Patents

Literature

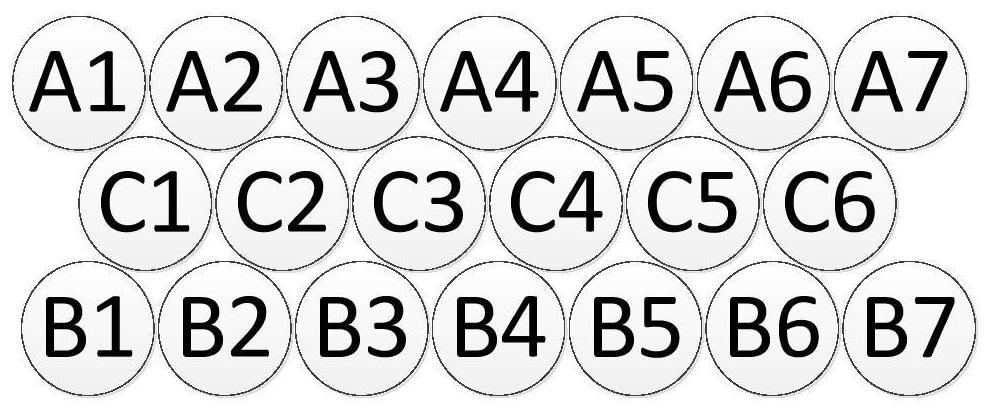

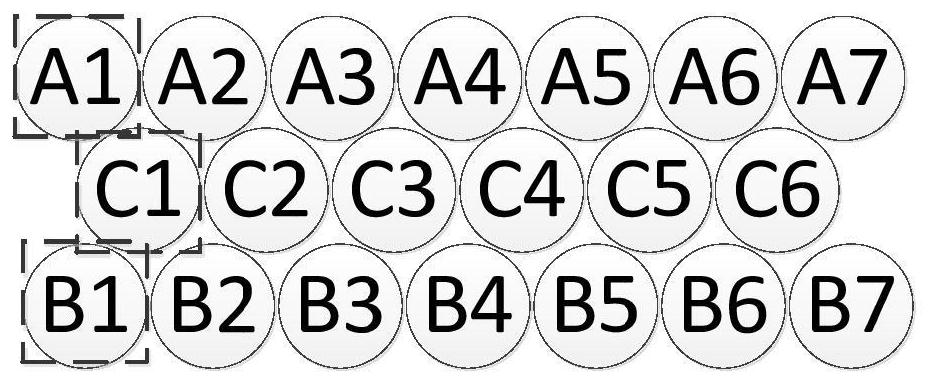

46results about How to "Overcome positioning error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

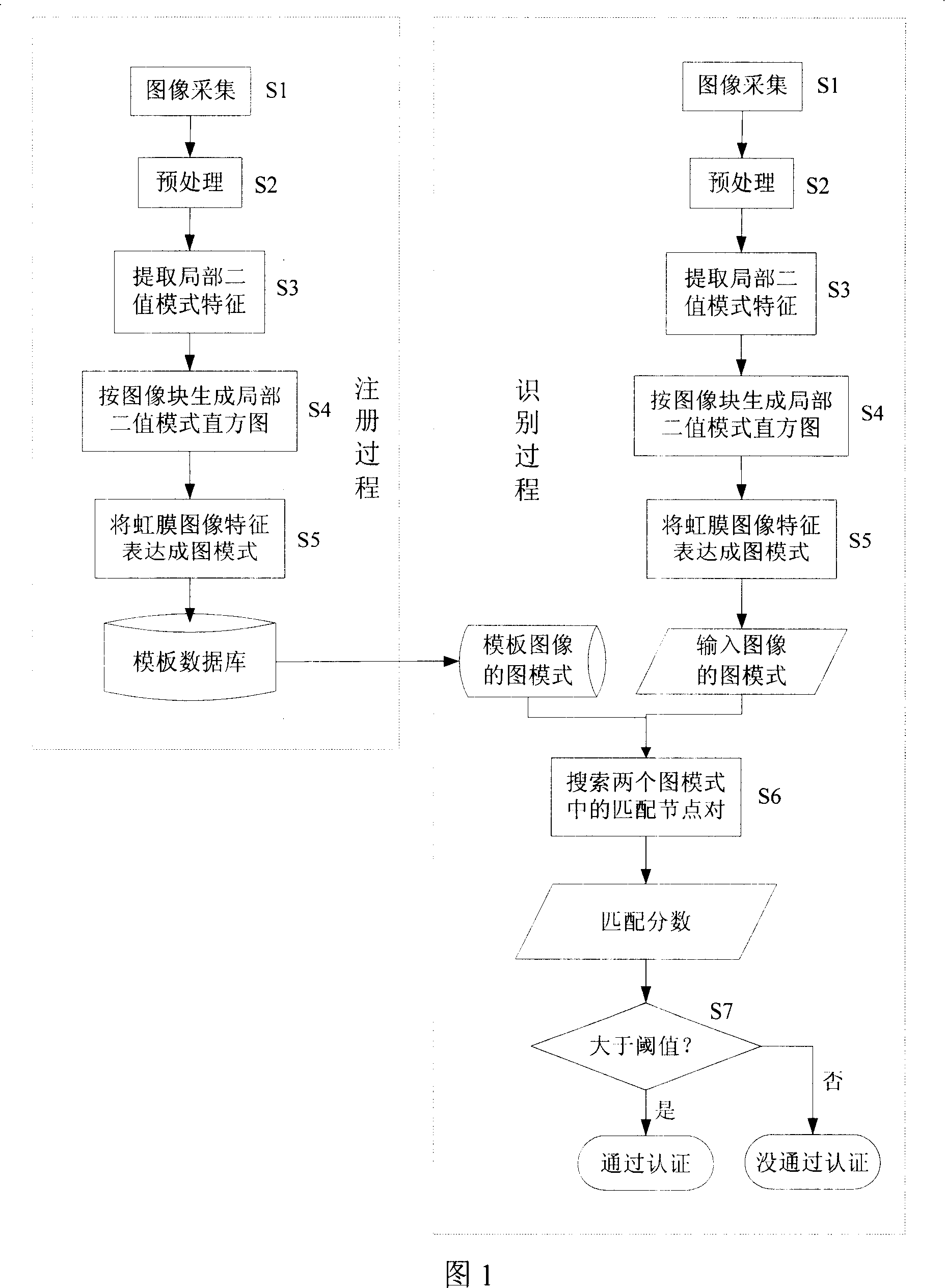

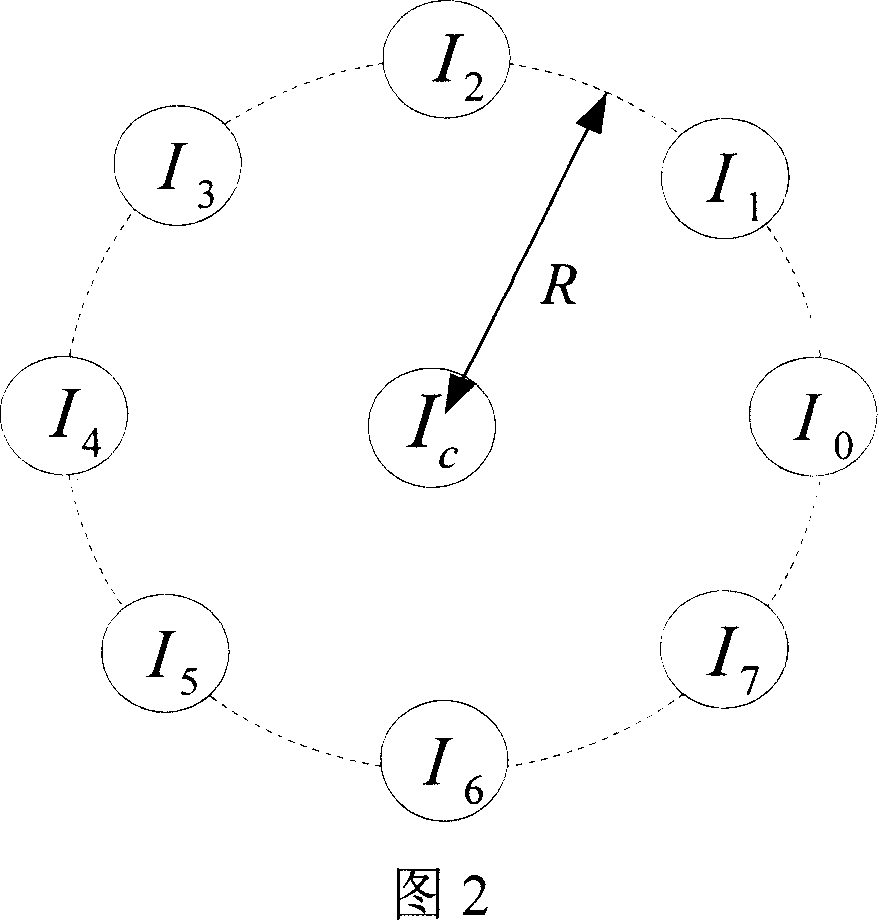

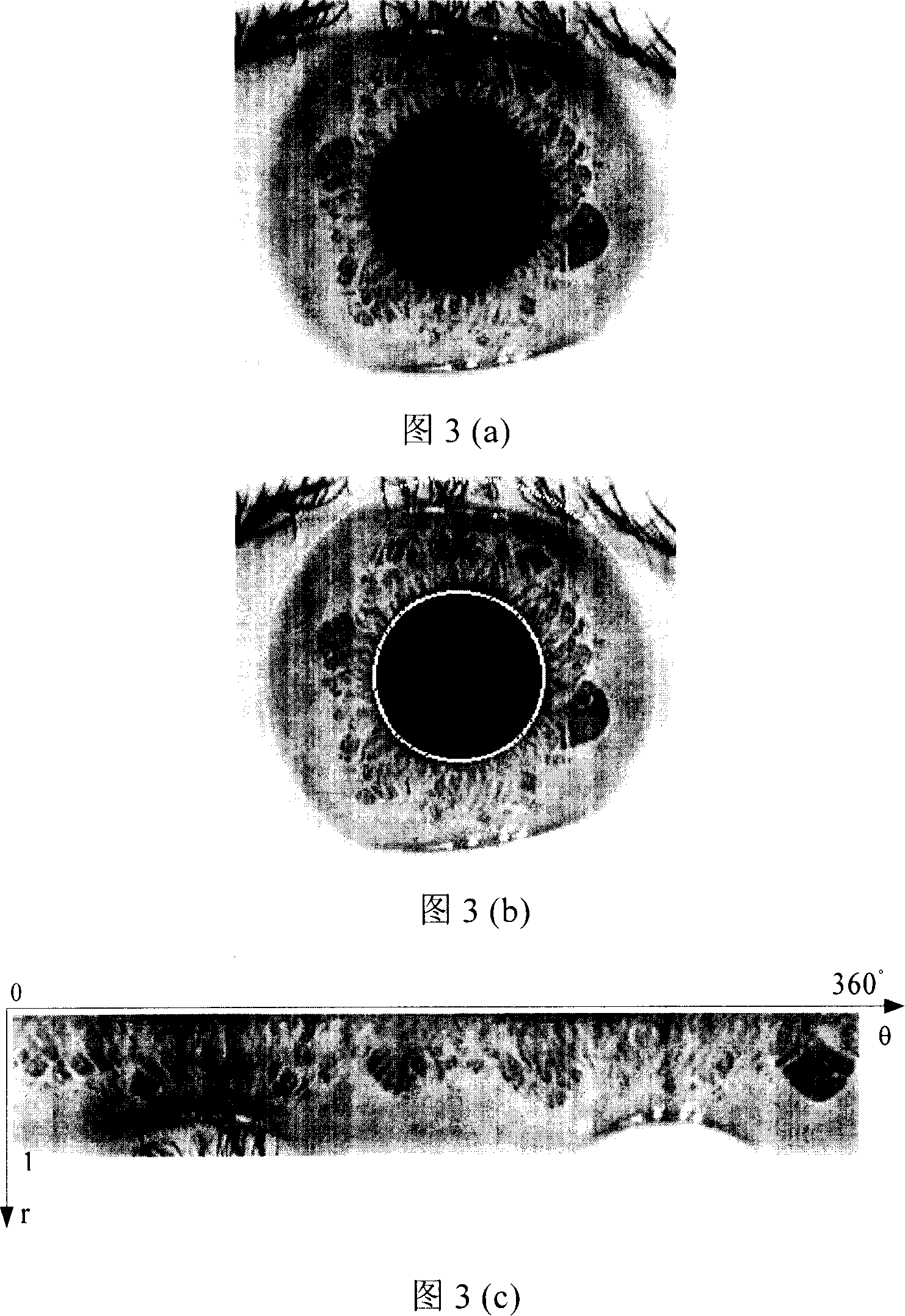

Method for recognizing iris with matched characteristic and graph based on partial bianry mode

InactiveCN101154265AImprove computing efficiencyMeet real-time requirementsCharacter and pattern recognitionLight irradiationIris image

The invention discloses an iris recognition method based on local two-value mode feature and graph matching. Firstly local two-value mode code is picked up according to the ordinal relation of each two pixel grey-scale values in an iris image neighborhood for describing the iris oriented texture feature having a constant characteristic under light irradiation; secondly the iris image is divided into a plurality of image pieces, and a local two-value mode histogram in each piece is calculated to describe the iris oriented texture statistical characterization having robustness on translation and deformation; each image piece is viewed as a node, the local two-value mode histogram in each piece is viewed as the attribute of the node, and the feature of each iris image is presented as a graph mode; during iris recognition, the graph matching method is used for searching matching node pairs in two graph modes; image recognition and registration of the number of the matching node pairs in the graph modes are carried out to show the similarity between the two graph mode, thereby judging the ID of a user. The invention is used for automatic identification in the application fields such as entrance guard, attendance check and clearance.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

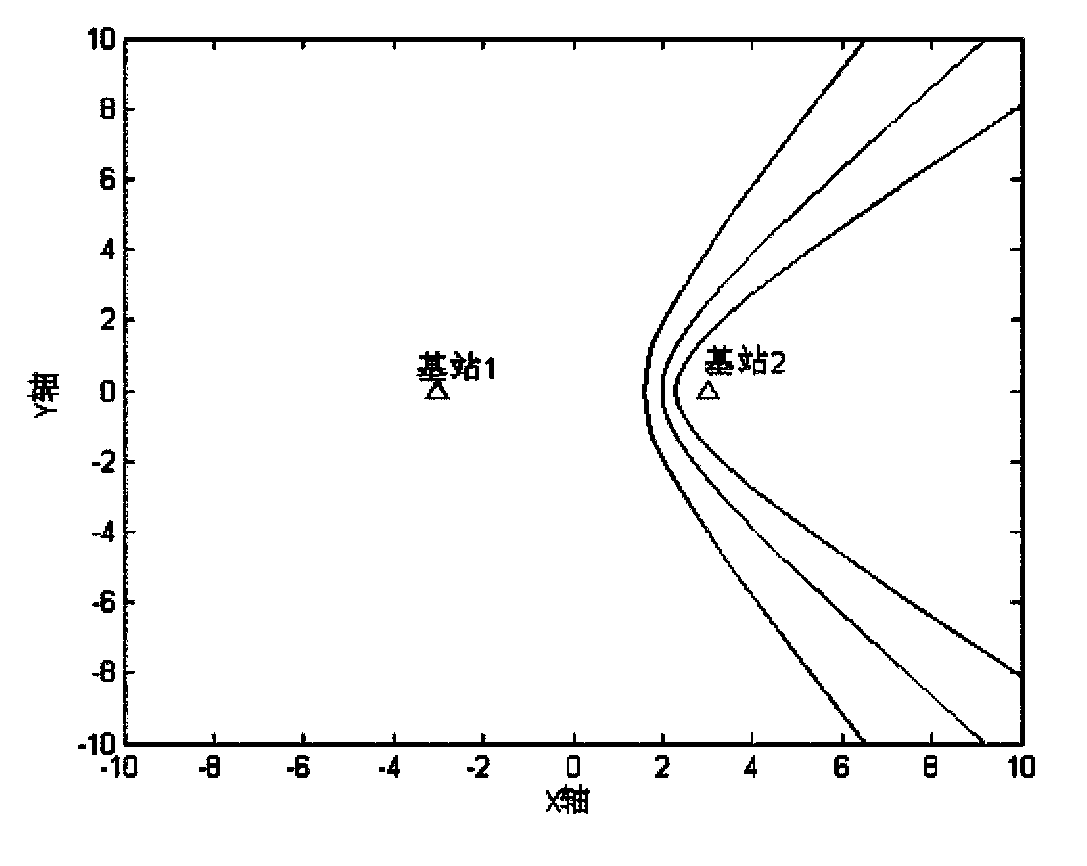

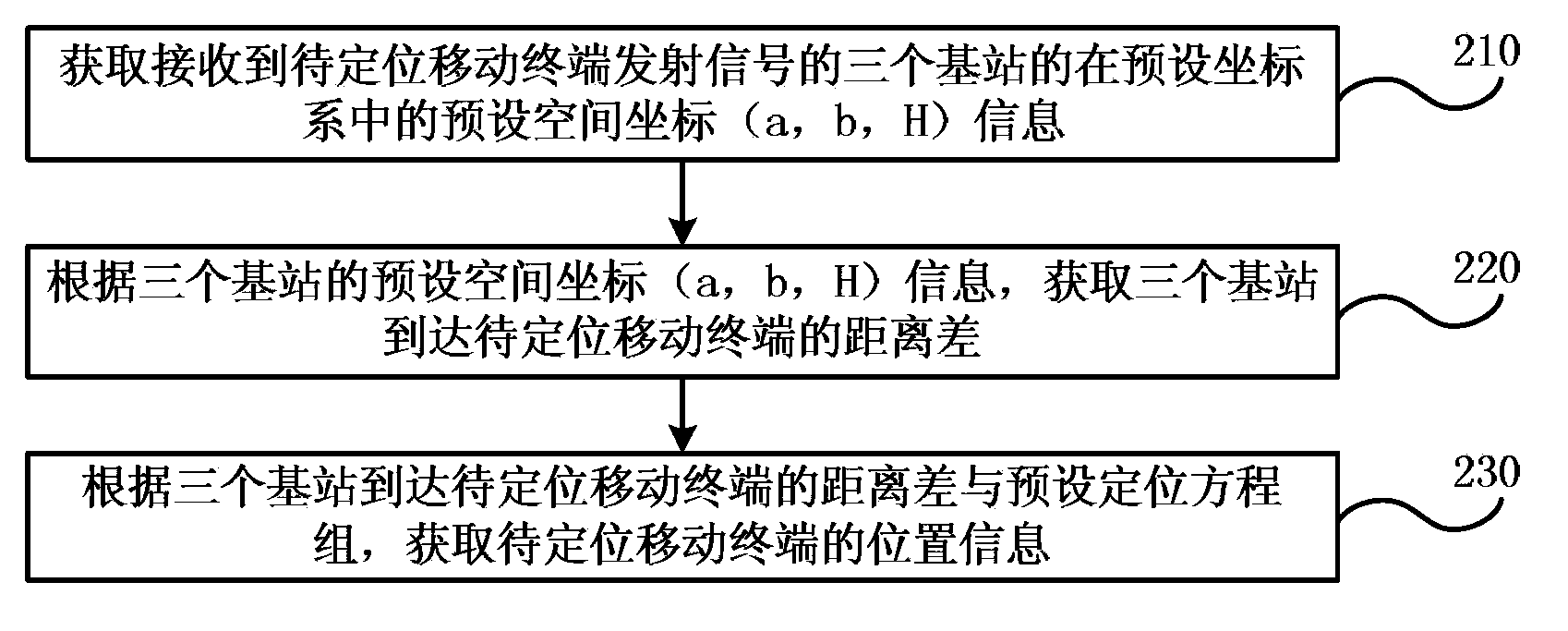

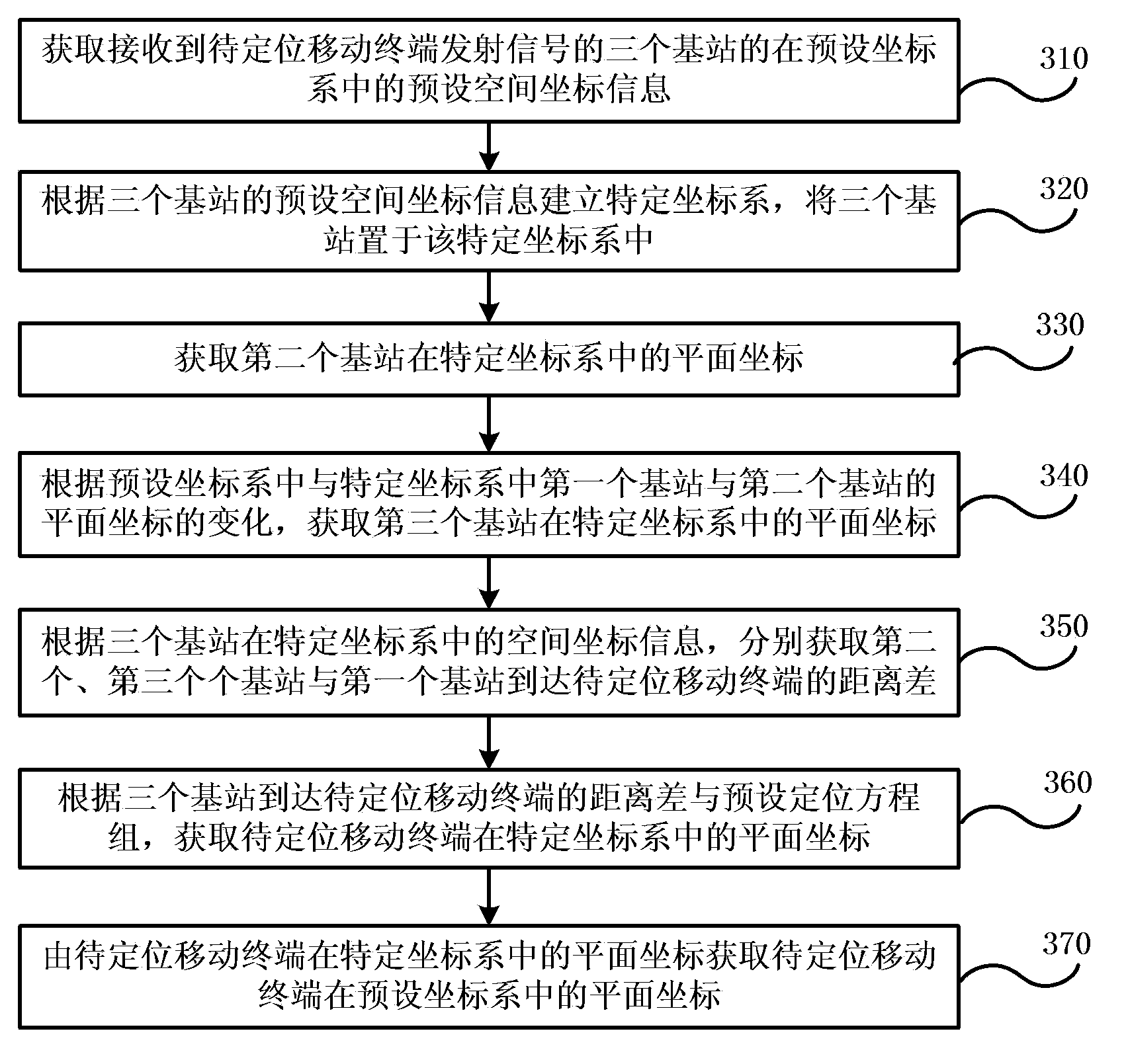

Three-point stereo base station positioning method and device

ActiveCN103857035AAccurate and precise positioningOvercome positioning errorWireless communicationTelecommunicationsPosition error

Owner:CHINA TELECOM CORP LTD

Method for detecting coaxiality and verticality of large container by optical instrument

ActiveCN101929852AEasy and fast measurementRealize autonomous measurementUsing optical meansOptical axisEngineering

The invention relates to a method for detecting coaxiality and verticality of a large container by an optical instrument. The large petrochemical containers have common characteristics such as complicated structure, large geometric dimension and high manufacturing precision requirement. The method for detecting coaxiality and verticality of the large container by the optical instrument comprises the two steps of: (1) establishing a datum axis line by using a micro-alignment telescope, mounting a triangular centre bracket at a measured seal head, and reading an offset value of the bracket centre relative to the datum axis line by a micro-drumwheel; and (2) arranging a verticality measuring scale at the end face of the measured seal head, enabling an auto-collimation image to be completely superposed with a local image with an auto-collimation method when a reflector or a large reflection object in front of the telescope is vertical to the principal optical axis of the telescope, if the auto-collimation image is not superposed with the local image, adjusting the included angle between the large reflection object and the principal optical axis of the telescope to enable the auto-collimation image to be completely superposed with the local image, and computing the value of the verticality by using the scale value of a displacement graticule on the telescope and the read value of the micro-drumwheel. The invention is used for detecting the coaxiality and the verticality of the large container.

Owner:HARBIN BOILER

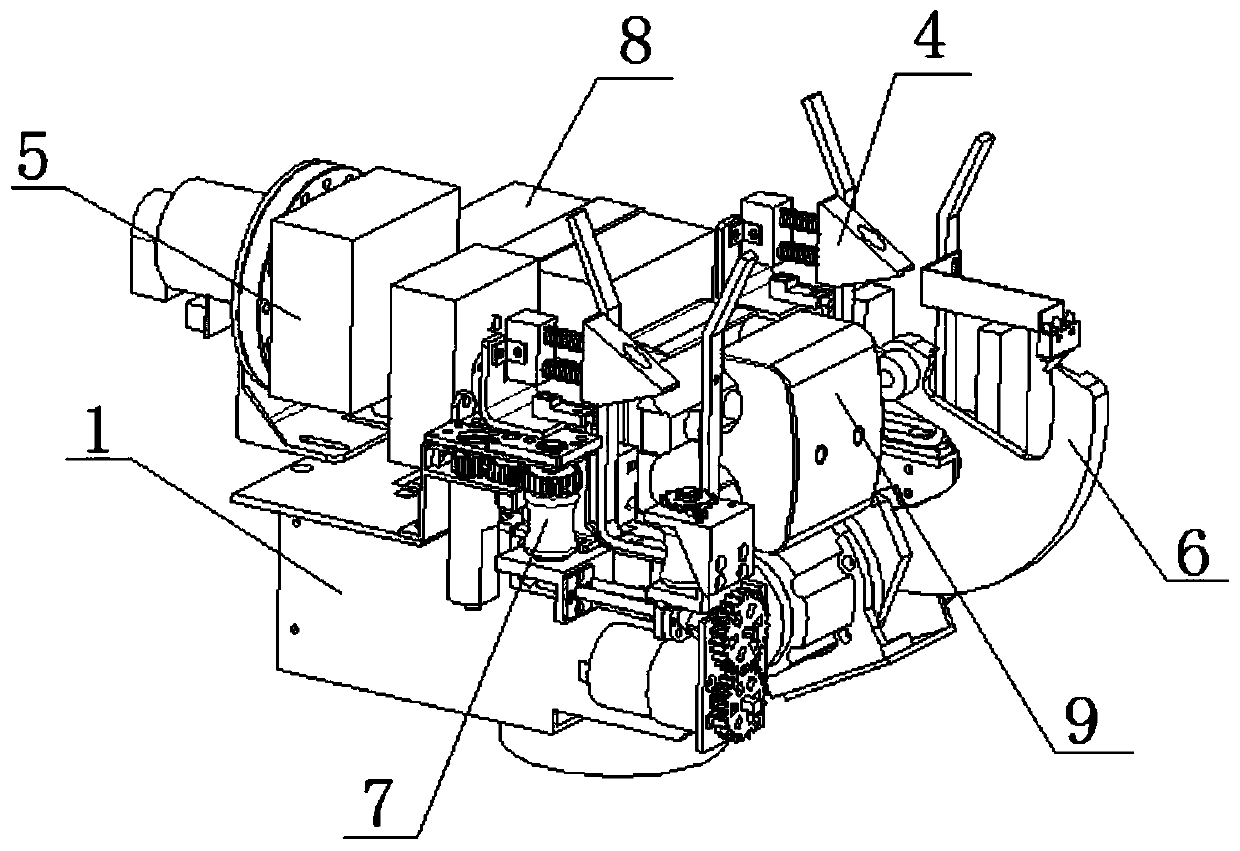

Special tool for 10KV circuit live-wire work robot drainage wire connecting work

ActiveCN110021898AAvoid clutterBeautiful lengthApparatus for cutting/splicing cablesApparatus for joining/termination cablesEngineeringElectrical and Electronics engineering

The invention discloses a special tool for 10KV circuit live-wire work robot drainage wire connecting work. The special tool comprises a cable stretch-in end and a cable stretch-out end, wherein a puncture cable clamp is positioned between the cable stretch-in end and the cable stretch-out end. The special tool comprises a substrate, and is characterized by comprising a drainage wire shearing mechanism installed on the substrate, wherein the drain wire shearing mechanism comprises an electric cutter; and the electric cutter is positioned at the cable stretch-out end. According to the special tool, robot live-wire wiring work can be realized, manual live-wire wiring work also can be realized, and the special tool has the function of shearing unnecessary drainage wires.

