Conducting film integrated structure

A technology integrating structure and conductive film, which is applied in the input/output process of electrical digital data processing, instruments, and data processing, etc., can solve the problems of ITO surface cracking or fragmentation, and achieves omitting the surface concave and convex shape and extremely complex structure, Stable use effect and durable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

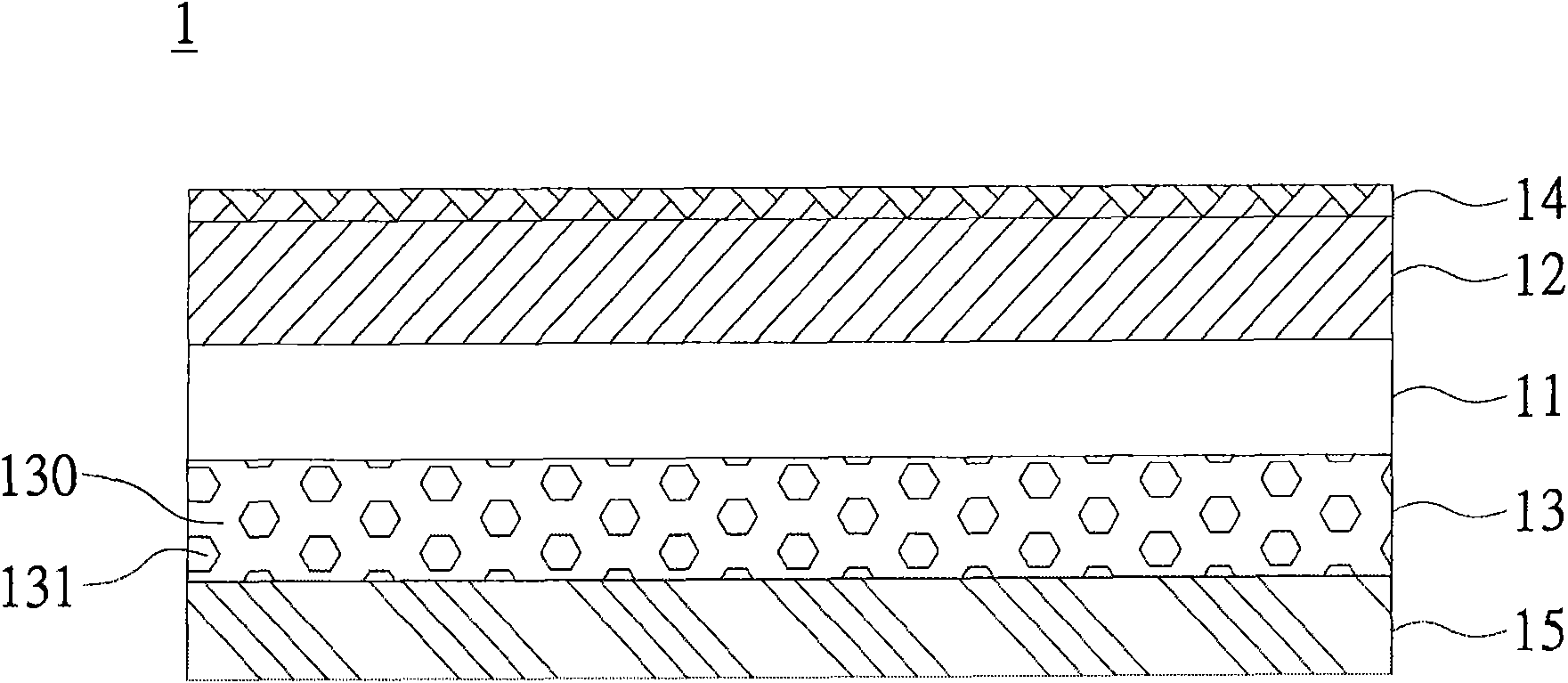

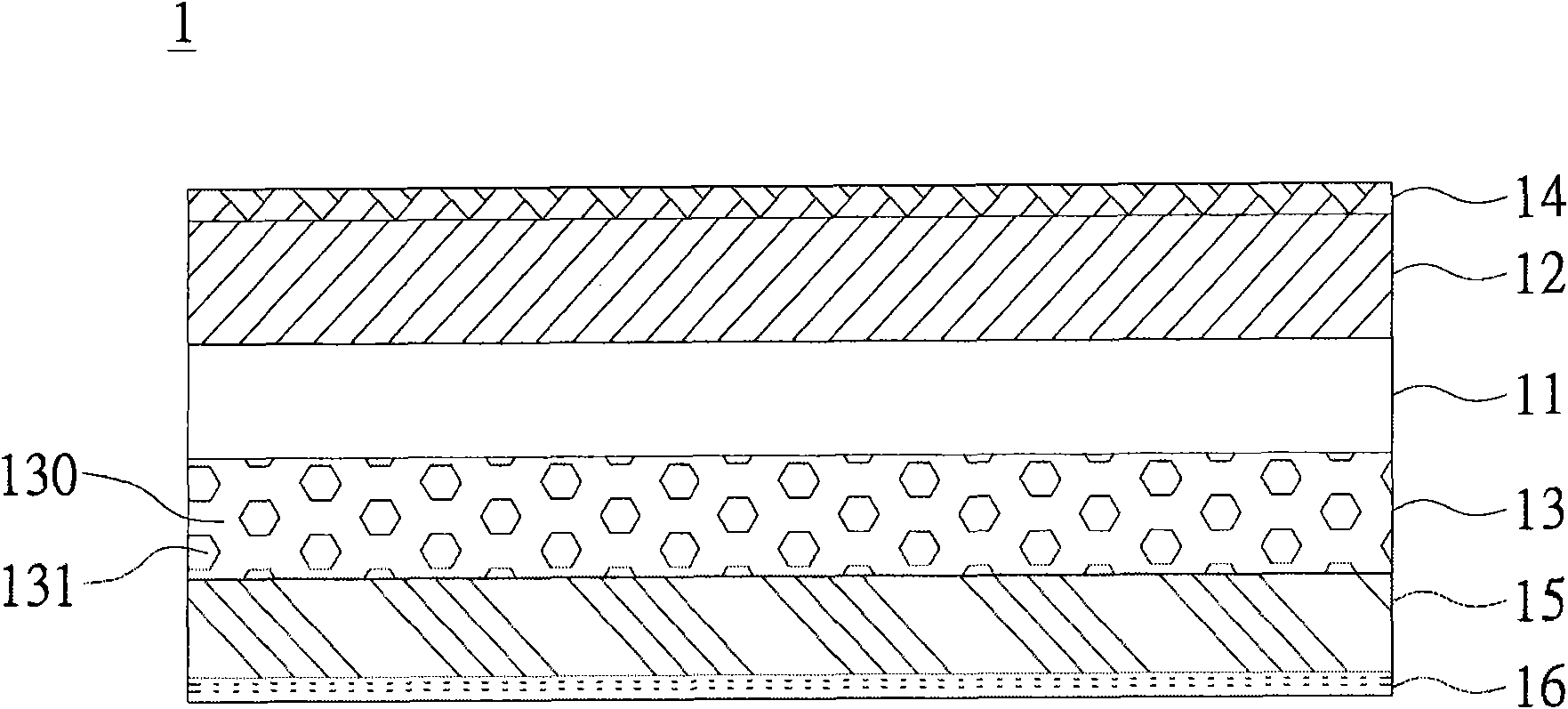

