Patents

Literature

109 results about "Phosphonium chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tetrakis(hydroxymethyl)phosphonium chloride (THPC) is an organophosphorus compound with the chemical formula [P(CH2OH)4]Cl. The cation P(CH2OH)4+ is four-coordinate, as is typical for phosphonium salts.

D1369 d radiation curable secondary coating for optical fiber

A new radiation curable Secondary Coating for optical fibers is described and claimed wherein said composition comprises a Secondary Coating Oligomer Blend, which is mixed with a first diluent monomer; a second diluent monomer; optionally, a third diluent monomer; an antioxidant; a first photoinitiator; a second photoinitiator; and optionally a slip additive or a blend of slip additives; wherein said Secondary Coating Oligomer Blend comprises:α) an Omega Oligomer; andβ) an Upsilon Oligomer;wherein said Omega Oligomer is synthesized by the reaction ofα1) a hydroxyl-containing (meth)acrylate;α2) an isocyanate;α3) a polyether polyol; andα4) tripropylene glycol; in the presence ofα5) a polymerization inhibitor; andα6) a catalyst;to yield the Omega Oligomer;wherein said catalyst is selected from the group consisting of dibutyl tin dilaurate; metal carboxylates, including, but not limited to: organobismuth catalysts such as bismuth neodecanoate; zinc neodecanoate; zirconium neodecanoate; zinc 2-ethylhexanoate; sulfonic acids, including but not limited to dodecylbenzene sulfonic acid, methane sulfonic acid; amino or organo-base catalysts, including, but not limited to: 1,2-dimethylimidazole and diazabicyclooctane; triphenyl phosphine; alkoxides of zirconium and titanium, including, but not limited to Zirconium butoxide and Titanium butoxide; and Ionic liquid phosphonium salts; and tetradecyl(trihexyl)phosphonium chloride; andwherein said Upsilon Oligomer is an epoxy diacrylate.