Owner:山东乐普韦尔自动化技术有限公司

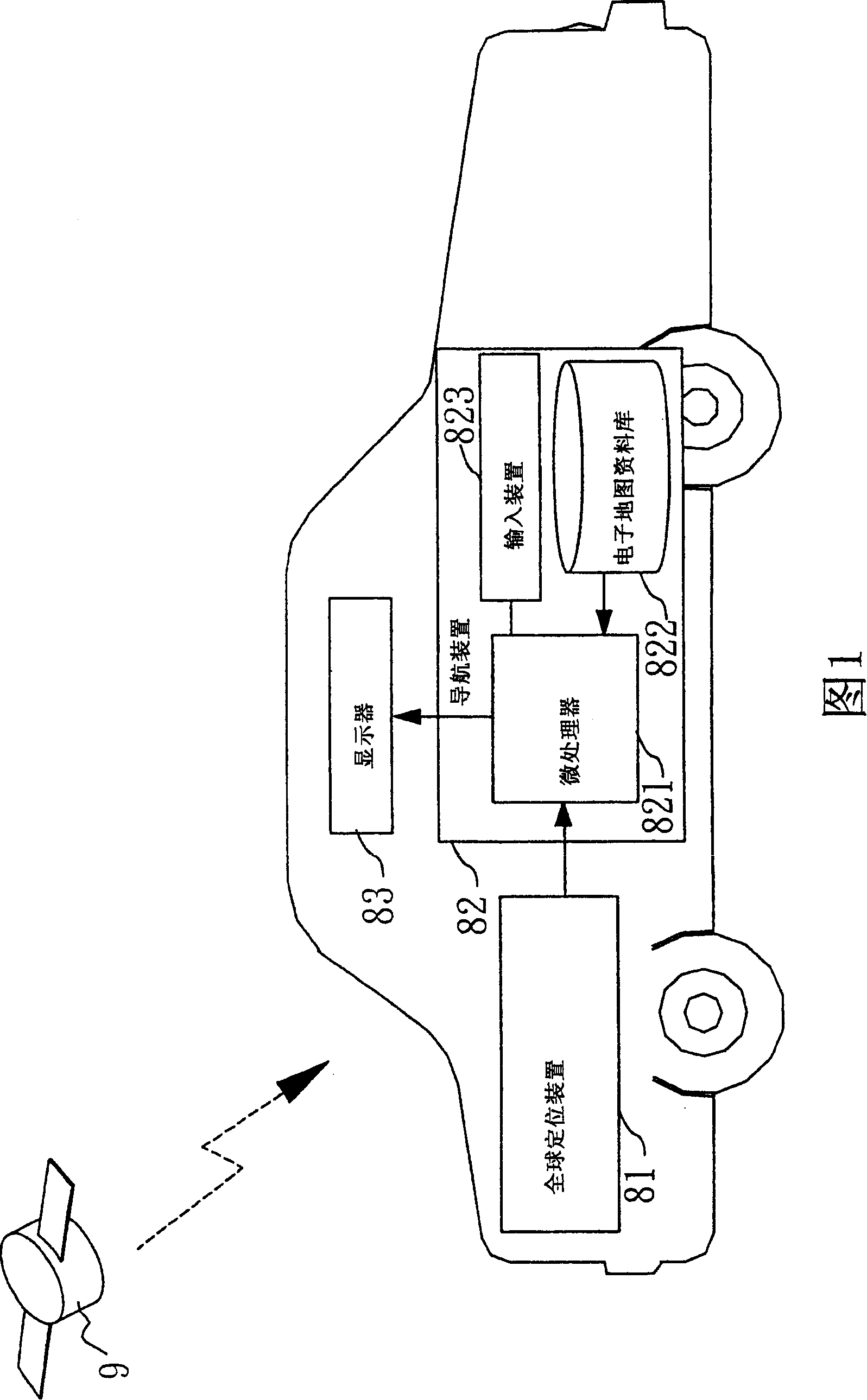

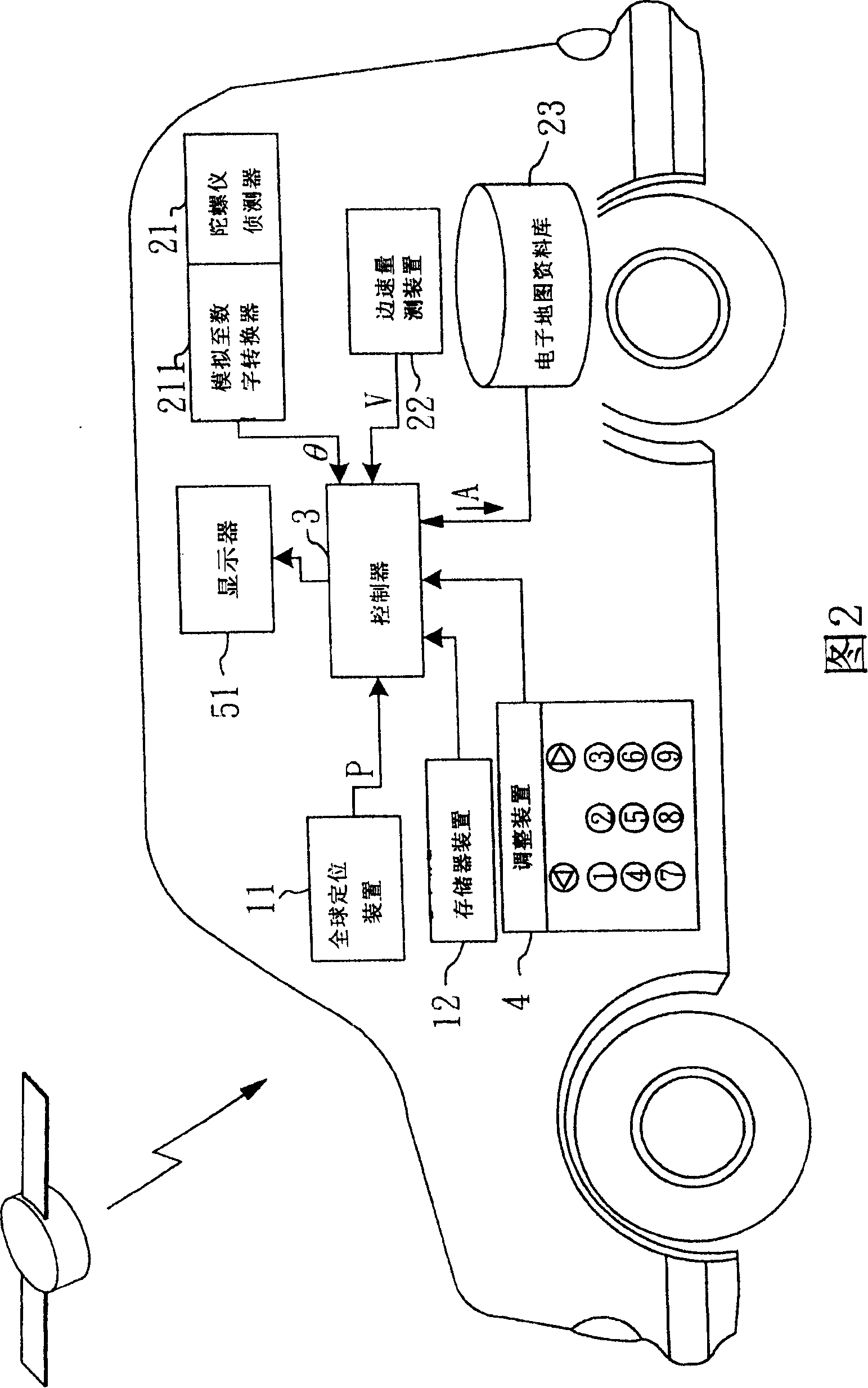

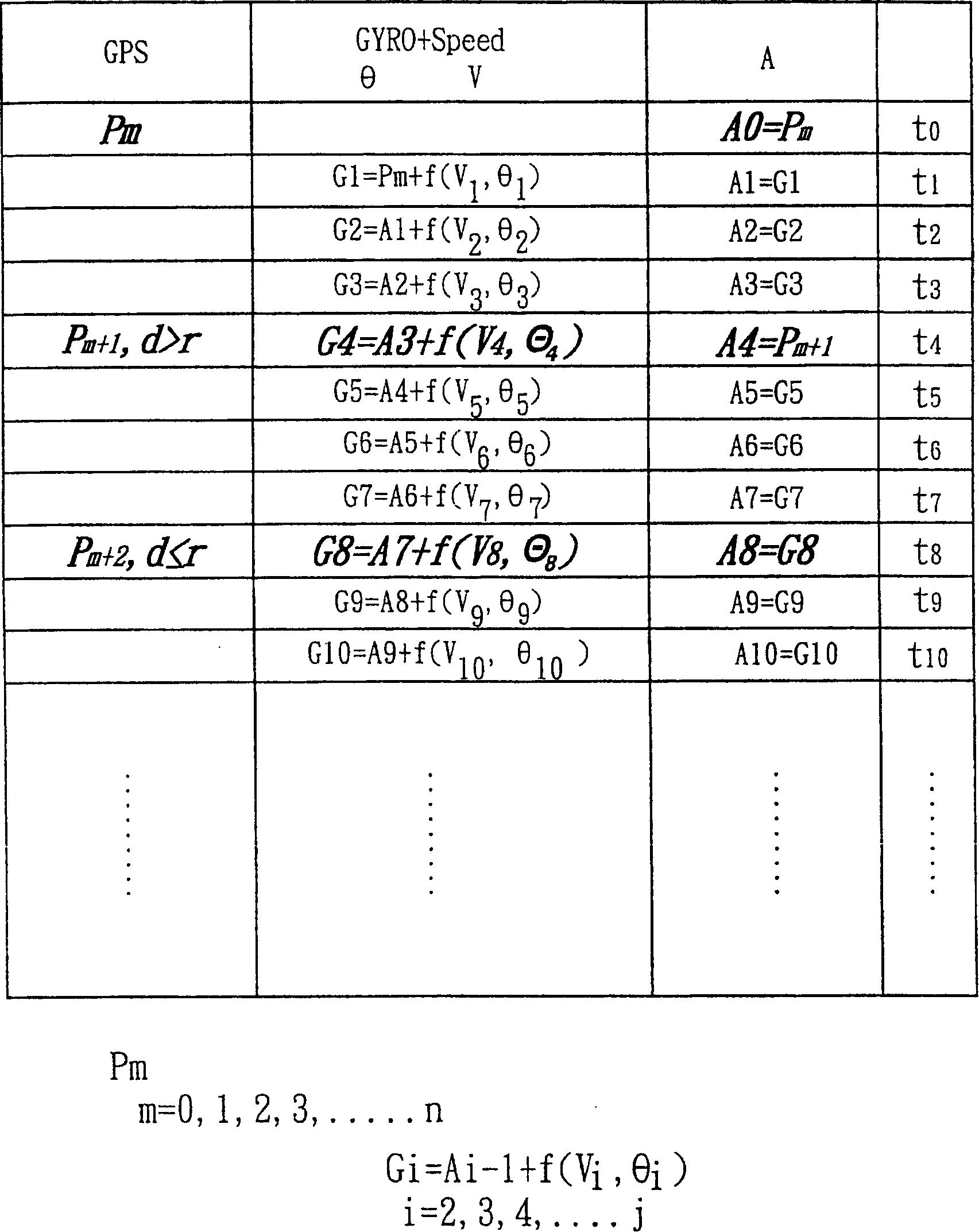

Accurate positioning system and method for vehicle

InactiveCN101173860AAccurate locationOvercome positioning errorInstruments for road network navigationNavigational calculation instrumentsGyroscopePositioning system

The invention relates to an accurate vehicle positioning system and the method thereof, being assembled and used on a vehicle, which comprises a global positioning device, a gyroscope detector, a speed measuring device and a controller. When the global positioning device outputs the next global positioning coordinate, the controller calculates the next reference position coordinate according to the gyroscope detector and the speed measuring device of the vehicle, and calculates the spacing distance between the next global positioning coordinate and the next reference position coordinate, therefore when the spacing distance is larger than a specific distance, the controller designates the next global positioning coordinate as the next accurate position coordinate and outputs the coordinate; contrarily, the controller designates the next reference position coordinate as the next accurate position coordinate and outputs the coordinate.

Owner:XINGYI SCI & TECH

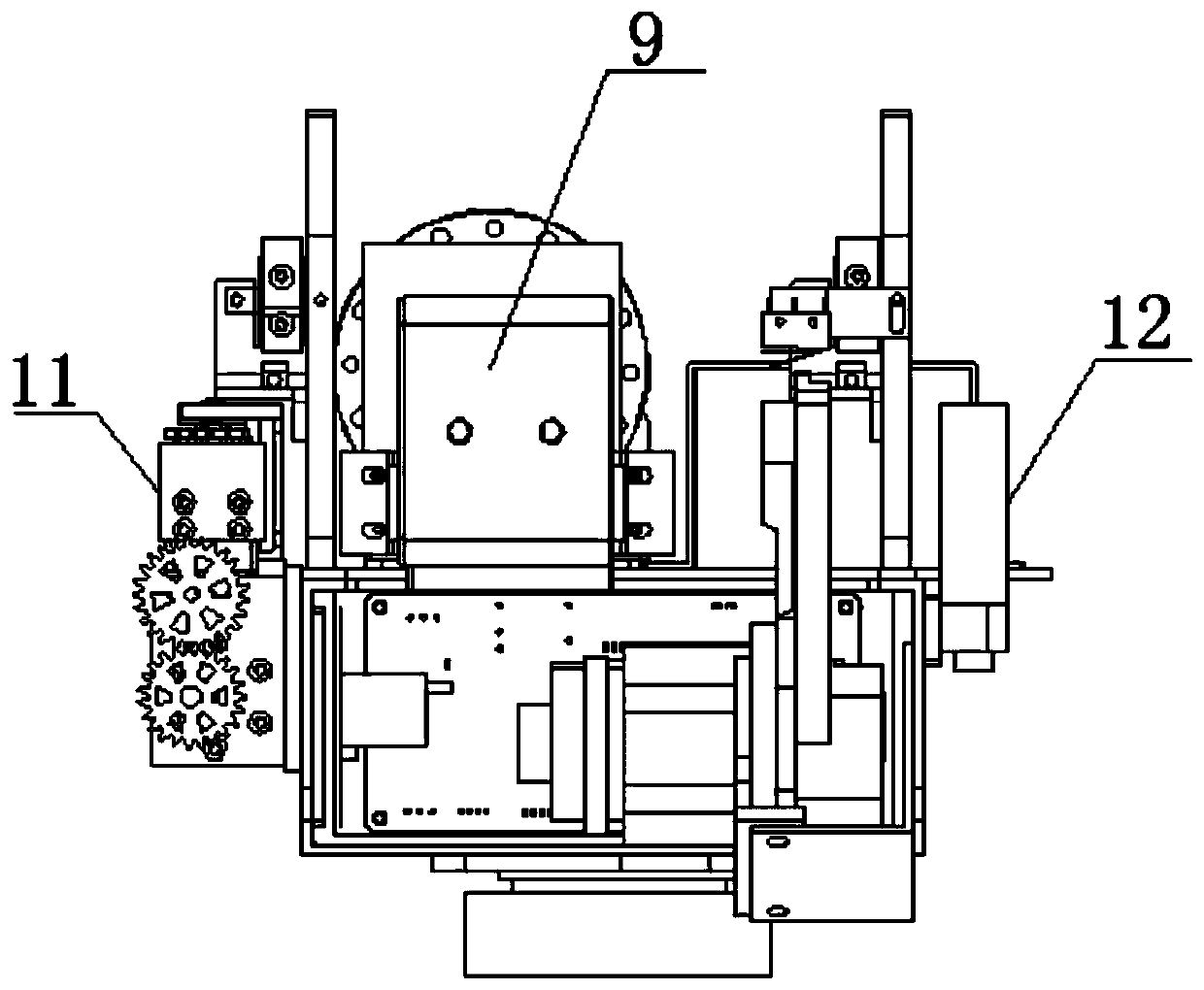

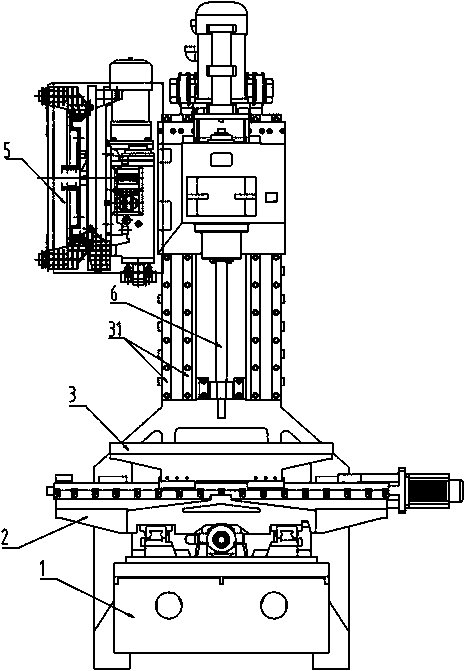

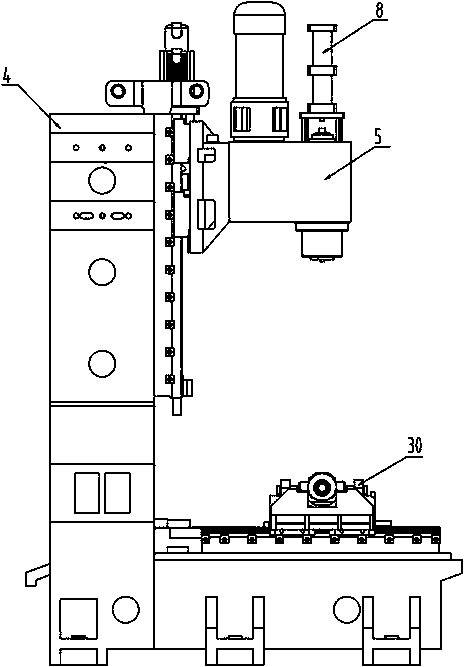

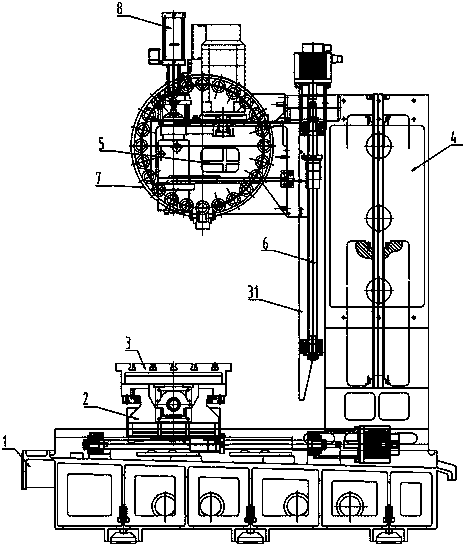

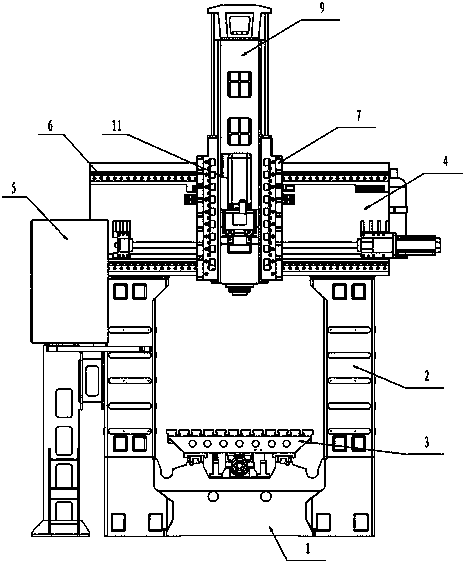

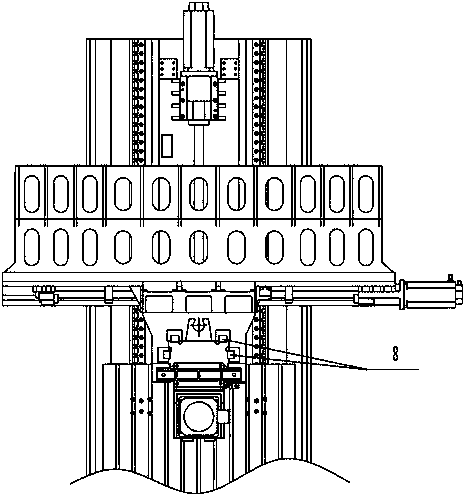

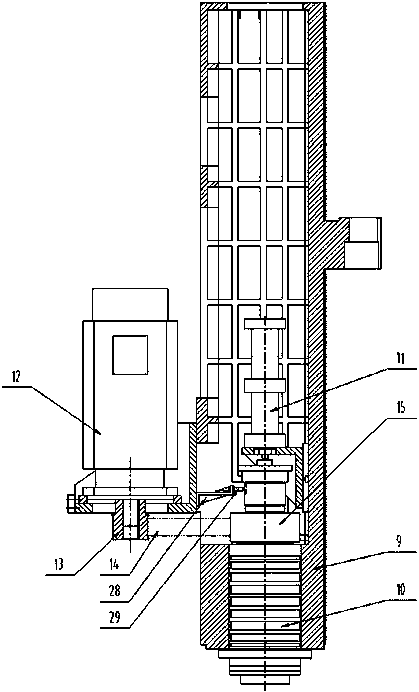

High-rigidity large-torque vertical machining center

InactiveCN103358185AImprove rigidityImprove efficiencyLarge fixed membersDriving apparatusFailure rateBall screw

The invention relates to a vertical machining center, in particular to a high-rigidity large-torque vertical machining center. The machining center mainly solves the technical problems that high-grade and low-grade reduction boxes are high in price, high speed gears operate in ultimate states, the failure rate is high, the use and maintenance costs are high, the machining requirements of other reduction ratios such as 1:2 / 1:3 cannot be met, the rigidity of a spindle is poor, and the tool changing failure frequency is high in vertical machining in the prior art. The machining center comprises a honeycomb type bed, wherein a double-layer ribbed carriage and a workbench are arranged on the honeycomb type bed; a herringbone frame upright is also arranged on the bed and connected with a spindle box by a guide rail in a sliding manner; a ball screw is arranged on the herringbone frame upright; the spindle box is in threaded connection with the ball screw; a tool magazine and an unclamping cylinder is arranged on the spindle box; the spindle box is internally provided with a 1:2 / 1:4 / 1:8 speed reducer; a spindle location device is arranged on a spindle of the spindle box; and the vertical machining center is provided with an electric and numerical control system.

