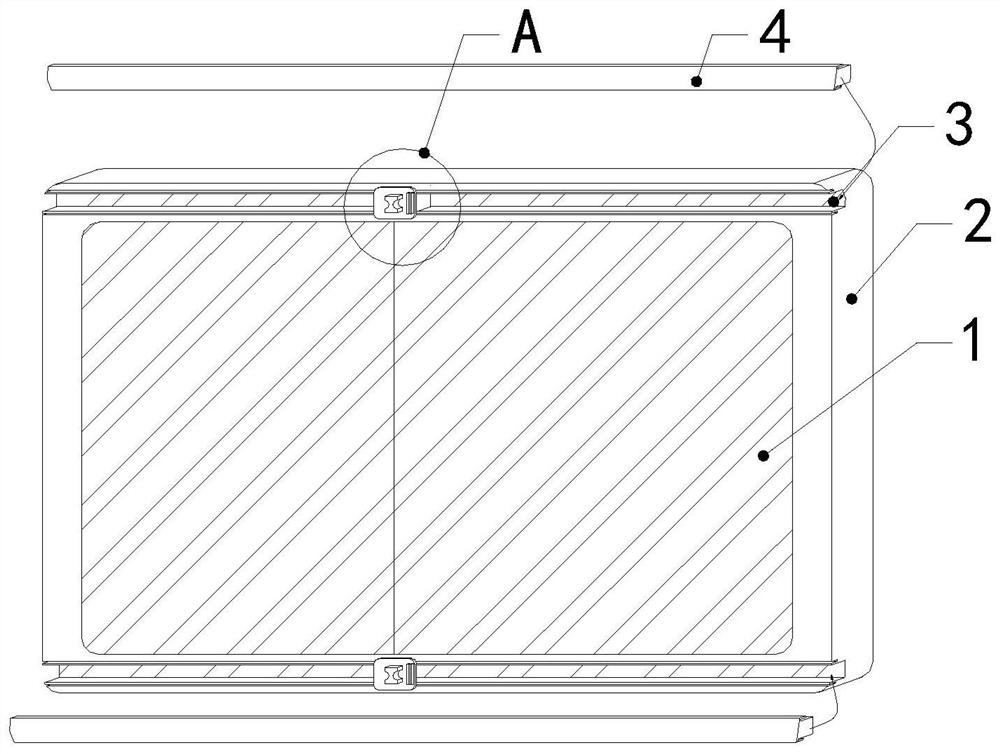

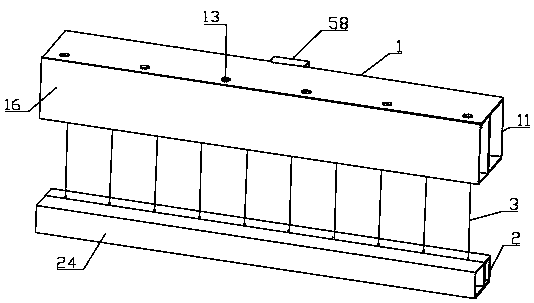

Beating-up mechanism with function of controlling post-forming thickness of double-layer fabric

The invention relates to a beating-up mechanism with function of controlling post-forming thickness of double-layer fabric. The beating-up mechanism comprises a reed and a take-up roll. A plurality of height fixing plates are disposed between a cloth-fell and the take-up roll. An upper base cloth layer is formed on the upper surfaces of the height fixing plates; a lower base cloth layer is formed on the lower surfaces of the height fixing plates; the height fixing plates are spaced via gaps serving as rib connections. A plurality of height fixing plate retainers are fixed on a frame; each height fixing plate corresponds to one height fixing plate retainer; a height fixing plate presser strip is connected to each height fixing plate retainer; the other end of each height fixing plate presser strip is connected with a height fixing plate presser rod; the lower ends of the height fixing plate presser rods are in contact with the upper base cloth layer. The upper base cloth layer is allowed to slide between the upper surfaces of the height fixing plates and the lower ends of the height fixing plate presser rods. The cloth-fell is higher than the positions where the take-up roll takes up the upper base cloth layer and the lower base cloth layer. The beating-up mechanism has the advantage that identical tension can be kept for the upper base cloth layer and the lower base cloth layer.