Owner:DSM IP ASSETS BV

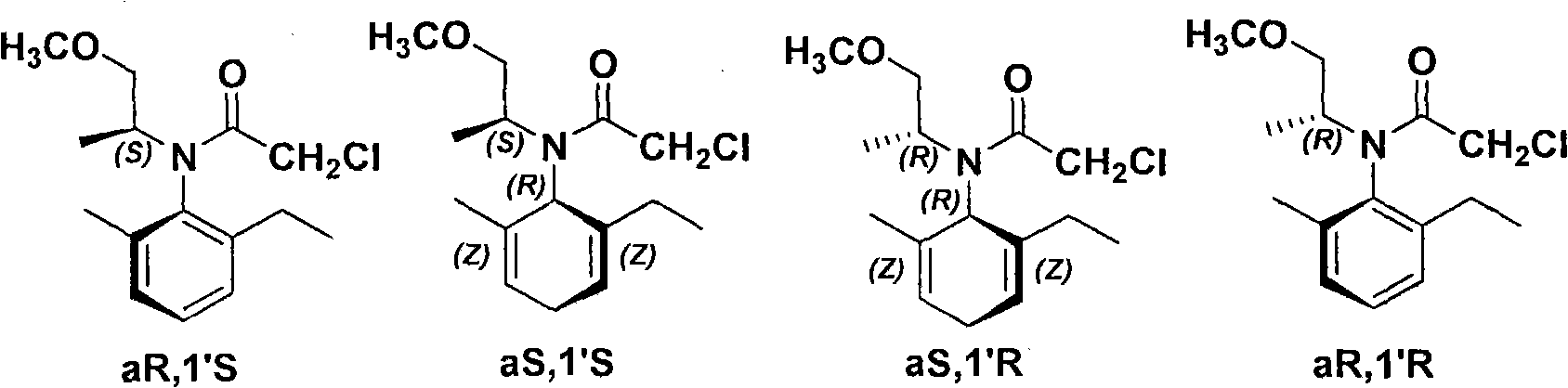

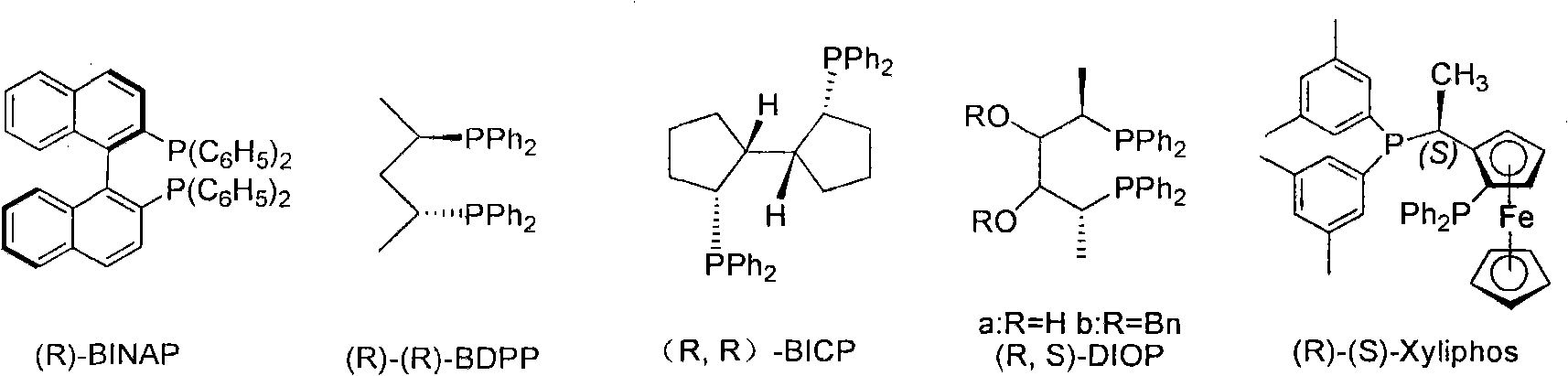

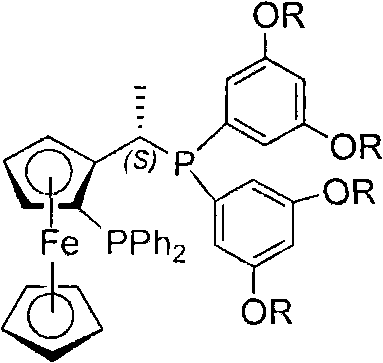

Chiral diphosphite ligand and iridium composite catalyst and preparation thereof method and application to asymmetrical hydrogenization synthesis (S)-metolachlor

ActiveCN101857612AOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAlkaneDiphosphines

The invention relates to a kind of chiral diphosphite ligands, an iridium composite catalyst thereof, a preparation method and application thereof. The ligands are obtained through using chiral (R)-(S)-1-dimethylamino ethyiferroene as raw materials to react with diphenyl phosphonium chloride under the effect of butyl lithium and then to carry out displacement reaction with diaryl phosphine alkane. The chiral diphosphite ligands respectively act with homotropilidene compositions of iridous chloride, tetrabutyl ammonium iodide and glacial acetic acid, and imine asymmetrical hydrogenization catalysts can be obtained. When the iridium-diphosphine catalysts are used for catalyzing 2-methyl-6-ethyl-N-methylene aniline (EMA-imine) hydrogenization reaction, (S)-N-(1-anisyl-2-propyl)-2-methyl-6- ethylaniline ((S)-NNA) can be obtained, and the antimer excessive value (ee) can reach 86.5 percent. The (S)-NNA and chloracetyl chloride carry out acylation reaction to obtain (S)-metolachlor with the ee value of 86 percent. Thereby, the ligands provided by the invneiton can be used for synthesizing chiral herbicidal chemicals of (S)-metolachlor.