Owner:HANGZHOU DATIAN CNC MACHINE TOOL

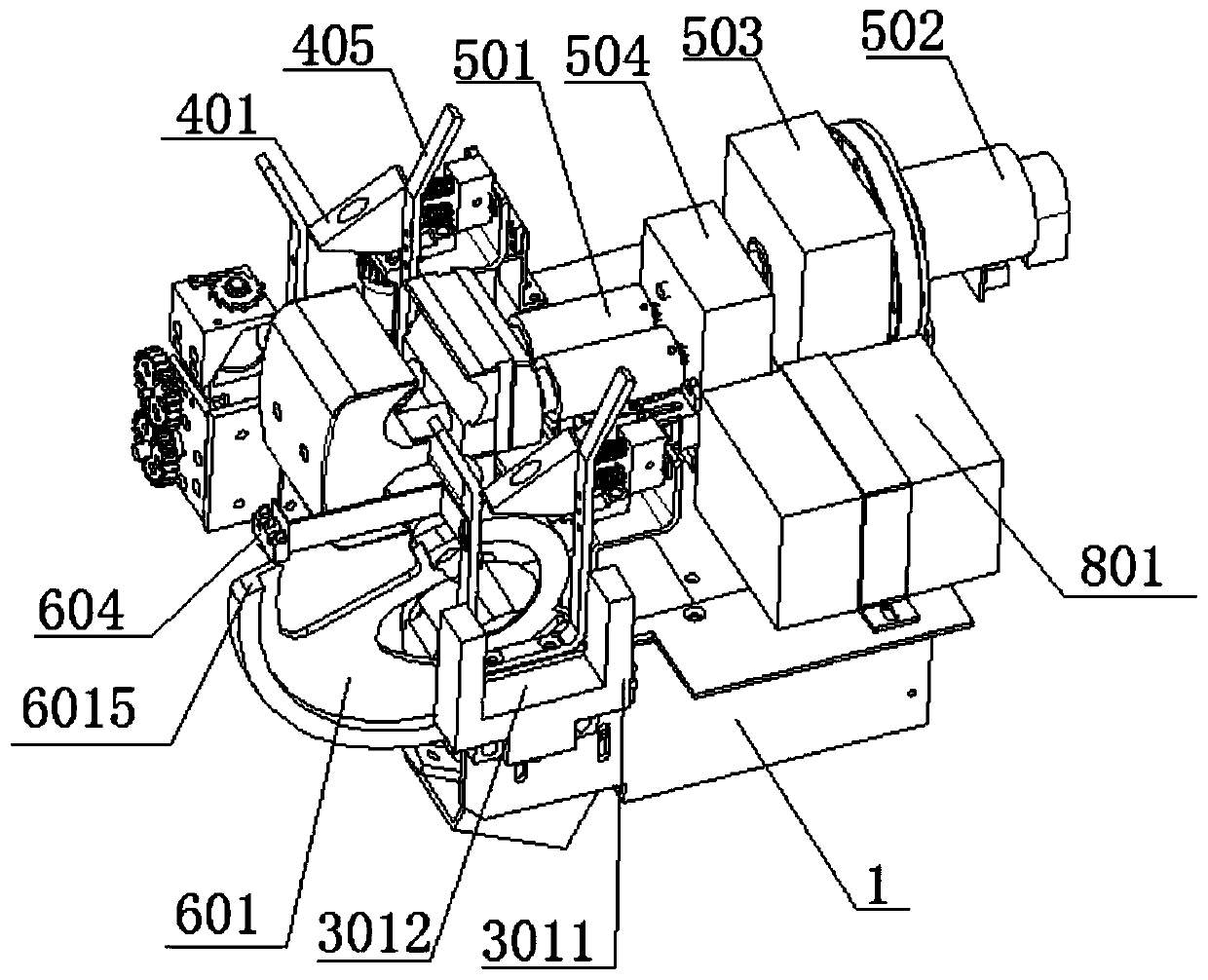

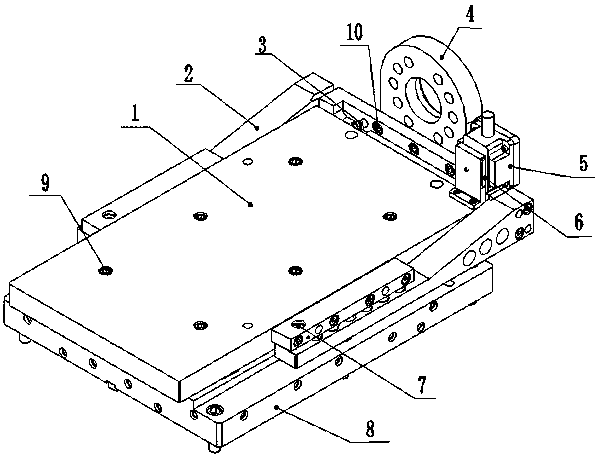

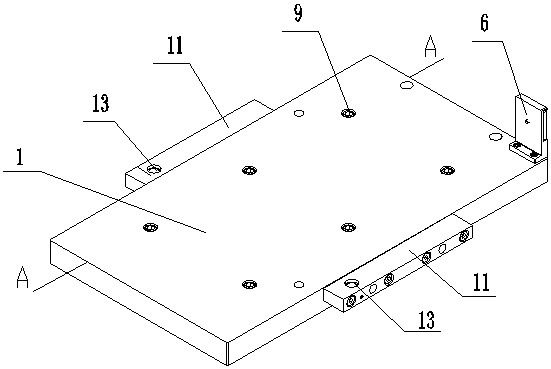

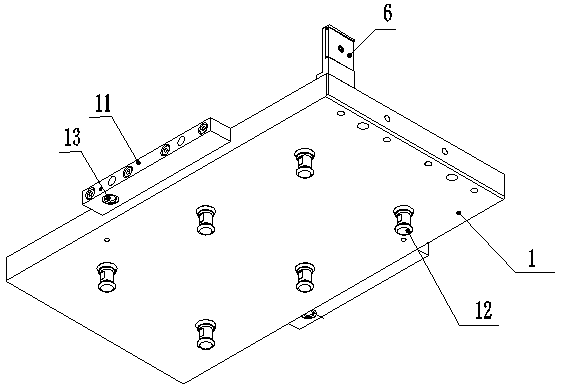

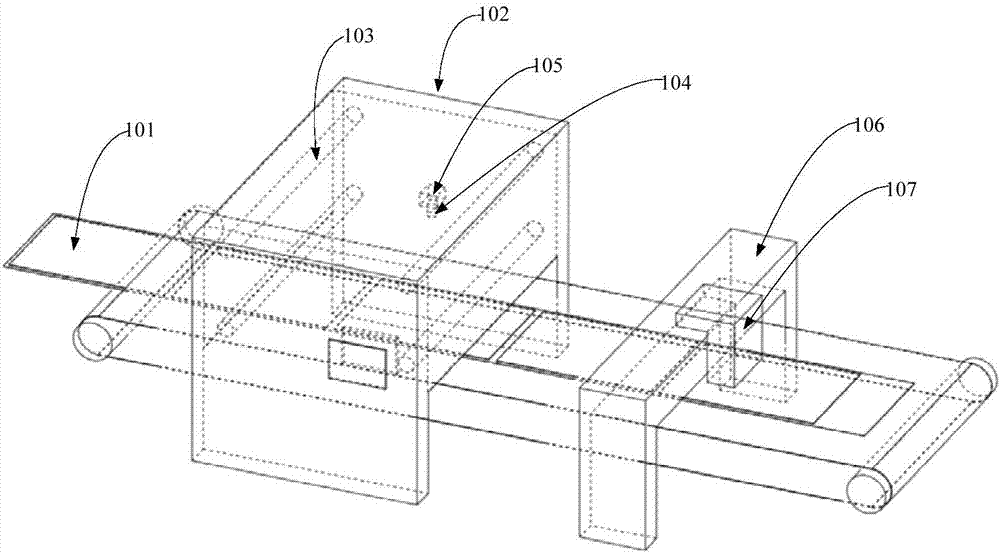

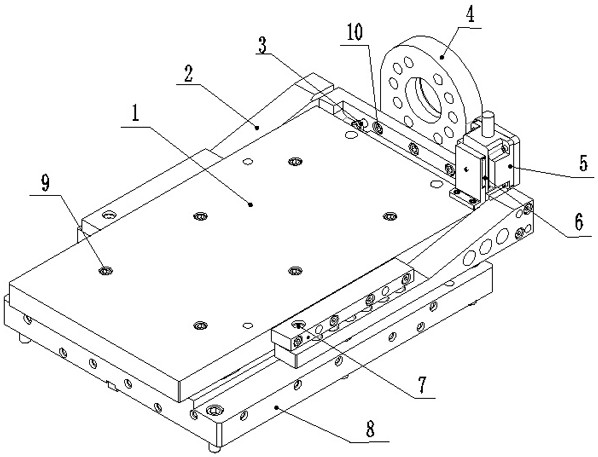

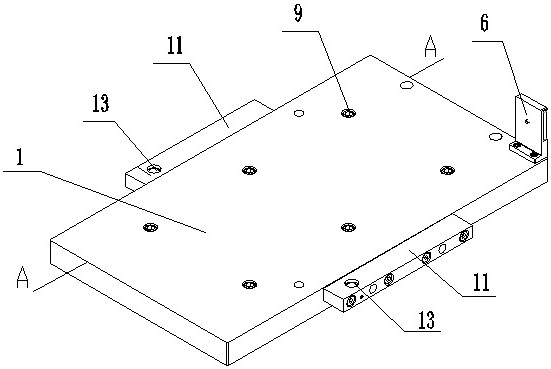

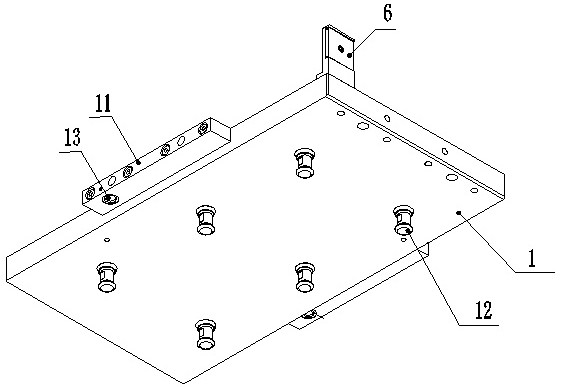

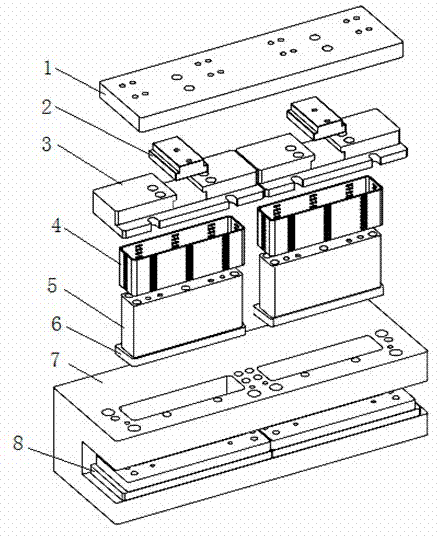

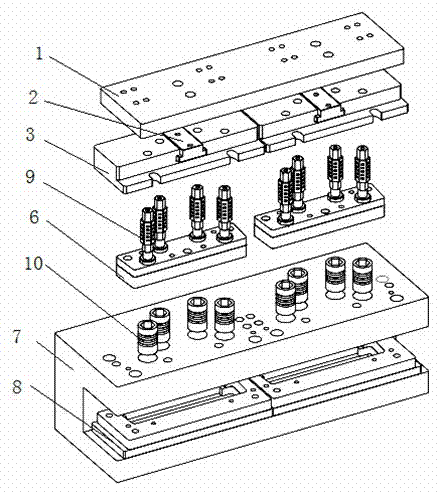

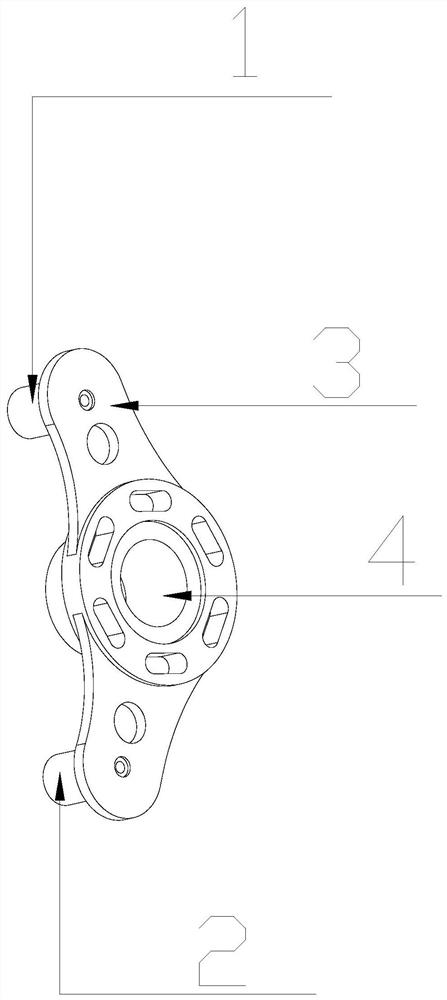

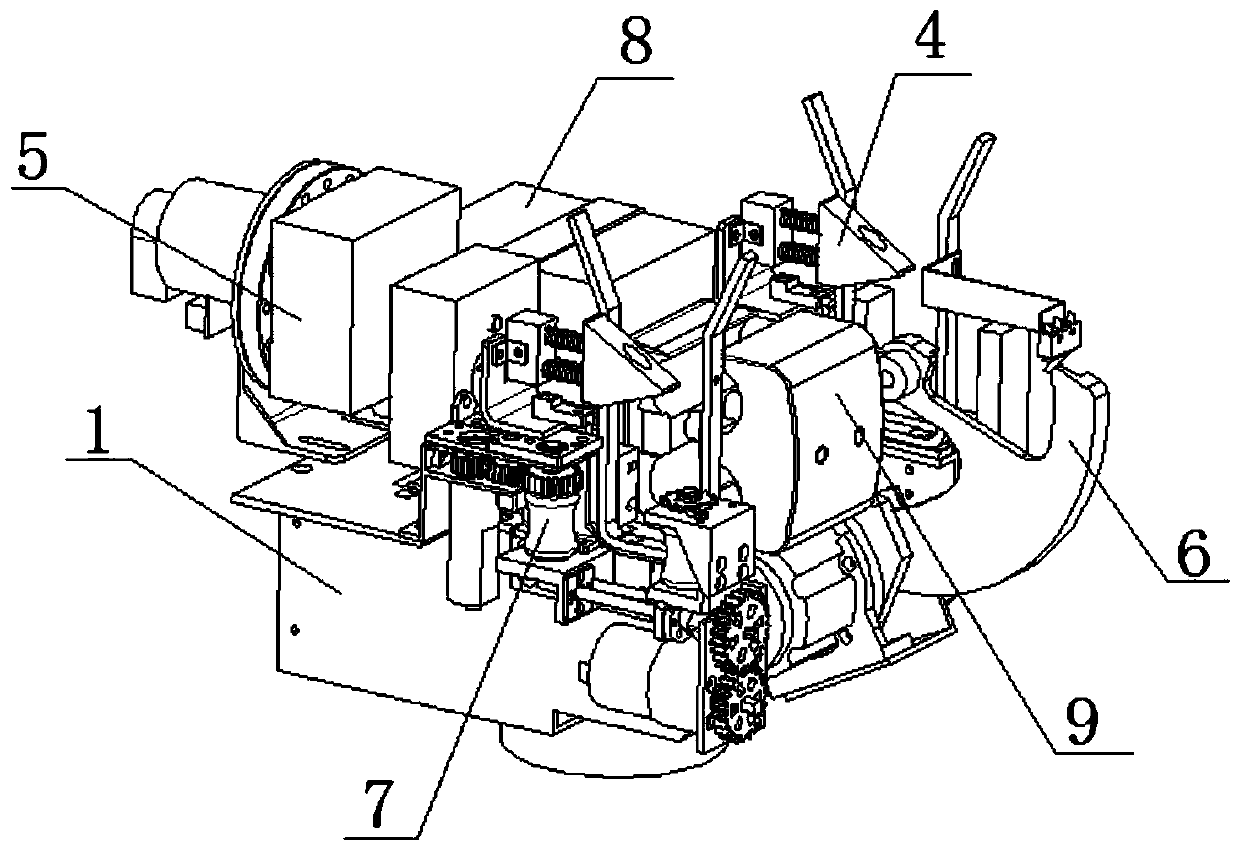

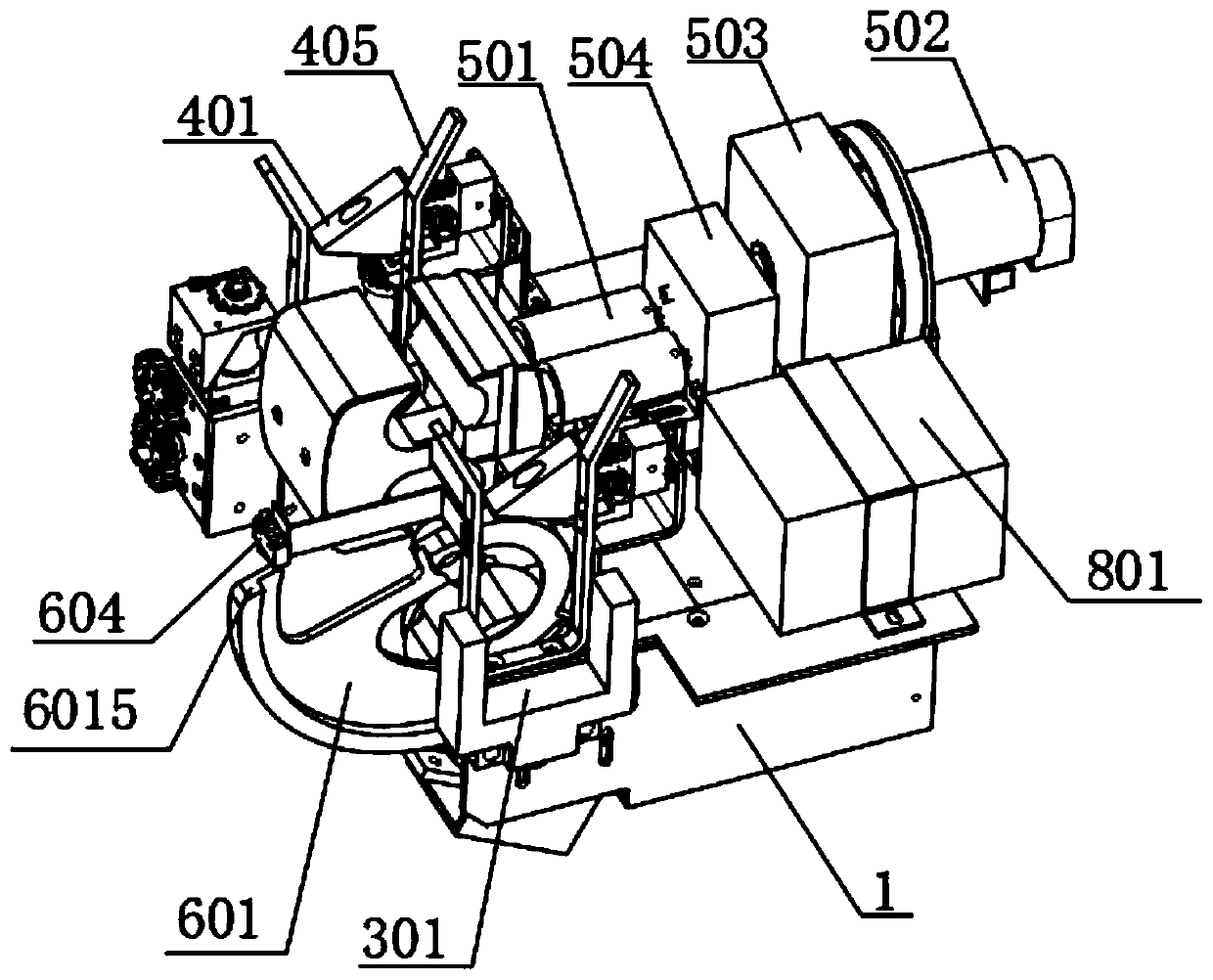

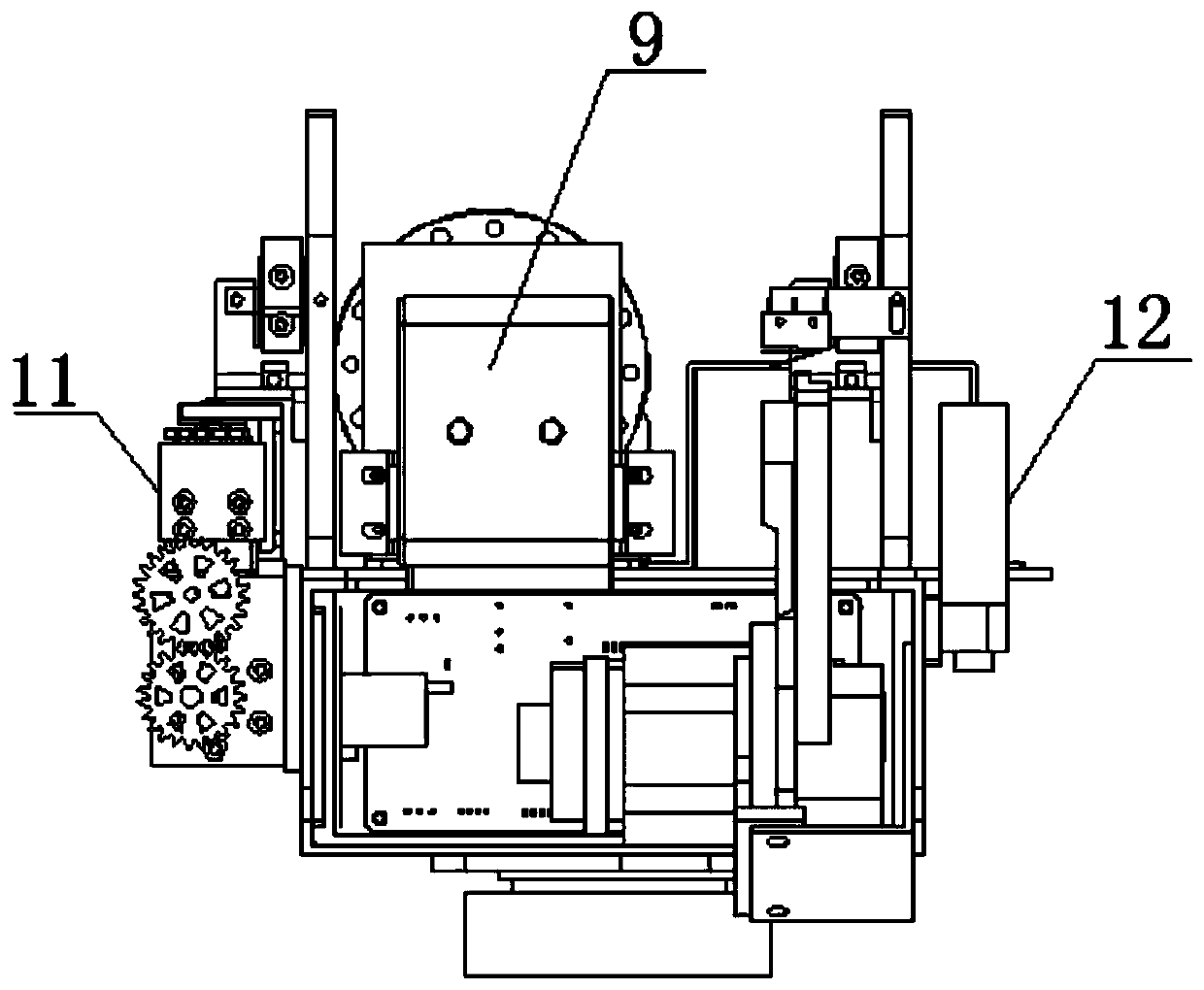

Feeding, discharging and positioning device suitable for robot feeding and discharging flexible production line

ActiveCN109366242ASolve the positioning errorWide range of useMetal working apparatusPosition sensorFlange

The invention discloses a feeding, discharging and positioning device suitable for a robot feeding and discharging flexible production line. A fork-shaped feeding and discharging device, a plurality of pull nails, an auxiliary workbench and a plurality of zero point positioning systems are included. The multiple pull nails are evenly arranged on a rapid replacement tray, two lug plates provided with positioning holes are arranged, and an RFID code is fixed to the corner. A robot flange assembly is fixed to the center of a transverse arm of a U-shaped fork-shaped assembly, a position sensor anda code reader are fixed to the two ends, and positioning pin installing holes for fixing positioning pins are formed in the two vertical walls. The zero point positioning systems are fixed to the positions, corresponding to the pull nails, of the auxiliary workbench. During work, the positioning holes of the rapid replacement tray are inserted and connected in the positioning pins of the fork-shaped assembly. The pull nails are arranged in pull nail zero point positioning holes of the zero point positioning systems, and inverted cone faces of the upper ends of the pull nails are clamped and connected in inverted cone holes of the zero point positioning systems. The feeding, discharging and positioning device is used in the robot feeding and discharging flexible production line, can adaptto diversity of workpieces and is high in recognition accuracy, good in grabbing reliability and high in zero point positioning precision.

