Electronic Belt Scale Swing Type Belt Tensioner

An electronic belt scale and tensioning device technology, which is applied in measuring devices, transportation and packaging, instruments, etc., can solve the problems of excessive eccentric load, heavy equipment, heavy mechanism, etc., and achieve labor-saving tensioning and slack, saving the share Space, the effect of reducing manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

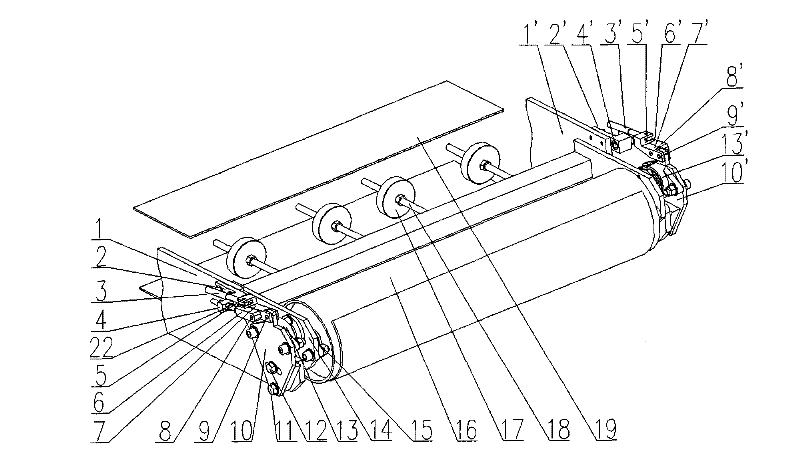

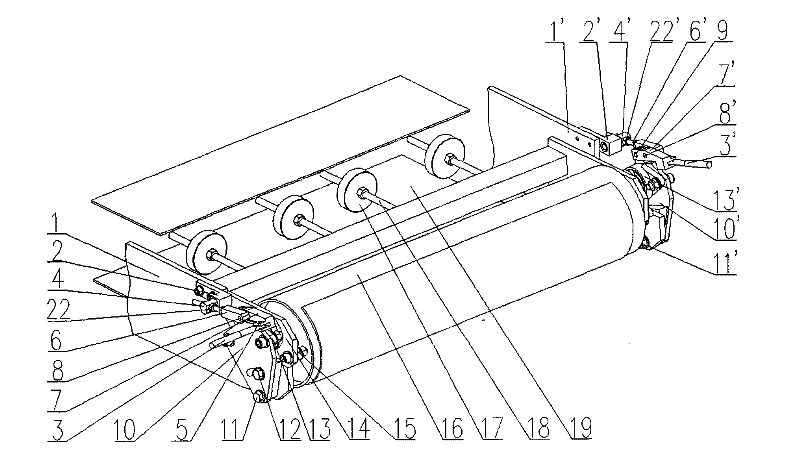

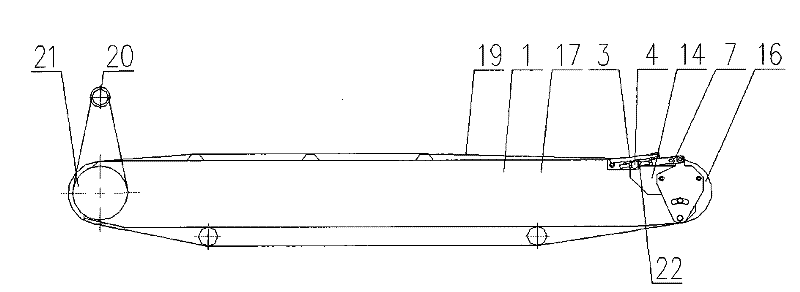

[0022] Such as figure 1 , figure 2 As shown, the present invention includes a tensioning frame 14 straddling the two ends of the driven roller 16 of the electronic belt scale and positioned between the upper and lower belts, the fuselage side panels 1, 1' symmetrically arranged on the two outer sides of the tensioning frame, and being installed on the machine. Linkages on the side panels. The connecting rod mechanism is composed of bases 2, 2', first connecting rods 6, 6', second connecting rods 7, 7', and deflection plates 10, 10' connected in sequence. The bases 2, 2' are fixed on the side panels of the fuselage. The first connecting rod 6,6' is hinged with the base 2,2' through the first rotating shaft 4,4', and the connecting section between the first connecting rod 6,6' and the base 2,2' is a screw rod, and the Adjusting nuts 22, 22' are installed, and the screw rod is inserted into the radial installation hole of the first rotating shaft. The second connecting rods ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com