Owner:HANGZHOU CHUANGXING WEAVING EQUIP TECH

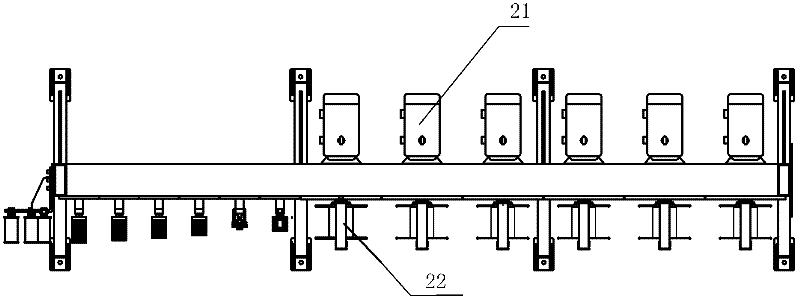

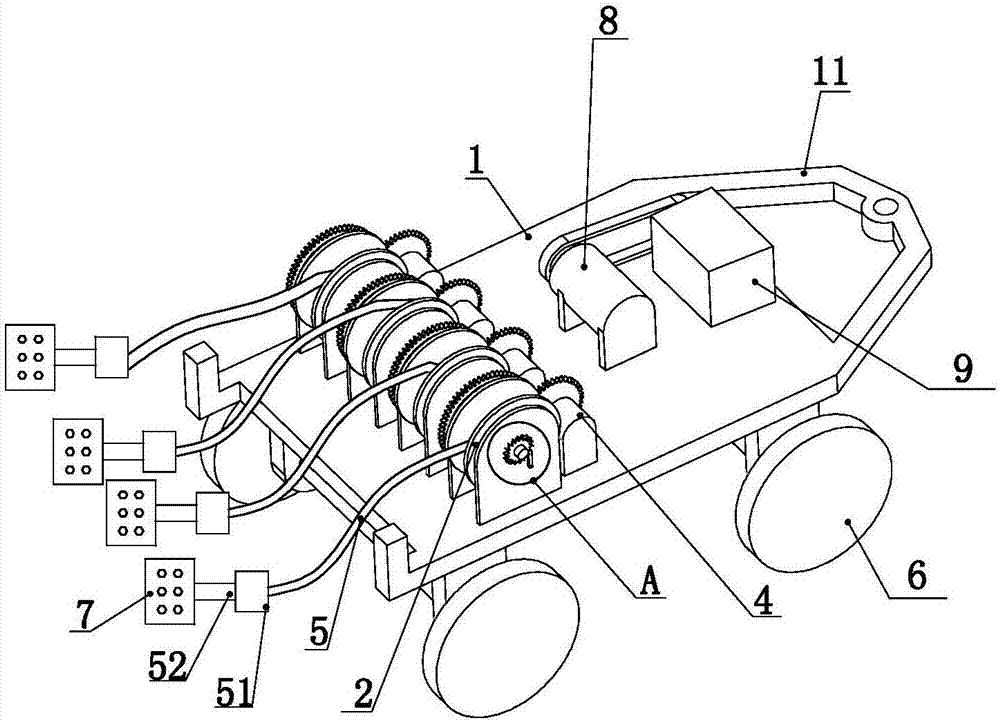

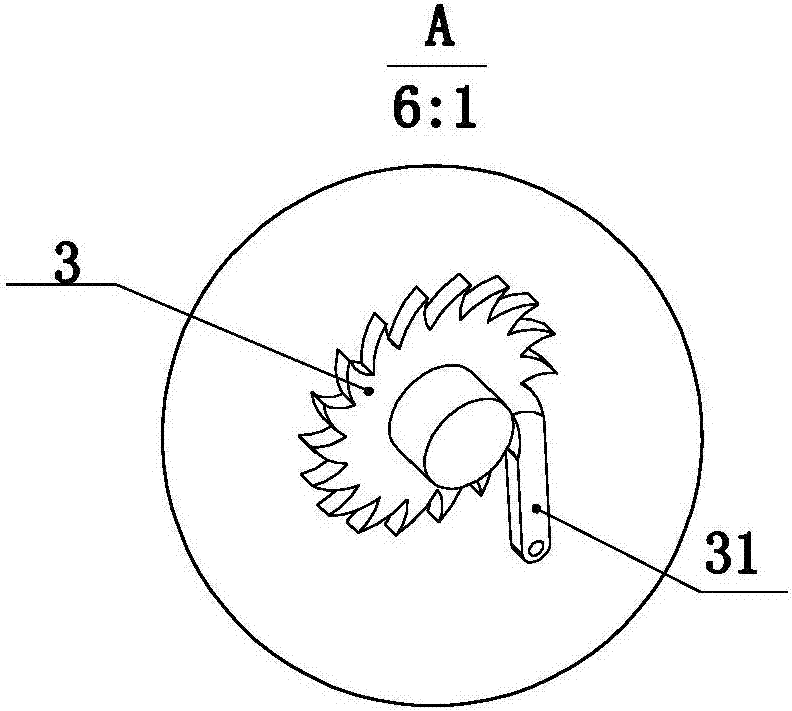

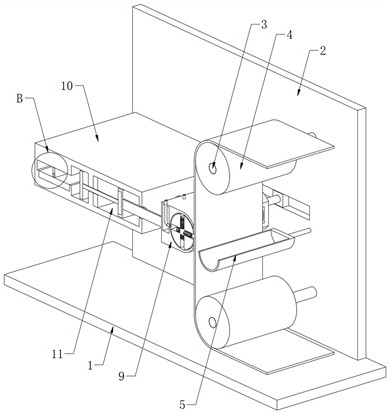

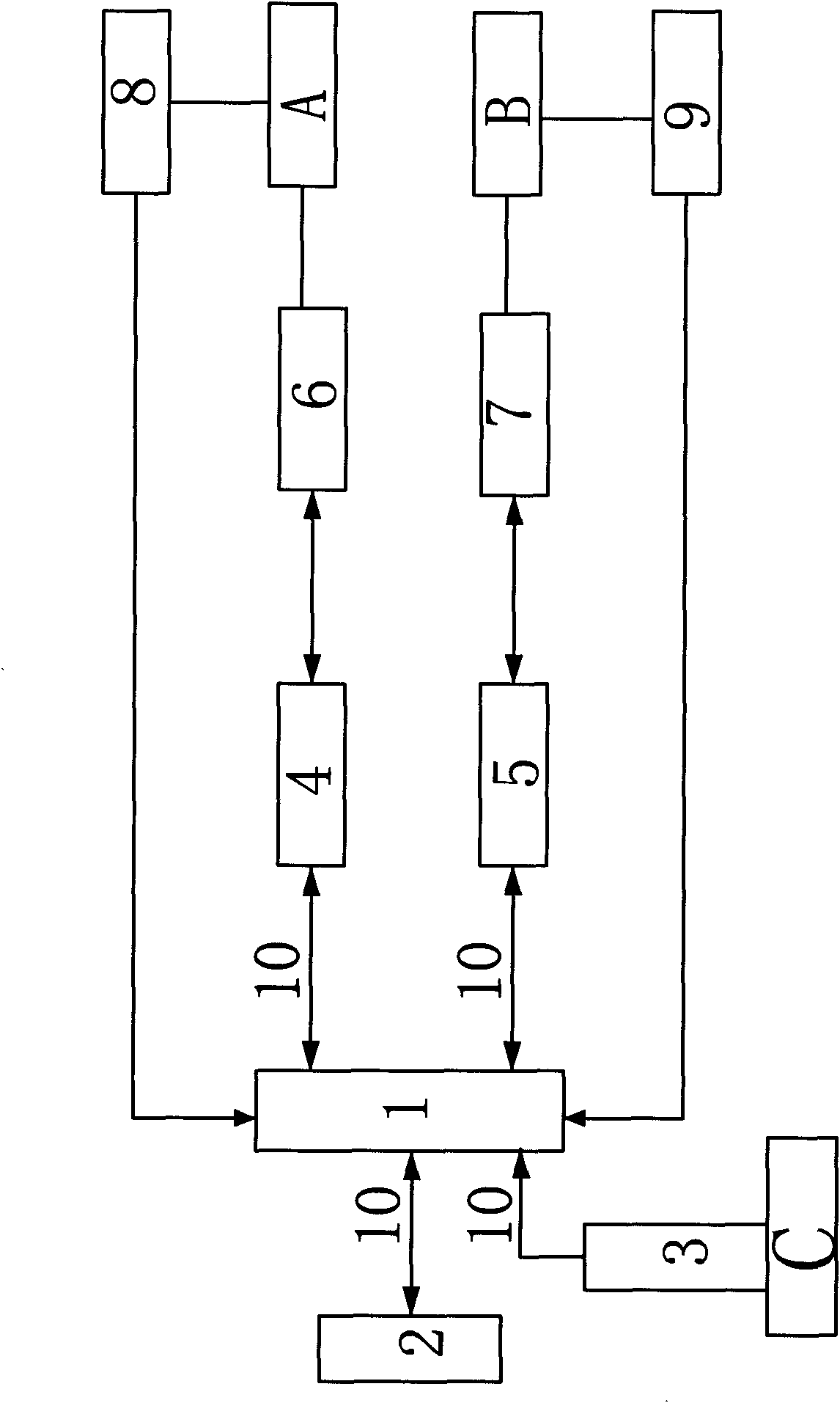

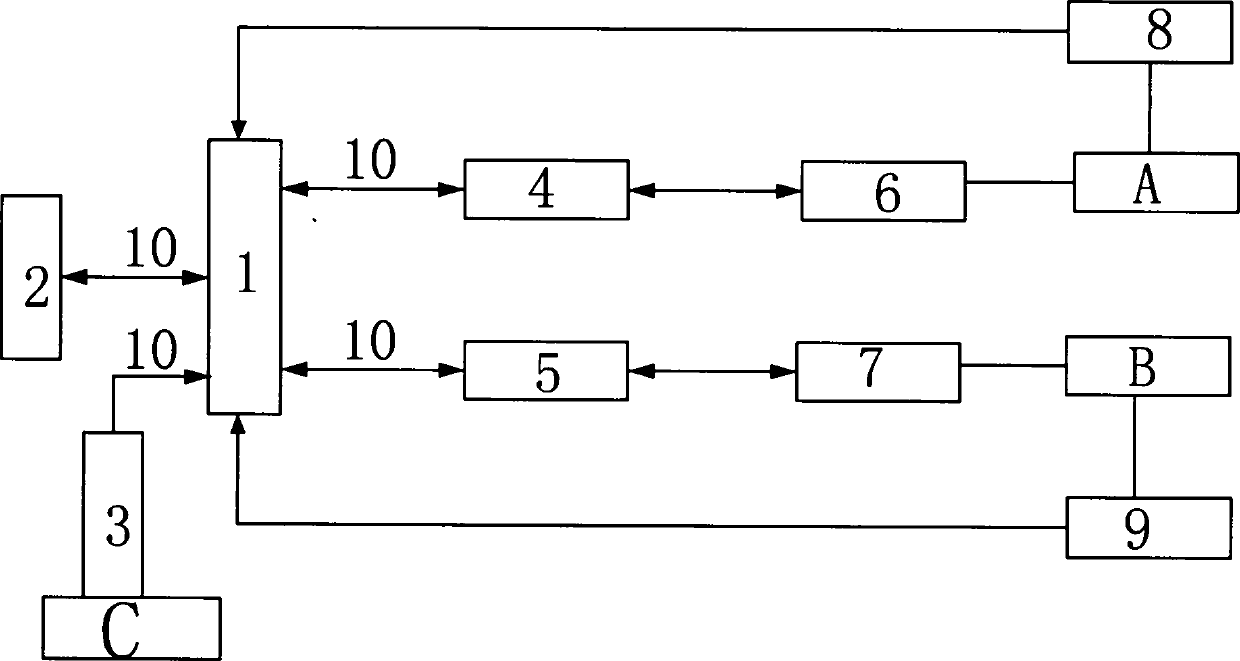

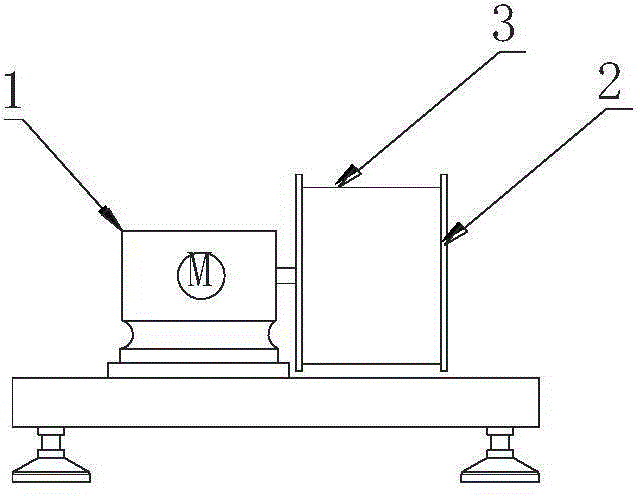

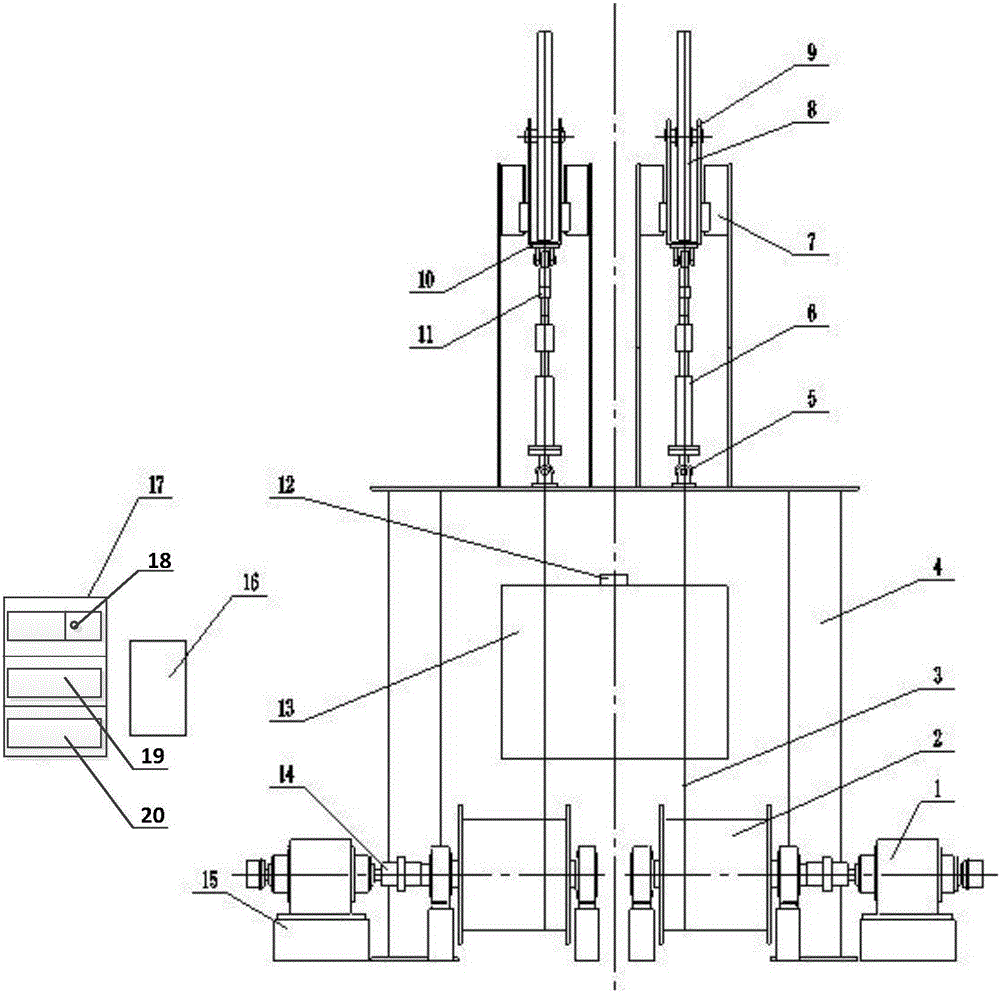

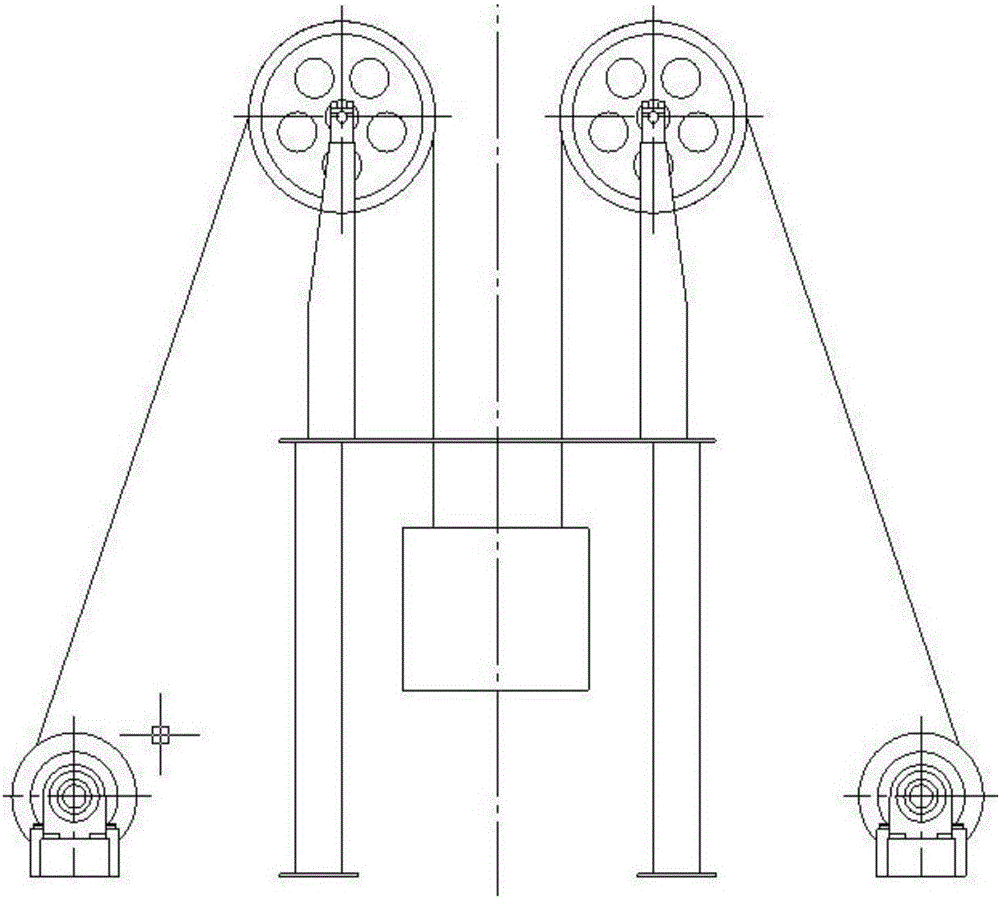

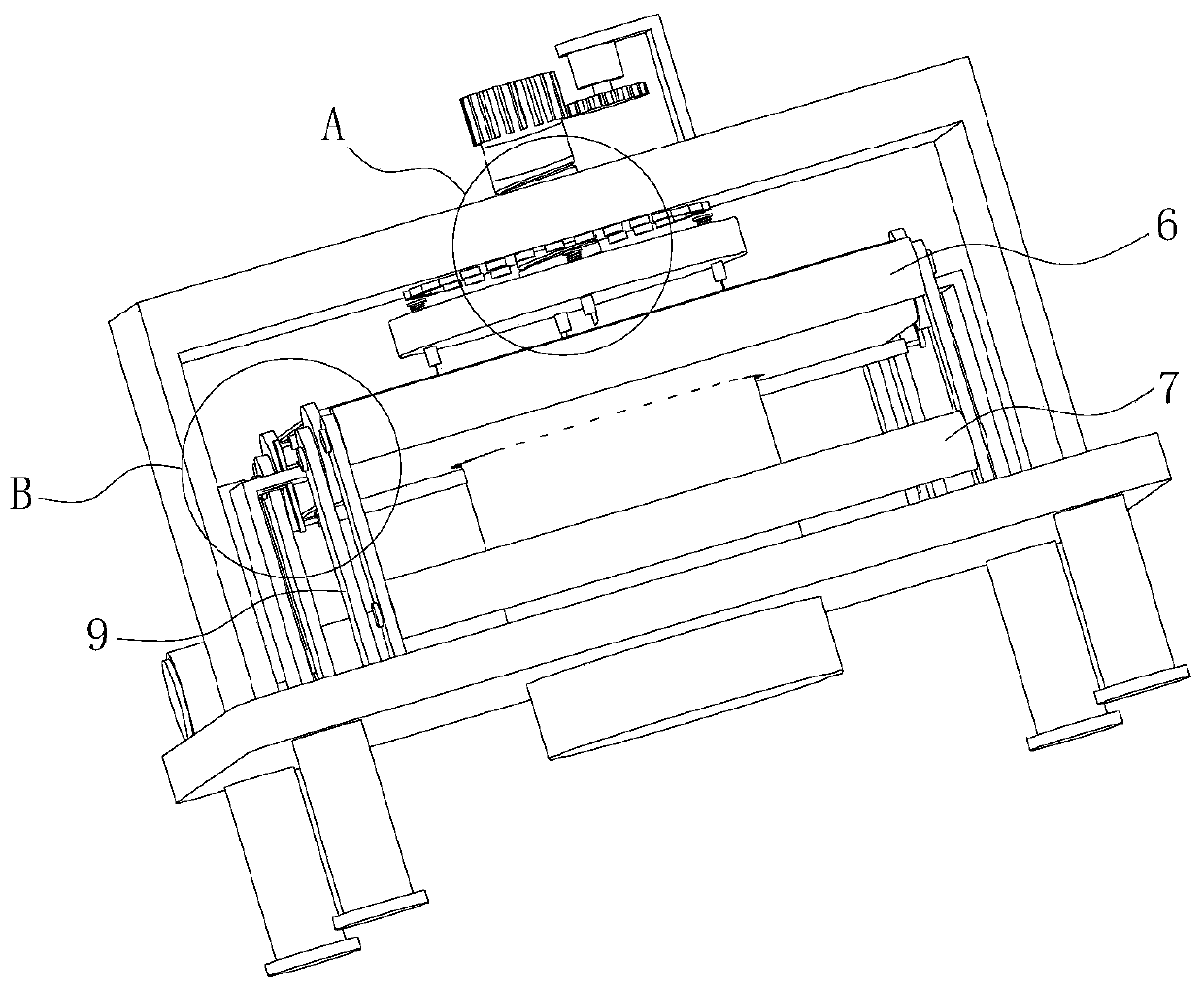

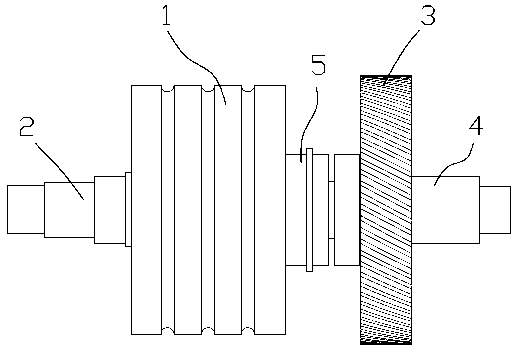

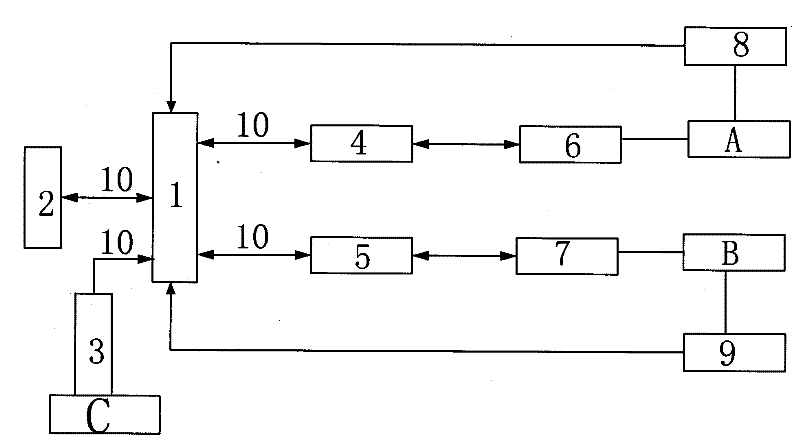

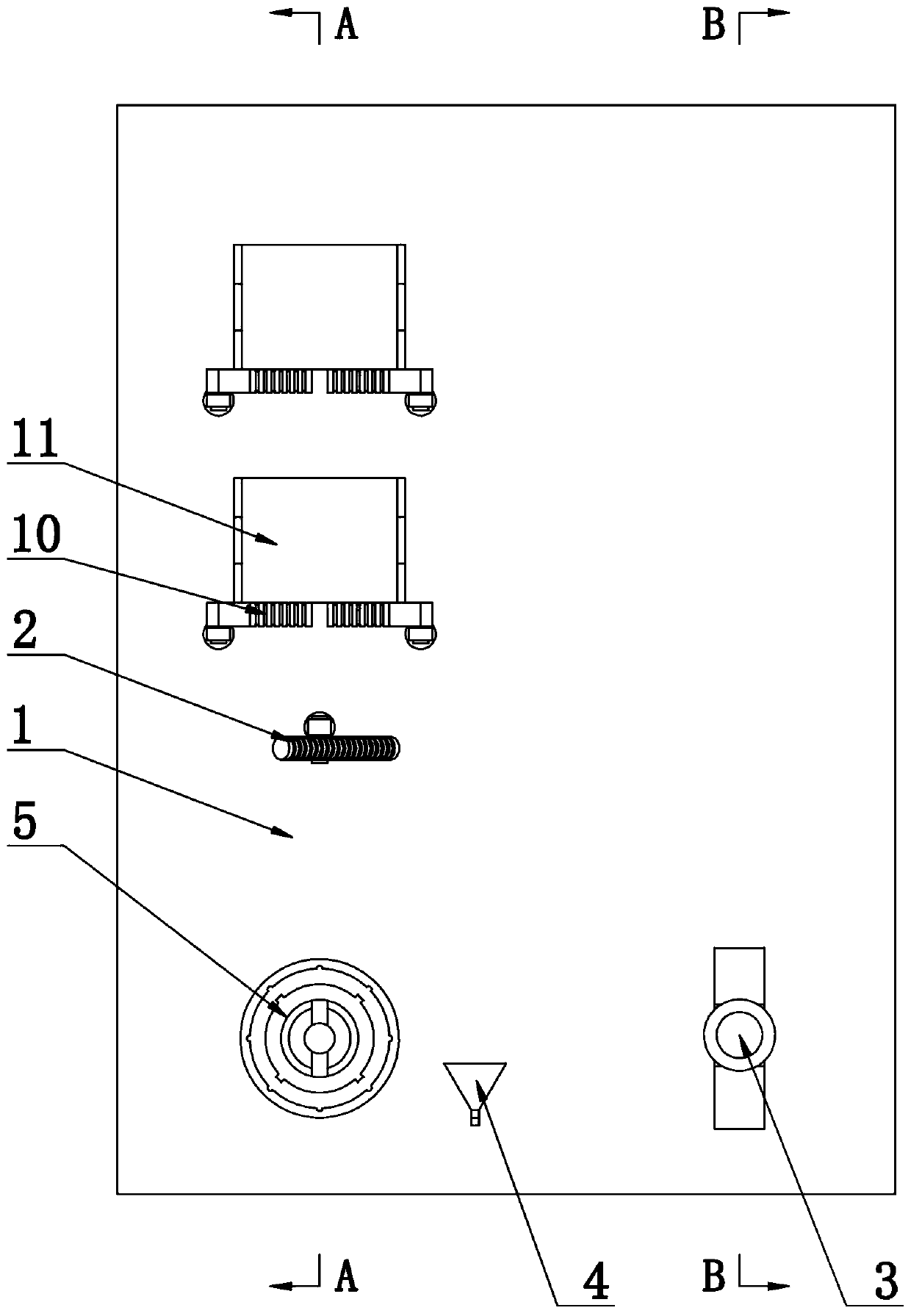

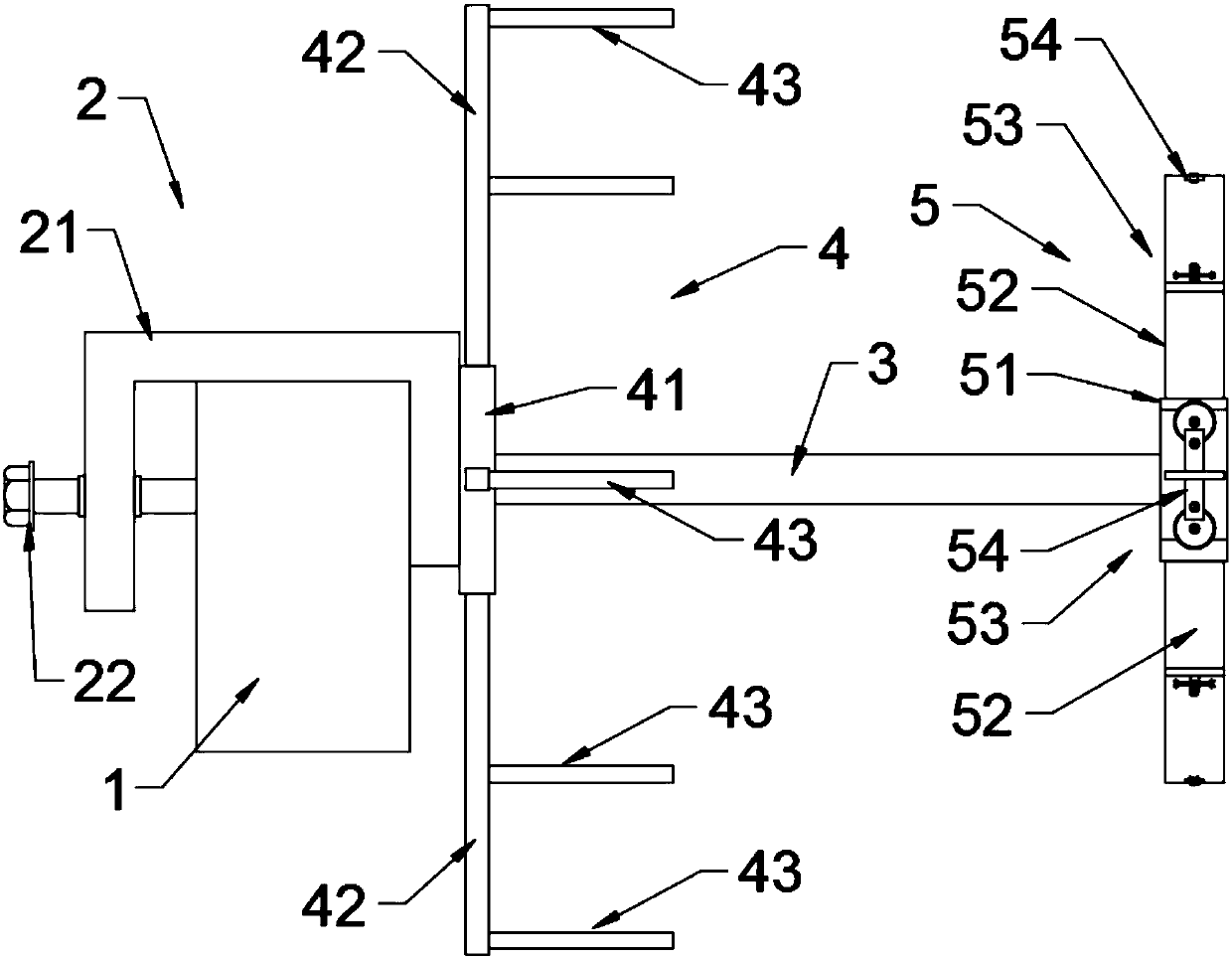

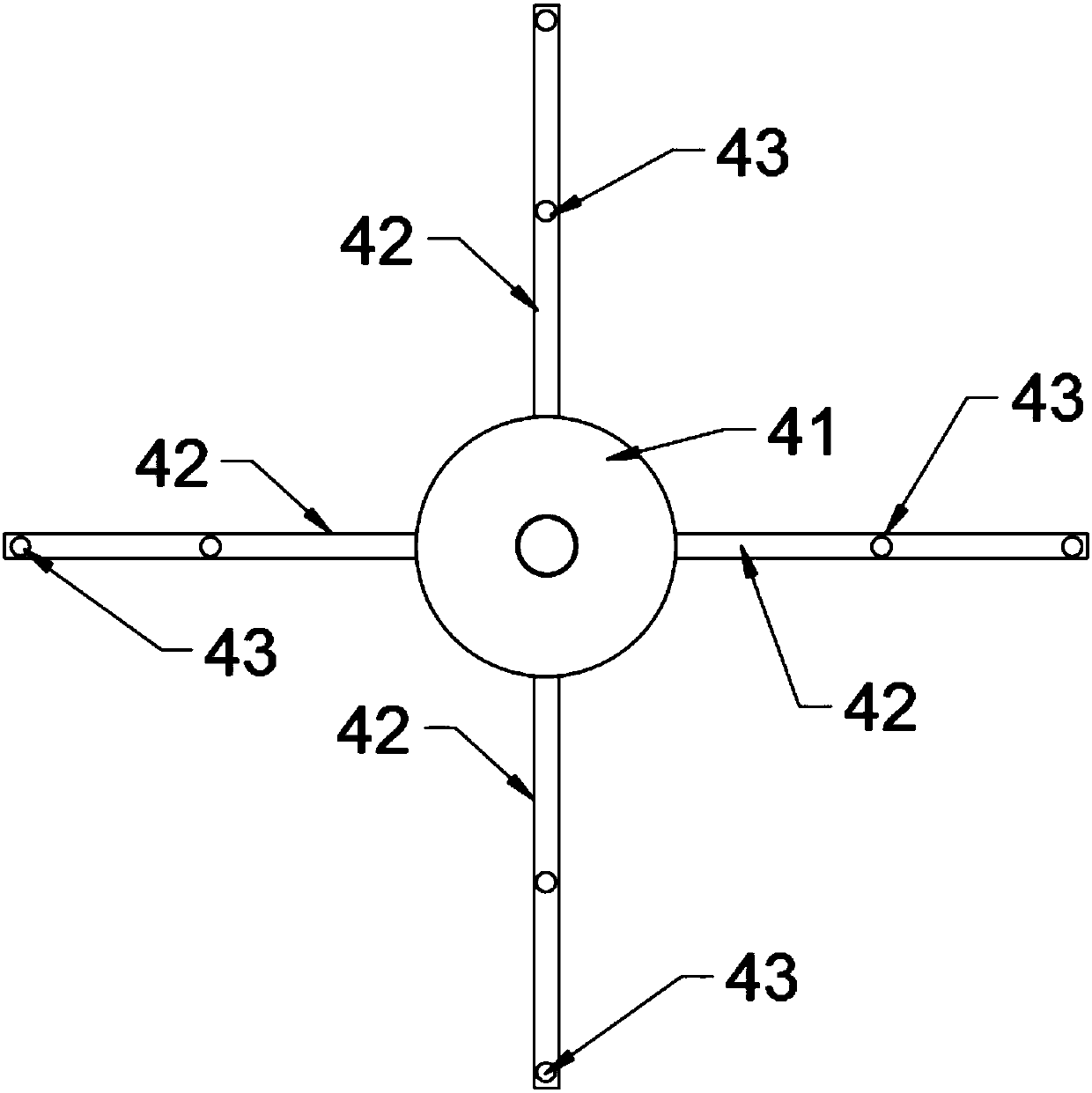

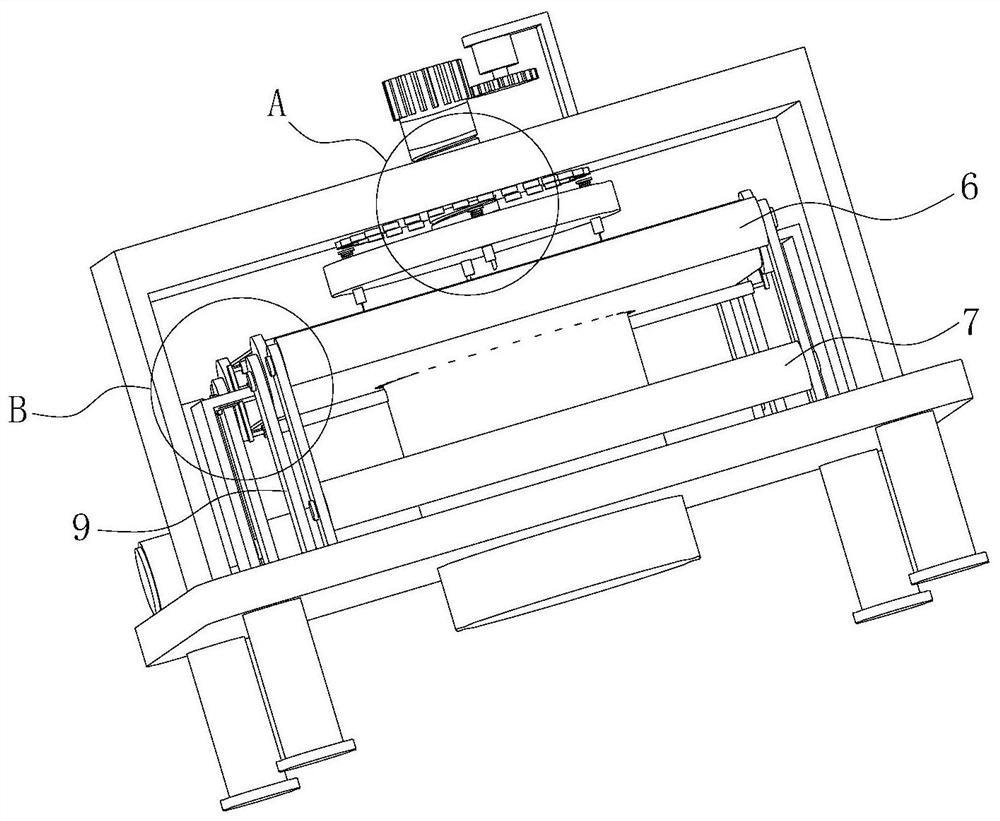

An ultra-deep mine hoist multi-rope cooperative control system test bench

ActiveCN105366455BReduce tensionLevel adjustmentElevatorsMine liftsHydraulic motorHydraulic cylinder

A multi-rope cooperative control system testbed for an ultradeep mine hoist, which relate to multi-rope cooperative control system testbeds for hoists. A hydraulic motor (1) is connected to a roller (2) by means of a coupling (14). The roller (2) is provided with to