A circuit board solder mask printing machine

A technology for circuit boards and printing machines, which is applied in the secondary treatment of printed circuits, coating of non-metallic protective layers, etc. It can solve the problems of wrong position of circuit board solder resistance, wrong position of screen printing traces, unqualified, etc., and achieve accurate The effect of improving the degree, increasing the friction, and ensuring the tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

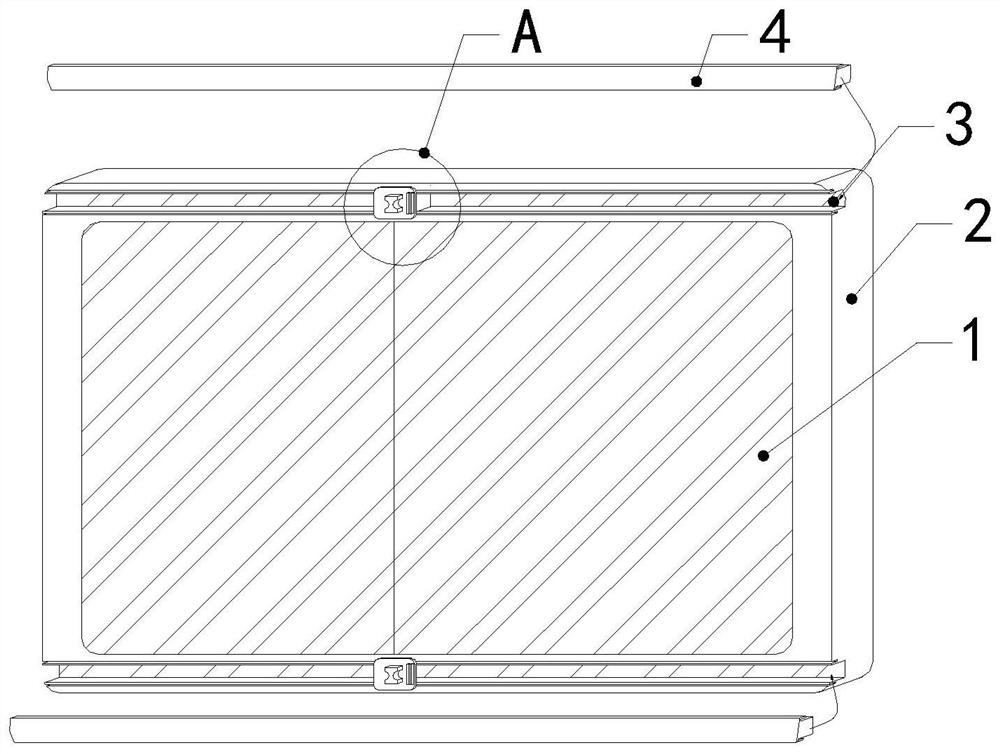

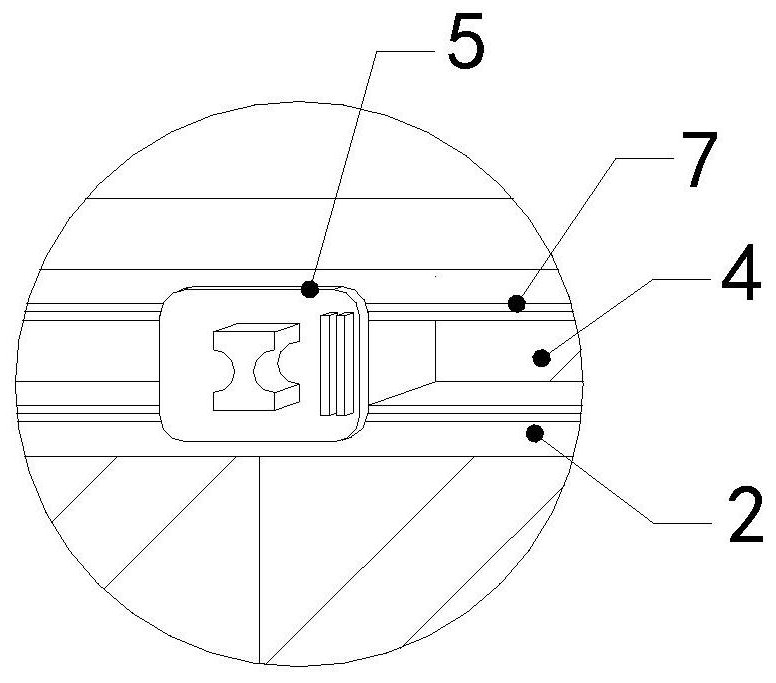

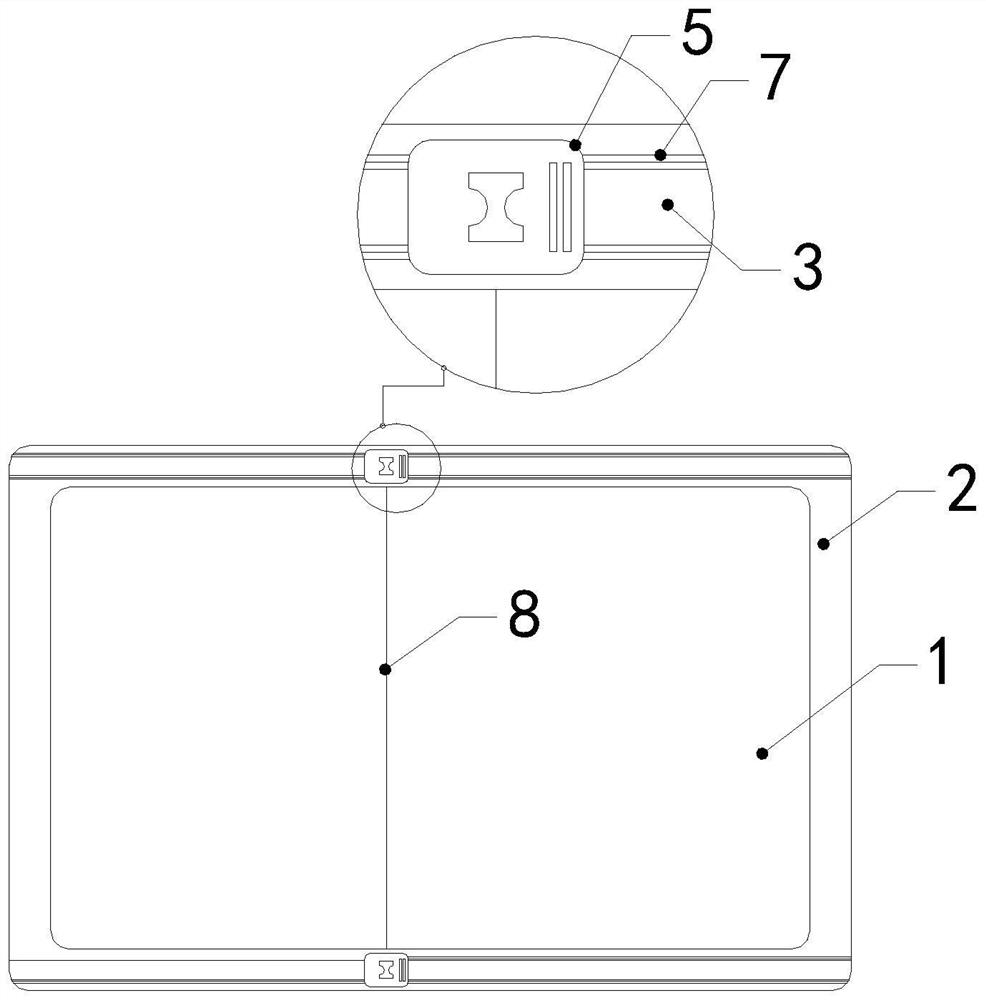

[0024] see Figure 1-Figure 5 , the present invention provides a circuit board solder resist printing machine, the structure of which consists of a body, a transmission device, a motor, an electromagnetic clutch, a reducer, a speed regulating mechanism, a screen printing frame, etc., and the structure of the screen printing frame includes a screen installation port 1, Frame body 2, pressing opening 3, embossing plate 4, and pressing slide block 5, the upper and lower sides of the frame body 2 are provided with mutually symmetrical pressing openings 3, and the pressing opening 3 is provided with a matching embossing plate 4 and a pressing slide block 5, the space in the middle of the frame body 2 is a screen installation opening 1, and the pressing slide block 5 matching therewith is installed in the pressing opening 3.

[0025] The pressing slider 5 is composed of a top plate 5-1, a sliding rod 5-2, and a bottom plate 5-3. The top plate 5-1 and the bottom plate 5-3 are vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com