Owner:BAODING XIANGYANG AVIATION PRECISION MACHINERY

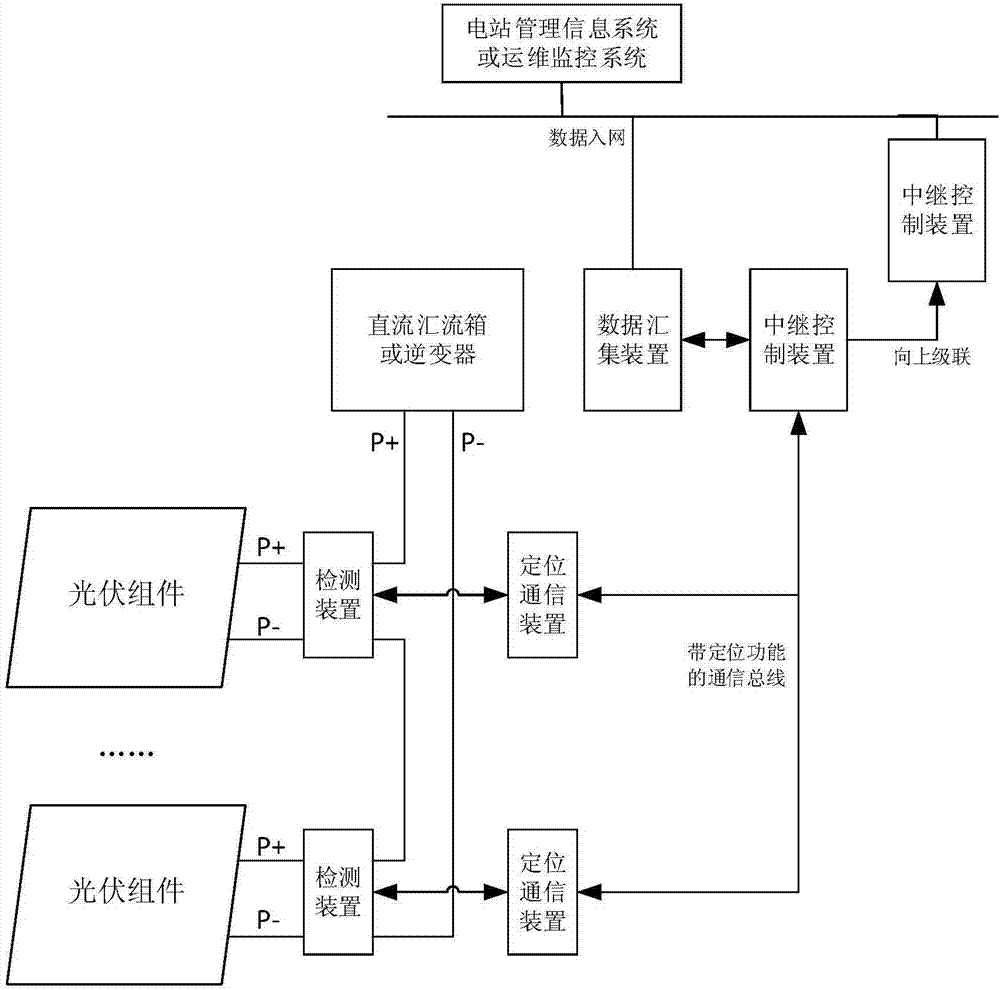

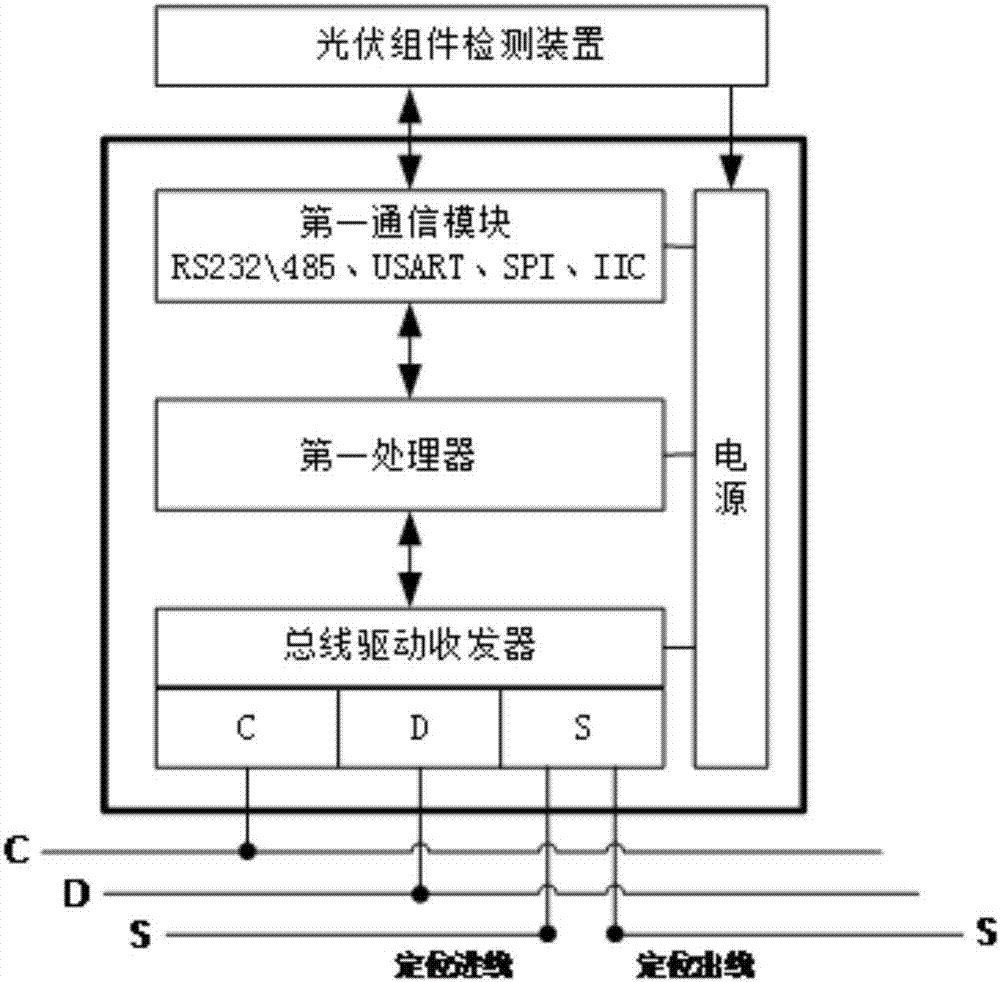

Positioning system and method

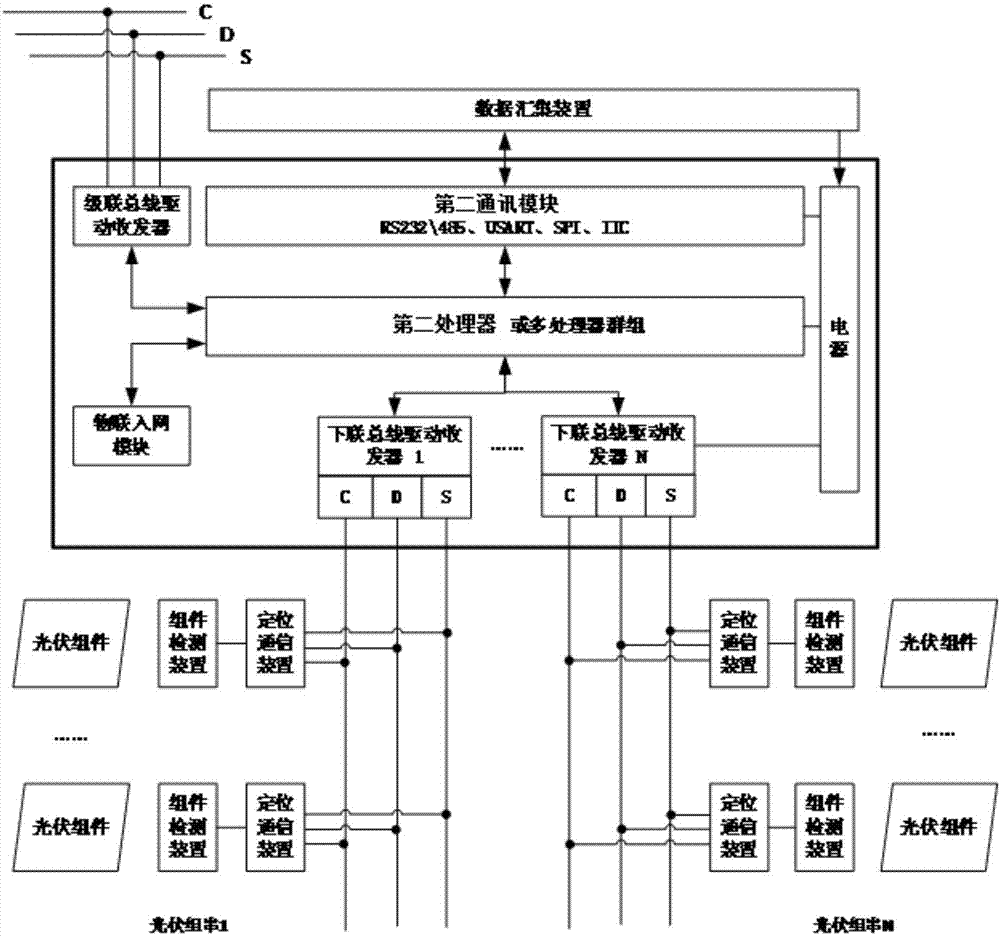

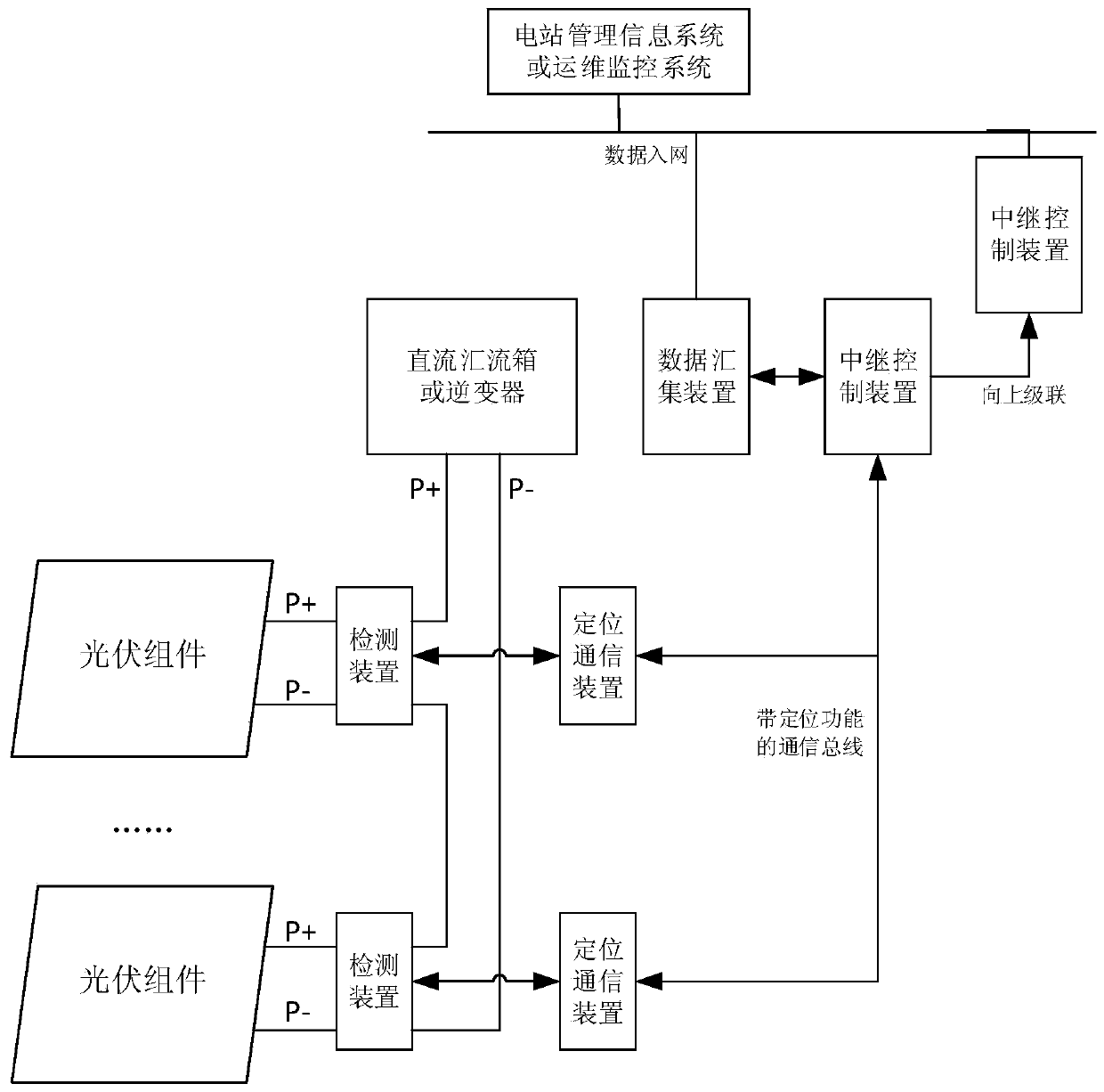

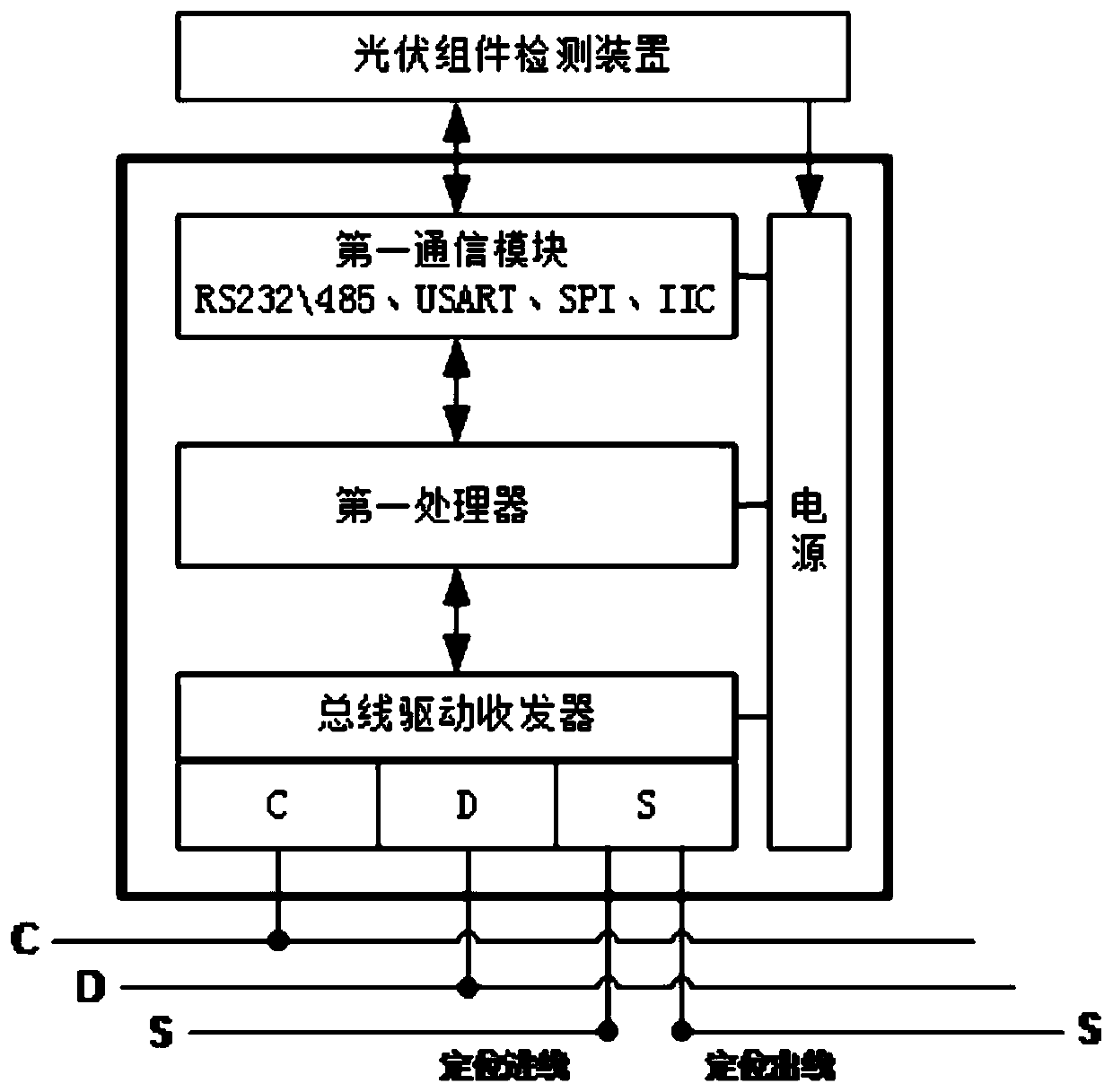

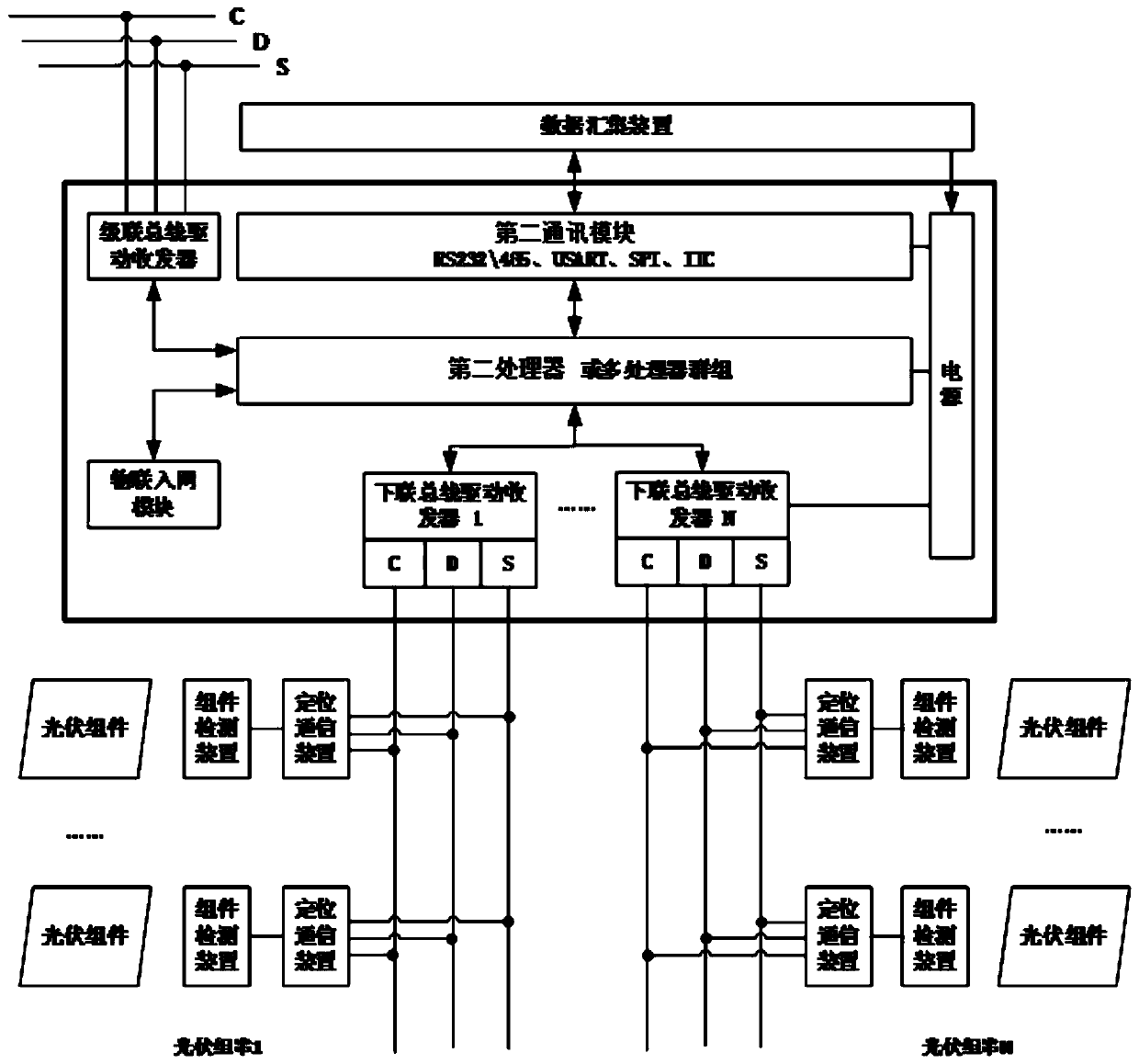

ActiveCN107276632AReduce workloadImprove work efficiencyLine-transmission monitoring/testingBus networksReal-time computingData lines

The invention discloses a positioning system and method. The system comprises a positioning communication device, a relay control device and a server; a clock line of the positioning communication device is in communication connection with the clock line of the relay control device, a data line of the positioning communication device is in communication connection with the data line of the relay control device, and a positioning line of the positioning communication device is in communication connection with the positioning line of the relay control device; and the relay control device is in communication connection with the server. The positioning system adopts a wireless communication scheme combining positioning with data communication, that is, the positioning lines and the data lines supplement each other to cooperate to accomplish an automatic alignment function, and the positioning system also has a data communication function. During work, the relay control device sends a positioning instruction to the positioning communication device, the positioning communication device accomplishes positioning, and the technical problems of large workload and large errors in the prior art are solved.