Owner:NANJING UNIV OF TECH +2

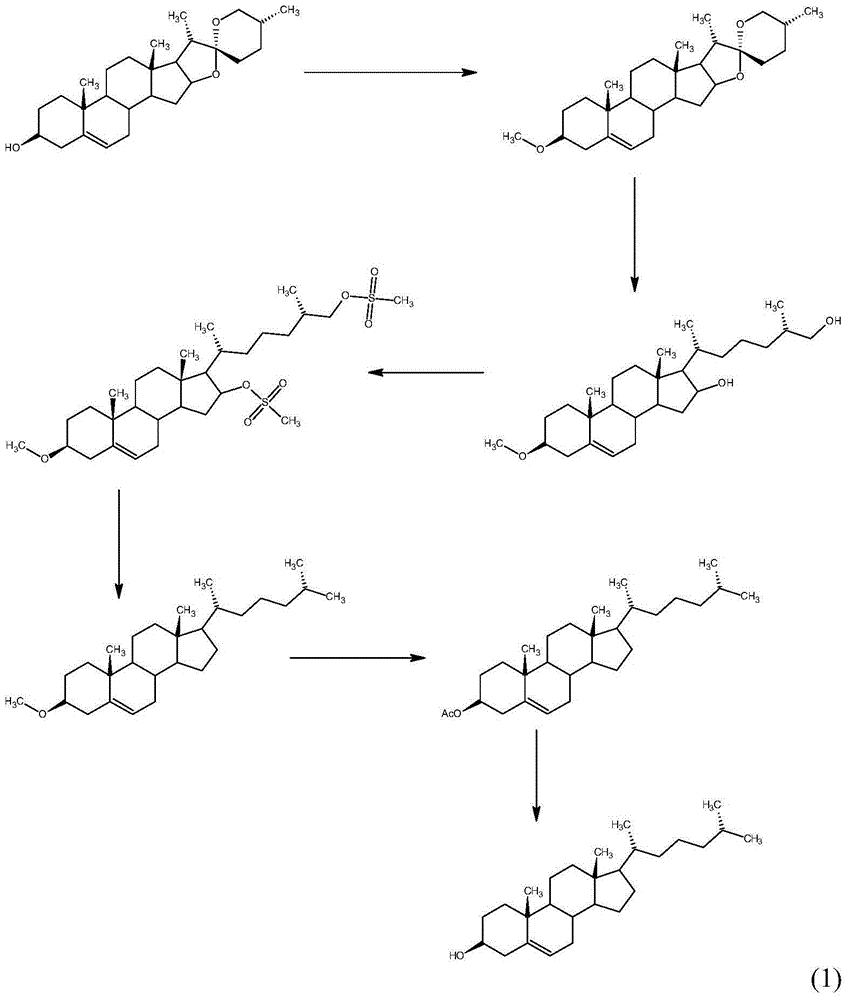

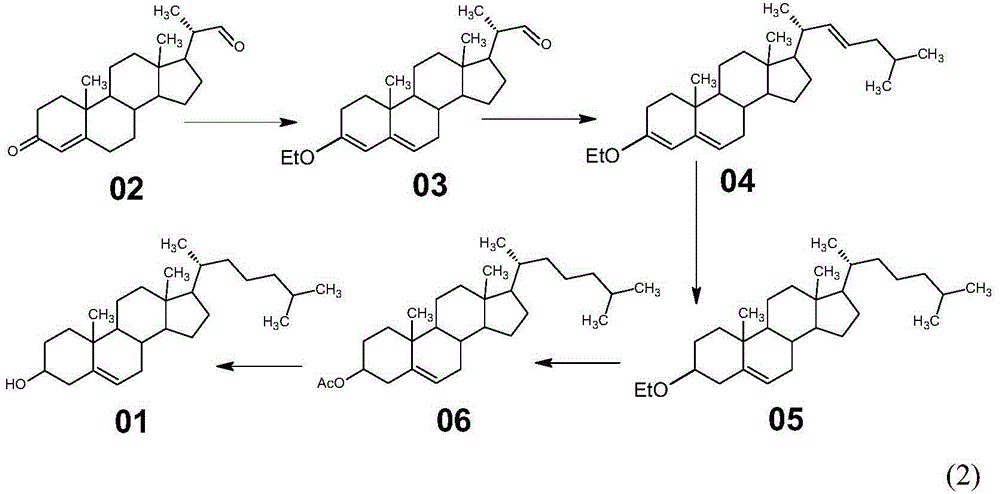

Method for synthesizing cholesterol by using stigmasterol degradation products as raw materials

The invention provides a method for synthesizing cholesterol by using stigmasterol degradation products as raw materials. The method comprises the following steps: 1) performing an etherification reaction on 3-carbonyl-4-pregnene-22-aldehyde and triethyl orthoformate to obtain 3-ethyoxyl-3,5-pregnadiene-22-aldehyde; 2) preparing a 3-methylbutyltriphenyl phosphonium chloride solution; 3) adding potassium tert-butoxide into the 3-methylbutyltriphenyl phosphonium chloride solution, performing a wittig reaction on the 3-methylbutyltriphenyl phosphonium chloride solution and the 3-ethyoxyl-3,5-pregnadiene-22-aldehyde to obtain 3-ethyoxyl-3,5,22-triene cholestane; 4) catalyzing the 3-ethyoxyl-3,5,22-triene cholestane to perform a selective hydrogenation reaction to obtain 3-ethyoxyl-5-ene cholestane; 5) performing a reaction on the 3-ethyoxyl-5-ene cholestane and acetic anhydride to obtain 3-acetyl-5-ene cholestane; 6) performing a hydrolysis reaction on the 3-acetyl-5-ene cholestane to obtain the cholesterol. The synthesizing method is simple in process, and the mole yield of the cholesterol exceeds 85 percent by using the stigmasterol degradation products which are cheap and easily obtained as the raw materials; the production cost is low, the process is environmentally friendly, and the method is economical and environmentally friendly, and facilitates industrial implementation.