a steel wire rope (3). The steel wire rope (3) is connected to a cage (13). A tension sensor (11) is placed on the steel wire rope (3) to detect tensile force of the steel wire rope and feed back a signal. A servo hydraulic cylinder (6) is fixed on a hinge (9), and the upper end is connected to a head sheave bracket (9). A head sheave (8) is connected to the head sheave bracket (9), and the head sheave bracket (9) is fixed on a linear guide rail (7). The hinge (9) and the linear guide rail (7) are connected to a steel structural bracket (4). The servo hydraulic cylinder (6) drives the head sheave (8) to move up and down by means of the head sheave bracket (9). The tension sensor (11) is placed on the steel wire rope (3) to detect the tensile force of the steel wire rope (3). A pressure sensor (10) is placed on the head sheave bracket (9) to detect a pressure applied to the head sheave (8). A spiral instrument (12) is fixed above the cage (13) to detect whether the cage (13) is horizontal. The cage (13) is located in the steel structural bracket (4). The hydraulic motor (1) is mounted on a motor base (15). In the testbed, the cage is perpendicularly hoisted by using a mode of the drag of the hydraulic motor, thereby making the operations simple, and helping to carry out maintenance.

Owner:CHINA UNIV OF MINING & TECH

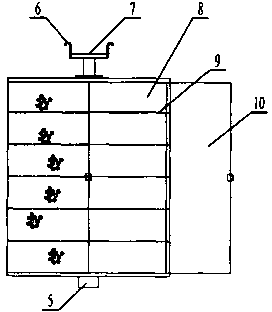

Novel skein cage

The invention relates to a tube cylinder, in particular to a novel skein cage used in the tube cylinder for skein dyeing. The novel skein cage comprises a circular cage body (8), and at least one layer of horizontal separation plate which separates the cage body (8) into relatively independent spaces is arranged in the cage body (8). The novel skein cage is simple in structure and even in stress of yarns in the cage body, does not produce overlapped dead angles, and is good in product quality and high in production efficiency. At least one layer of horizontal separation plate is arranged in the cage body, the yarns cannot be overlapped together during yarn dyeing, the overlapped dead angles and the like cannot be produced, pressure borne by the yarns is even and unanimous, tensile force borne by the yarns during dyeing is same, elasticity of the yarns after dyeing is even, dyeing is even, and quality is unified.