Owner:THE SECOND CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU +1

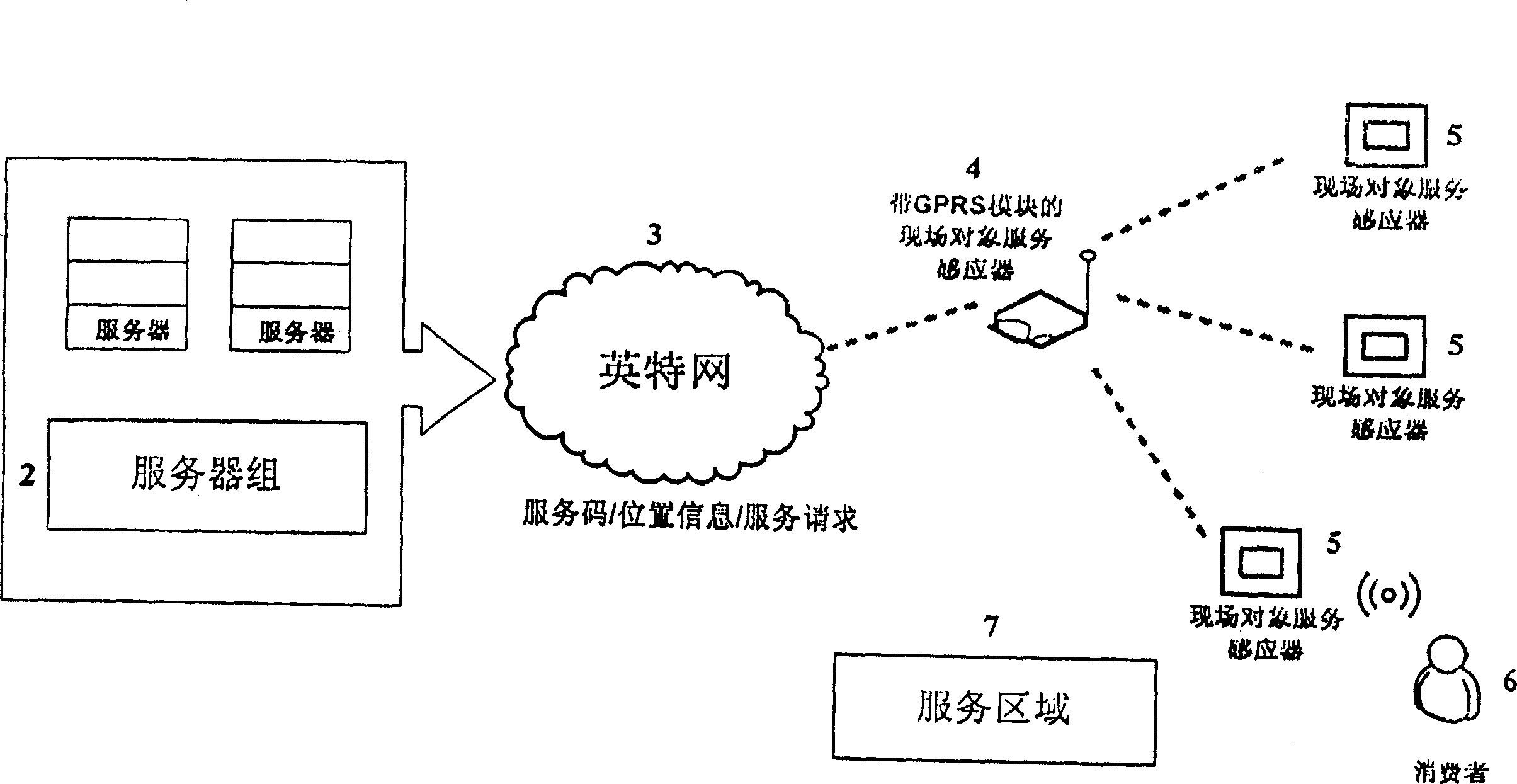

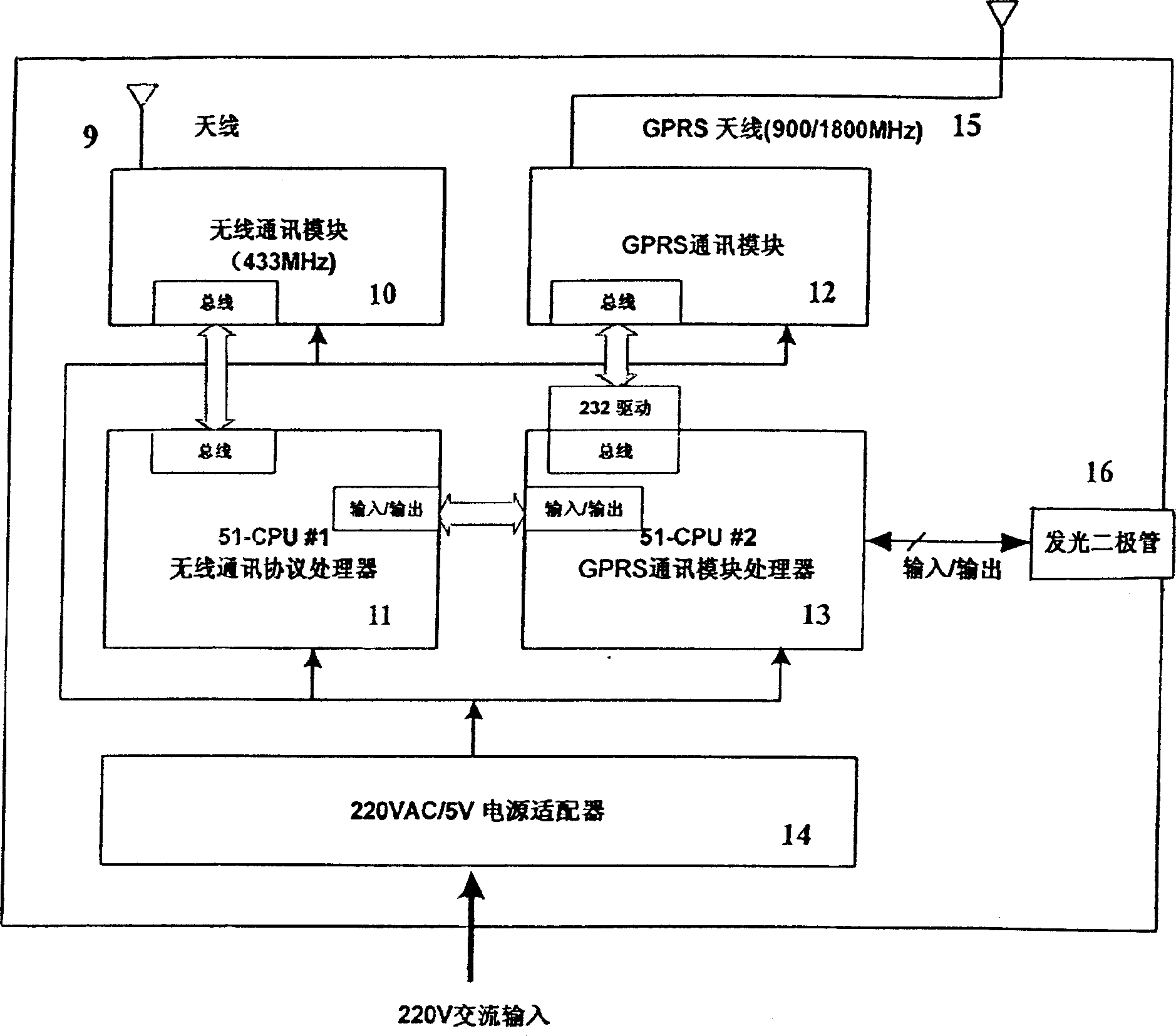

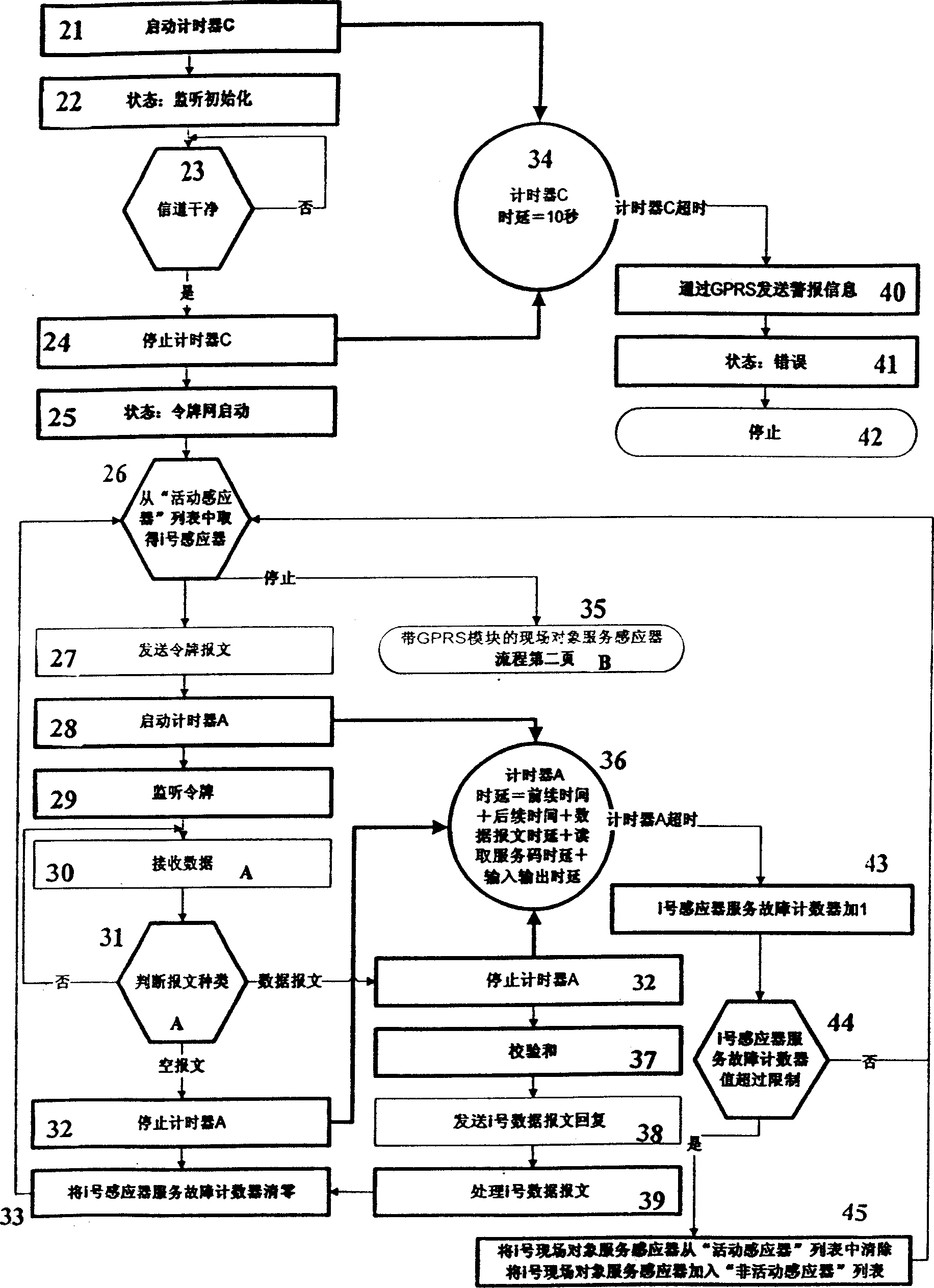

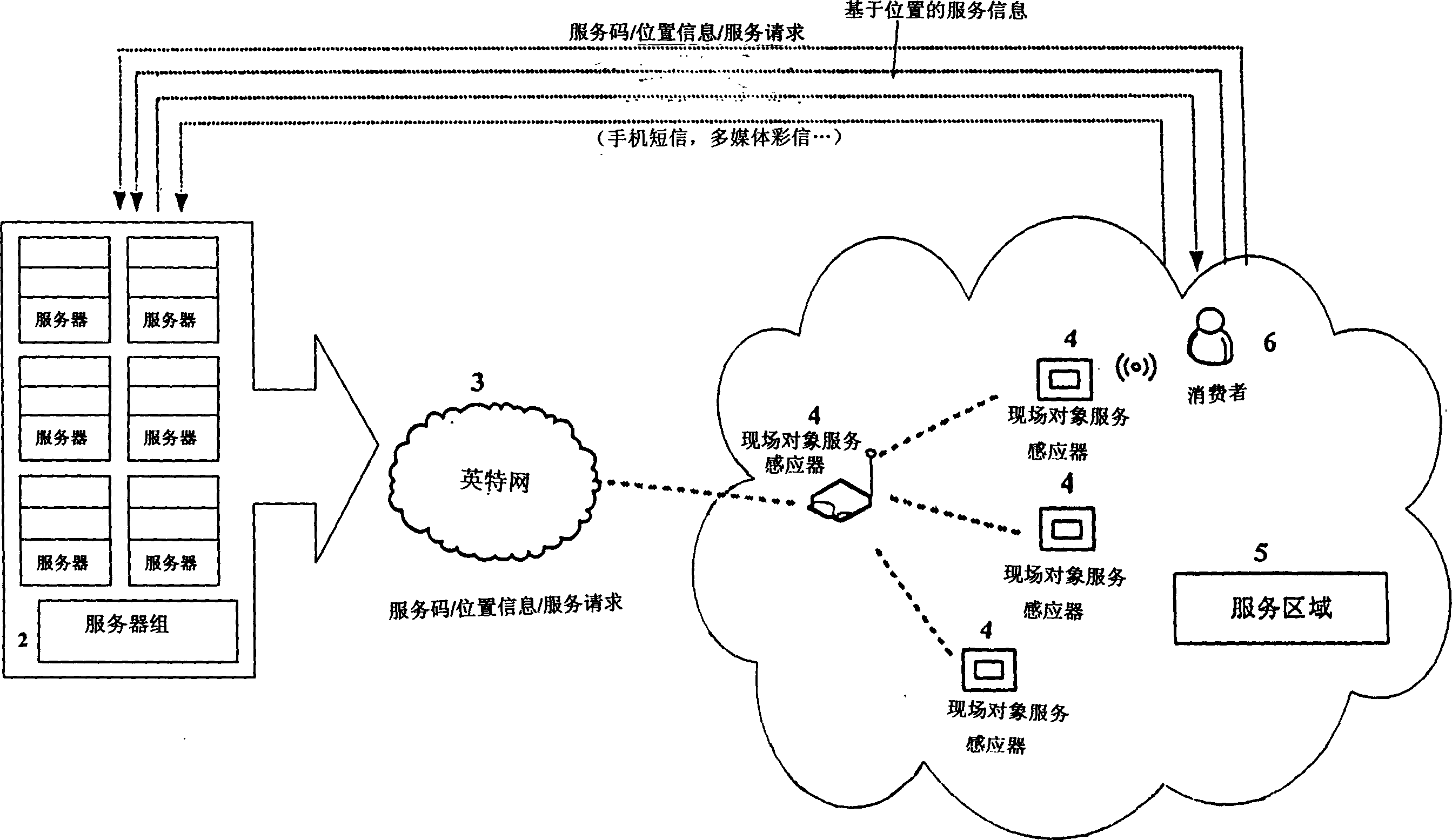

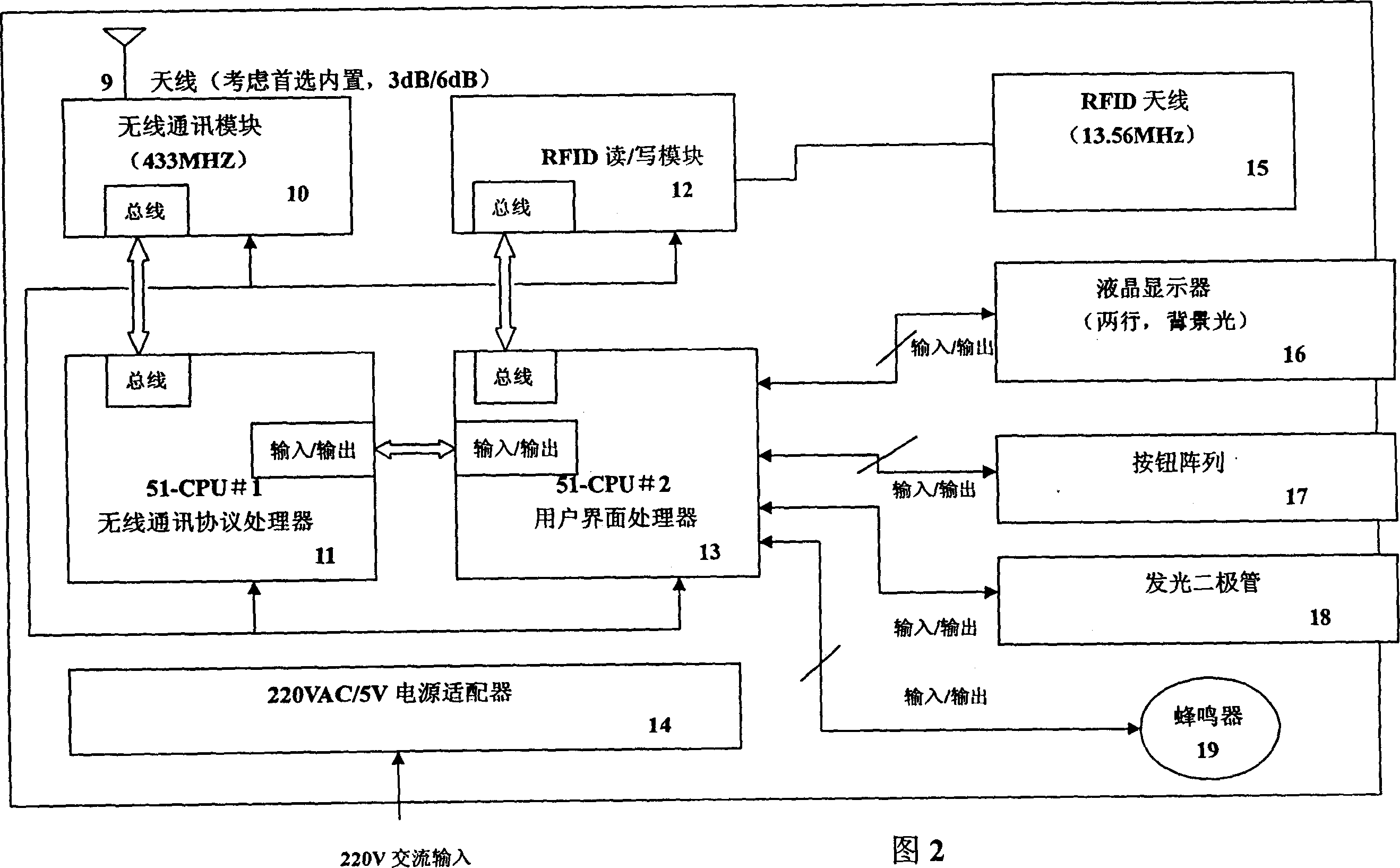

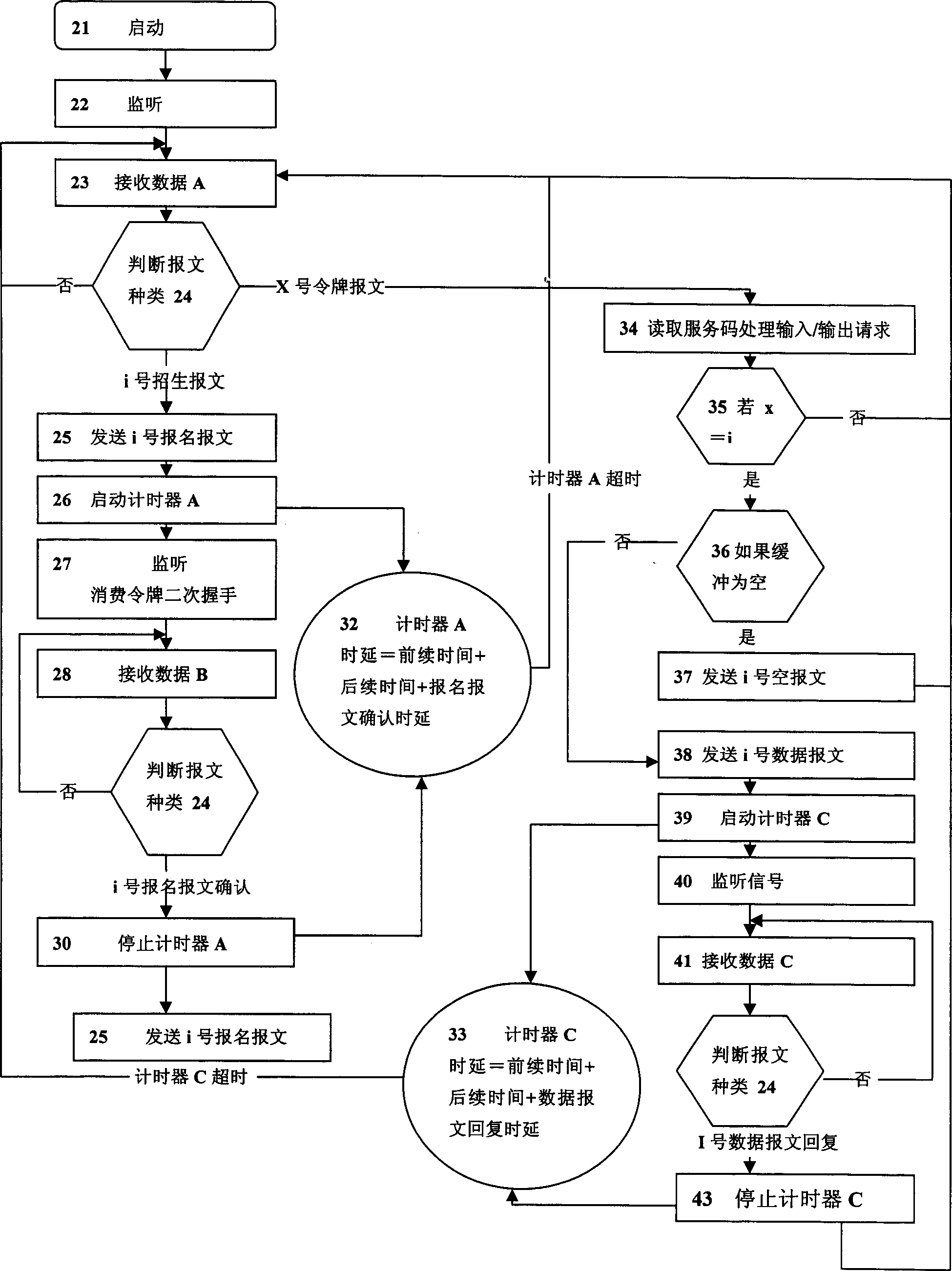

Locale object aggregation router its data-transmission method in Ad Hoc network

InactiveCN1767497AGuaranteed maximum effectivenessOvercome positioning errorData switching by path configurationRadio/inductive link selection arrangementsData connectionComputer module

This invention relates to a location device and a method for the radio signal transmission field, especially to a site object accumulating router installed in the service covering region for a site object sensor for collecting user RF card information and a data transmission method in its self-organization network, in which, said device is composed of a server set, a site object service sensor of a GPRS module, service region and a consumer environment, the method includes setting up network data connection between a set of site object service sensors placed dispersedly by a central mode token control protocol and taking one set as the central unit to interact data with the Internet and communication networks.

Owner:上海宽鑫信息科技有限公司

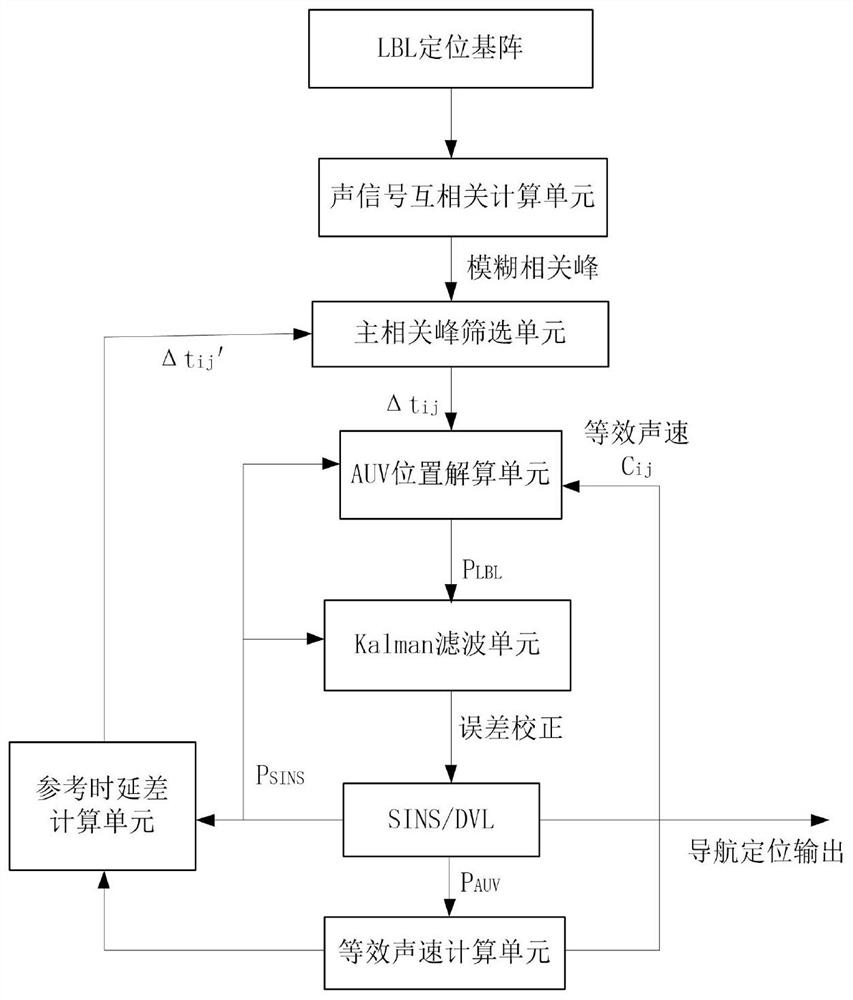

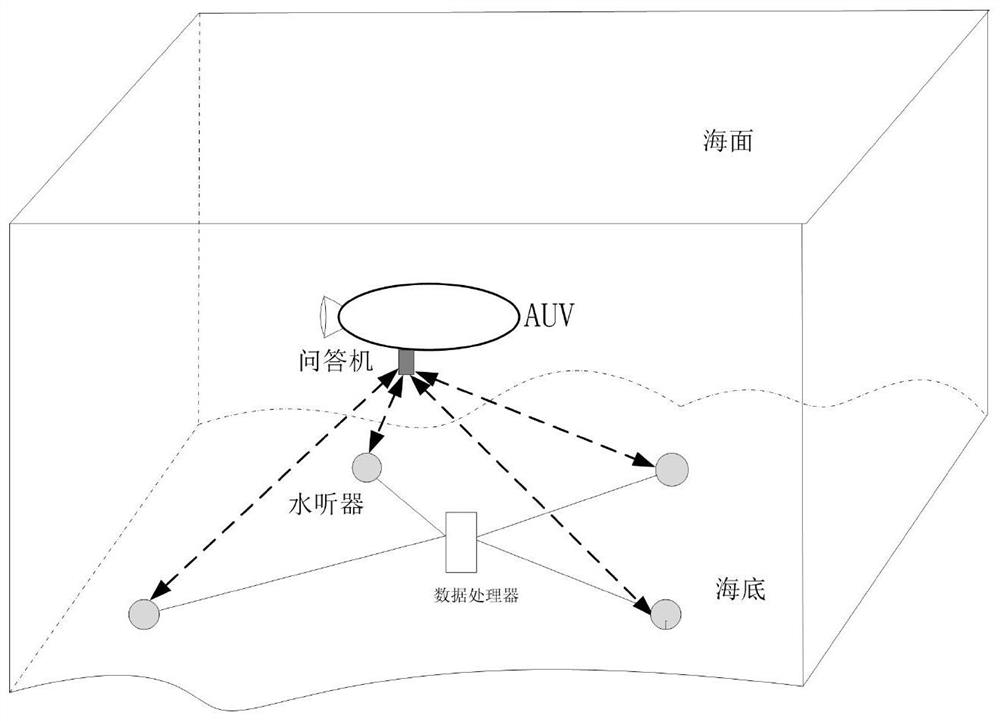

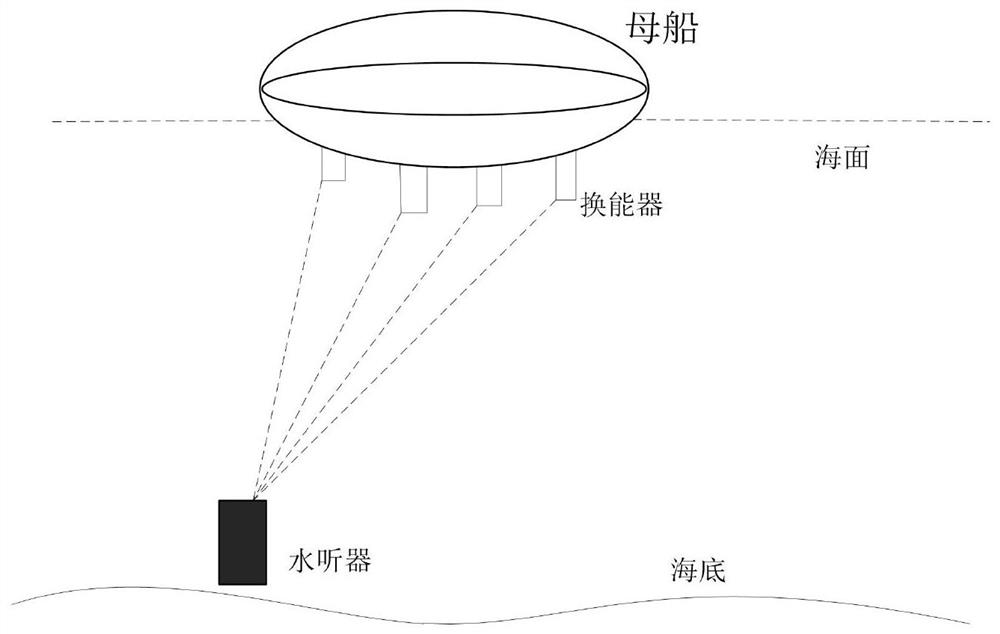

AUV (Autonomous Underwater Vehicle) underwater positioning method based on long-baseline underwater acoustic system aided navigation

InactiveCN113156442AReduce distractionsHigh positioning accuracyAcoustic wave reradiationKaiman filterSound sources

The invention discloses an AUV (Autonomous Underwater Vehicle) underwater positioning method based on long-baseline underwater acoustic system aided navigation. The method comprises the following steps of: firstly, carrying out laying and position calibration on a hydrophone, receiving a signal sent by an AUV sound source by a long-baseline underwater acoustic system, and carrying out generalized cross-correlation operation to obtain a fuzzy correlation peak; calculating the current position of the AUV through the SINS to screen a main peak to obtain a delay inequality; selecting an initial position coordinate of the AUV, performing iteration by adopting a Taylor series expansion method, and resolving position information through a long-baseline hydrophone array; and finally, inputting the difference value of the position coordinates calculated by the SINS and the long baseline underwater acoustic system into a Kalman filter for filtering, and correcting various errors of the SINS and the DVL according to a filtering result to obtain accurate AUV position information. According to the method, accumulative errors in the underwater navigation process of the AUV are corrected, interference of multiple correlation peaks generated by sound ray bending and a multi-path effect on delay inequality estimation is reduced, and the underwater positioning precision of the AUV is improved.

Owner:HOHAI UNIV

On-site object service inductor and its data transmission method in Ad Hoc network

InactiveCN1791061AGuaranteed maximum effectivenessOvercome positioning errorData switching by path configurationSensing record carriersData connectionThe Internet

The disclosed field object service sensor arranged on service cover area to collect user RF card information comprises a location sense point, a location device, a server group, a field object service sensor, a service area, and a consumer environment. Wherein, it uses center mode token to control protocol, and builds network data connection between a group of discrete sensors with one as center machine to exchange data with internet and communication network. This invention provides a new sensor / sense point for interaction with sense device on mobile terminal, has simple structure and low cost.

Owner:上海宽鑫信息科技有限公司

Gantry machining center with high rigidity and large torque

The invention relates to a machining center, and in particular to a gantry machining center with high rigidity and large torque. The gantry machining center mainly solves the technical problems existing in the prior art that a high-low gear reduction gearbox is expensive, a high speed gear works in the limiting condition, the failure rate is high, and the cost of using and maintenance is high; requirements of processing at the reduction ratio of 1:2 / 1:3, and the like cannot be satisfied; the rigidity of a main shaft of a vertical processing is bad, tool changing failure frequency is high, and the like. The gantry machining center comprises a lathe bed, wherein the lathe bed is provided with a vertical column and a working table; a cross beam is arranged at the upper end of the vertical column; a tool magazine is arranged at one end of the cross beam; the cross beam is provided with a cross beam guide rail, a sliding saddle is slidably connected with the cross beam; the sliding saddle is provided with a ram of a high rigid guide rail structure; the ram is provided with the main shaft and a tool hitting cylinder; the main shaft is connected with a main motor through a reducing gear with wheels; the main shaft is further provided with a main shaft positioning device; the gantry machining center is provided with an electrical and numerical control system.

Owner:HANGZHOU DATIAN CNC MACHINE TOOL

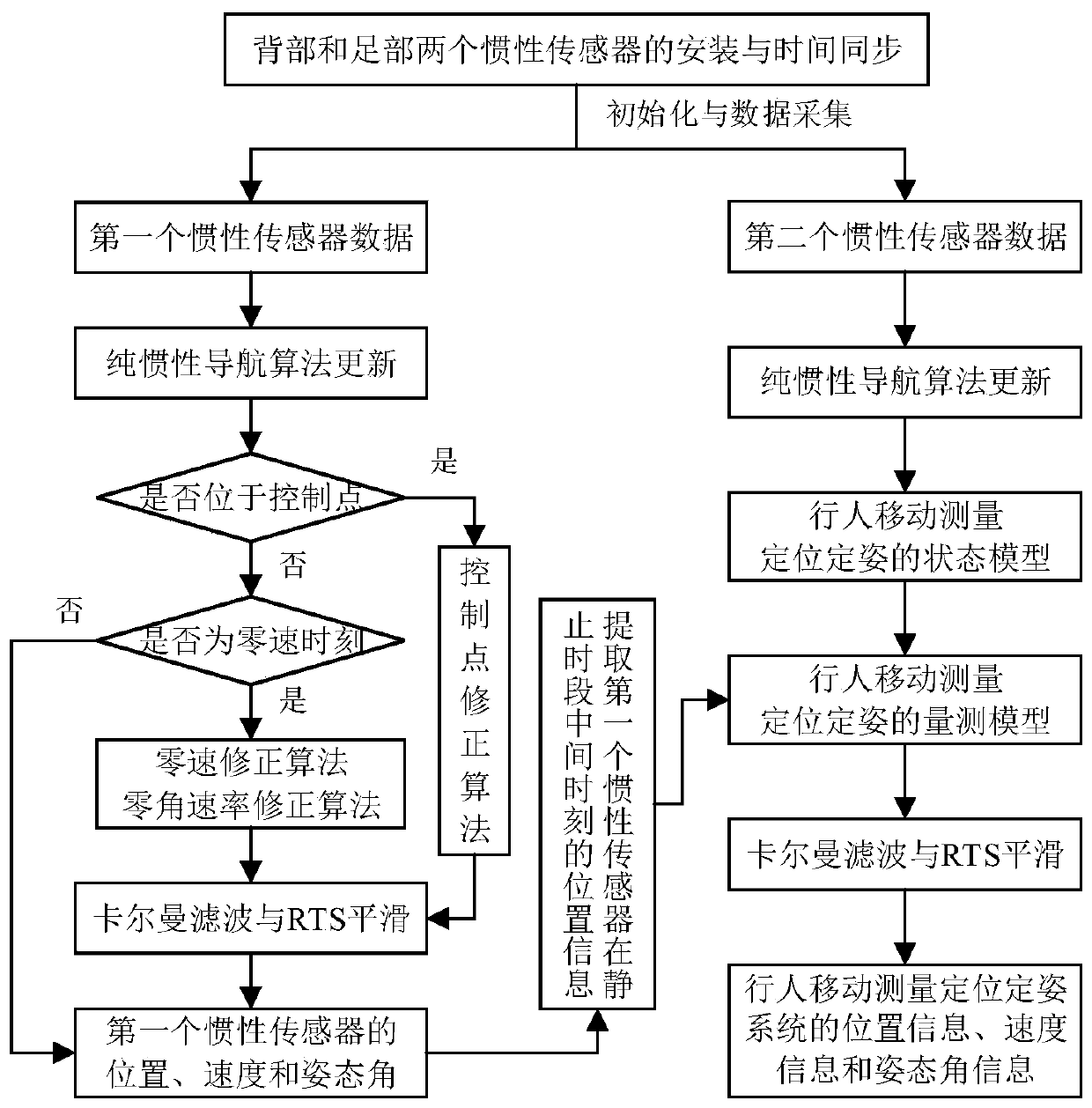

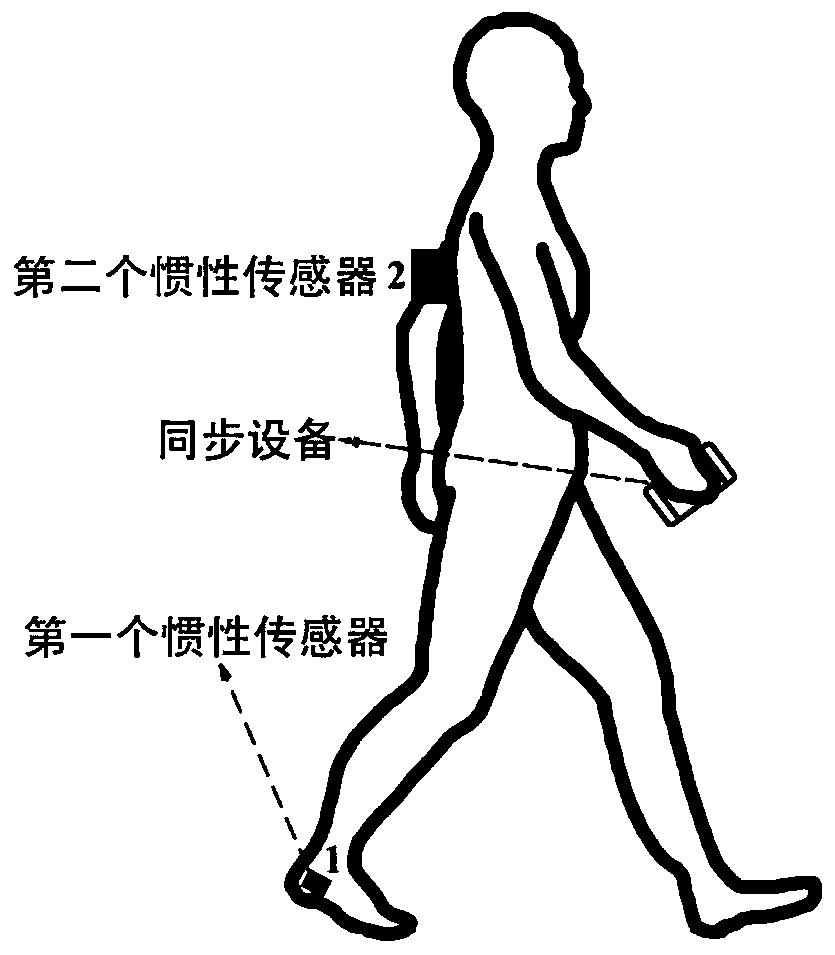

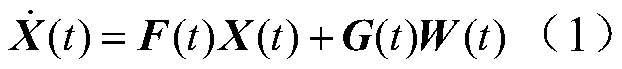

Method and system for indoor movement measurement, positioning and attitude determination method and system based on foot inertial sensors

ActiveCN110260860AHigh precisionOvercome positioning errorNavigational calculation instrumentsNavigation by speed/acceleration measurementsMathematical modelMovement measurement

The invention provides a method and a system for indoor movement measurement, positioning and attitude determination method and system based on foot inertial sensors. The method comprises the steps of: installing a first inertial sensor at the position of an operator's foot heel, installing a second inertial sensor at the position of the operator's back, and performing time synchronization; resolving the position, the speed and the attitude angle information of the first inertial sensor; extracting position information of the first inertial sensor at the middle moment of a static period according to the condition that the relative positions of the back and the foot of a pedestrian are unchanged at the middle moment of the static period in the process of upright walking; and combining the data of the inertial sensor acquired by the second inertial sensor, constructing a mathematical model of the pedestrian movement measurement positioning and attitude determination system, performing resolving to obtain the position, speed and attitude angle information of the back of the pedestrian, and providing accurate position and attitude angle information for the indoor pedestrian movement measurement system. The method and the system for indoor movement measurement, positioning and attitude determination method and system based on foot inertial sensors can achieve the indoor movement measurement positioning and attitude determination with high precision, high efficiency, low cost and simple operation.