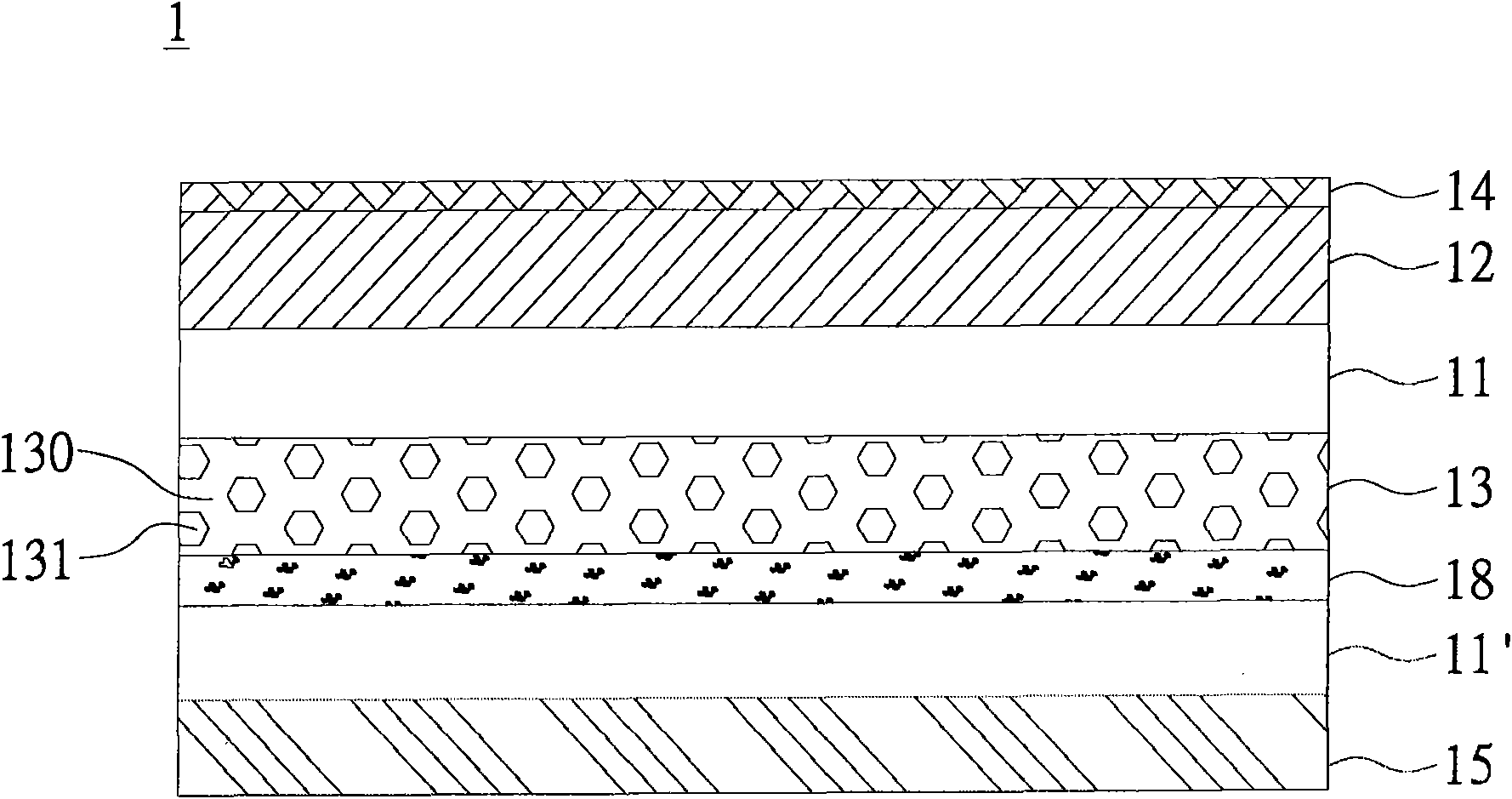

[0035] see figure 1 Shown is a schematic view of the first embodiment of the conductive film integrated structure 1 of the present invention. The conductive film integrated structure 1 of this embodiment includes: a substrate 11, an anti-glare layer (Anti-Glare Layer, AG) 12, an anti-Newton (Anti-Newton ring Layer, ANR) ring layer 13, a hard layer 14, and a transparent conductive film 15.

[0036] The substrate 11 is a transparent resin, which is polyethylene terephthalate (PET), cellulose triacetate (TAC), polyethylene naphthalate (PEN), polypropylene glycol, polyimide Amine, polyether, polycarbonate, polyamine, polyethylene, polypropylene or polyvinyl alcohol, polystyrene, polymethyl methacrylate, polyvinyl chloride, epoxy resin, phenolic resin, etc. or their equivalents.

[0037] The anti-glare layer 12 is arranged on one side of the base material 11, and the surface of the anti-glare layer 12 has a light-guiding microstructure (not shown), which is used to increase the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com