Owner:CHANGZHOU POLYACE TEXTILE & YARN

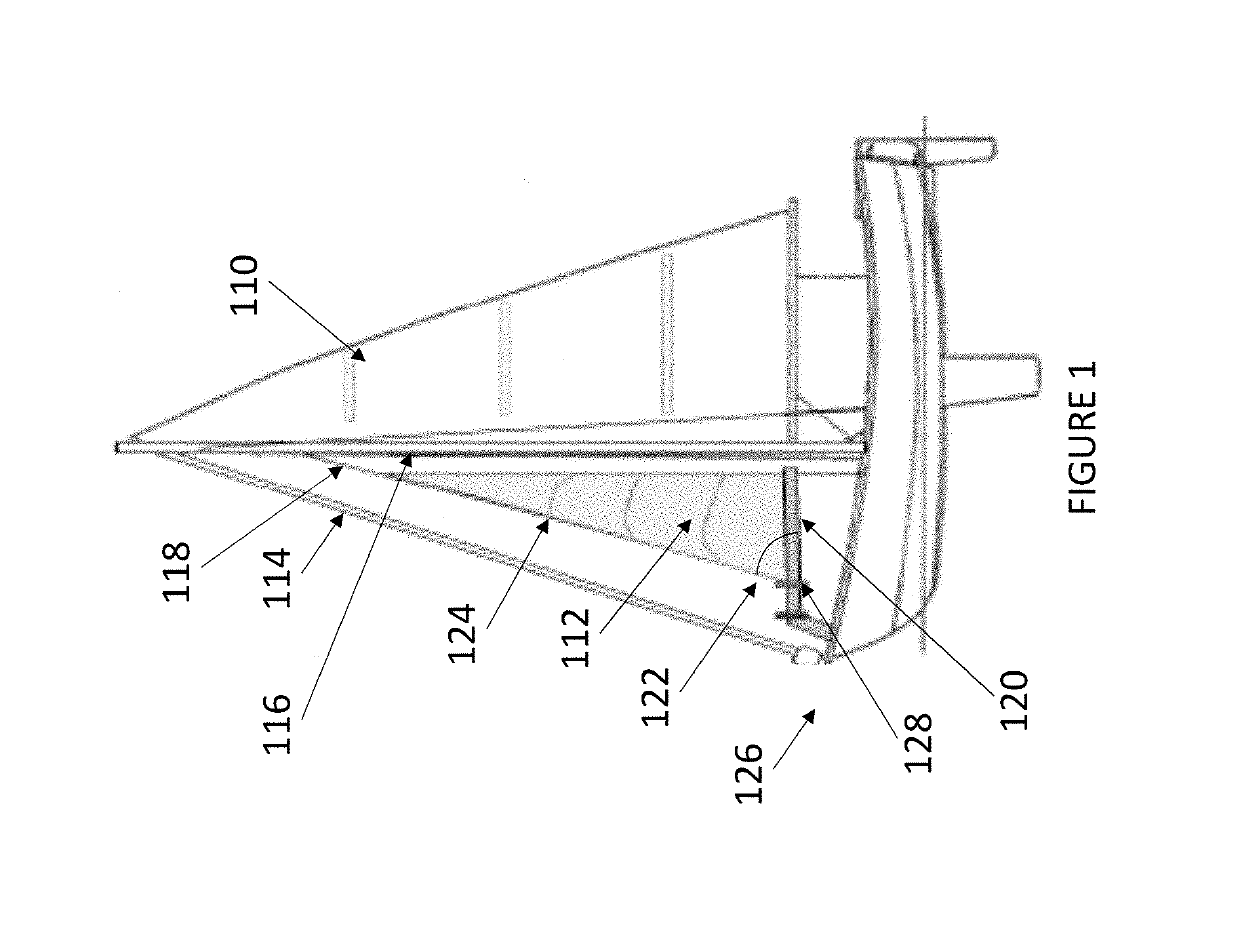

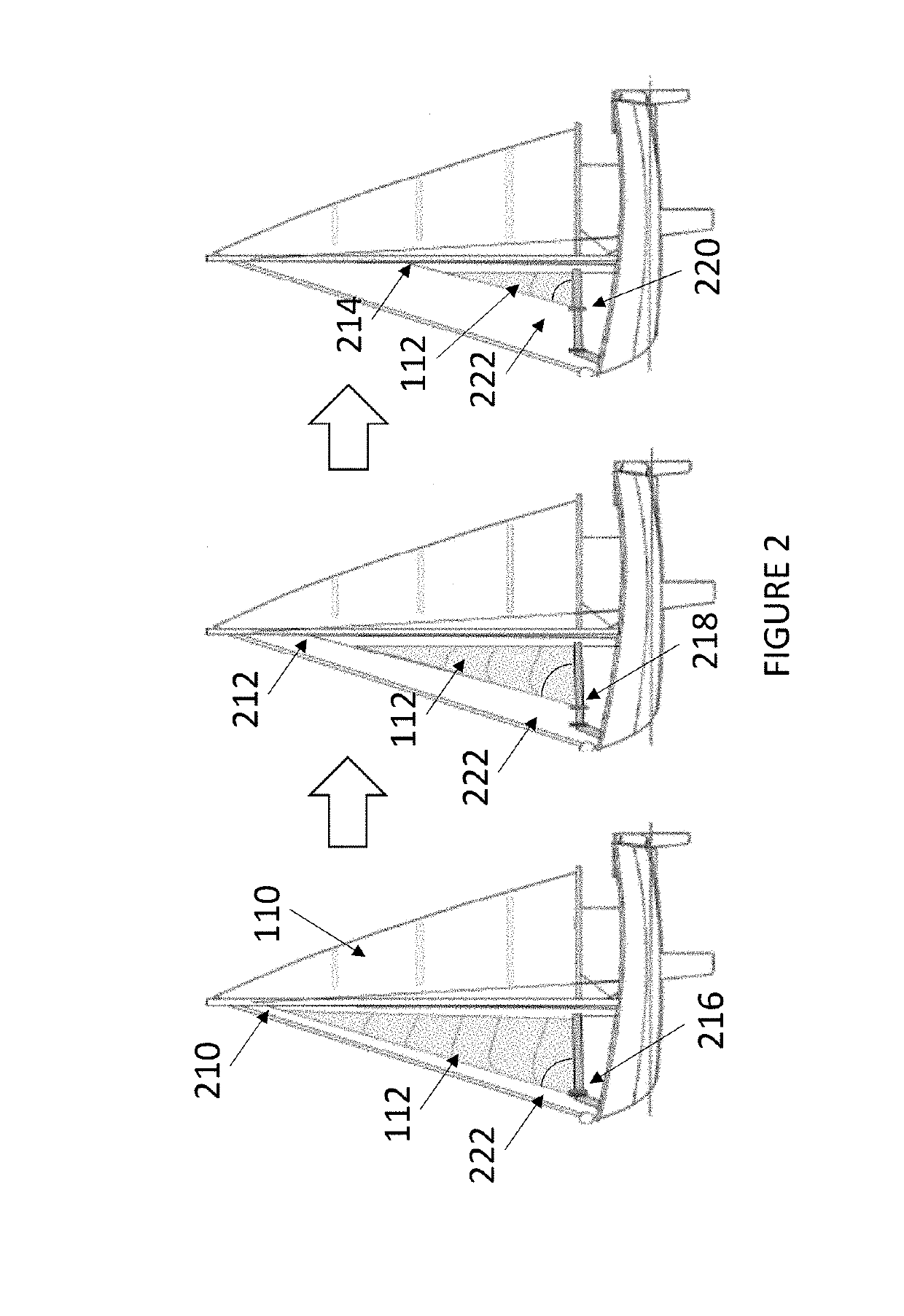

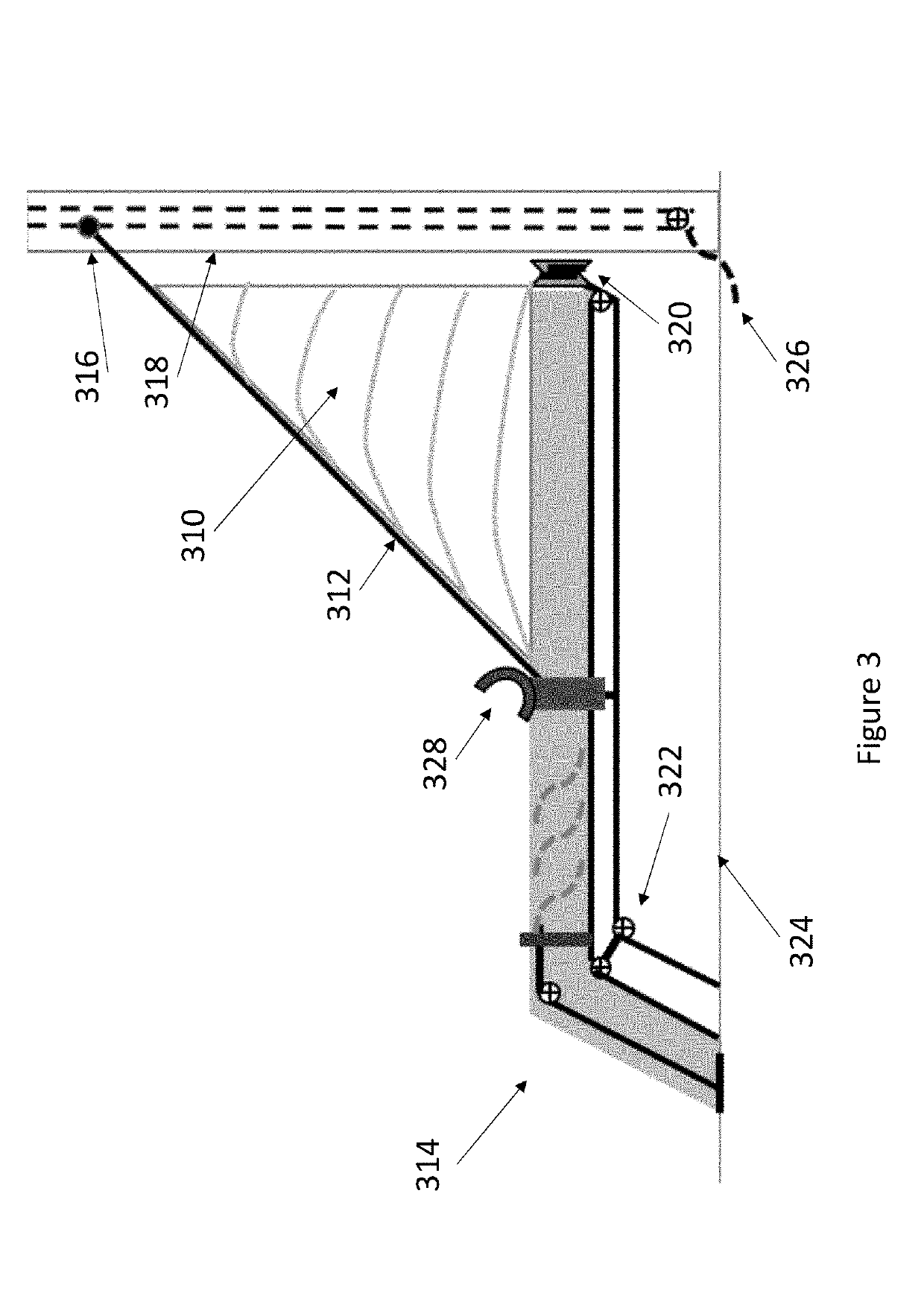

Headsail roller-furling boom

InactiveUS20190176947A1Increase stabilityLow center of gravityVessel superstructuresVessel mastsMarine engineeringWeather condition

The present invention relates to a movable stay connected between a boom and the mast, capable of furling a sail, such as a headsail or jib. The furling and deployment movements should be proportional so the sail angle remains constant throughout use. By furling sails toward the mast and deck, the center of gravity for the sailboat is lowered. During a capsize or just harsh weather conditions, lower center of gravity helps in righting a ship or preventing it from capsizing in the first place. Other embodiments will allow for automatic detection of an anticipated capsize and an immediate automated furling of sails.

Owner:CHARLTON GUY

Intelligent die-cutting machine for preparing polyester plastic film sheets

ActiveCN111438761AAvoid harmImprove processing efficiencyMetal working apparatusPolyesterEngineering

The invention belongs to the technical field of new material manufacturing, and particularly relates to an intelligent die-cutting machine for preparing polyester plastic film sheets. The intelligentdie-cutting machine comprises a base plate. A first reversing roller, a winding roller, a second reversing roller, a conveying roller, a first driving roller and a second driving roller which are parallel to one another are installed on the base plate. A first sealing barrel, a second sealing barrel and a portal frame are also installed on the base plate. A conveying belt is installed on the outersurface of the first driving roller and the outer surface of the second driving roller. Two circular through grooves are formed in the conveying belt, and through holes are evenly formed around the circular through grooves. A hollowed sealing ring is installed on the outer side face of the first sealing barrel, and a first piston barrel is installed on the outer side of the hollowed sealing ring.A second piston barrel is installed on the outer side of the top of the second sealing barrel. A cutting mechanism is installed on a top plate of the portal frame. When the intelligent die-cutting machine is used for circularly cutting polyester plastic films, processing efficiency is improved, harm to the hands of operators by cutting blades is avoided, no wrinkle can be formed on polyester filmstrips in the cutting process, and the edges of the circular sheets are smooth without sawteeth.

Owner:佛山市郭氏绝缘材料有限公司

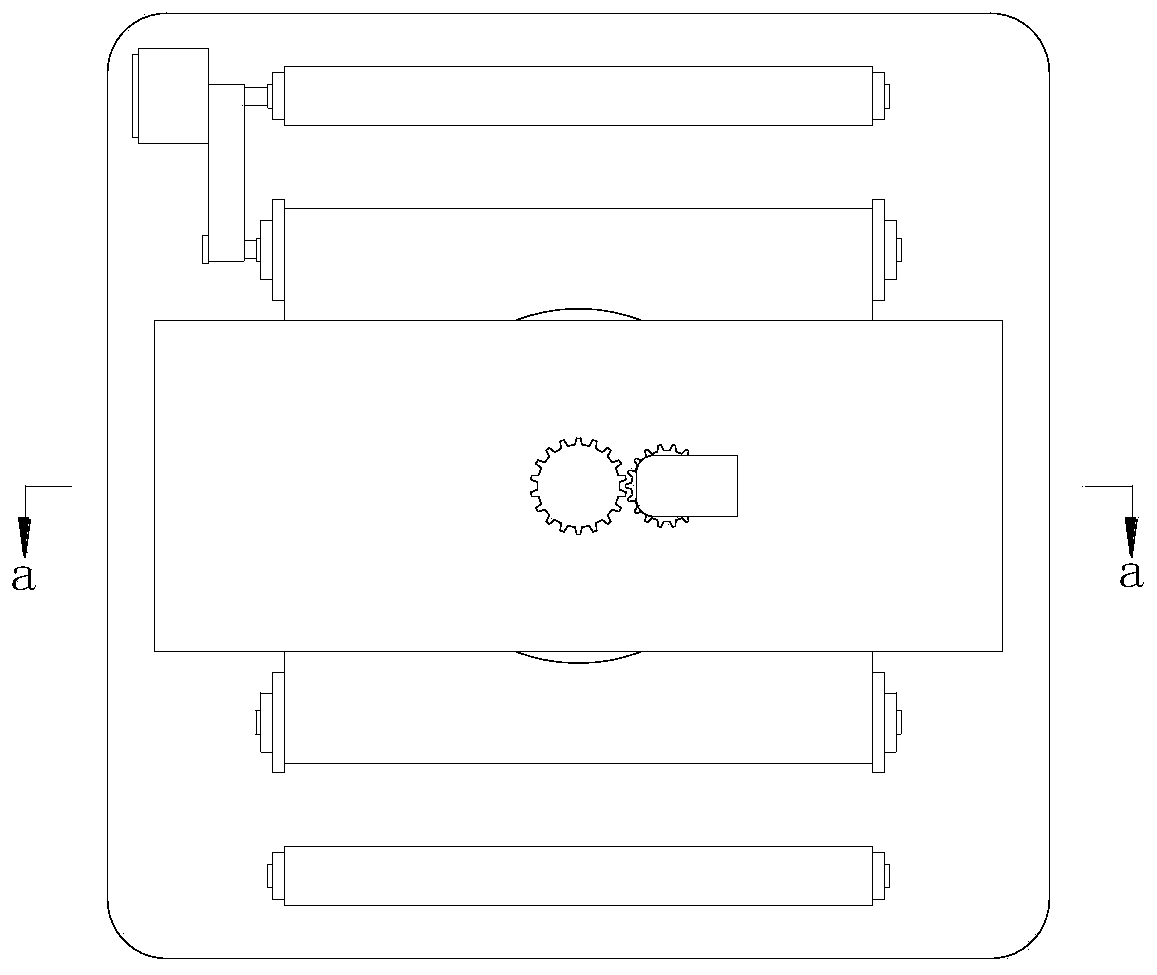

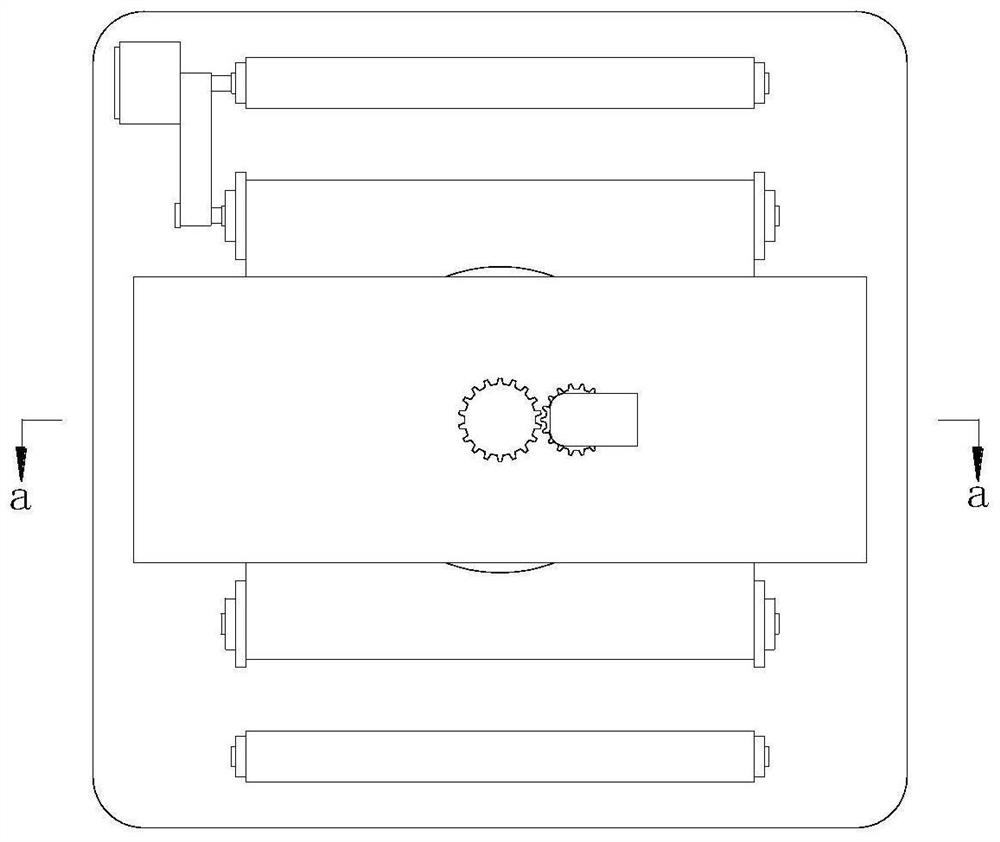

A circuit board solder mask printing machine

ActiveCN110719703BAvoid wrinklesSame tensionNon-metallic protective coating applicationScreen printingNylon material