Owner:WUHAN UNIV

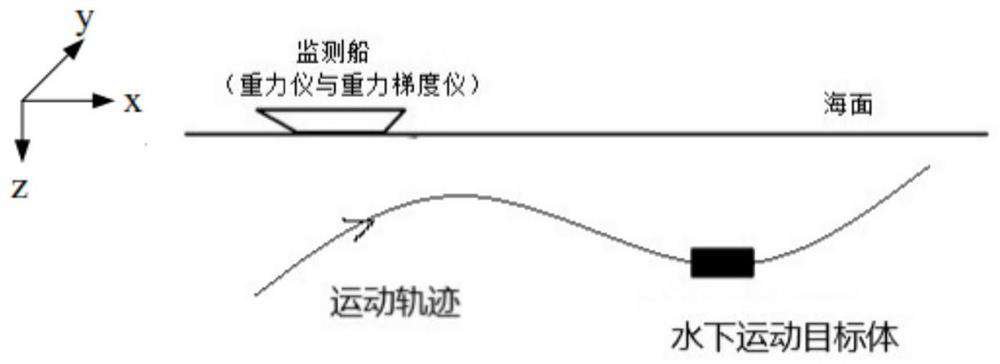

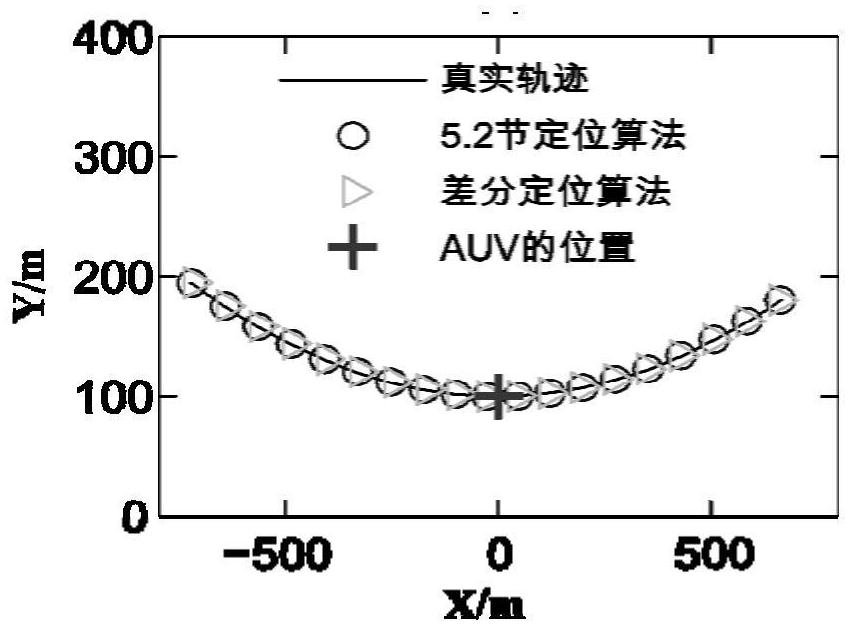

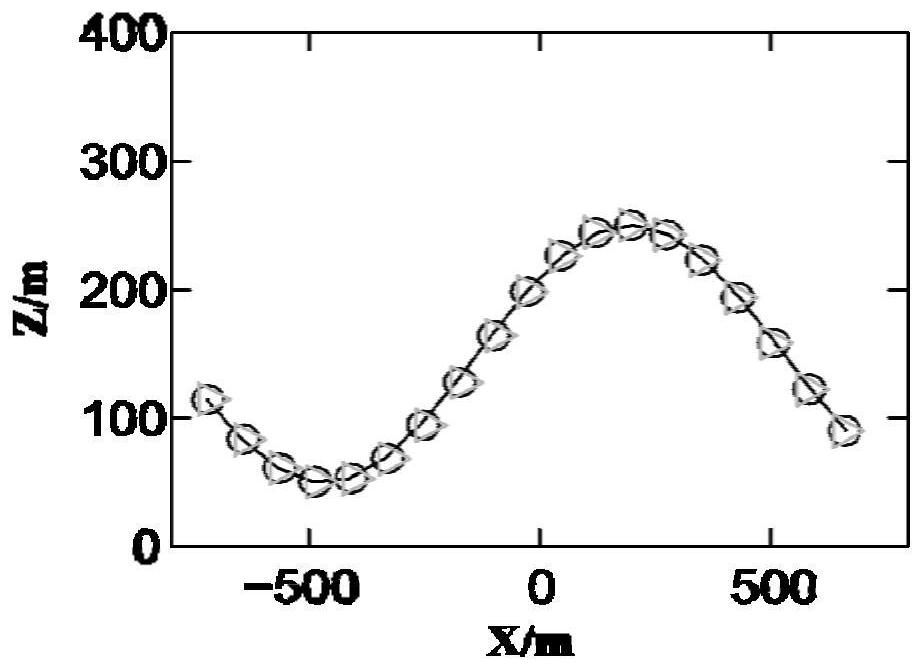

Differential positioning method and device based on gravity vectors and gravity gradients

ActiveCN111721301AOvercome positioning errorReliable Location TrackingNavigational calculation instrumentsGravitational wave measurementObservation pointLocation determination

The invention discloses a differential positioning method and device based on gravity vectors and gravity gradients. The method comprises the steps: S1, obtaining two groups of gravity vectors and gravity gradients recorded by an observation station, wherein the two groups of gravity vectors and gravity gradients are obtained through the recording of the same observation station at an adjacent moment or the recording of the adjacent observation station at the same moment; and S2, acquiring the position of a target body based on the gravity vectors and the gravity gradients recorded in the stepS1, wherein the distance vector between the observation point and the target body is calculated firstly, and then the position of the target body is determined based on the distance vector and the position of the observation point. According to the invention, a core algorithm for monitoring the coordinate position of a moving target body based on gravity vectors and gravity gradient tensors measured by two adjacent observation stations or adjacent moments is provided, the influence of the earth gravity background field is eliminated, and accurate target positioning is realized.

Owner:CENT SOUTH UNIV

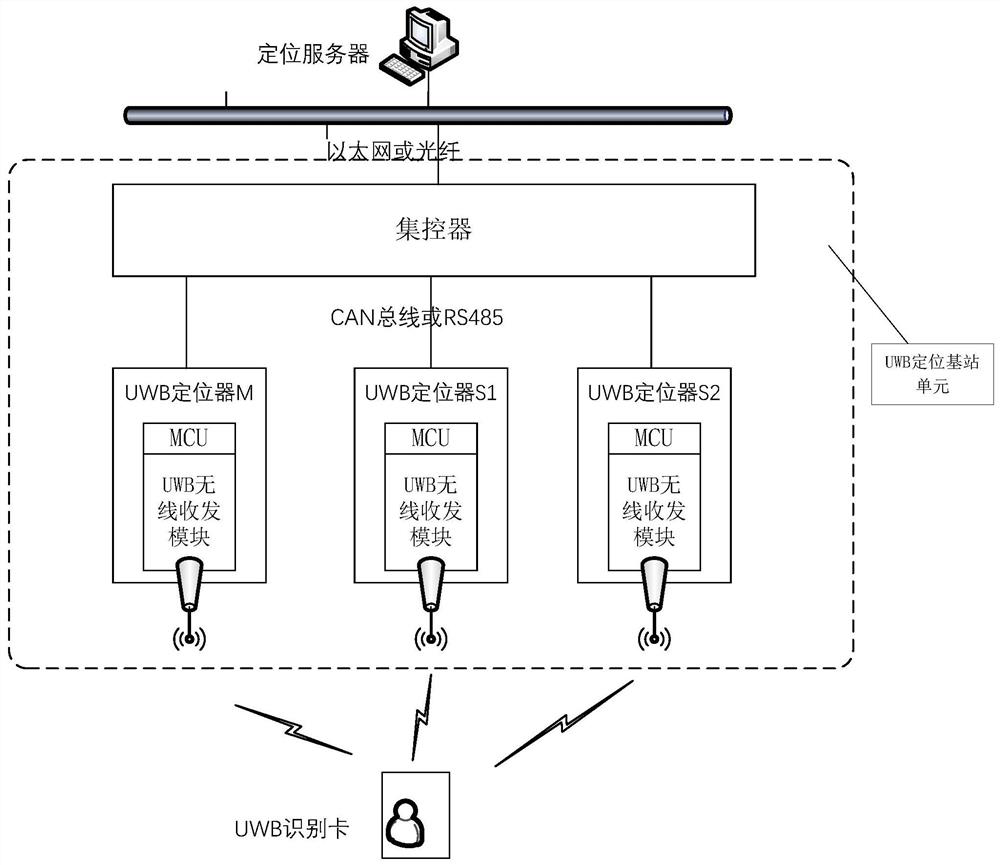

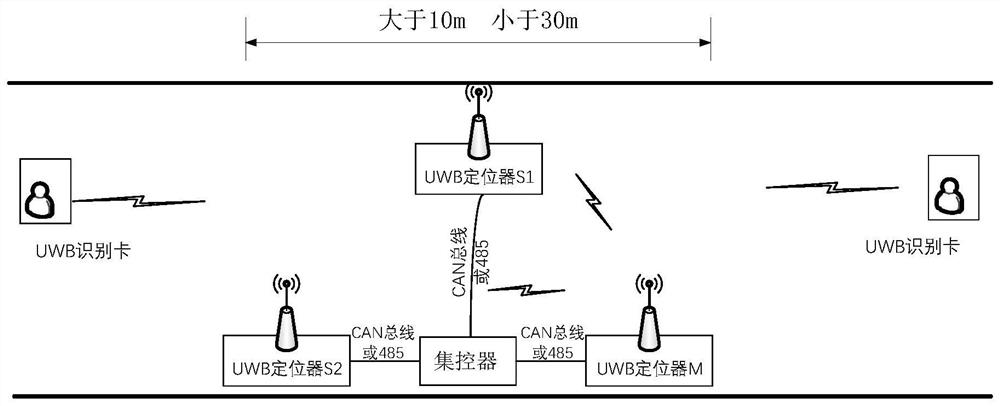

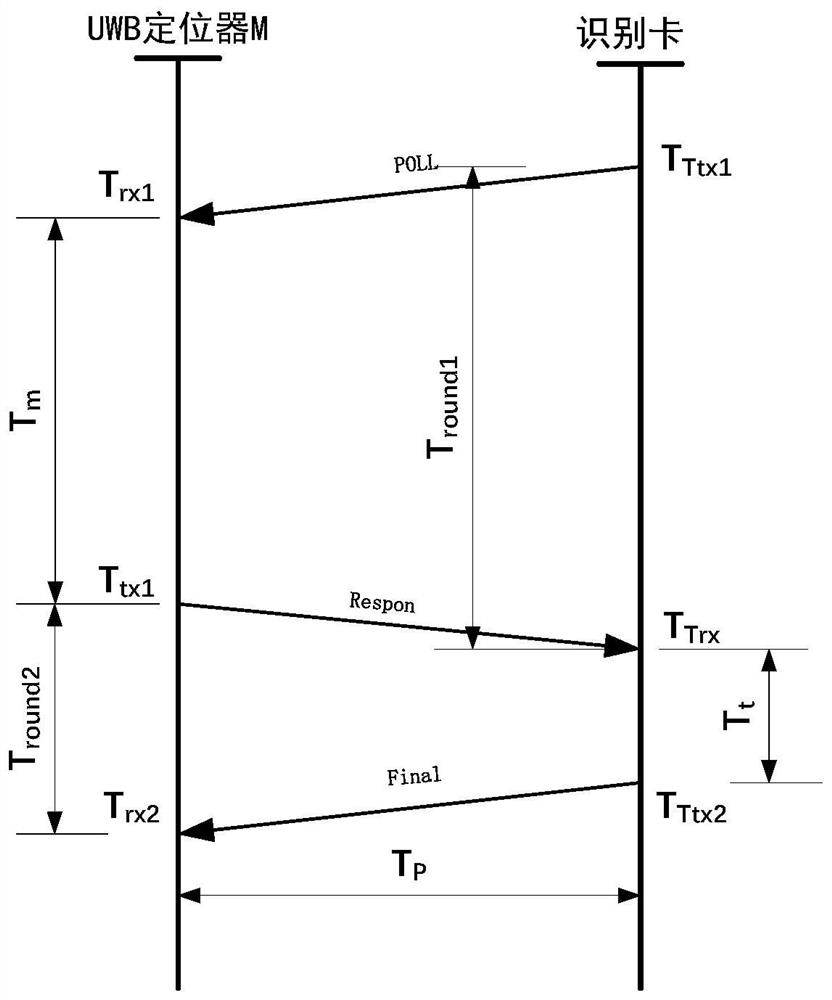

Downhole two-dimensional positioning method combining TDOA and DSTWR based on UWB technology

PendingCN113038364AOvercome positioning errorMeet the positioning technical requirementsSynchronisation arrangementLocation information based serviceTime differenceCoal

The invention discloses a TDOA and DSTWR combined underground two-dimensional positioning method based on a UWB technology, and the method comprises the steps: obtaining the two-dimensional coordinate of a moving point by employing a Chan algorithm by employing a time difference of arrival (TDOA) value when an identification card arrives at a plurality of UWB positioners and a TOA value when the identification card arrives at one UWB positioner, and combining the measurement calculation values of the TDOA and the TOA; wherein a wireless clock synchronization method based on Kalman filtering is adopted to realize TDOA calculation, so that sub-nanosecond-level clock precision is realized; a TOA distance measurement value of a base station is increased, the precision of coal mine underground two-dimensional long-distance positioning is effectively improved, and the problem of unstable precision of an underground single TDOA positioning algorithm is solved; meanwhile, the method can greatly reduce the coupling degree of the system and improve the stability of the system.

Owner:杨亦非

Device and method for aligned digital printing for towels

PendingCN107984918ARealize automatic alignmentOvercome positioning errorTypewritersOther printing apparatusEngineeringDigital printing

The invention discloses a device for aligned digital printing for towels. The device comprises a printing guide belt, a light-shading shell, an auxiliary illuminating system, towel edge recognition sensors, a towel position recognizer, a digital printer and a digital printer controller, wherein the light-shading shell covers the printing guide belt and is used for shading environment light; the auxiliary illuminating system is arranged in the light-shading shell and is used for providing light for an environment in the shell; the towel edge recognition sensors are fixedly mounted in the light-shading shell and are used for recognizing towel edges; the towel position recognizer is fixedly mounted in the light-shading shell, is used for calculating the value of deviation between the locations of the towels and a standard position according to the towel edges acquired by the towel edge recognition sensors, and transmits the value of deviation to the digital printer; the digital printer covers the printing guide belt; and the digital printer controller is arranged on the digital printer, and is used for controlling and adjusting the size of a printing pattern which is about to be printed by the digital printer. By the device provided by the invention, automatic alignment of the towels can be realized, and the size of the printing pattern is adjusted according to the size of a nexttowel detected in real time to adapt to the size of the towel.

Owner:杭州开源电脑技术有限公司

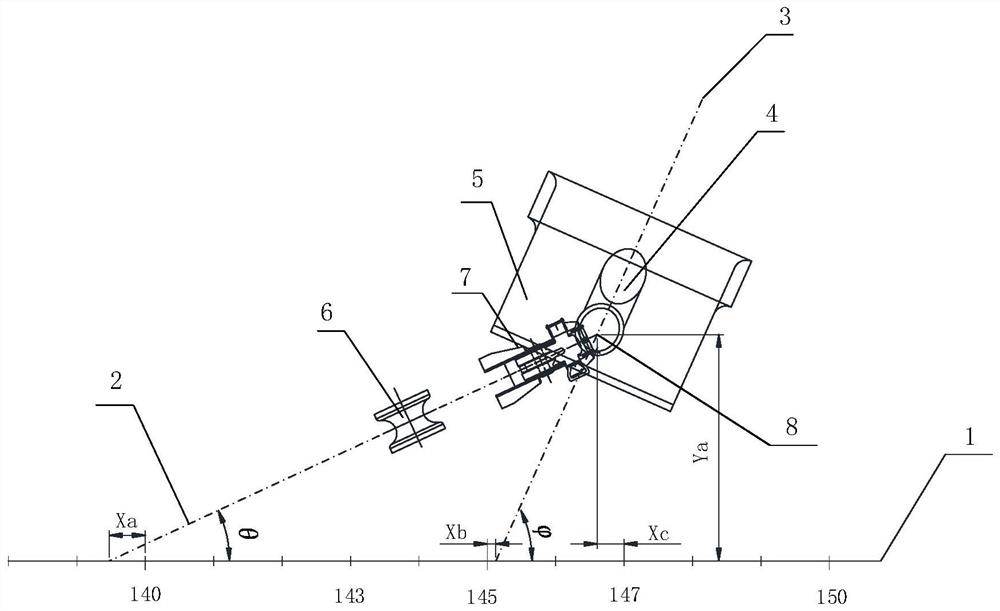

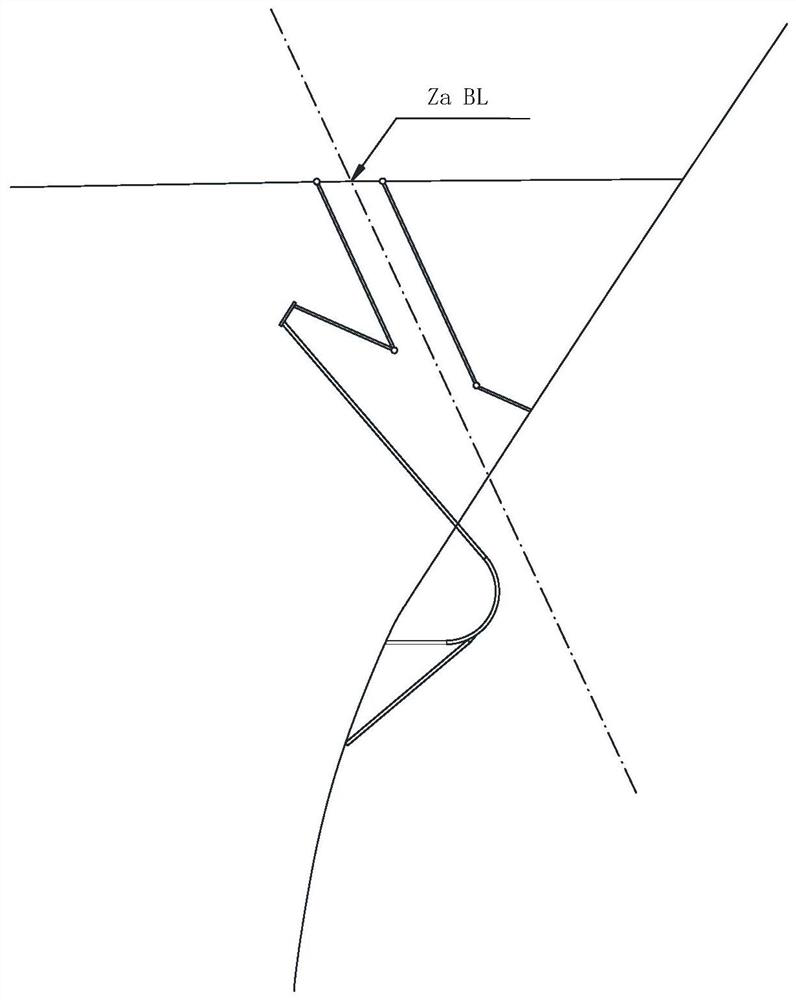

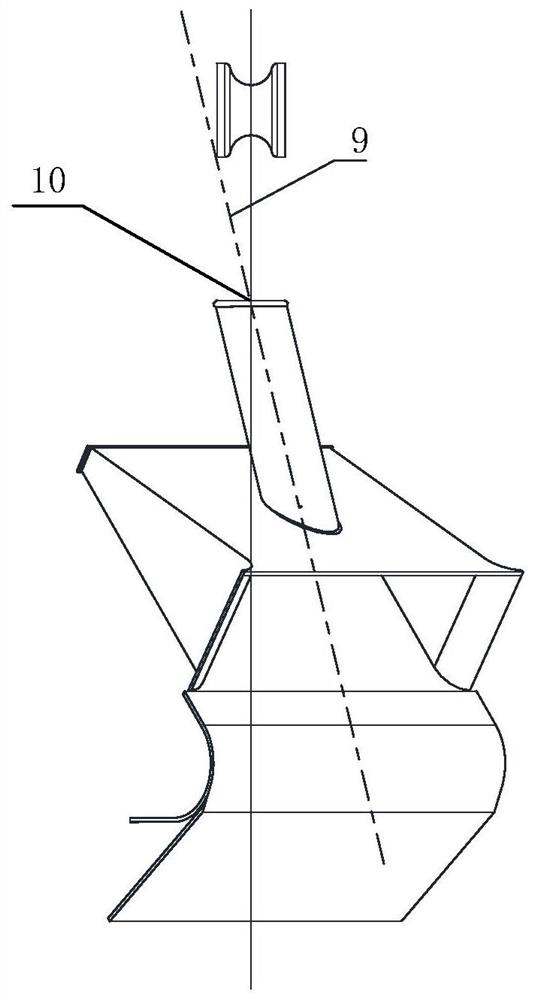

Design and adjustment method of inclined guide chain type anchor system

ActiveCN111806651AHigh positioning accuracyShorten the installation cycleGeometric CADVessel designingControl engineeringIndustrial engineering

The invention discloses a design and adjustment method of an inclined guide chain type anchor system. The design and adjustment method comprises a series of processes of digital model establishment, anchor system part designing and positioning, position verification and adjustment, dynamic calculation and analysis, knife switch chain stopper adjustment and the like. According to the inclined guidechain type anchor system design and knife switch chain stopper adjustment method, digital modeling, space positioning and dynamic calculation are applied so that the design positioning and adjustmentmodes of an anchor system part model are visual. The method has advantages that a new technology is comprehensively applied, the design method and the success rate of the current inclined guide chaintype anchor system are improved, the knife switch chain stopper positioning adjustment method can be given in a design stage, the adjustment work of installation and positioning of the real ship anchor system is greatly reduced, and a later workload and working time are saved.

