High-rigidity large-torque vertical machining center

A vertical machining center and high torque technology, applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of low production efficiency, high maintenance cost and high tool change failure frequency of ferrous metal processing, and achieve Improvement of machine tool structure, improvement of production efficiency, and reduction of tool change failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

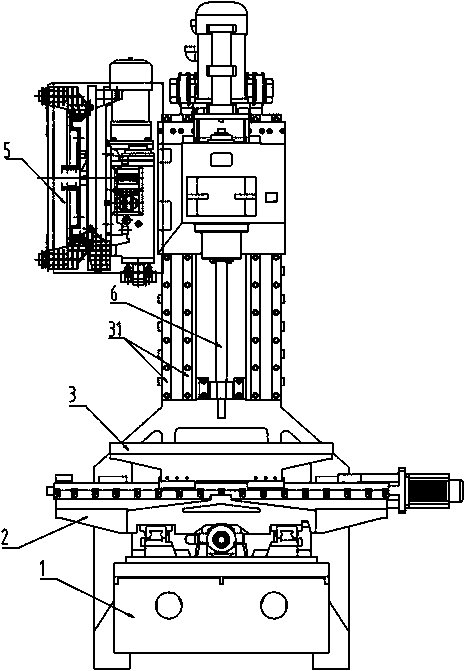

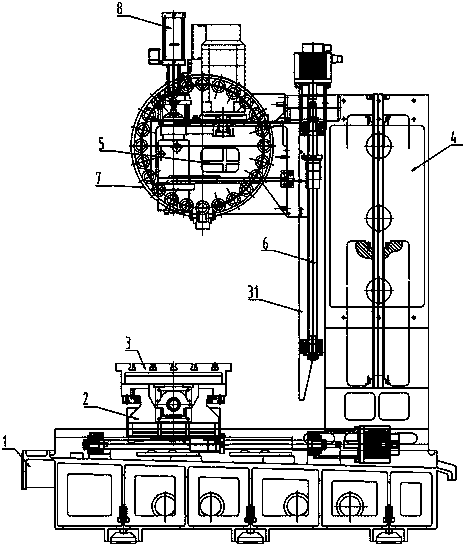

[0048] Embodiment 1: The high-rigidity and high-torque vertical machining center of this example, such as figure 1 , figure 2 , image 3 , including a honeycomb bed 1, which is provided with a double-layer densely ribbed saddle 2, a workbench 3, and a herringbone frame column 4 on the bed, which is slidably connected to a headstock 5 through a guide rail. , the workbench 3 is provided with a workbench guide rail 30, and the guide rail of the herringbone frame column 4 is a linear ball guide 31 larger than the workbench guide rail specification. The herringbone frame column is provided with a ball screw 6, the spindle box is threadedly connected to the ball screw, the spindle box is provided with a tool magazine 7 and a tool cylinder 8, and the spindle 9 of the spindle box is provided with a spindle positioning device, such as Figure 4 , the spindle positioning device includes a positioning pin provided on the spindle 9, a detection switch 29 is fixed on the spindle box by ...

Embodiment 2

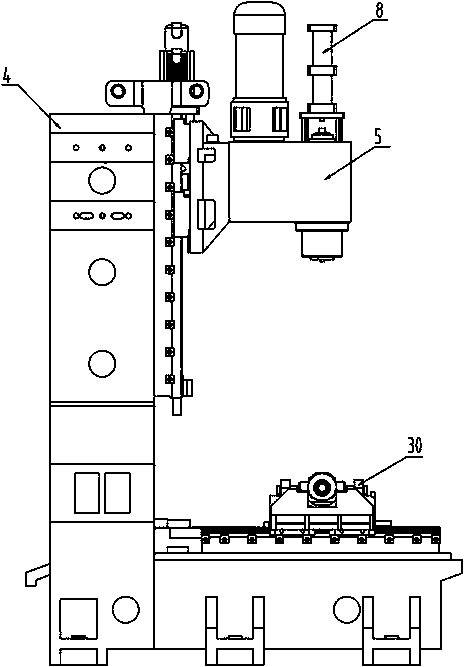

[0050] Embodiment 2: the high-rigidity and high-torque vertical machining center of this example, such as Figure 5 , Figure 6 , including a honeycomb bed 1, which is provided with a double-layer densely ribbed saddle 2, a workbench 3, and a herringbone frame column 4 on the bed, which is slidably connected to a headstock 5 through a guide rail. , the workbench 3 is provided with a workbench guide rail 30, and the guide rail of the herringbone frame column is a guide rail 32 larger than the workbench guide rail width. The herringbone frame column is provided with a ball screw 6, the spindle box is threadedly connected to the ball screw, the spindle box is provided with a tool magazine 7 and a tool cylinder 8, and the spindle 9 of the spindle box is provided with a spindle positioning device, such as Figure 7 , the spindle positioning device includes a positioning pin provided on the spindle 9, a detection switch 29 is fixed on the spindle box by a detection switch bracket 2...

Embodiment 3

[0052] Embodiment 3: the high-rigidity and high-torque vertical machining center of this example, such as Figure 8 , the spindle positioning device includes a mounting seat 22 and a base plate 23 fixed on the spindle box, the base plate is provided with an encoding shaft 24, the encoding shaft is connected with an encoder synchronous pulley 25, and the encoder synchronous pulley is connected to the main shaft 9 through a synchronous belt. , the encoder synchronous pulley is connected to the encoder 27 through the encoder mount 26 . The vertical machining center is equipped with electrical and numerical control systems. The spindle box is provided with a main motor 10, the main motor is connected to the first synchronous pulley 13 through the main motor pulley 11 and the synchronous belt 12, and the first synchronous pulley is connected to the main shaft through the first shaft body 14 and the first gear 16. The gear is threaded on the third shaft body 33 . A main shaft spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com