Owner:HUNAN KEREY BIOTECH

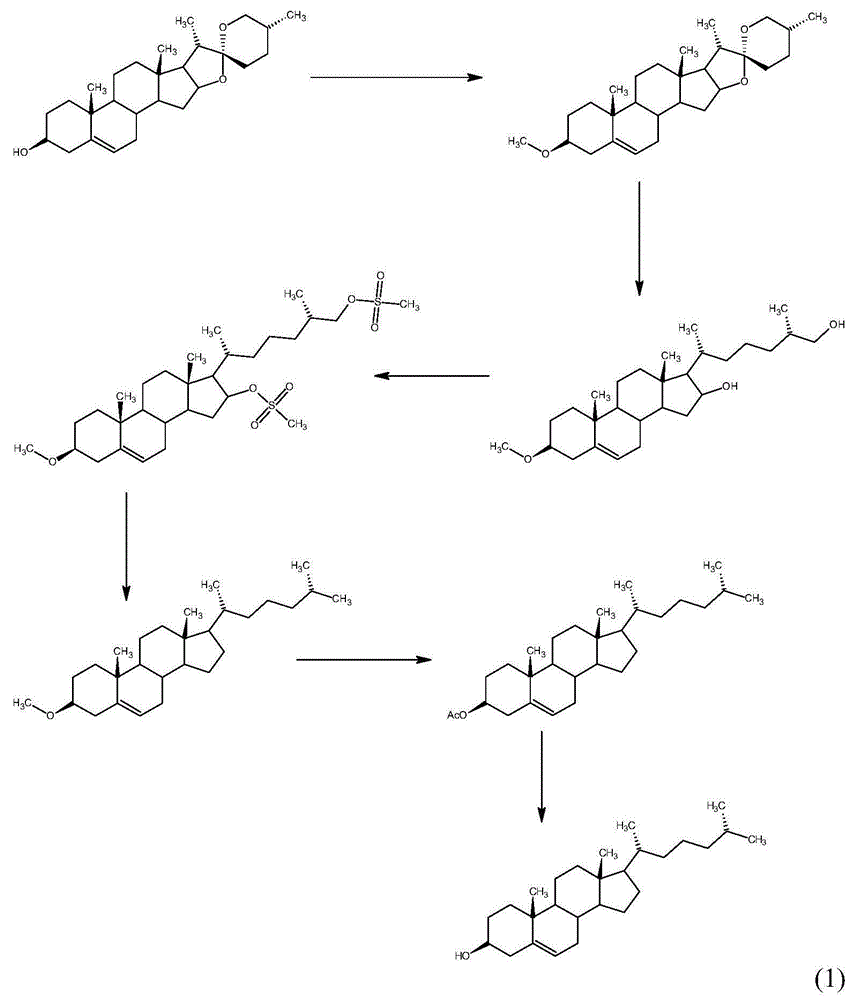

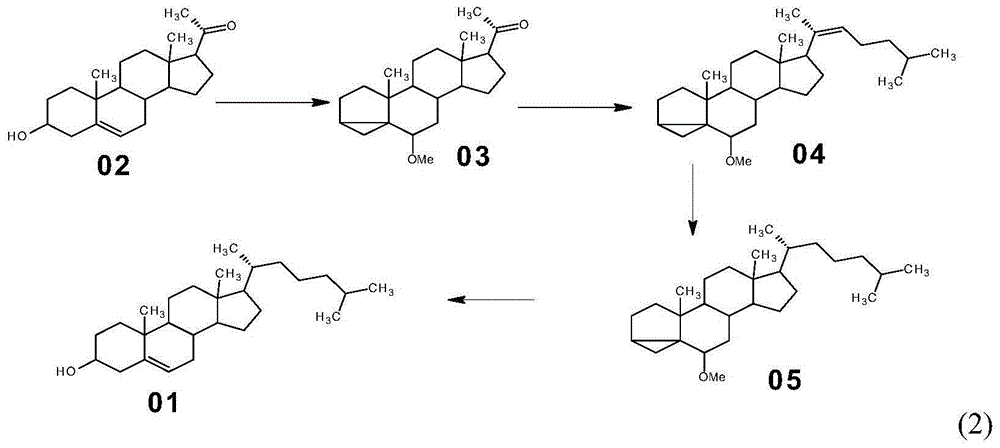

Method for synthesizing cholesterol by using pregnenolone as raw material

The invention provides a method for synthesizing cholesterol by using pregnenolone as a raw material. The method comprises the following steps: 1) adding potassium acetate into methyl alcohol, and performing a reaction on sulfonate to obtain 6-methoxyl-3,5-cyclo-5alpha-pregn-20-one; 2) performing a reaction on triphenylphosphine and 1-chloro-4-methylpentane in an aprotic solvent to obtain a 4-methylbutyltriphenyl phosphonium chloride solution; 3) adding potassium tert-butoxide into the 4-methylbutyltriphenyl phosphonium chloride solution, and performing a wittig reaction; 4) under the catalysis of a rhodium catalyst, performing an asymmetric hydrogenation reaction to obtain 6-methoxyl-3,5-cyclo-5alpha-cholestane; 5) performing a catalytic hydrolysis deprotection reaction by using sulfuric acid to obtain the cholesterol. The method provided by the invention has the advantages that six-step reactions in the conventional method are simplified into four-step reactions, and a ring-opening reaction in which a great number of hydrochloric acid and a large number of zinc powder are consumed in a route of using saponin as an initial raw material. The synthesizing method is simple in process, the consumption of the raw material and auxiliary materials is low, and the mole yield is high; the method is economical and environmentally friendly, and facilitates industrial implementation.