Owner:JIANGSU UNIV OF SCI & TECH

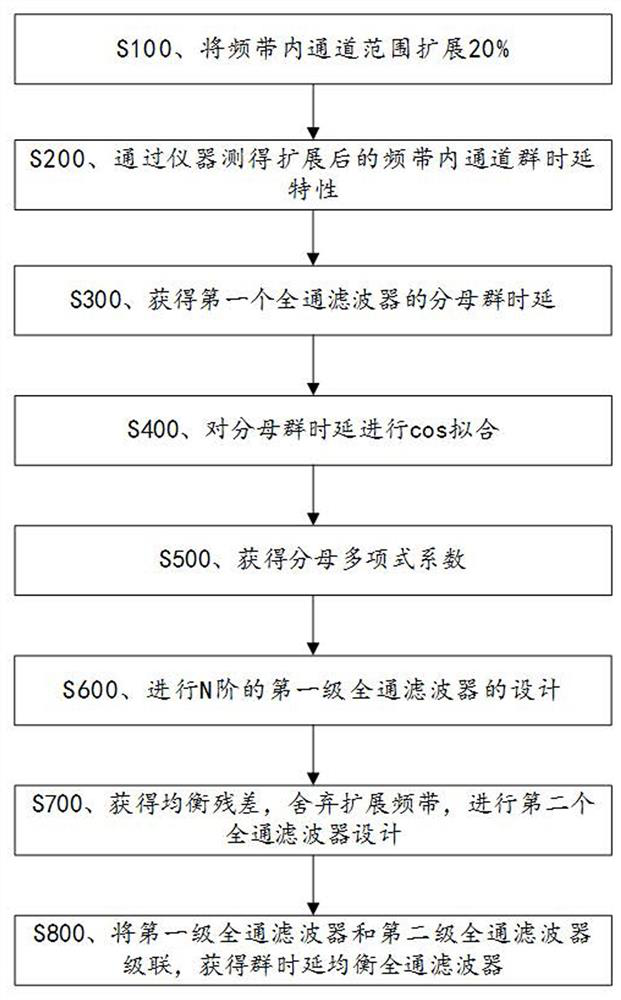

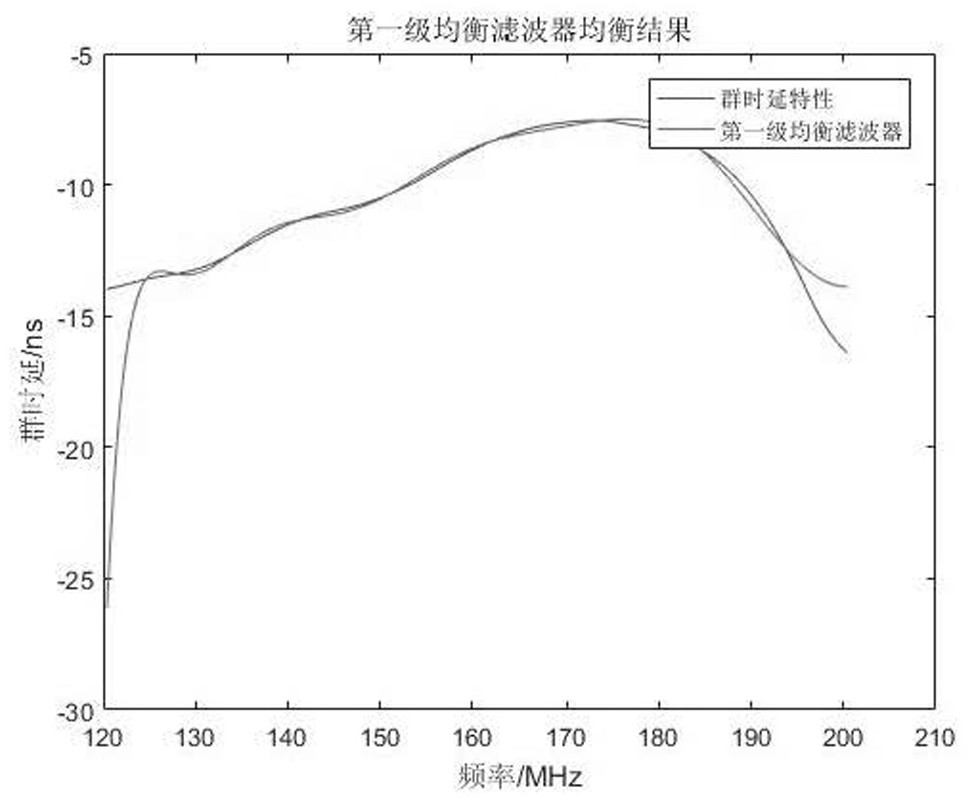

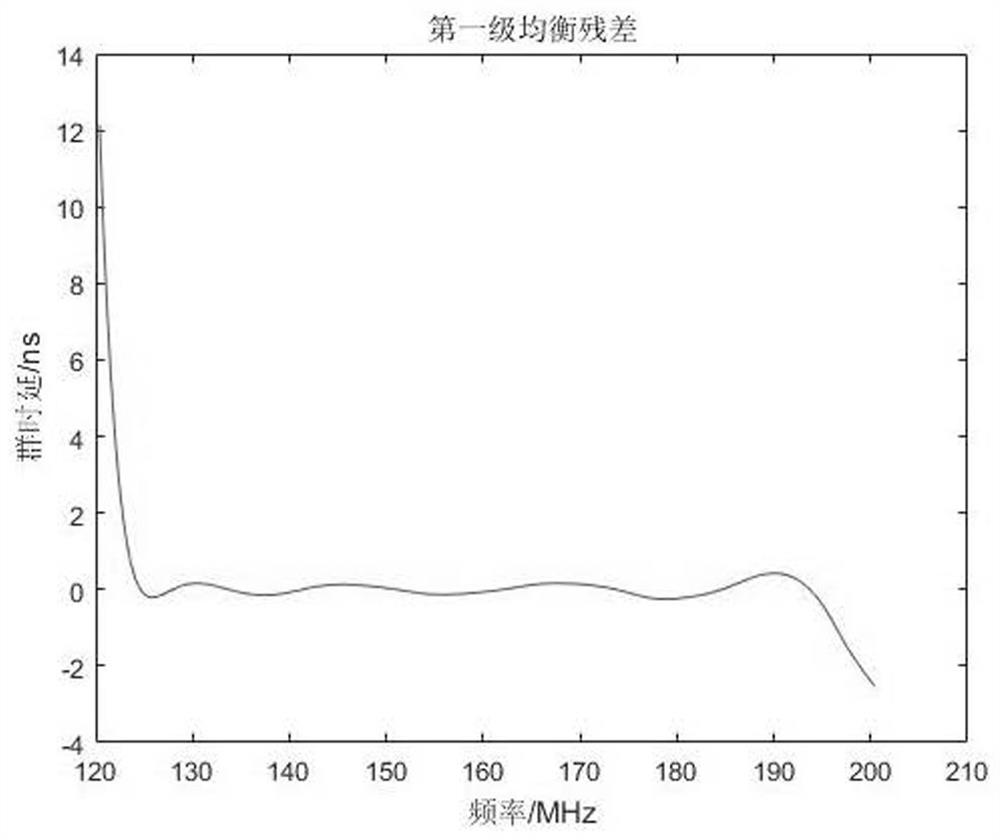

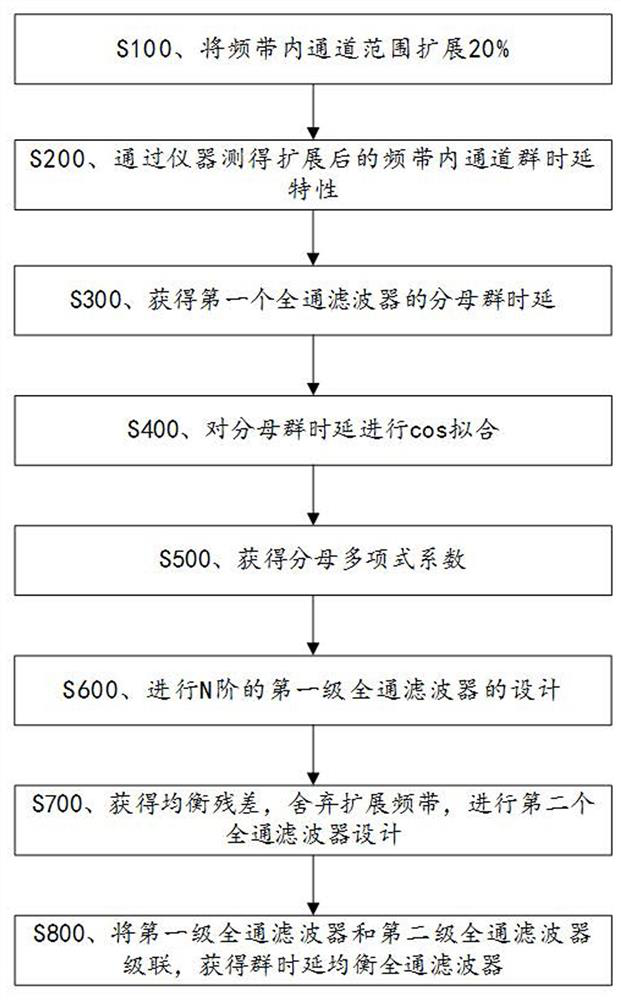

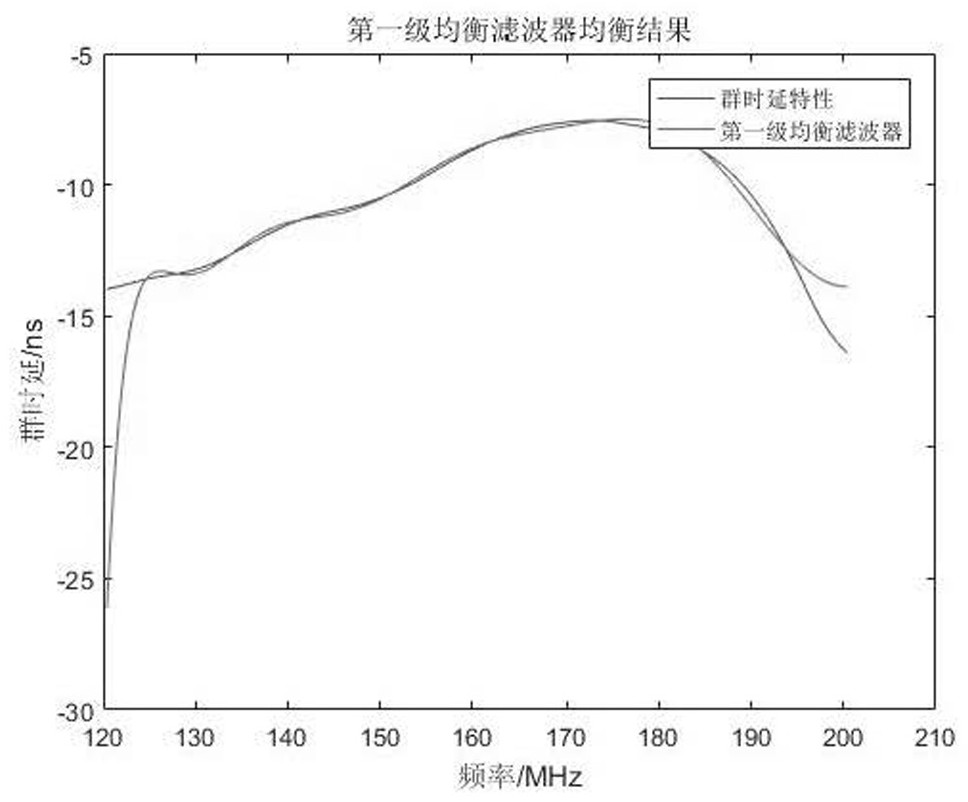

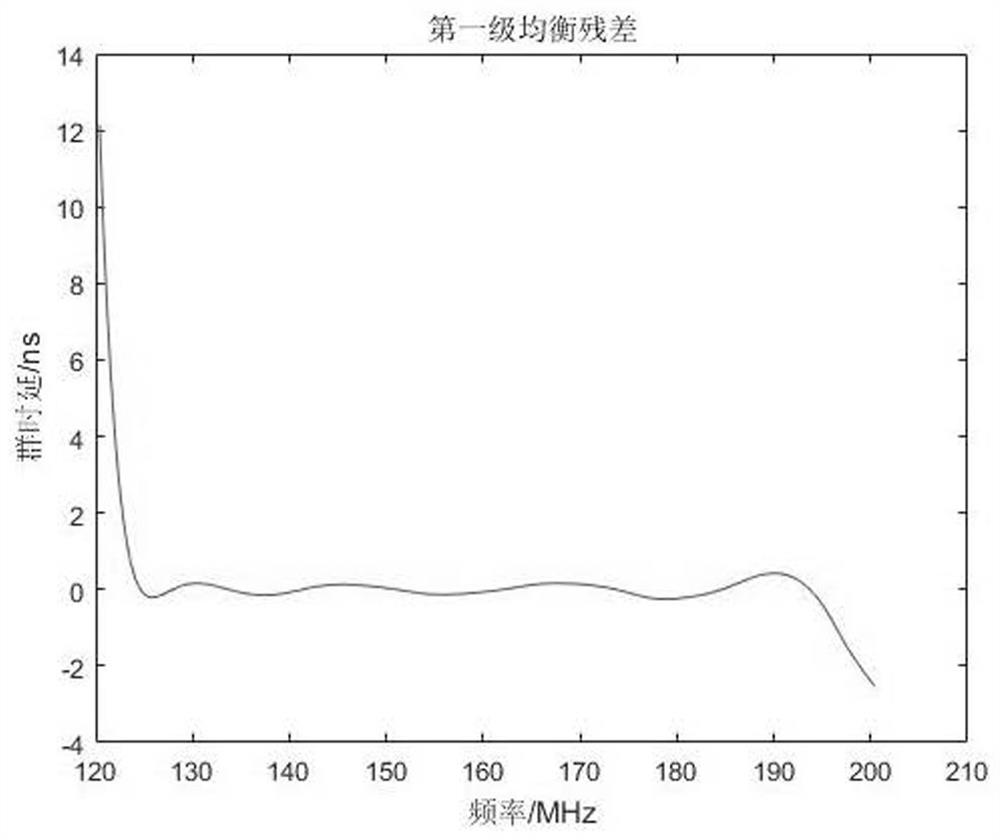

Navigation receiver radio frequency front end group delay characteristic equalization design method and device

ActiveCN113176592AGroup Delay EqualizationHigh frequency of fluctuationsSatellite radio beaconingTransmitter/receiver shaping networksEqualizationControl theory

The invention discloses a navigation receiver radio frequency front end group delay equalization design method and device. The method comprises the following steps: expanding a channel range in a frequency band by M%; measuring the time delay characteristic of the channel group in the expanded frequency band; obtaining denominator group delay of an all-pass filter; carrying out cos fitting on the denominator group time delay, and acquiring a denominator coefficient of the all-pass filter; obtaining a denominator polynomial coefficient; designing a first-stage all-pass filter; acquiring a balanced residual error, abandoning the extended frequency band, and designing a second-stage all-pass filter; and cascading the first-stage all-pass filter and the second-stage all-pass filter to obtain the group delay equalization all-pass filter. According to the invention, the all-pass filter of any group delay is designed by using a complex cepstrum theory, secondary equalization is performed according to the equalization residual error, and finally the group delay can be equalized by using the finite filter order in the specified passband so that the problem of a positioning error caused by related peak distortion brought by the group delay is solved.

Owner:NAT UNIV OF DEFENSE TECH

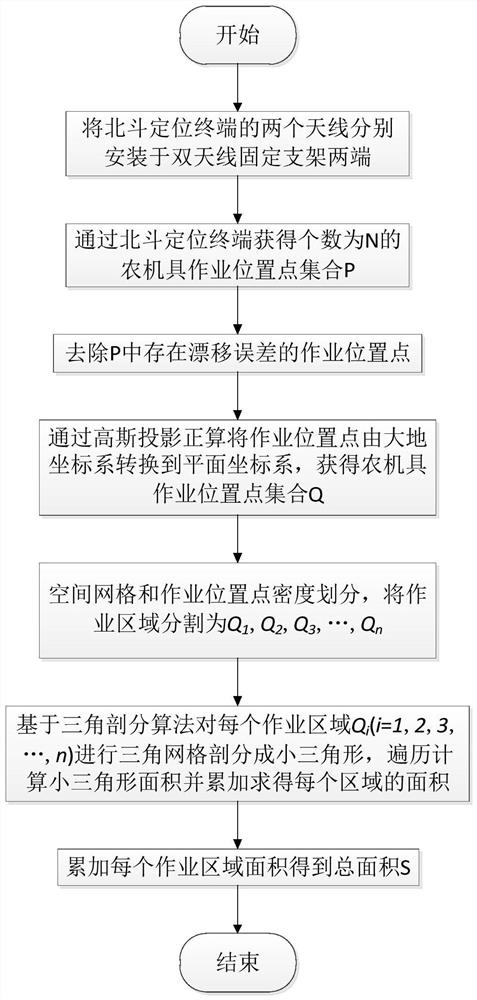

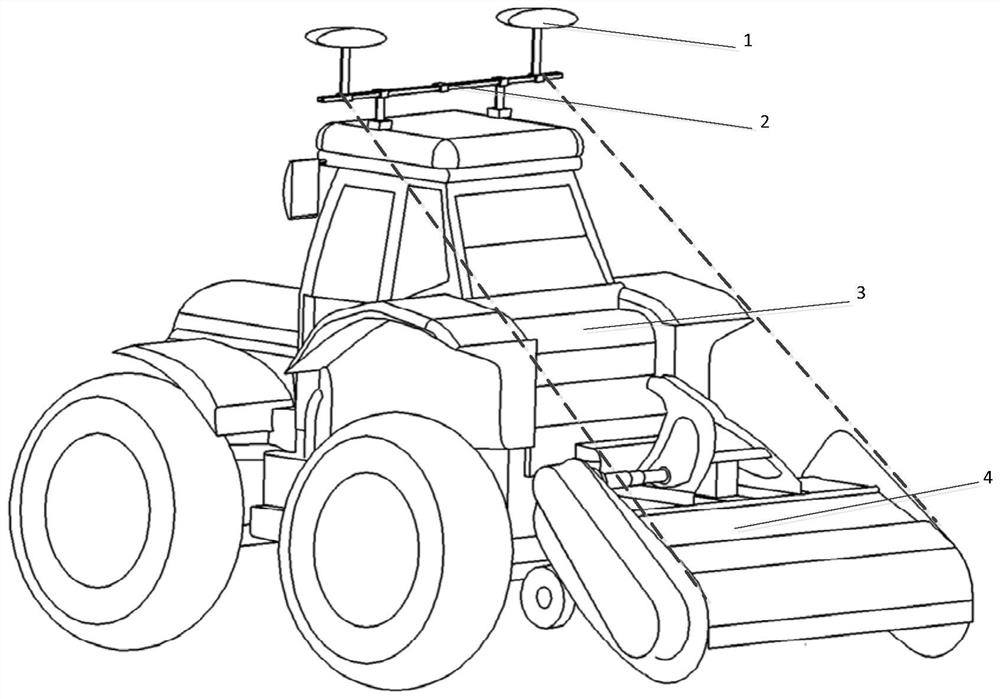

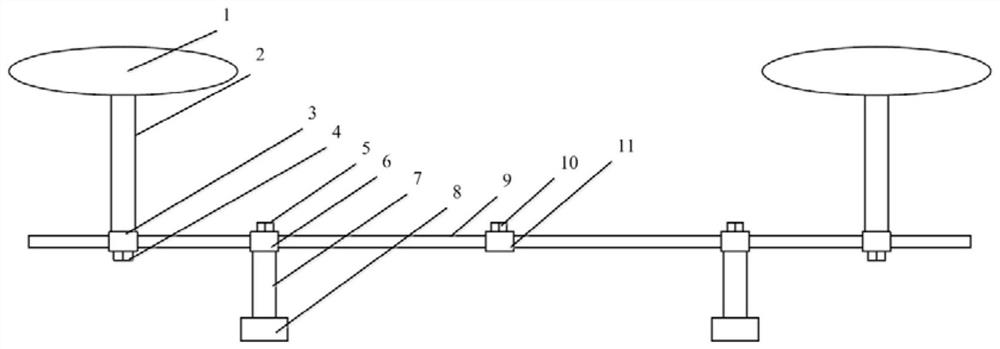

Agricultural machinery operation region measuring method and device based on triangulation

ActiveCN112665503AImprove adaptabilityAccurate measurementElectric/magnetic area measurementsSatellite radio beaconingData setTriangulation

The invention discloses an agricultural machinery operation region measuring method and device based on triangulation. The agricultural machinery operation region measuring method comprises the steps of: carrying out ground operation through using an agricultural machinery tool with a satellite positioning receiving antenna, and acquiring the operation position data of the agricultural machinery tool through the satellite positioning receiving antenna; preprocessing the operation position data set to remove error position data in the operation position data set, and projecting the operation position data set from a geodetic coordinate system to a plane space coordinate system by adopting Gaussian projection positive calculation; performing region division on all position points of the operation position data set based on the breadth and the maximum speed of agricultural implement operation; for each region, performing triangulation on the region by adopting a triangulation algorithm according to all operation position data in the region, and calculating the area of each triangulation to obtain the area of the region; accumulating the areas of all regions to obtain the total operation area of the agricultural machinery. The agricultural machinery operation area measuring method and the device are suitable for all-terrain area measurement, and the measurement precision is high.

Owner:湖南省农业装备研究所 +1

Unloading and positioning device suitable for robot loading and unloading flexible production line

ActiveCN109366242BOvercome positioning errorAdapt to diversityMetal working apparatusProduction lineControl engineering

The invention discloses a loading and unloading and positioning device suitable for a flexible robot loading and unloading production line. Pull the nail, set two ear plates with positioning holes, and fix the RFID code at the corner; the center of the cross arm of the U-shaped fork component is fixed with the robot flange component, and the two ends are fixed with the position sensor and the code reader. There is a positioning pin installation hole on the wall for fixing the positioning pin; the auxiliary workbench is fixed with a zero point positioning system at the position corresponding to the pull stud; when working, the positioning hole of the quick change tray is plugged into the positioning pin of the fork component; The pull stud is placed in the zero point positioning hole of the pull stud of the zero point positioning system, and the reverse taper surface at its upper end is clamped in the reverse taper hole of the zero point positioning system. The invention is used in a flexible production line for robot loading and unloading, can adapt to the diversity of workpieces, has high identification accuracy, good grasping reliability, and high zero point positioning accuracy.

Owner:BAODING XIANGYANG AVIATION PRECISION MACHINERY

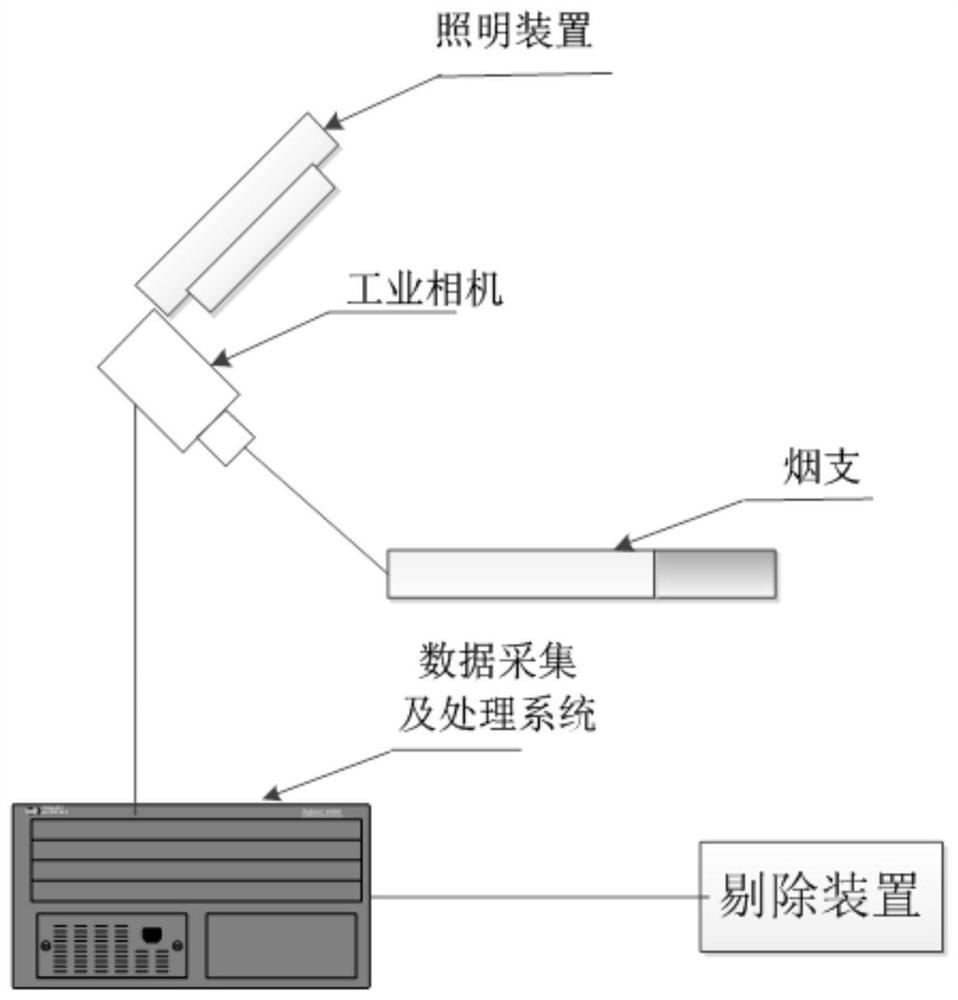

Cigarette positioning device and method based on deep learning

PendingCN113421235AAchieve adaptiveReduce consumptionImage enhancementImage analysisComputer visionData preparation

The invention discloses a cigarette positioning device and method based on deep learning, and belongs to the technical field of industrial detection and computer vision. The cigarette positioning device comprises a lighting device, an industrial camera, a data acquisition and processing system and a rejection device which are connected in sequence; the industrial camera and the lighting device are installed on the fixing support and located on the inclined upper side of the cigarette. The data acquisition and processing system is used for triggering the industrial camera and acquiring and processing cigarette image data; and the removing device is used for removing unqualified cigarettes. According to the cigarette positioning method, the cigarette positioning device based on deep learning is adopted to carry out positioning detection on cigarettes; the positioning detection method comprises a data preparation stage, a model training stage and a model application stage. Cigarette detection is carried out through the model based on deep learning, cigarettes in a cigarette packet are accurately positioned, the problem of cigarette positioning errors existing in a traditional cigarette detector is solved, target self-adaption in the equipment debugging process is achieved, and consumption of manpower and material resources is reduced.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

Navigation receiver radio frequency front-end group delay characteristic equalization design method and device

ActiveCN113176592BOvercome positioning errorDelay characteristic equalizationSatellite radio beaconingTransmitter/receiver shaping networksEqualizationControl theory

The invention discloses a navigation receiver radio frequency front-end group delay equalization design method and device, comprising the following steps: expanding the channel range in the frequency band by M%; measuring the extended channel group delay characteristics in the frequency band; obtaining all-pass filtering The denominator group delay of the filter; Cos fitting is performed on the denominator group delay to obtain the denominator coefficient of the all-pass filter; obtain the denominator polynomial coefficient; carry out the design of the first-stage all-pass filter; obtain the equalization residual and discard the extended frequency band , to design the second-stage all-pass filter; cascade the first-stage all-pass filter and the second-stage all-pass filter to obtain a group delay equalization all-pass filter. The present invention uses the complex cepstrum theory to design an all-pass filter with any group delay, performs secondary equalization according to the equalization residual error, and finally can use the finite filter order to equalize the group delay within the specified passband, thus solving the problem of group delay The positioning error problem caused by the correlation peak distortion brought by the delay.

Owner:NAT UNIV OF DEFENSE TECH

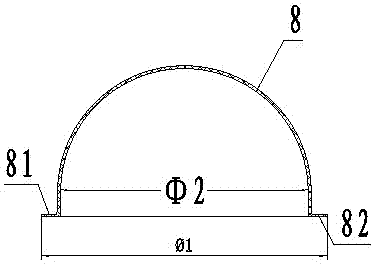

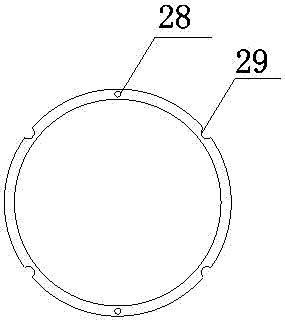

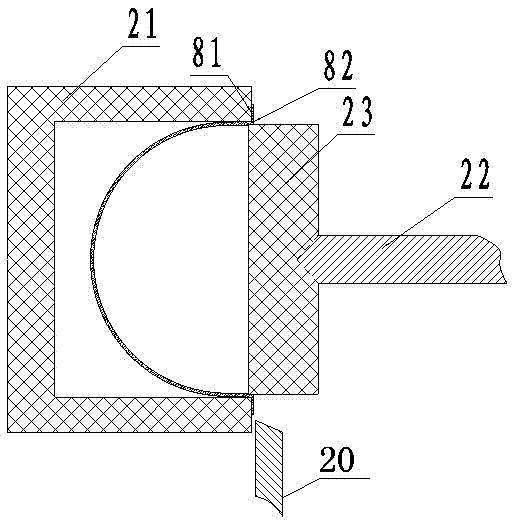

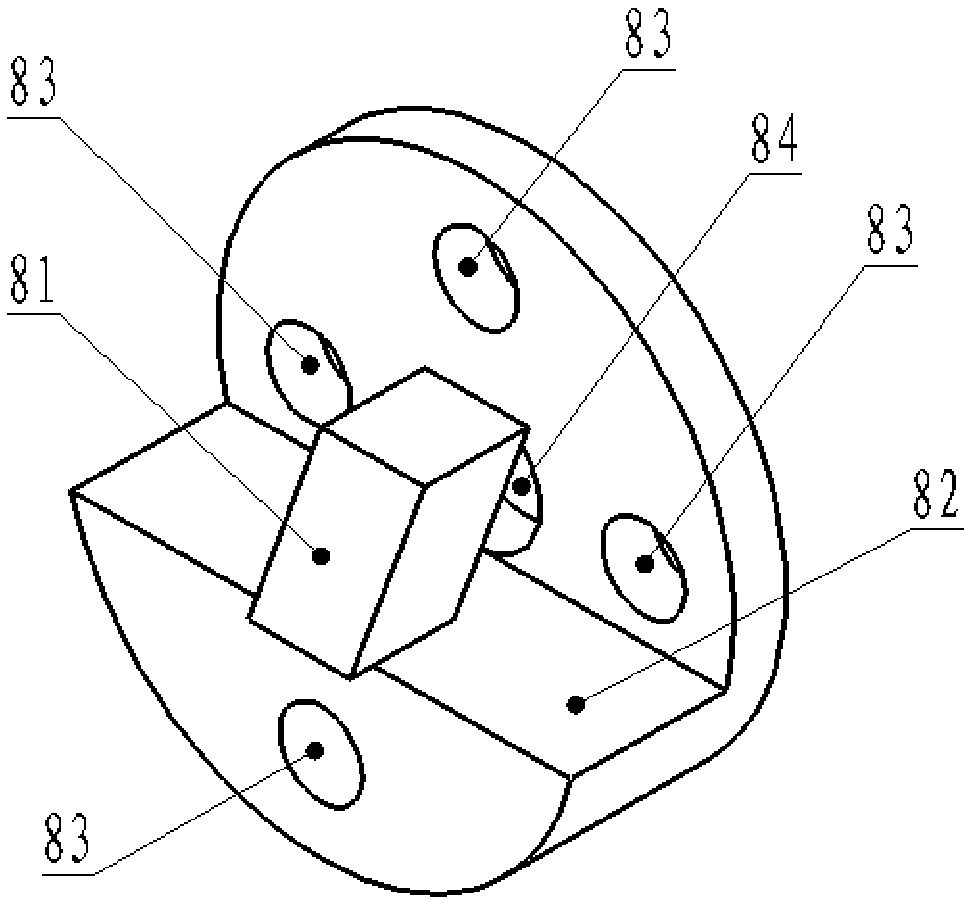

Clamp for machining of resin dome cover flanged edge and with one-time clamping formation function and machining method for resin dome cover flanged edges

ActiveCN107052856AEasy to processOvercome positioning errorPositioning apparatusMetal-working holdersEngineeringStructural engineering

A clamp for machining of a resin dome cover flanged edge and with a one-time clamping formation function is characterized in that a clamp framework is formed by a bottom plate, guide columns, a supporting air cylinder, a movable plate and a top plate; a vacuum fixing base is arranged on the movable plate; an inner cavity of the vacuum fixing base is matched with the outer surface of a dome cover; the upper end of the vacuum fixing base is provided with two layers of steps; the external diameter of the inner edge face of the first step is smaller than the dimension of the machined external diameter portion of the dome cover flanged edge; the external diameter of the inner edge face of the second step is equal to the dimension of the non-machined external diameter portion of the dome cover flanged edge; a stepped hole is formed in the center of the top plate; a dome cover positioning ring is embedded in the stepped hole of the top plate; a vacuum generating device is connected with a normally open one-way electromagnetic valve and a normally closed one-way negative-pressure electromagnetic, connected with the vacuum fixing base and used for conducting vacuumizing on the inner cavity of the vacuum fixing base; and the movable plate, the vacuum fixing base and the dome cover make vertical motion along the guide columns as the supporting air cylinder moves. According to the clamp, a vacuum clamping mode is adopted, all machining operations are completed through one time of clamping, the machining procedures are optimized dramatically, and the machining efficiency and product yield are improved.

