Method for preparing silane vitrification agent

The technology of a ceramizer and a silane coupling agent is applied in the field of preparing silane ceramizers, which can solve the problems of difference in the effect of silane ceramizers, reduce the difference in the effect of silane ceramizers, etc., and achieve the effect of stabilizing the use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for preparing a silane ceramic agent, comprising the following steps:

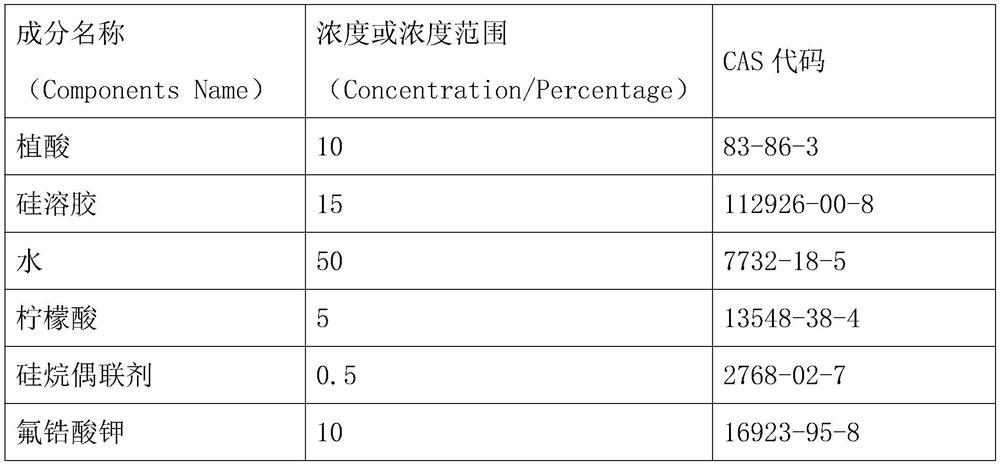

[0024] S1. The raw materials required for the preparation of silane ceramics: phytic acid, silica sol, citric acid, potassium fluorozirconate and silane coupling agent are divided into different parts according to the weight of 20 grams, and the raw materials are subjected to water treatment. deionize;

[0025] S2, deionized water is added in the reactor, and the temperature inside the reactor is raised, then the silica sol is added into the reactor and mixed with water, and then stirred and mixed with deionized water;

[0026] S3, continue to heat up the inside of the reactor, and add phytic acid inside the reactor, and stir and mix inside the reactor;

[0027] S4, add citric acid inside the reactor, stir after the citric acid is added into the reactor, and then continue to heat after standing for a period of time;

[0028] S5, adding potassium fluorozirconate and silane coupling agent i...

Embodiment 2

[0039] A method for preparing a silane ceramic agent, comprising the following steps:

[0040] S1. The raw materials required for the preparation of silane ceramics: phytic acid, silica sol, citric acid, potassium fluorozirconate and silane coupling agent are divided into different parts according to the weight of 30 grams, and the raw materials are subjected to water treatment. deionize;

[0041] S2, deionized water is added in the reactor, and the temperature inside the reactor is raised, then the silica sol is added into the reactor and mixed with water, and then stirred and mixed with deionized water;

[0042] S3, continue to heat up the inside of the reactor, and add phytic acid inside the reactor, and stir and mix inside the reactor;

[0043] S4, add citric acid inside the reactor, stir after the citric acid is added into the reactor, and then continue to heat after standing for a period of time;

[0044] S5, adding potassium fluorozirconate and silane coupling agent i...

Embodiment 3

[0054] A method for preparing a silane ceramic agent, comprising the following steps:

[0055] S1. The raw materials required for the preparation of silane ceramics: phytic acid, silica sol, citric acid, potassium fluorozirconate and silane coupling agent are divided into different parts according to the weight of 20 grams, and the raw materials are subjected to water treatment. deionize;

[0056] S2, deionized water is added in the reactor, and the temperature inside the reactor is raised, then the silica sol is added into the reactor and mixed with water, and then stirred and mixed with deionized water;

[0057] S3, continue to heat up the inside of the reactor, and add phytic acid inside the reactor, and stir and mix inside the reactor;

[0058] S4, add citric acid inside the reactor, stir after the citric acid is added into the reactor, and then continue to heat after standing for a period of time;

[0059] S5, adding potassium fluorozirconate and silane coupling agent in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com