Owner:HUNAN KEREY BIOTECH

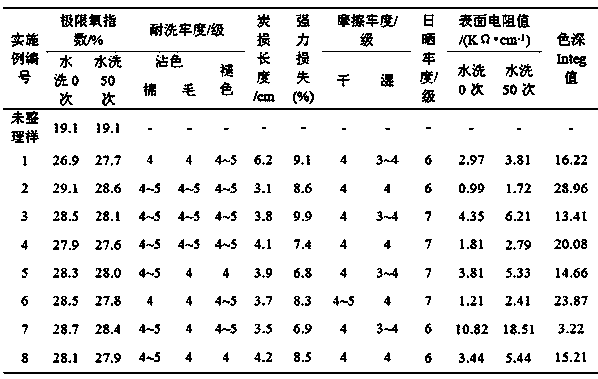

Flame-retardant jean fabric

ActiveCN103233360ABreathable and moisture-permeableImprove wash resistanceBiochemical fibre treatmentDry-cleaning apparatus for textilesCelluloseTetrakis(hydroxymethyl)phosphonium chloride

The invention relates to a flame-retardant jean fabric. The flame-retardant jean fabric is prepared by comprising the following steps: (1) placing jean fabric in a jig dyeing machine, adding water and desizing enzyme for processing, then discharging liquid and washing with water; (2) enzyme washing: adding the desized jean fabric, water and neutral cellulose enzyme into the jig dyeing machine, performing temperature rise, discharging liquid and cleaning with water; (3) flame retardant padding-batching: mixing tetrakis hydroxymethyl phosphonium chloride, urea, etherified hexamethylol melamine resin and penetrating agent JFC to obtain flame-retardant finishing liquid, padding and batching the jean enzyme-washed fabric into the flame-retardant finishing liquid, performing twice padding and twice batching; (4) ammonia fumigation: performing ammonia fumigation to the flame retardant-padded-and-batched jean fabric in an ammonia fumigation flame-retardant machine; and (5) later-stage arrangement: performing once padding and once batching to the ammonia-fumigated jean fabric in hydrogen peroxide, and storing after padding and batching; and drying after being washed. According to the flame-retardant jean fabric, the excellent flame-retardant property of the jean fabric is endowed, and the added value of the product can be improved.

Owner:邦威防护科技股份有限公司

Method for preparing amphiphilic Janus gold nano particles in one step with liquid/liquid interface reaction

InactiveCN103611945AEasy to operateImprove stabilityNanotechnologyN dimethylformamideUltrasonic oscillation

The invention discloses a method for preparing amphiphilic Janus gold nano particles in one step with a liquid / liquid interface reaction. The method for preparing the amphiphilic Janus gold nano particles in one step with the liquid / liquid interface reaction comprises the steps of (1) preparing a toluene solution, a sodium hydroxide aqueous solution and a tetrakis hydroxymethyl phosphonium chloride aqueous solution for use, wherein the concentration of chloro(triphenylphosphine)gold in the toluene solution is 1-5mmol / L, the concentration of the sodium hydroxide aqueous solution is 10-40mmol / L, and the concentration of the tetrakis hydroxymethyl phosphonium chloride aqueous solution is 50mmol / L; (2) mixing a sodium hydroxide solution of 5-10mL and the toluene solution, of 5-10mL, with the chloro(triphenylphosphine)gold, injecting the tetrakis hydroxymethyl phosphonium chloride aqueous solution into an aqueous phase, and standing for 20-24 hours to form an amphiphilic Janus gold nano particle self-assembled membrane, wherein the volume of the tetrakis hydroxymethyl phosphonium chloride aqueous solution ranges from 100 micro-litres to 200 micro-litres; (3) moving the amphiphilic Janus gold nano particle self-assembled membrane out of a toluene / water interface through a glass slide, drying the amphiphilic Janus gold nano particle self-assembled membrane, respectively cleaning the amphiphilic Janus gold nano particle self-assembled membrane with water and acetone, drying the amphiphilic Janus gold nano particle self-assembled membrane again, placing the glass slide with the amphiphilic Janus gold nano particle self-assembled membrane into analytically pure N,N-dimethylformamide of 10mL, and carrying out ultrasonic oscillation for 10min to obtain a monodisperse amphiphilic Janus gold nano particle colloidal solution. According to the method for preparing the amphiphilic Janus gold nano particles in one step with the liquid / liquid interface reaction, operation is easy, good stability and good reproducibility are achieved, and the amphiphilic Janus gold nano particles can be conveniently applied to various related fields.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Method for synthesizing diphenyl phosphonium chloride

InactiveCN102942591AReduce dosageDoes not destroy activityGroup 5/15 element organic compoundsChemical recyclingLiquid layerBenzene

