Method for compensating tension of elastane yarns of vertical elastane yarn warping machine

A technology of yarn tension and compensation method, which is applied in the field of textile and weaving, can solve the problems of inconsistent and different specifications of the coiled head, affecting the quality of the cloth surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

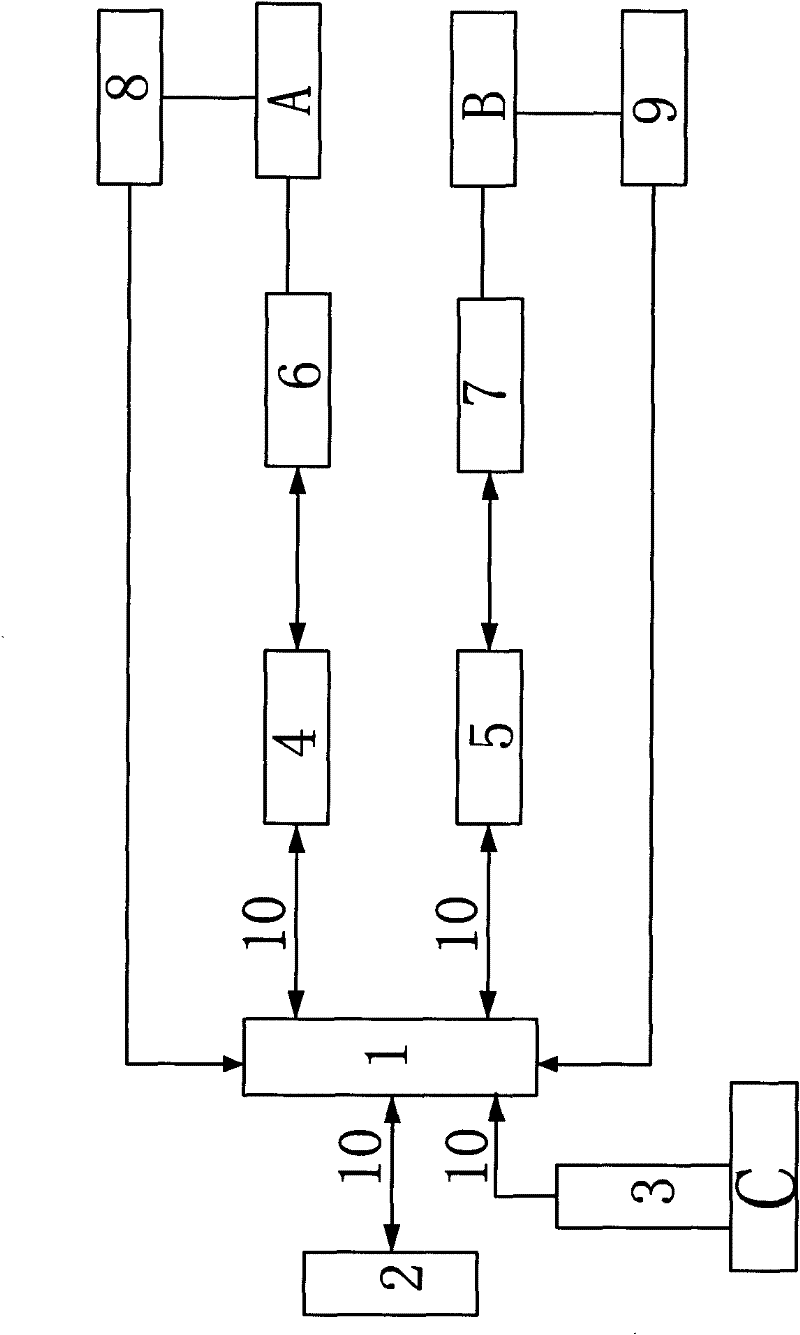

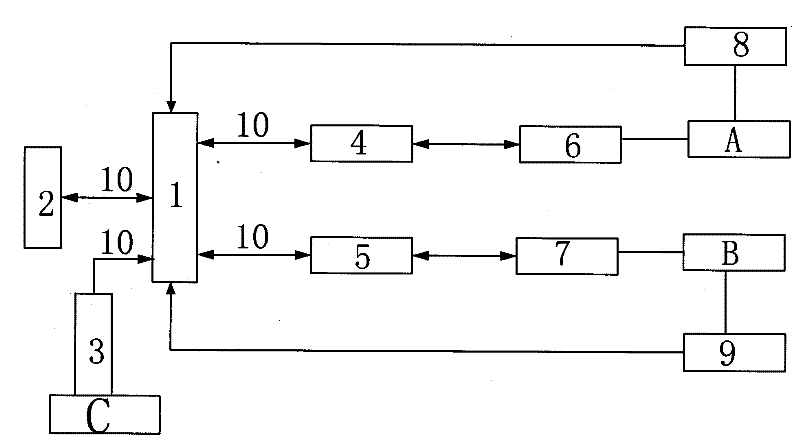

[0027] Such as figure 1 As shown, a vertical elastic yarn warping machine elastic yarn tension compensation method includes a programmable controller 1, a man-machine interface 2, a tension detection device 3, a first servo controller 4, and a second servo controller 5. The first servo motor 6, the second servo motor 7, the first encoder 8 and the second encoder 9, the human-machine interface 2 communicates with the programmable controller 1 through the bus 10, and the tension detection device 3 through the bus 10 Send a signal to the programmable controller 1. The first servo controller 4 and the second servo controller 5 communicate with the programmable controller 1 via the bus 10. The first servo controller 4 and the second servo controller 5 Drive the first servo motor 6 and the second servo motor 7, respectively, the first encoder 8 is set at the roller of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com