Tension detection device for textile fabric production

A tension detection and textile fabric technology, applied in thin material handling, transportation and packaging, winding strips, etc., can solve the problem of insufficient control and adjustment of tension, avoid yarn breakage, prevent fabric deviation, Use good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

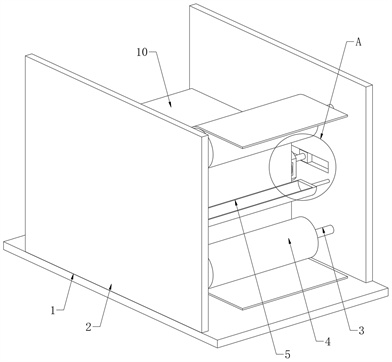

[0019] refer to figure 1 , a tension detection device for textile fabric production, comprising a base plate 1, two vertical plates 2 are vertically and fixedly connected symmetrically to the upper end surface of the base plate 1, and a fixed block 10 is fixedly connected horizontally between the two vertical plates 2, and the two vertical plates Between the boards 2, a stopper 9 is slid through a limit mechanism, and a detection mechanism that cooperates with the stopper 9 is provided in the fixed block 10, and a transmission mechanism that cooperates with the stopper 9 is provided between the two vertical plates 2. 9 is provided with a cooling mechanism.

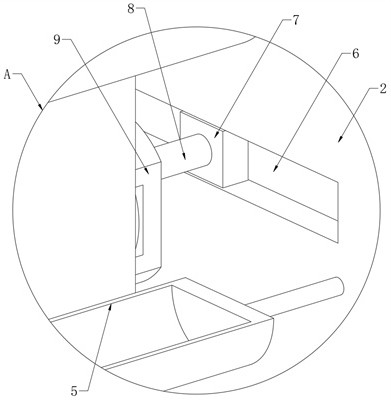

[0020] refer to figure 2 , the position-limiting mechanism comprises two chute 6s provided on the opposite sides of the vertical plates 2, each chute 6 is slidably connected with a slider 7, and each slider 7 is fixedly connected horizontally with the abutting block 9. Connecting rod 8.

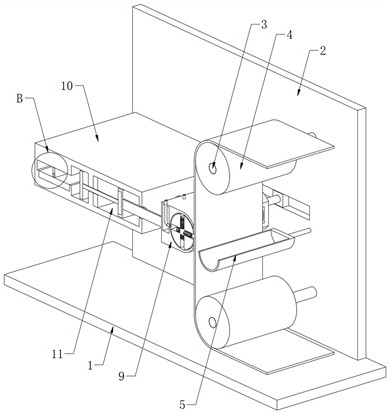

[0021] refer to image 3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com