The invention discloses a method for synthesizing diphenyl phosphonium chloride. The method includes: performing reaction on raw materials of phosphorus trichloride and excessive benzene under catalyzing effect of Lewis acid ionic liquid, wherein after the reaction, the reaction liquid is divided into two layers, one layer is an ionic liquid layer, and the other layer is a mixed liquid layer. Through direct liquid separation, the ionic liquid layer is extracted, the extract liquor is mixed with the mixed liquid layer, and the mixture is respectively performed with normal pressure distillation and decompression distillation to obtain the target object diphenyl phosphonium chloride and byproduct phenyl phosphonium chloride. The ionic liquid is performed with normal pressure and decompression distillation so as to remove impurities and recover the diphenyl phosphonium chloride. Compared with the existing industrial process, the method has the advantages of being small in catalyst amount, requiring no decomplexing procedure, being easy to operate and control, not generating large amount of waste residue, being low in production cost, environment-friendly in production process and the like, and the catalyst is recoverable.

Owner:SHANDONG UNIV OF SCI & TECH

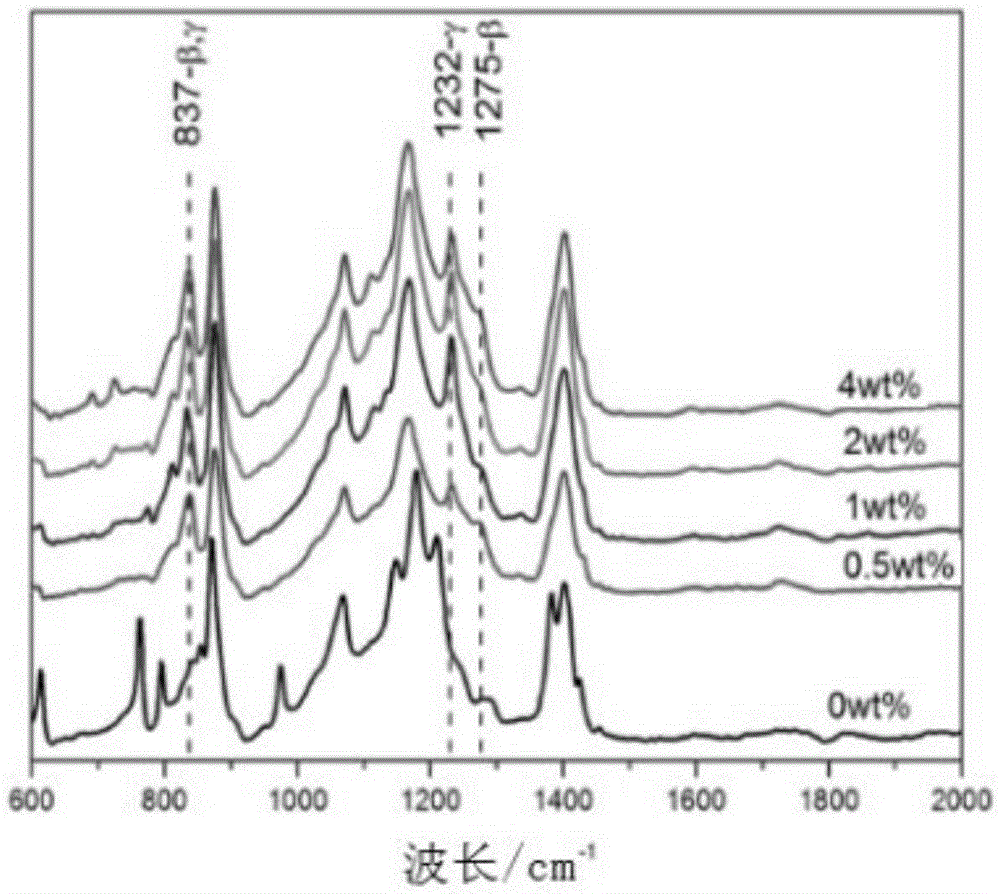

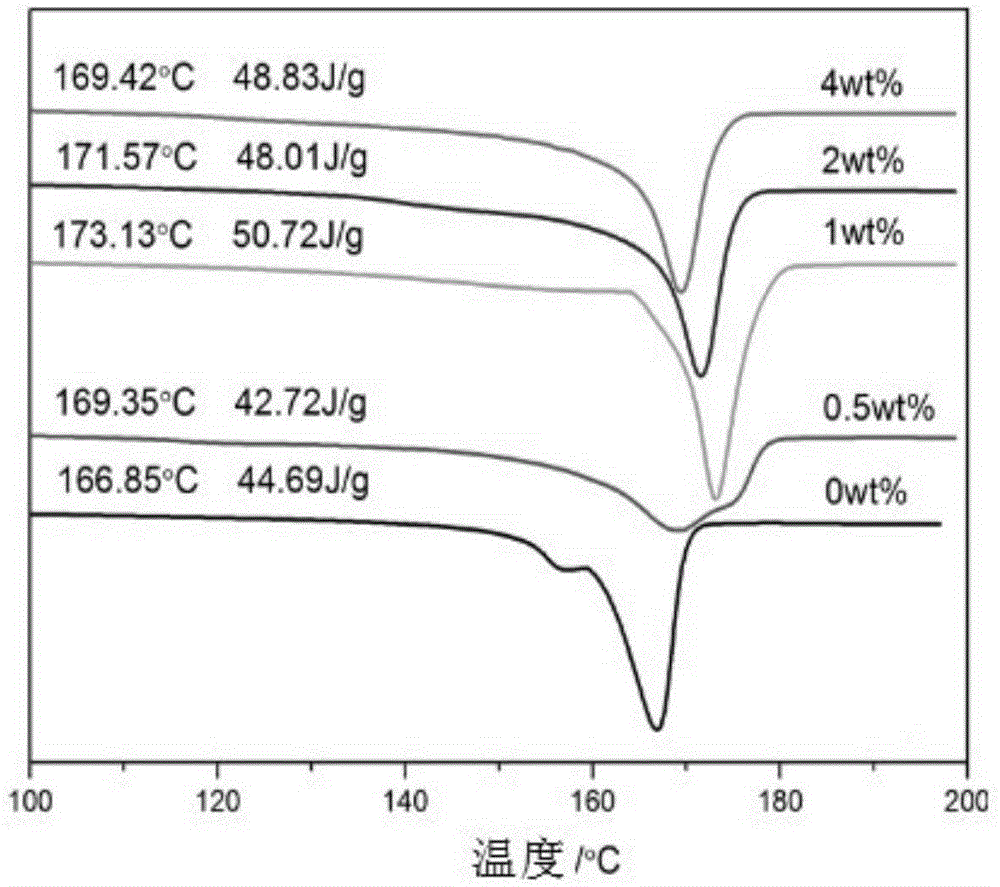

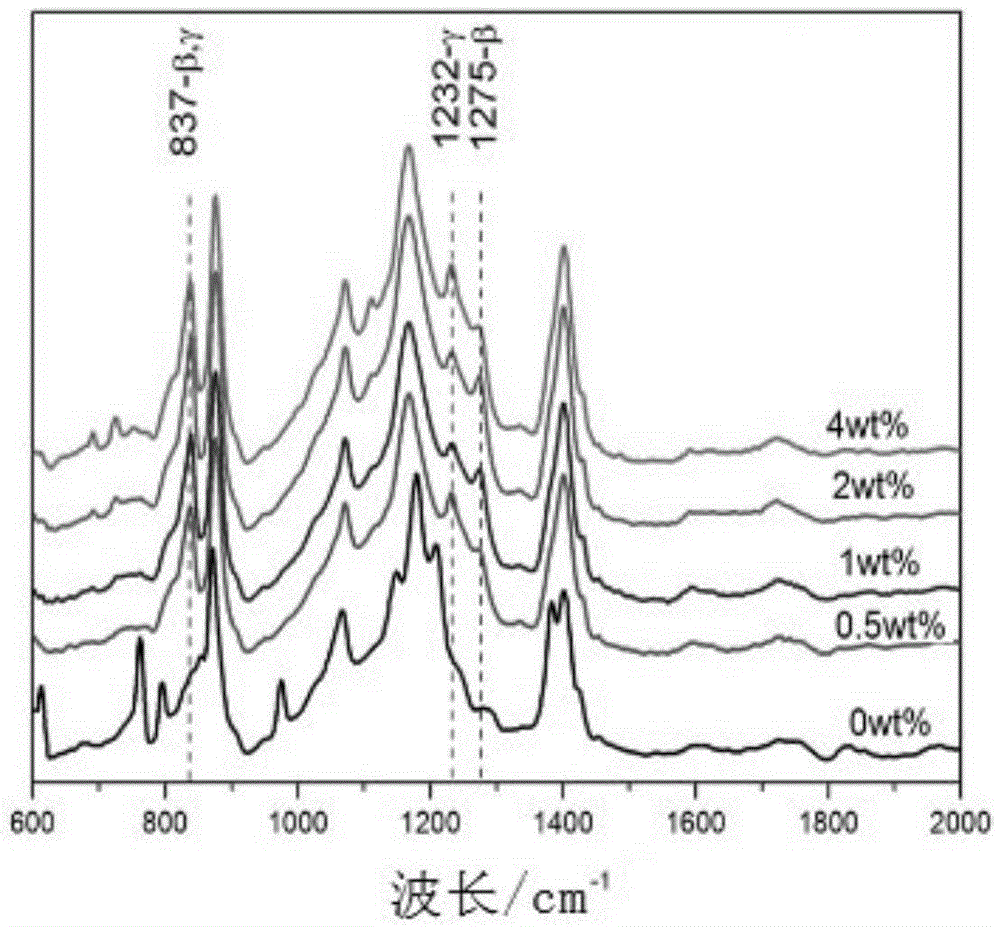

Polyvinylidene fluoride composite material, preparation method and applications thereof