Owner:嘉兴华竹电子有限公司

Solder resist printing machine for circuit board

ActiveCN110719703AAvoid wrinklesSame tensionNon-metallic protective coating applicationScreen printingNylon material

The invention discloses a solder resist printing machine for a circuit board. The structure of a screen printing frame comprises a screen mounting opening, a frame body, a pressing opening, an imprinting plate and a pressing sliding block. Symmetrical pressing openings are formed in the upper side and the lower side of the frame body; an impressing plate and a flattening sliding block which are matched with the impressing opening are arranged on the impressing opening; the space in the middle of the frame body is a silk screen mounting opening; a flattening sliding block matched with the pressing opening is mounted in the pressing opening. According to the invention, the two flattening sliding blocks are used for smoothly sliding in the pressing opening provided with the silk screen, thereby preventing a screen made in an inclined weaved manner or made of a nylon material from creasing; by means of the design of the shifting block and the stopping block on the flattening sliding block,the stopping block is convenient for an operator to hold, the stopping block is arranged in front of the flattening sliding block for stopping and increasing friction when the operator holds the flattening sliding block, thereby further preventing an operation from being separated from the handle.

Owner:嘉兴华竹电子有限公司

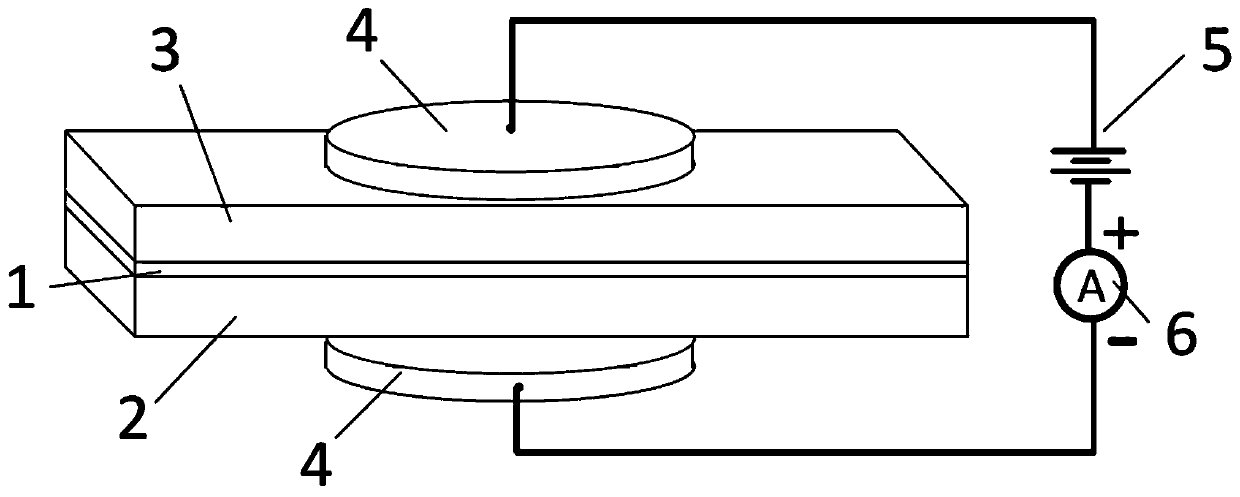

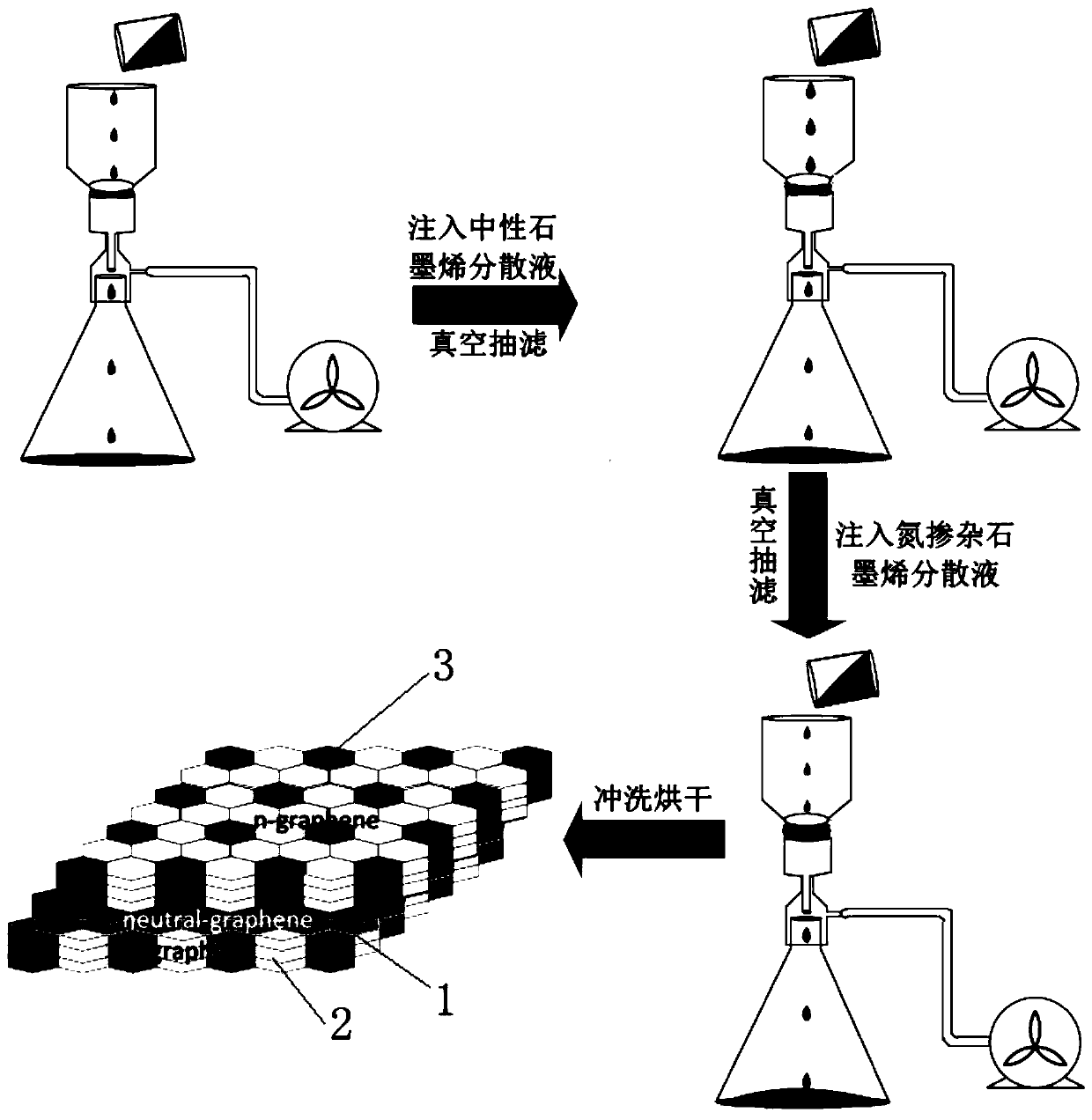

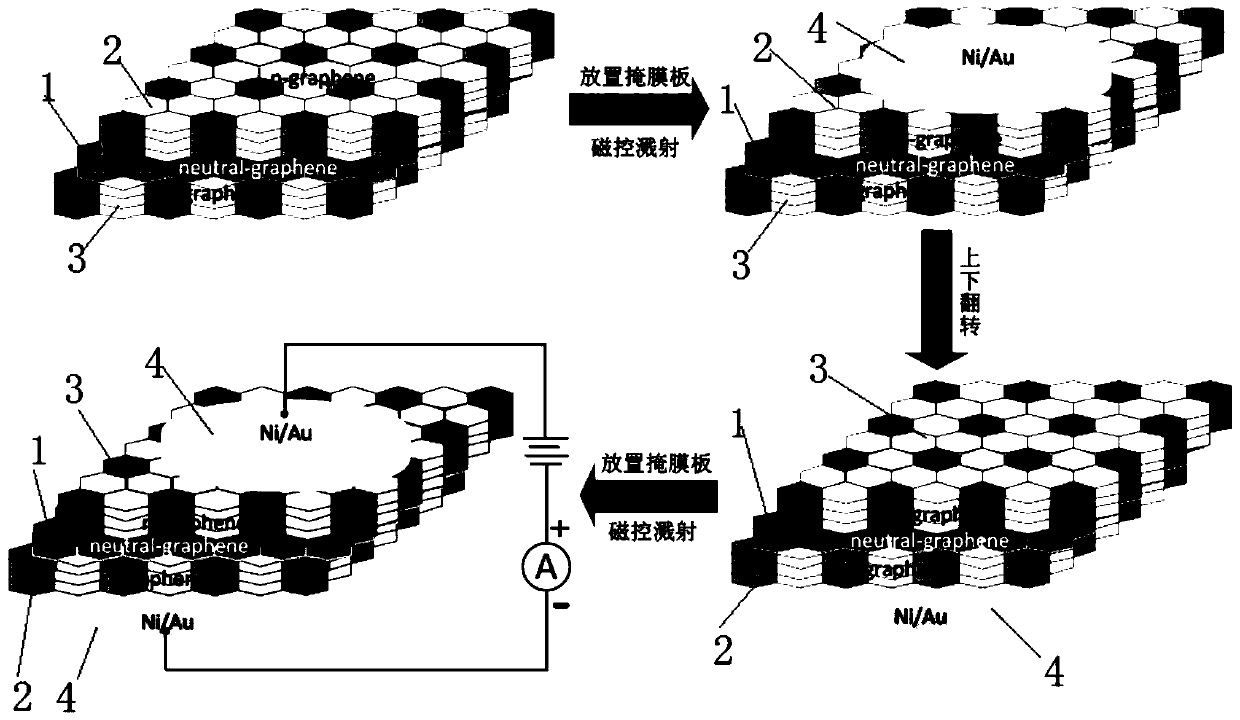

Graphene homogeneous p-n junction structure and preparation method thereof

PendingCN111244162ASame shrinkageSame tensionSemiconductor/solid-state device manufacturingSemiconductor devicesFlexible electronicsHomojunction

The invention discloses a graphene homogeneous p-n junction structure and a preparation method thereof. The graphene homogeneous p-n junction structure comprises a neutral graphene layer, a p-type graphene layer, an n-type graphene layer and an electrode, wherein the p-type graphene layer is arranged on the surface of one side of the neutral graphene layer, the n-type graphene layer is arranged onthe surface of the other side of the neutral graphene layer, and electrodes are arranged on the surface of the p-type graphene layer and the surface of the n-type graphene layer. According to the invention, the characteristics of the same material of graphene that the thermal expansion coefficient, the electron affinity, the band gap width and the lattice constant are the same are utilized; therefore, the complex interface problem generated by heterogeneous p-n junctions made of different materials and the problems of structural instability, low efficiency and the like of the heterogeneous p-n junctions are avoided, and meanwhile, the p-n junction structure has excellent flexibility and performance and can be used for structural design of flexible electronic devices and research and development of a high-performance miniaturized fine display technology.

Owner:XI'AN PETROLEUM UNIVERSITY

Electronic Belt Scale Swing Type Belt Tensioner

ActiveCN101726347BGuaranteed to workSimplify workConveyorsWeighing apparatus detailsDrive shaftEngineering

Electronic belt scale sway type belt tensioning device, including a tensioning frame straddling the two ends of the driven roller of the electronic belt scale and located between the upper and lower belts, body side panels symmetrically arranged on both sides of the tensioning frame, installed on the machine The link mechanism on the body side plate, the link mechanism is composed of a base, a first link, a second link, and a yaw plate connected in sequence, the base is fixed on the side plate of the fuselage, the first link passes through the first The rotating shaft is hinged with the base, the second connecting rod is hinged with the first connecting rod through the second rotating shaft, the yaw plate is respectively hinged with the second connecting rod through the third rotating shaft and the side plate of the fuselage through the fourth rotating shaft; A set bolt is arranged on the plate; a wrench is installed on the second connecting rod; the yaw plate is also connected with the tensioning frame through the first bearing, and the tensioning frame is connected with the center shaft of the driven roller through the second bearing. The invention has a light structure, can quickly and labor-savingly realize the tension or relaxation of the belt, and the tension force can be precisely adjusted in real time.