Owner:福建富兰光学股份有限公司

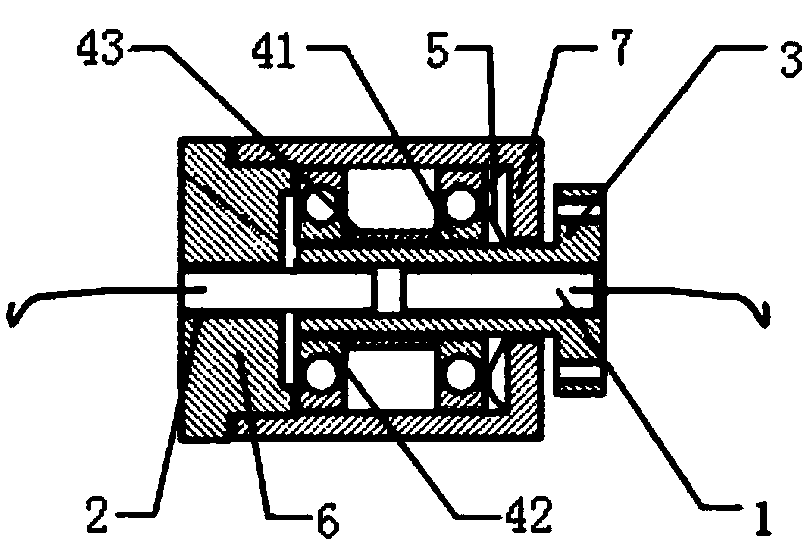

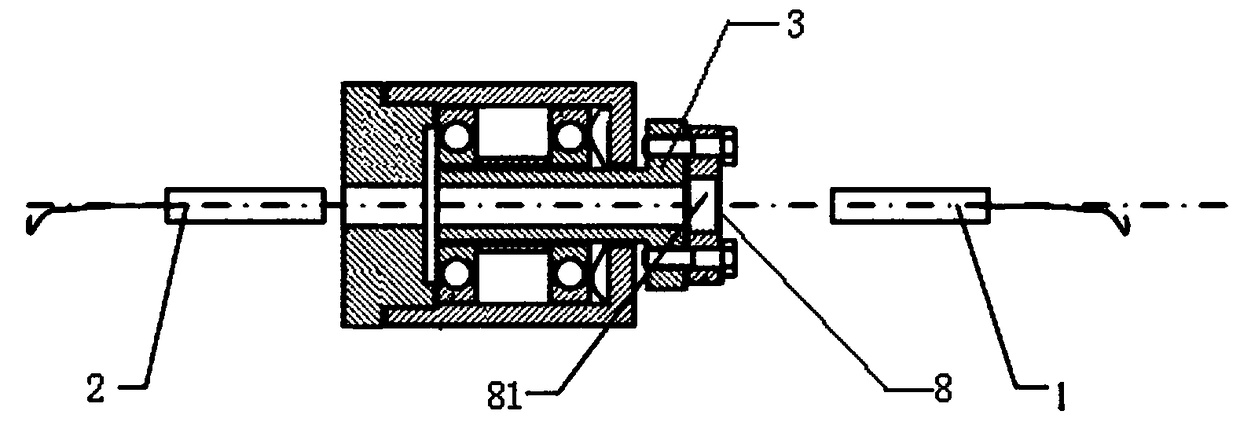

Guiding integrated structural punching die provided with male die or female die

InactiveCN107952889ASolve the position deviationPrecise zero and small gap blankingShaping toolsPosition errorEngineering

The invention discloses a guiding integrated structural punching die provided with a male die or a female die. The guiding integrated structural punching die provided with the male die or the female die comprises a rack connecting plate, a fixing plate connected with the rack connecting plate through a connecting plate, a puncher pin piece fixedly mounted on the fixing plate, a guiding assembly mounted on a seat body and used for conducting guiding stabilizing on the puncher pin piece and the female die mounted on the seat body. According to the guiding integrated structural punching die provided with the male die or the female die, a guiding column, the male die and the seat body are integrated, the guiding column can be designed into a proper shape according to the shape and size of themale die and can also adopt standard piece specifications commonly used in the market, the problem of position error between the male die and the guiding column of a tradition punching die structure is thoroughly solved, the problems of lateral force generated through imbalance of an unbalanced-loading punching die and position deviation generated by deformation of an upper template and a lower template of the traditional punching die structure are solved, high-speed, stable and accurate zero-clearance punching can be achieved, the die stability is improved, and the life of the die is prolonged.

Owner:广东日信高精密科技有限公司

Butt-joint type single-core optical rotating connector with optical fiber collimator and installation method thereof

PendingCN109239858AImprove environmental stabilityReduce machining accuracyCoupling light guidesPosition errorCollimator

The invention discloses a butt-joint type single-core optical rotating connector with an optical fiber collimator and an installation method thereof. The butt-joint type single-core optical rotating connector with the optical fiber collimator comprises rotating end optical fiber collimators, stationary end optical fiber collimators, rotors, bearing assemblies, stationary end installation covers and installation shells. The bearing assemblies comprise first bearings, second bearings and bearing blocking rings. The butt-joint type single-core optical rotating connector is characterized in that the bearing assemblies are fixed between the rotors and the installation shells, and elastic elements are located between bearings and the installation covers. According to the butt-joint type single-core optical rotating connector with the optical fiber collimator, the bearings can be compressed, clearance in the axial direction is reduced, and stability of components under the conditions of temperature change and vibration impact is improved. According to the installation method of the butt-joint type single-core optical rotating connector with the optical fiber collimator, the problem of angle and position errors between the optical rotating connector and rotating shafts during installation is solved, and the collimator can be installed quickly and effectively.

Owner:上海传输线研究所

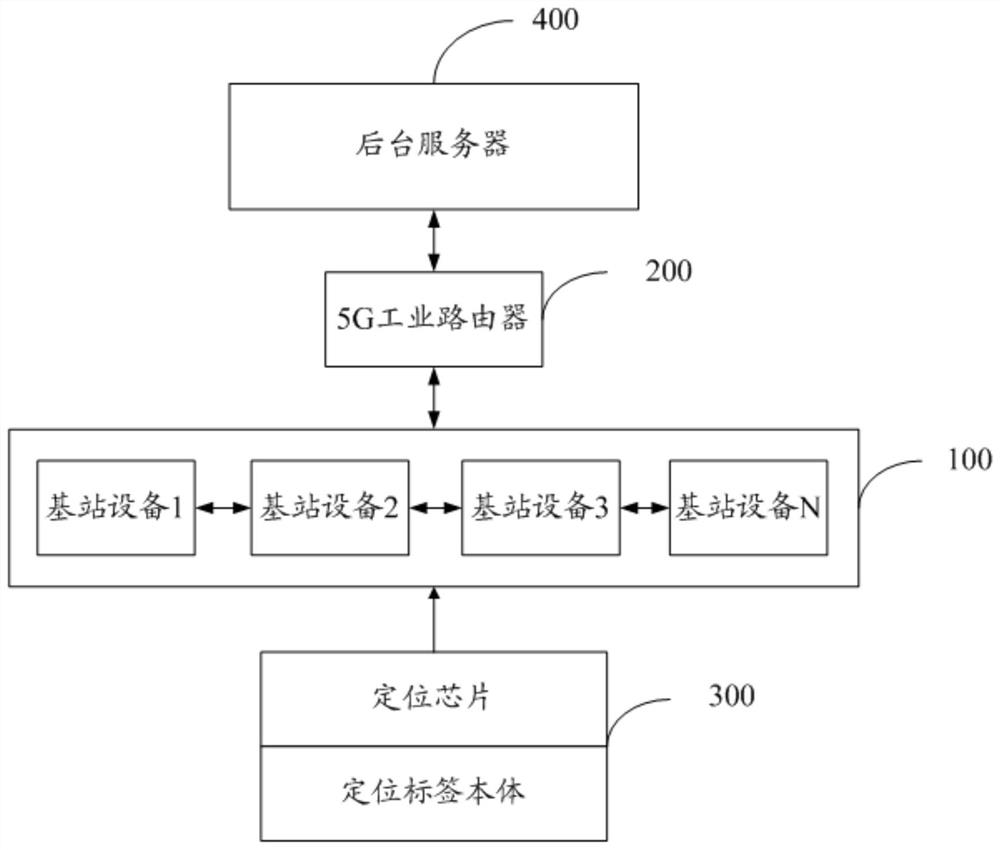

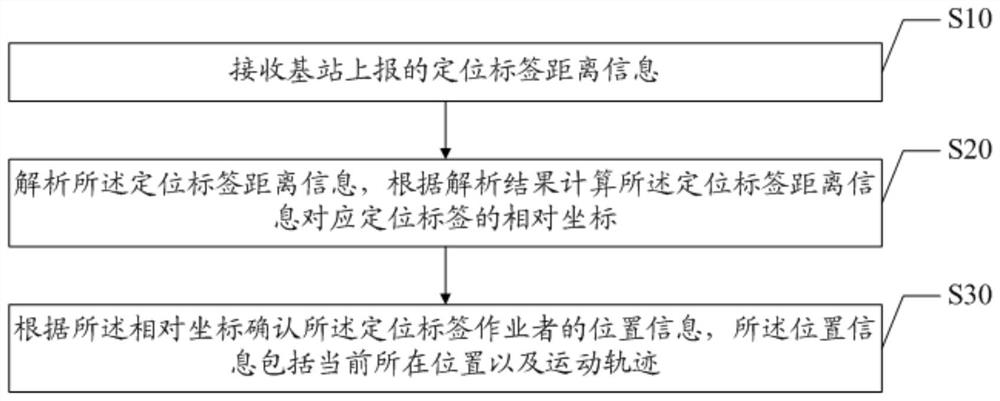

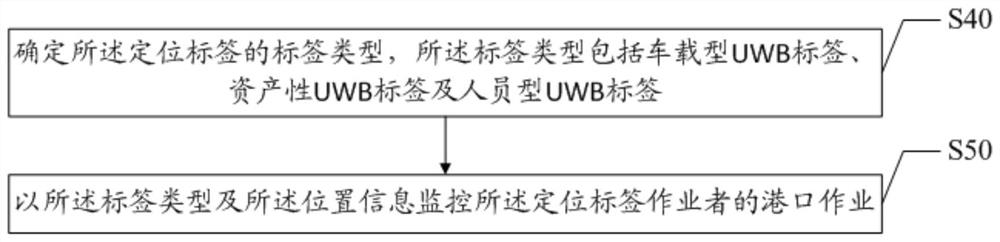

Port area positioning system and method

PendingCN112543505AHigh positioning accuracyOvercome positioning errorWireless communicationHigh level techniquesEmbedded systemRouter

The invention discloses a port area positioning system, which comprises a base station positioning mechanism, a 5G industrial router, a positioning label assembly and a positioning management server,and is characterized in that the positioning label assembly comprises a plurality of positioning label devices, and a positioning chip is arranged in a positioning label body and is electrically connected with the positioning label body; the base station positioning mechanism is in communication connection with the positioning label assembly; and the mobile terminal and the positioning managementserver are in communication connection with the 5G industrial router. The invention also discloses a port area positioning method, which comprises the following steps: receiving the positioning labeldistance information reported by the base station, and calculating the relative coordinates of the positioning label corresponding to the positioning label distance information according to the positioning label distance information; and confirming the position information of the positioning label operator according to the relative coordinates. Through the UWB technology, the positioning precisionof port personnel, equipment and vehicles is improved, and the high-precision positioning technology meets the requirements for high-precision visual management of a container dangerous goods storageyard and high-precision positioning of vehicles under a quay crane / yard bridge.

Owner:CHINA MERCHANTS HLDG INT INFORMATION TECH COMPANY

Centering tool for engine gearbox and engine body

InactiveCN112676824ASolve positioning and installation errorsLow input costMetal working apparatusFlywheelMain bearing

The invention provides a centering tool for an engine gearbox and an engine body. The centering tool for the engine gearbox and the engine body comprises a first supporting shaft, a second supporting shaft, a supporting disc frame and a pipe sleeve, a through hole is formed in the middle of a supporting disc frame, the pipe sleeve is of a hollow cylindrical structure, the periphery of one end of a crankshaft and the periphery of the upper end of the pipe sleeve are connected into the through hole in a sleeved mode, the periphery of the lower end of the pipe sleeve is sleeved with a gearbox main bearing hole, the first supporting shaft and the second supporting shaft are installed at the two ends of the supporting disc frame respectively and are arranged in parallel, and the lower end of the first supporting shaft and the lower end of the second supporting shaft are fixedly connected into two inert shaft holes respectively. According to the using method, when the engine body and the gearbox are assembled, errors of the positioning and mounting of a split type gearbox can be solved, the centering of the gearbox and an engine body main bearing hole can be achieved without combined machining and pin hole positioning, and the device is suitable for large marine diesel engines as well as diesel engines for split type gearboxes, engine bodies, and flywheel housings that require coaxiality.

Owner:CHINA NORTH ENGINE INST TIANJIN

Special tool for 10kv line live work robot connection and drainage line operation

ActiveCN110021898BAvoid clutterBeautiful lengthApparatus for cutting/splicing cablesApparatus for joining/termination cablesStructural engineeringMechanical engineering

The invention discloses a special tool for 10KV circuit live-wire work robot drainage wire connecting work. The special tool comprises a cable stretch-in end and a cable stretch-out end, wherein a puncture cable clamp is positioned between the cable stretch-in end and the cable stretch-out end. The special tool comprises a substrate, and is characterized by comprising a drainage wire shearing mechanism installed on the substrate, wherein the drain wire shearing mechanism comprises an electric cutter; and the electric cutter is positioned at the cable stretch-out end. According to the special tool, robot live-wire wiring work can be realized, manual live-wire wiring work also can be realized, and the special tool has the function of shearing unnecessary drainage wires.

Owner:山东乐普韦尔自动化技术有限公司

A positioning system and method

ActiveCN107276632BReduce workloadImprove work efficiencyLine-transmission monitoring/testingBus networksComputer hardwareWired communication

The invention discloses a positioning system and method. Wherein, the system includes: a positioning communication device, a relay control device and a server; the clock line of the positioning communication device is communicatively connected with the clock line of the relay control device, and the data line of the positioning communication device is communicatively connected with the data line of the relay control device , the positioning line of the positioning communication device communicates with the positioning line of the relay control device; the relay control device communicates with the server. The present invention adopts a wired communication scheme that combines the functions of "positioning" and "data communication", that is, "positioning line" and "data line" complement each other, cooperate together to complete the automatic alignment function, and also have the form of data communication function. When working, the positioning command is sent to the positioning communication device through the relay control device, and the positioning communication device completes the positioning, which solves the technical problems of heavy workload and large errors in the prior art.

Owner:THE SECOND CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU +1

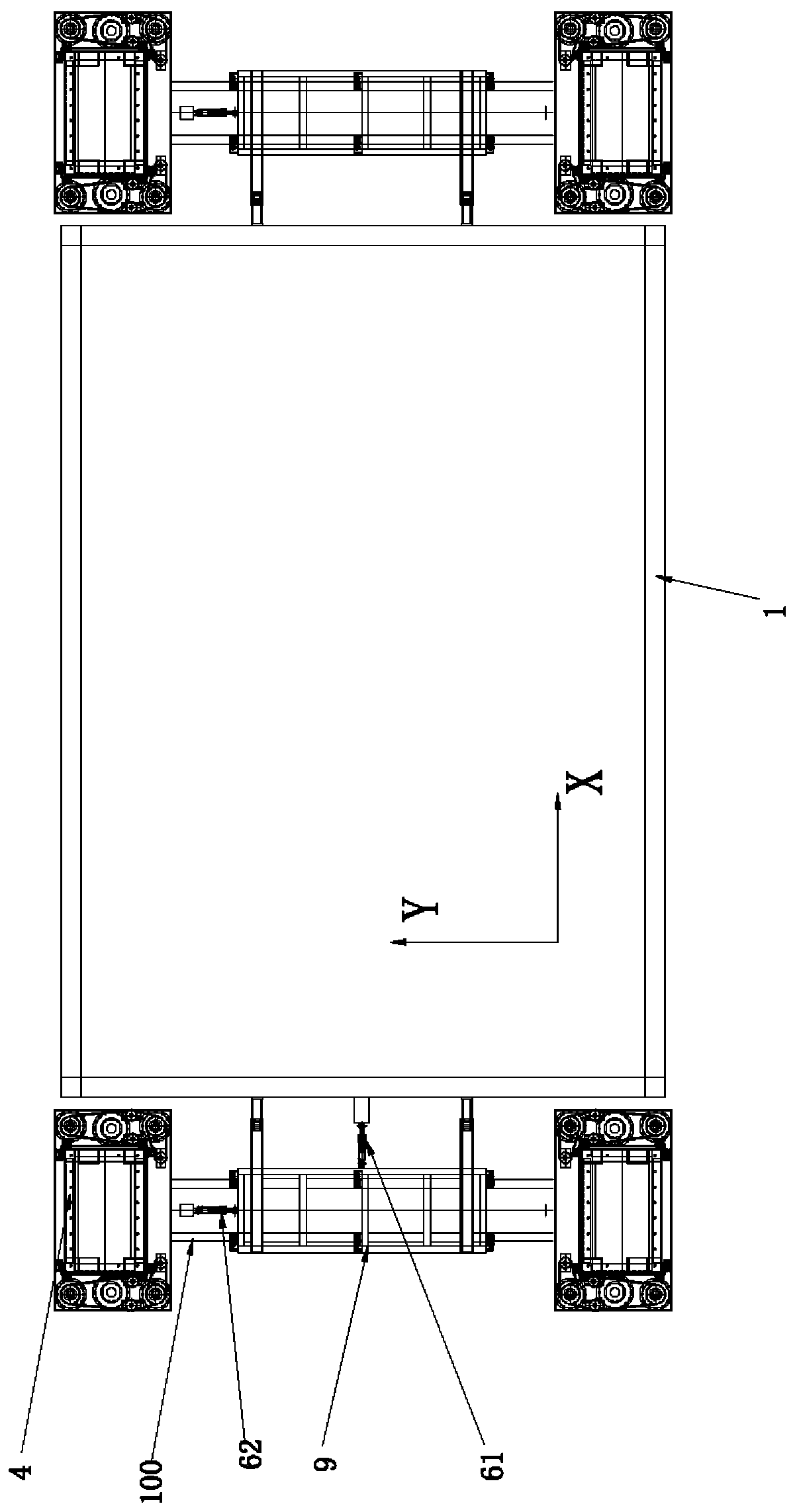

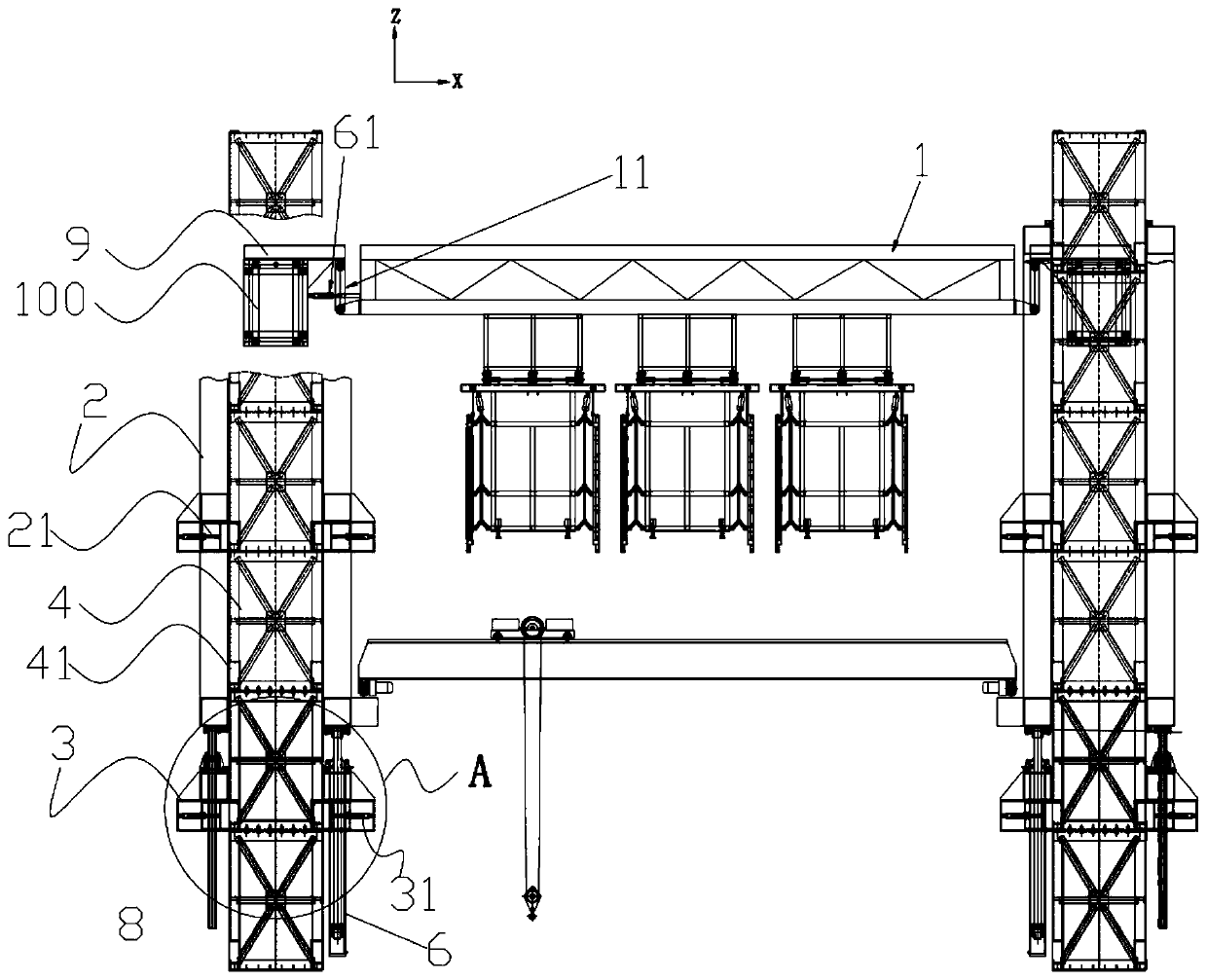

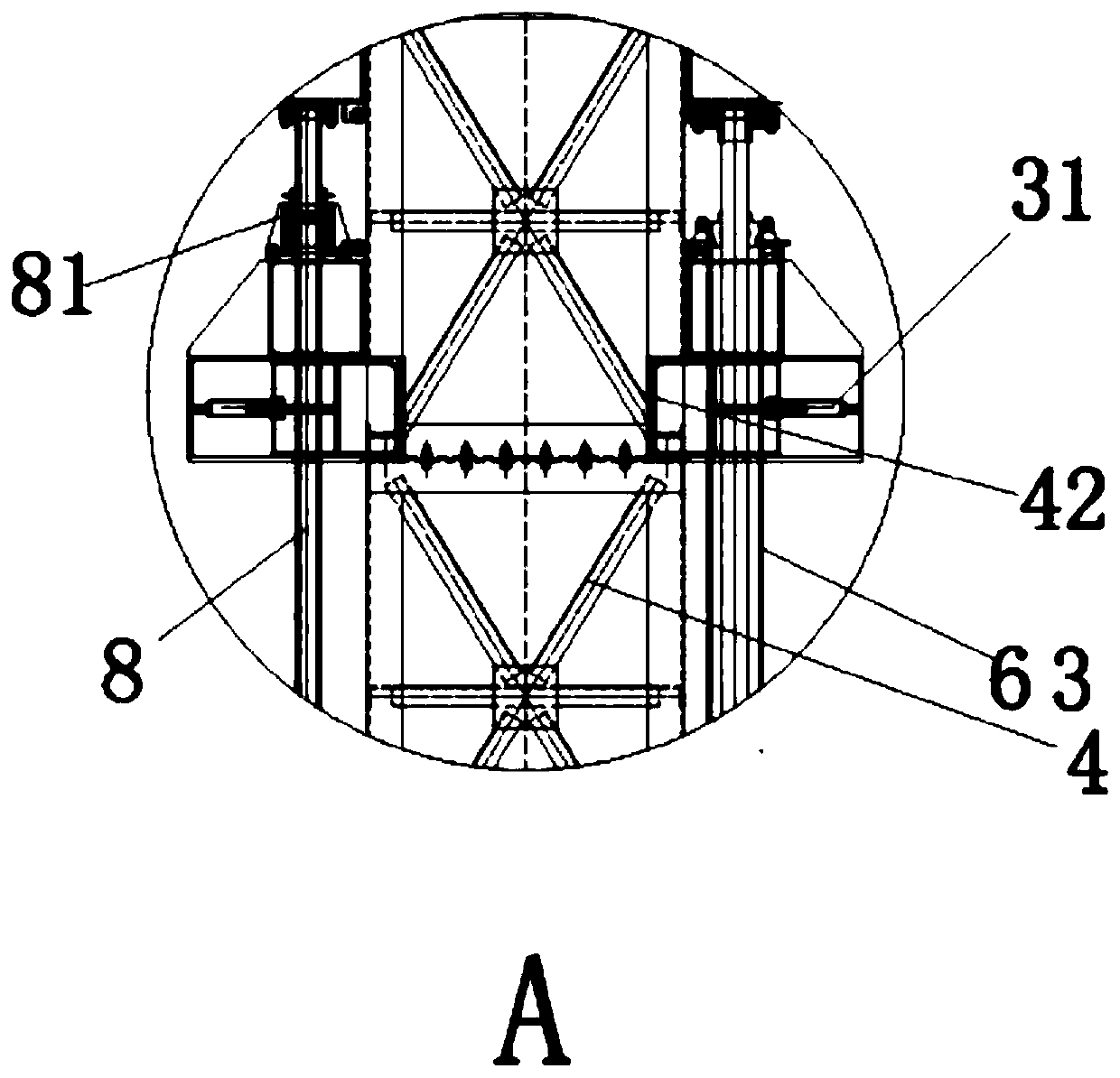

Template automatic alignment device of building machine

PendingCN110331856AAutomatic alignmentOvercome positioning errorForms/shuttering/falseworksEngineeringPosition error

The invention relates to the technical field of building machines, in particular to a template automatic alignment device of a building machine. The template automatic alignment device comprises at least four standard joint sets, jacking mechanisms and two truss sectional materials. The alignment device comprises alignment trolleys which are arranged on the truss sectional materials in a sleevingmanner and can slide along the truss sectional materials, and the alignment trolleys are further provided with X-axis adjusting mechanisms driving a template frame to move in the transverse direction.The truss sectional materials are provided with Y-axis adjusting mechanisms used for driving the alignment trolleys to move in the longitudinal direction. The alignment device further comprises a controller, an X-axis position sensor, a Y-axis position sensor and a Z-axis position sensor, wherein the X-axis position sensor, the Y-axis position sensor and the Z-axis position sensor are arranged ata building fixed end. The X-axis position sensor, the Y-axis position sensor, the Z-axis position sensor, the jacking mechanisms, the X-axis adjusting mechanisms and the Y-axis adjusting mechanisms are electrically connected with the controller and are controlled by the controller. Compared with the prior art, the problem of positioning errors generated in the construction process is solved, adjustment can be conducted at any time in the construction process, and the work efficiency is improved.

Owner:SHENZHEN EXCELLENCE INDZATION INTELLIGENT CONSTR DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com