Compensation method for steel wire rope synchronous compensation wheel of multi-rope winding type elevator

A technology of synchronous compensation and compensation method, which is applied in the direction of elevators, transportation and packaging, etc., can solve problems such as lifting container tilt, wire rope overload, etc., and achieve the effect of safe and reliable mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

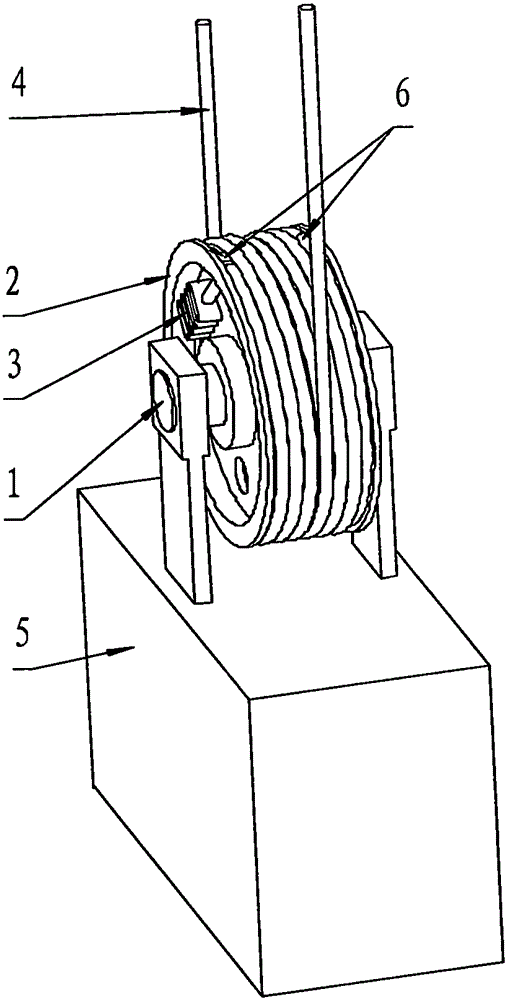

[0015] Two symmetrical wheel frame plates 7 are arranged in the upper middle part of the container 5, and the wheel body 2 is arranged between the two wheel frame plates 7. The center of the two wheel frame plates 7 and the wheel body 2 corresponds to a reserved hole, and the wheel shaft 1 is arranged in the hole; A steel wire rope 4 is set in the wheel groove of the wheel body 2, and rope holes 6 are reserved on both sides of the wheel groove; grippers 3 are set on the two side panels of the wheel body 2 corresponding to the rope hole 6, and the rope hole on both sides 6 and the gripper 3 are respectively provided with the rope ends of the steel wire rope 4; two steel wire ropes 4 are respectively arranged in the wheel groove, and the two steel wire ropes 4 are oppositely wound to set at least three turns; when the two steel ropes 4 of the hoist are lifting the container 5, When the tension changes due to different lengths, the wheel body 2 and the wheel shaft 1 will rotate ar...

Embodiment 2

[0017] In the process of lifting the container 5, when the length of one steel wire rope 4 is shortened and the force is heavy, the length of the other steel wire rope 4 is lengthened and the force is lightened. Lengthen stressed and alleviate direction to rotate, make two steel wire ropes 4 balance stressed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com