Owner:云南昆船电子设备有限公司

Strip crease preventing device of high-precision barcode printer

The invention discloses a strip crease preventing device of a high-precision barcode printer. The device comprises a strip crease preventing base plate. The left side of the strip crease preventing base plate is fixedly connected with a hairbrush plate through screws. The left side of the strip crease preventing base plate is fixedly connected with a cover. The top and the bottom of the cover are respectively provided with a first chute. The inner chamber of the cover is provided with a strip crease preventing cover plate. The top and the bottom of the strip crease preventing cover plate are fixedly connected with a first slide rod. One end, which is far from the strip crease preventing cover plate, of the first slide rod extends into the inner chamber of the first chute. One end, which is in the inner chamber of the first chute, of the first slide bar is movably connected with a first roller through a rotating shaft. The strip crease preventing device of the high-precision barcode printer can make the strip crease preventing cover plate perform transverse movement for keeping the strip crease preventing cover plate in a vertical state always, thereby keeping the same tension between top of the right side of the strip crease preventing cover plate and a carbon strip, improving adjustment precision for the strip crease preventing cover plate, and improving quality of a finished product.

Owner:李琼兵

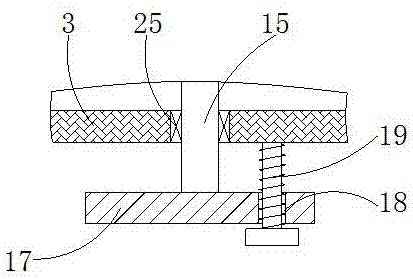

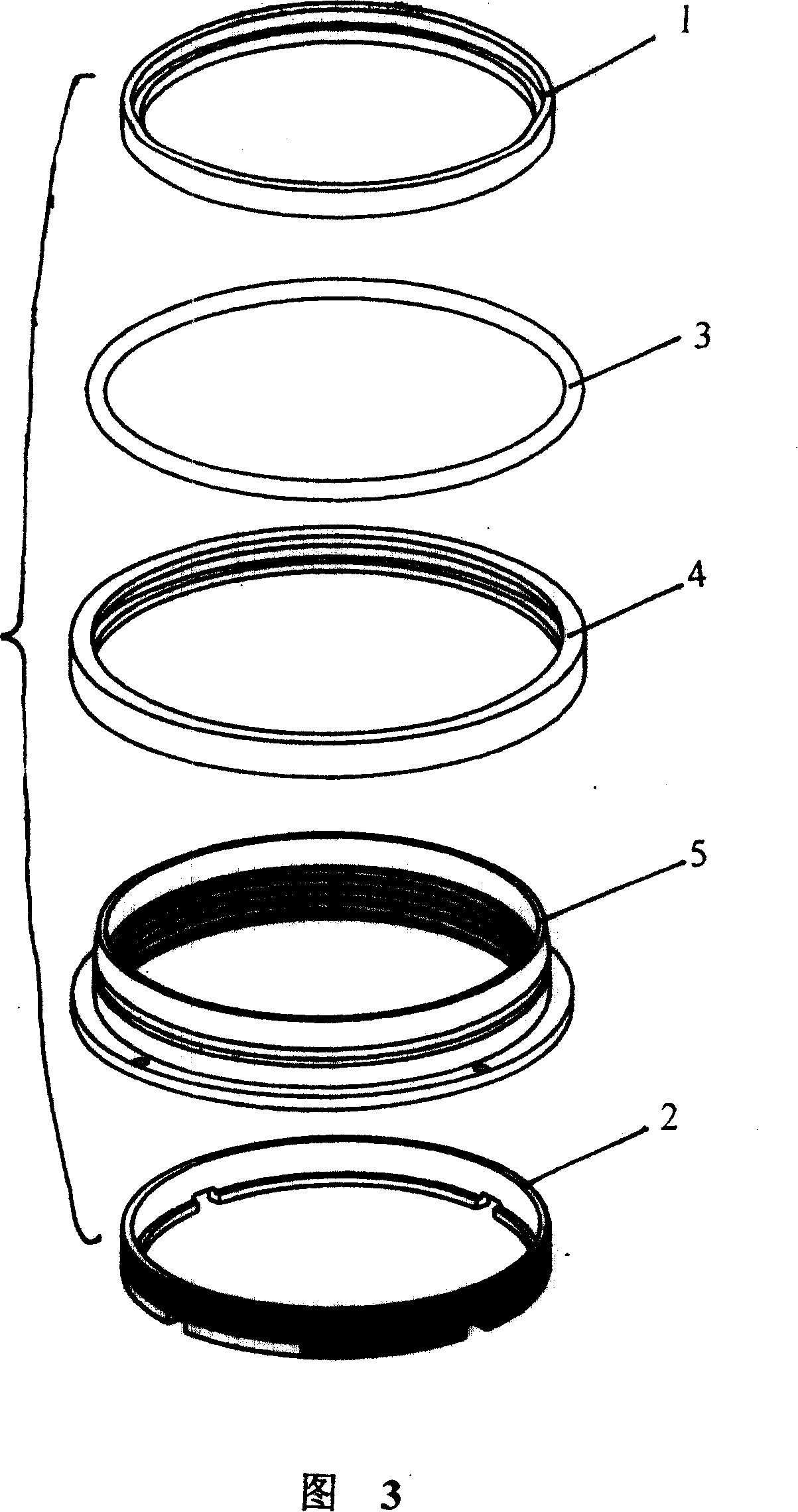

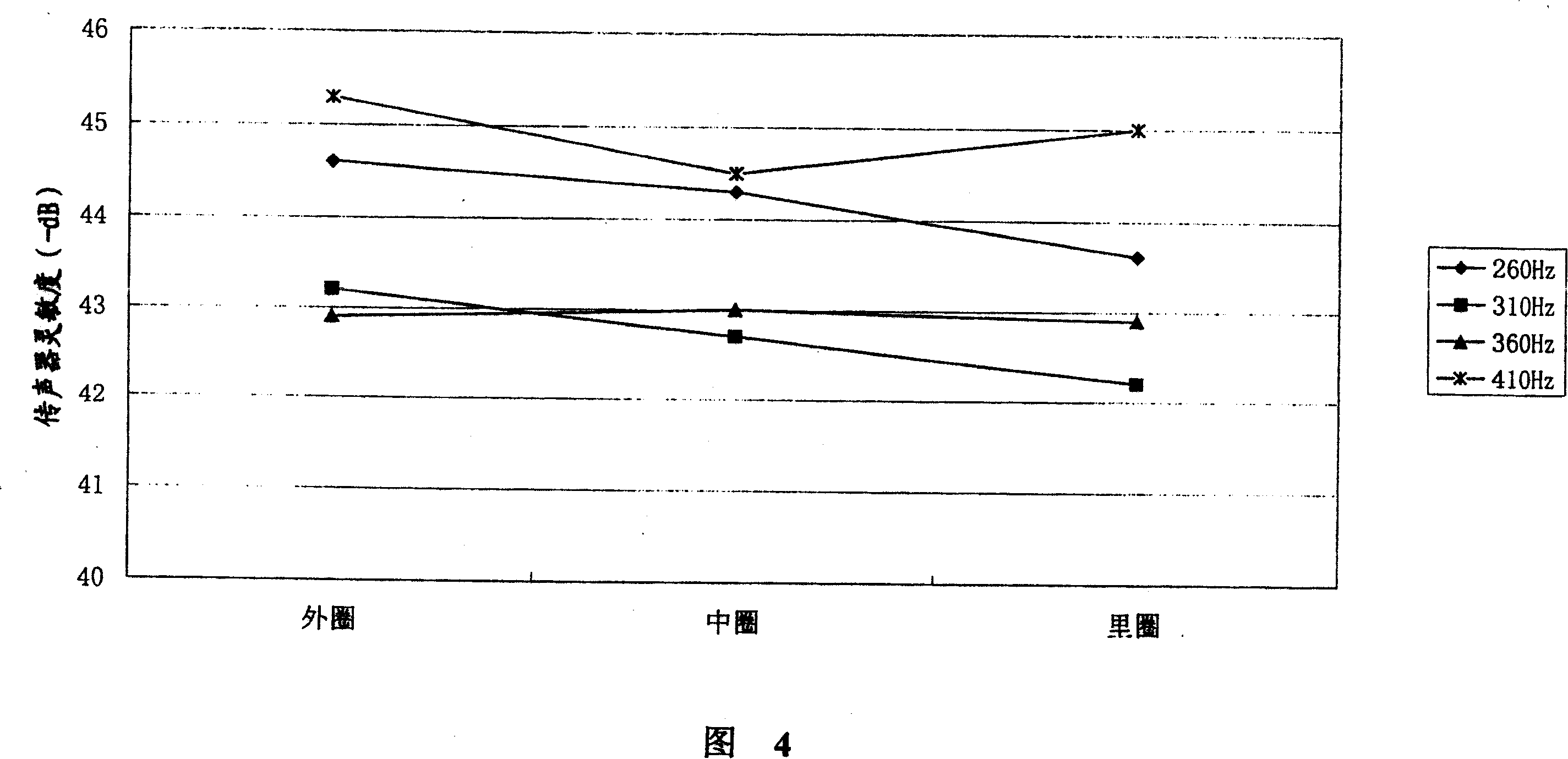

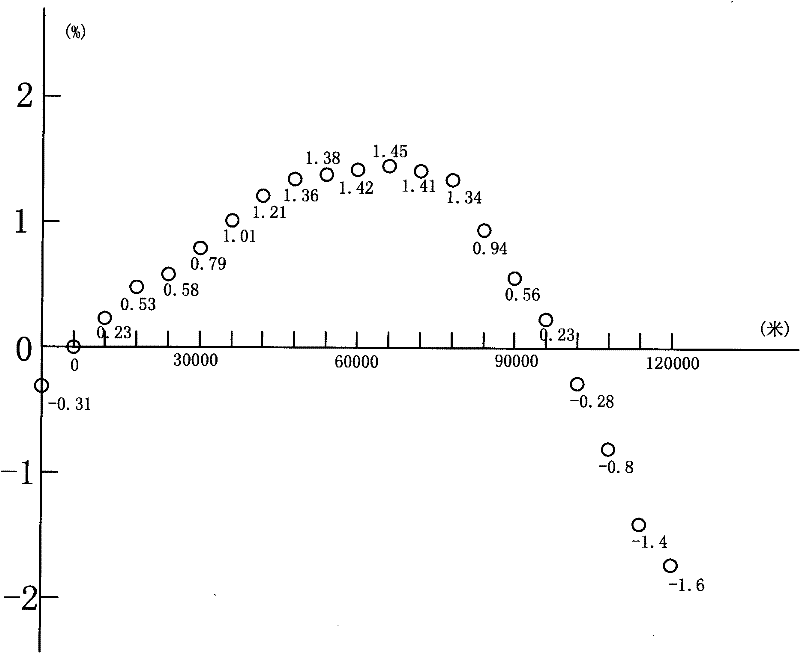

Process for making backing electrode electret condenser type microphones

InactiveCN100377622CImprove consistencyGuaranteed repeatabilityElectrical transducersPolyesterResonance

This invention relates to back electret capacitor microphone process method, which comprises the following steps: stretching the polyester film on the frock to form one fixation diaphragm and adjusting the film resonance frequency within designed range in the testing sound field to control the tension force place of the film; evaporating one layer nickel film with certain thickness in vacuum environment and again adjusting film tension force and then sticking it to one set of supportive rings; accomplishing flatting, baking and dividing programs to accomplish single diaphragm element process.

Owner:AAC TECH PTE LTD

Guide pulley

InactiveCN103318792ASame tensionAdapt to the needs of the structureWinding mechanismsCouplingGear wheel

The invention discloses a guide pulley. The guide pulley comprises a pulley main body, the pulley main body is provided with three ring grooves in parallel, the center of the pulley main body is connected with a first pulley shaft, the first pulley shaft is connected with a second pulley shaft through a coupler, and the second pulley shaft is connected with a bevel wheel. The bevel wheel is connected with the pulley main body and drives the pulley main body to rotate to transmit ropes drivingly; the three grooves can accommodate three ropes and guarantee the three ropes to be provided with the same tensioning degree; meanwhile, the bevel wheel can be replaced by other driving mechanisms according to the needs to meets the structural requirements.

