Metal coating and preparation process thereof

A metal coating and preparation process technology, applied in the field of coatings, can solve the problems of health hazards, large energy consumption, no energy saving and environmental protection, etc., and achieve the effects of low cost, prolonged service life, and stable use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

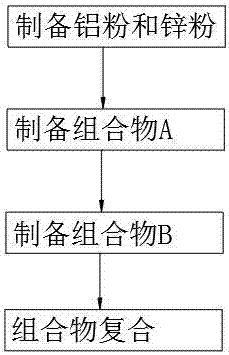

[0021] Embodiment 1: as figure 1 As shown, the present invention provides a kind of metal coating, and described metal coating comprises the raw material of following mass fraction: 50 parts of acrylic resin, 4 parts of amino resin, 3.6 parts of propylene glycol methyl ether acetic acid, 1.6 parts of polyorganosiloxane, polyorganosiloxane 1.7 parts of oxyethylene alkylphenol ether, 2.6 parts of polydimethylsiloxane, 1.5 parts of ethylene bis stearamide, 8.5 parts of pigment, 5 parts of filler, 1 part of potassium hydroxide, 2 parts of benzotriazole , 1 part of melamine, 2 parts of 12-hydroxystearic acid, 3 parts of methyl methacrylate, 2 parts of sodium lauryl sulfate, 3 parts of p-tert-amylphenol, 1 part of tetraethylamine tetrafluoroborate, benzyl 2 parts of triphenylphosphine chloride, 1 part of cobalt trifluoroacetylacetonate, 3 parts of methylene bromide, 10 parts of aluminum powder, 10 parts of zinc powder, 80 parts of deionized water, 1.5 parts of cosolvent and 1.5 part...

Embodiment 2

[0032] Embodiment 2: as figure 1 As shown, the present invention provides a kind of metal coating, and described metal coating comprises the raw material of following mass fraction: 68 parts of acrylic resin, 10 parts of amino resin, 4.2 parts of propylene glycol methyl ether acetic acid, 2.4 parts of polyorganosiloxane, polyorganosiloxane 2.5 parts of oxyethylene alkylphenol ether, 3.5 parts of polydimethylsiloxane, 2.5 parts of ethylene bis stearamide, 12 parts of pigment, 8 parts of filler, 4 parts of potassium hydroxide, 3 parts of benzotriazole , 2 parts of melamine, 6 parts of 12-hydroxystearic acid, 5 parts of methyl methacrylate, 5 parts of sodium lauryl sulfate, 7 parts of p-tert-amylphenol, 3 parts of tetraethylamine tetrafluoroborate, benzyl 4 parts of triphenylphosphine chloride, 2 parts of cobalt trifluoroacetylacetonate, 6 parts of methylene bromide, 20 parts of aluminum powder, 20 parts of zinc powder, 100 parts of deionized water, 8 parts of cosolvent and 2.5 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com