Process for making backing electrode electret condenser type microphones

A condenser microphone and electret technology, applied in sensors, electrical components, etc., can solve the problems of poor stability, inability to improve the sensitivity of the microphone, affecting product performance, etc., and achieve the effect of ensuring repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] DETAILED DESCRIPTION OF THE INVENTION The present invention will be described in detail below with reference to the accompanying drawings.

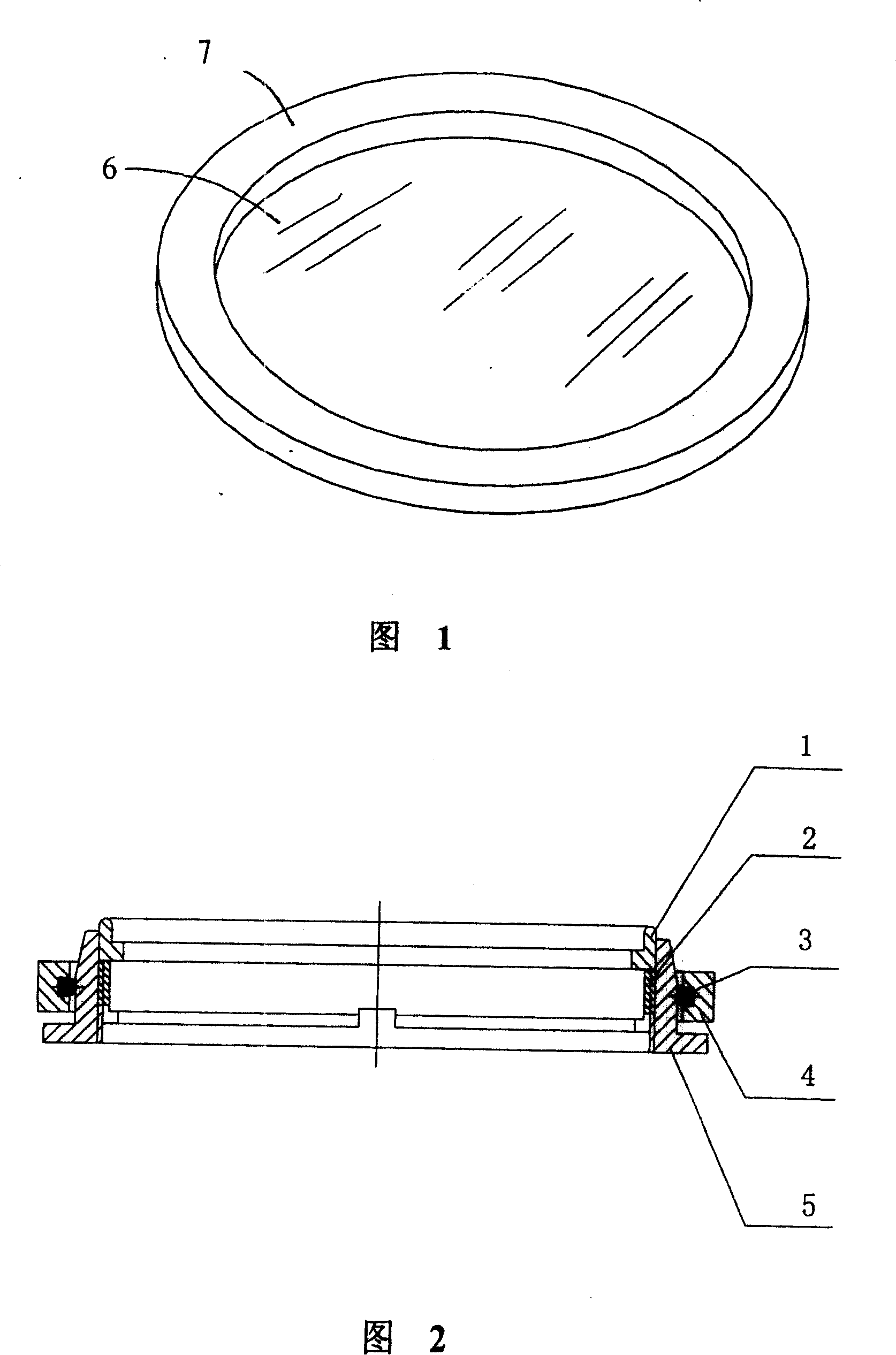

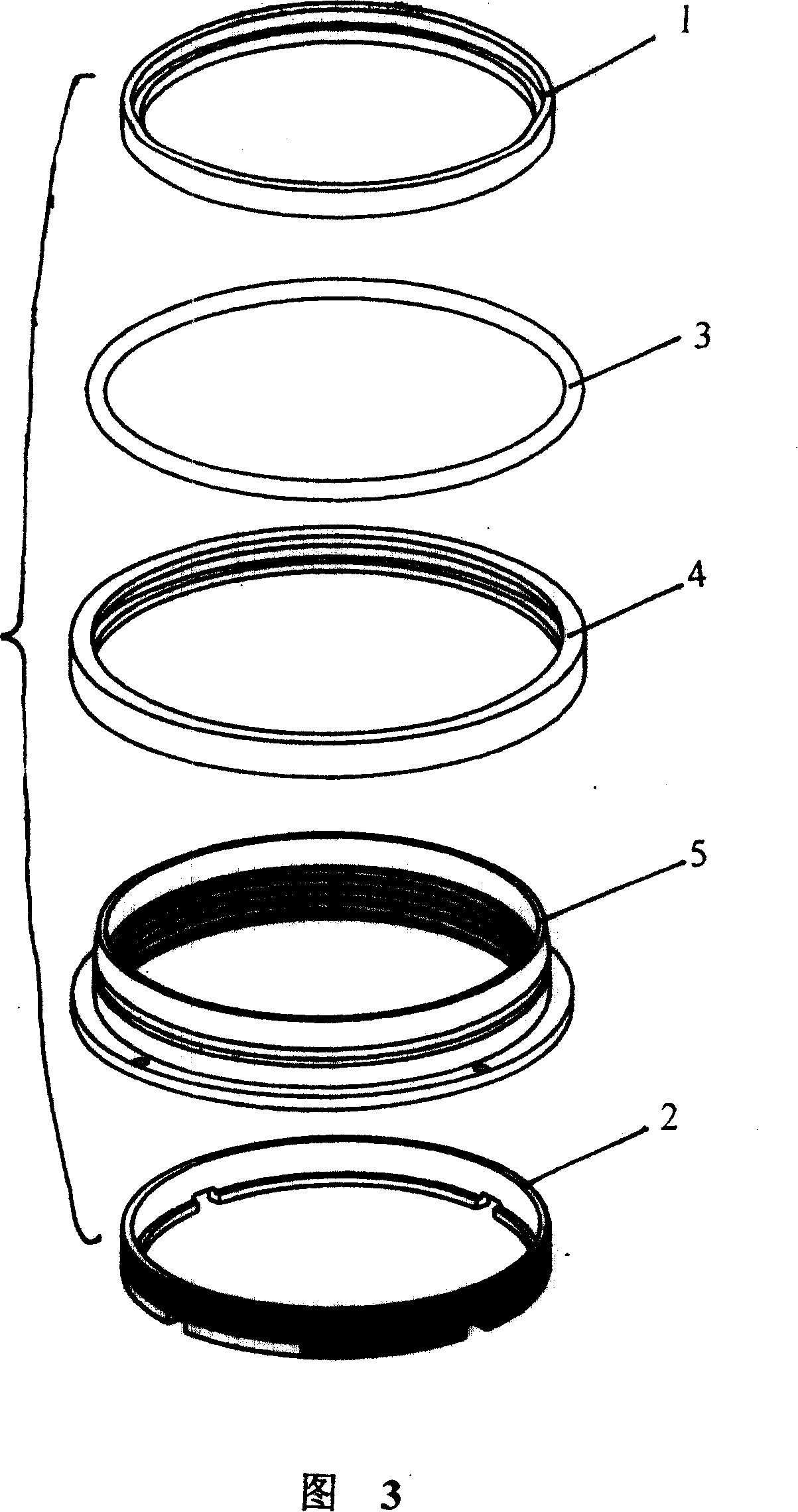

[0032] The back electret condenser microphone includes several core components: a diaphragm assembly (see Figure 1), a back plate covered with an electret film material, a gasket, and a PCB board with an impedance conversion circuit attached. The above components together with the back plate supporting device and the connecting device are packaged in a casing with a sound transmission hole.