Owner:JIANGYIN DONGSHENG BUILDING MACHINERY

Method for compensating tension of elastane yarns of vertical elastane yarn warping machine

InactiveCN101906687BSame tensionThe specifications of the winding head are the sameWarping machinesOther manufacturing equipments/toolsHuman–machine interfaceMathematical model

The invention provides a method for compensating tension of elastane yarns of a vertical elastane yarn warping machine. In the method, the total length of the elastane yarns and the preset linear velocity of a creel roller are inputted through an human-machine interface; a programmable controller divides the current elastane yarn into 20 equal parts in accordance with the total length according to the setting of the human-machine interface so as to obtain 21 points; tension values of the 21 points are detected by a yarn tension detecting device, and the final tension values of the 21 points are saved by the programmable controller, and a compensation curve is drawn; the length of the current elastane yarn is detected by an encoder, and the programmable controller calculates a compensationvalue of the elastane yarn corresponding to the current length according to a mathematical model; and the programmable controller can calculate the linear velocity of the creel roller of the current length according to the compensation value of the elastane yarn corresponding to the current length, which is calculated in the step d, and regulates the linear velocity of the creel roller so as to regulate the tension of the elastane yarn. The method can ensure stable warping quality for the elastane yarn under a condition of large variation of temperature and humidity.

Owner:CHANGZHOU DIBA TEXTILE MACHINERY

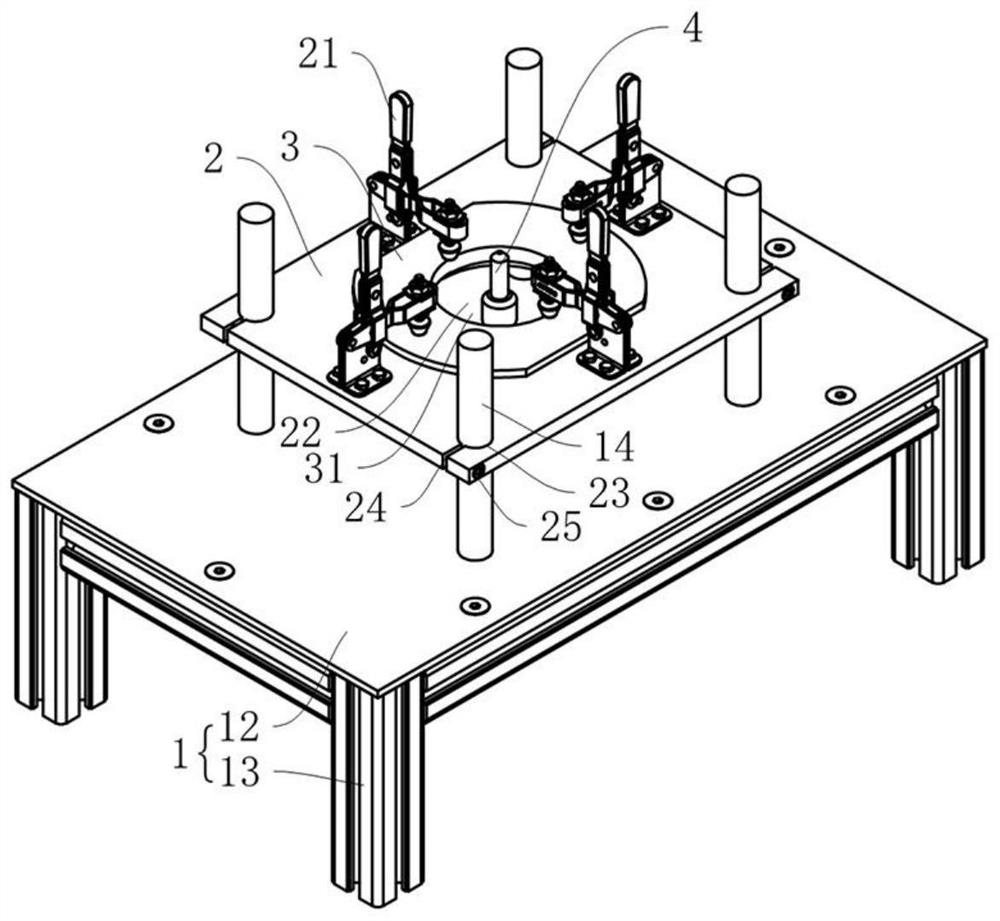

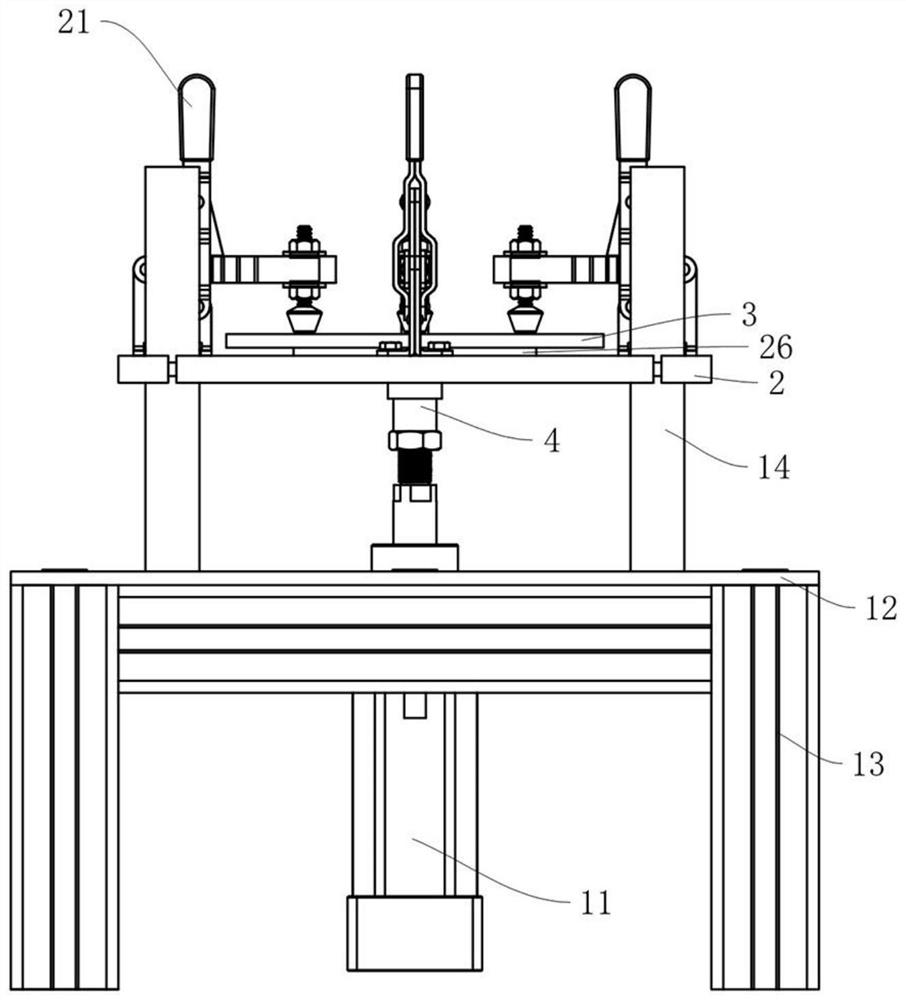

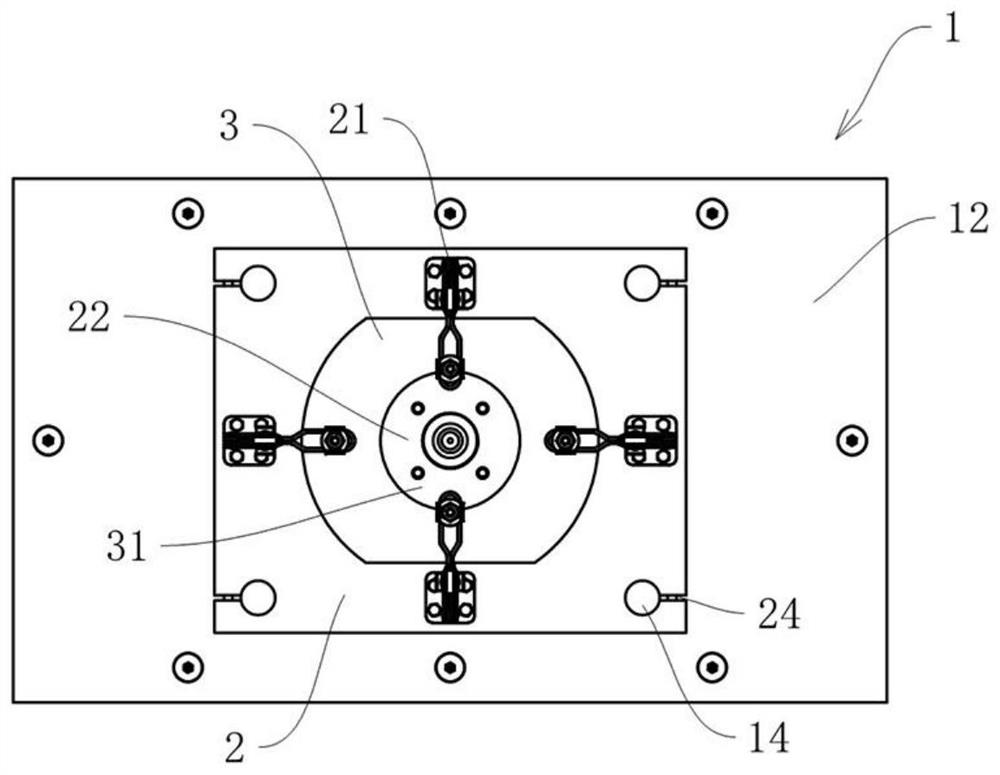

Synthetic leather whitening detection equipment and use method thereof

PendingCN113820320AReduce human errorAchieve standardizationOptically investigating flaws/contaminationWorkbenchMaterials science

The invention relates to the field of leather detection equipment, in particular to synthetic leather whitening detection equipment and a use method thereof. The synthetic leather whitening detection equipment comprises a workbench and a bottom plate arranged on the workbench; the bottom plate is horizontally arranged, a pressing plate is arranged on the bottom plate and used for compacting synthetic leather placed on the bottom plate, and a plurality of quick clamps are further arranged on the bottom plate and used for applying downward pressure to the pressing plate, so that the synthetic leather is firmly pressed on the bottom plate through the pressing plate. A jacking air cylinder is arranged at the bottom of the workbench, and a piston rod of the jacking air cylinder is provided with a detection cylinder for jacking the synthetic leather out of the protrusion. According to the invention, manual work is replaced by the pneumatic execution element and the rapid fixing clamp, manual errors are reduced, and detection results have high uniformity.

Owner:SEIREN SUZHOU CO LTD

Winding head of spinning machine

PendingCN111410088AEasy to control winding pitchGuarantee winding qualityFilament handlingYarnElectric machinery

The invention relates to a winding head of a spinning machine. The winding head comprises a box, a steering bar, a guide rod, a positioning rod and a winding drum. The winding drum comprises a rollingcylinder, a transverse moving cylinder, fixing sleeves, a rotary motor and a telescopic motor, wherein the rolling cylinder, the transverse moving cylinder and the fixing sleeves are in a hollow cylinder shape coaxially sleeved from inside to outside; one end of a rotary cylinder is rotationally connected with the box, the other end of the rotary cylinder extends out of the box, the transverse moving cylinder slidably sleeves the rolling cylinder in the length direction of the rolling cylinder, and the fixing sleeves slidably sleeve the transverse moving cylinder in the length direction of the transverse moving cylinder. The rotary motor is arranged in the box, a rotating shaft of the rotary motor is in transmission connection with the rolling cylinder, the telescopic motor is fixedly arranged in the rotary cylinder, and the end of a telescopic rod of the telescopic motor extends out of the circumferential side wall of the rotary cylinder and is fixedly connected with the transverse moving cylinder. The winding head aims to solve or at least alleviate the problem that the yarn winding distance and yarn winding tightness of an existing telescopic winding mechanism are not easy to control, and the winding head of the spinning machine is provided.

Owner:光山县群力化纤有限公司

An invisible anti-theft net

Owner:永春县产品质量检验所福建省香产品质量检验中心国家燃香类产品质量监督检验中心福建

Splicing apparatus on textile machine

The invention belongs to the technical field of textiles and relates to a splicing apparatus on a textile machine. The splicing apparatus comprises a mounting beam, a fastening seat, a horizontal bar,a bobbin holder, and a guide rack. The mounting beam is arranged above the feed end of the textile machine in a front-rear extension manner; the fastening seat is mounted on the mounting beam in front-rear moving manner and comprises a slide sleeve which sleeves a cross beam, and a fastening bolt bilaterally movably mounted at the left end of the slide sleeve; the right end of the fastening boltpenetrates the left wall of the slide sleeve and is abutted to the left end of the mounting beam; the right end of the mounting beam is abutted to the inner side of the right wall of the slide sleeve;the left end of the horizontal bar is fixed to the right end of the slide sleeve; the bobbin holder is mounted at the left end of the horizontal bar; the guide rack is mounted at the right end of thehorizontal bar. A broken yarn can be well added; yarn tension and equal normal textile yarns can be guaranteed, and spinning quality is guaranteed; during single weaving of double cloth, yarns of lowprice can be woven into edge cloth. The splicing apparatus is simple in structure, convenient to operate and widely applicable.

Owner:枝江市劳士德纺织有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com