Butt-joint type single-core optical rotating connector with optical fiber collimator and installation method thereof

A technology of optical fiber collimator and rotary connector, which is applied in the direction of light guide, optics, instrument, etc., can solve the problems of collimator and rotation axis angle and position error, device instability, etc., to reduce processing accuracy and labor force , easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

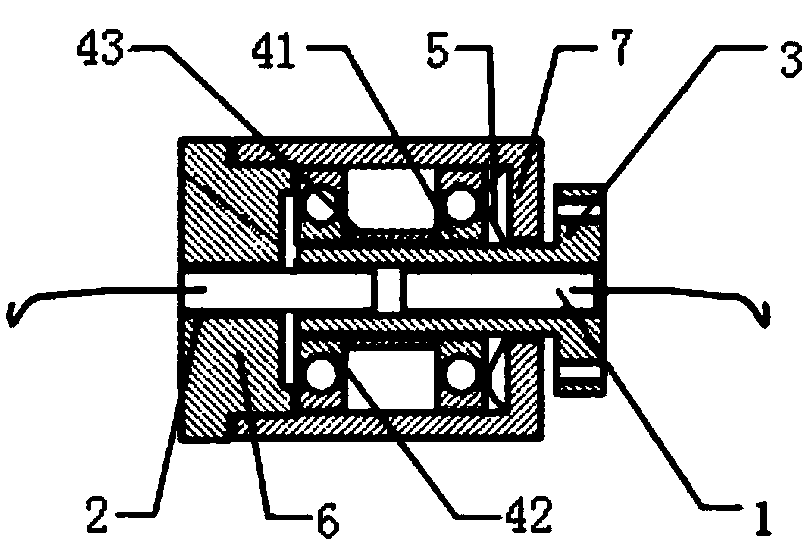

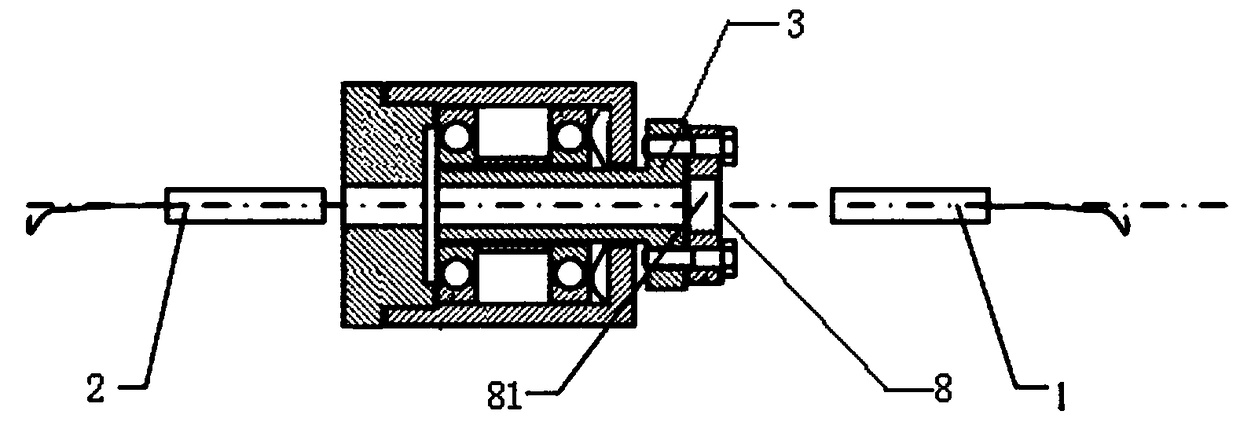

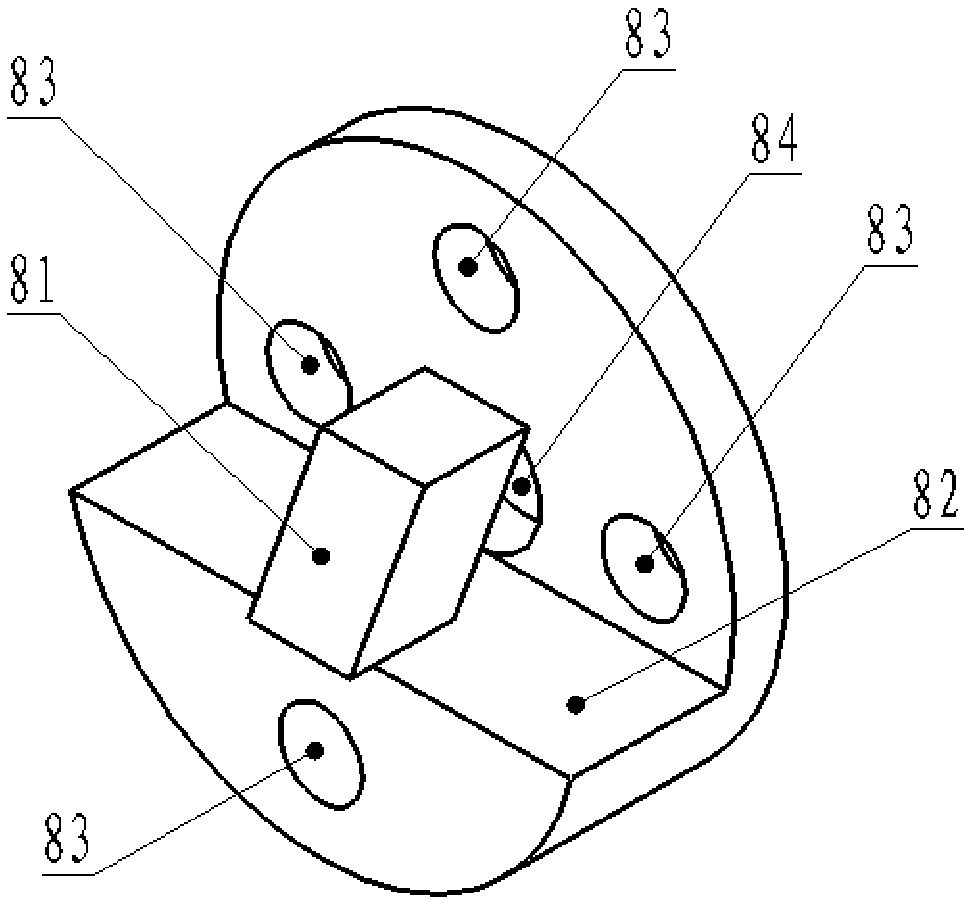

[0040] figure 1 It is a schematic diagram of the structure of the fiber collimator docking type single-core optical rotary connector of the present invention, as shown in the figure, including the rotating end fiber collimator 1, the stationary end fiber collimator 2, the rotor 3, the bearing assembly and the installation shell 7. The bearing assembly is located between the rotor 3 and the installation housing 7, the outer ring of the bearing is in interference connection with the installation housing 7, the inner ring of the bearing is in interference connection with the rotor 3, and the elastic element 5 is used on one side of the bearing assembly. The elastic element 5 is concentric with the two bearings, one side is in contact with the outer ring of the first bearing 41, and the other side is in contact with the installation shell 7; the elastic ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com