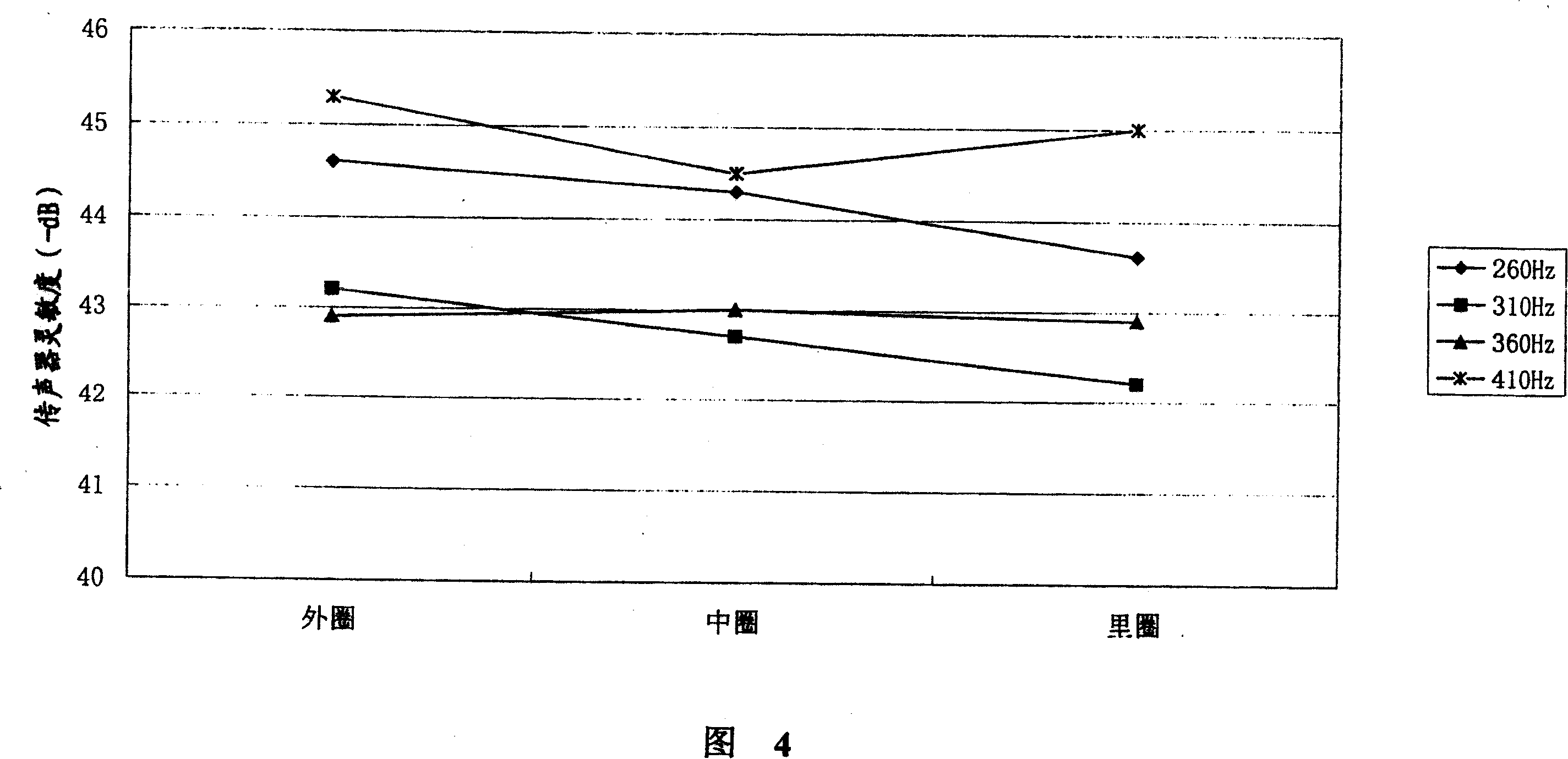

[0033] The electroacoustic performance indicators such as sensitivity, frequency response range and curve flatness of the back electret condenser microphone are mainly determined by the following factors: the surface charge density of the electret, the tension of the diaphragm, the diaphragm and the back plate The distance and performance of the impedance transformer that outputs the electrical signal of the microphone. In order to effectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com