The invention relates to a polyvinylidene fluoride composite material, a preparation method and applications thereof, and belongs to the technical field of composite materials. A purpose of the present invention is to solve the problem of low content of the polyvinylidene fluoride polar phase in the prior art. The composite material comprises, by weight, 85-95 parts of polyvinylidene fluoride, 0-5 parts of an inorganic additive, and 0.5-10 parts of an organic additive, wherein the organic additive is one or a mixture comprising a plurality of materials selected from tetraphenyl phosphonium bromide, tetraphenyl phosphonium chloride, tetraphenyl phosphonium iodide and tetraphenylphosphine imide according to any ratios. According to the present invention, the alpha phase-to-beta phase conversion of the polyvinylidene fluoride crystal is induced through the inorganic additive and the organic additive, such that the polar phase content in the polyvinylidene fluoride is substantially improved so as to substantially improve the piezoelectric property; and the polyvinylidene fluoride-based film prepared by using the composite material has the high piezoelectric constant, wherein the piezoelectric constant can achieve 25-35 pC / N.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

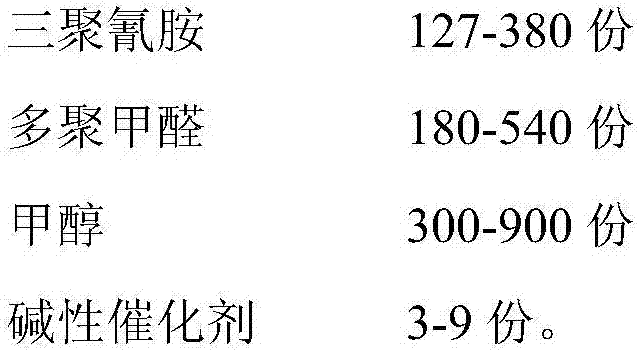

Preparation method of flame-retardant polyhydric alcohol and polyurethane foam and polyurethane sealant prepared from flame-retardant polyhydric alcohol

ActiveCN107459620AImprove flame retardant performanceAbundant productionPolyureas/polyurethane adhesivesChemical synthesisPolymer science

The invention belongs to the technical field of chemical synthesis, and particularly relates to a preparation method of flame-retardant polyhydric alcohol, and polyurethane foam and a polyurethane sealant prepared from flame-retardant polyhydric alcohol. The preparation method comprises the steps of heating melamine, paraformaldehyde, methanol and a basic catalyst for reaction to form a hydroxymethyl melamine mixture, adding acid into the hydroxymethyl melamine mixture to regulate a pH (potential of hydrogen), adding tetrakis hydroxymethyl phosphonium chloride for reaction, regulating the pH with water and the basic catalyst, then adding castor oil, performing pressure reduction to remove the water and methanol, reducing a water content to less than or equal to 0.5%, and performing suction filtration to form flame-retardant polyhydric alcohol. The method adopts a structure modification method; a cyclic structure containing flame-retardant elements P, N and melamine is added into a castor oil structure for synthesis of the flame-retardant rigid polyurethane foam and the flame-retardant polyurethane sealant; and flame-retardant polyhydric alcohol has higher flame retardancy.

Owner:山东联创聚合物有限公司

Arrangement antibacterial technology of hat knitting fabric

InactiveCN106758204AExcellent flame retardantGood antibacterialBiochemical fibre treatmentHeat resistant fibresSorbitanAntibacterial property

The invention discloses an arrangement antibacterial technology of a hat knitting fabric. The arrangement antibacterial technology comprises the following steps of feeding 1 to 2 parts of hydroxypropyl methyl cellulose, 1.2 parts of guanidine bactericide, 1.8 parts of polyethylene polyamine, and 2.1 parts of nanometer magnesium hydroxide into 20 parts of deionized water by mass, mixing, and uniformly stirring; slowly adding 0.4 parts of sorbitan fatty acid ester, 1.2 parts of schizonepeta volatile oil, 2.5 parts of tetrakis hydroxymethyl phosphonium chloride, and 1.8 parts of barbaloin by mass, continuing to stir, and fully and uniformly mixing, so as to obtain an arrangement liquid; performing antibacterial treatment. The post-arrangement technology of the hat knitting fabric has the advantages that the excellent flame-retardant, antibacterial, anti-wrinkle, and anti-static properties are realized, the washing-resistant property is realized, the antibacterial property of the fabric is improved, the antibacterial effect is good, and the use time is long.

Owner:NANTONG TONGZHOU DING DING HAT FACTORY

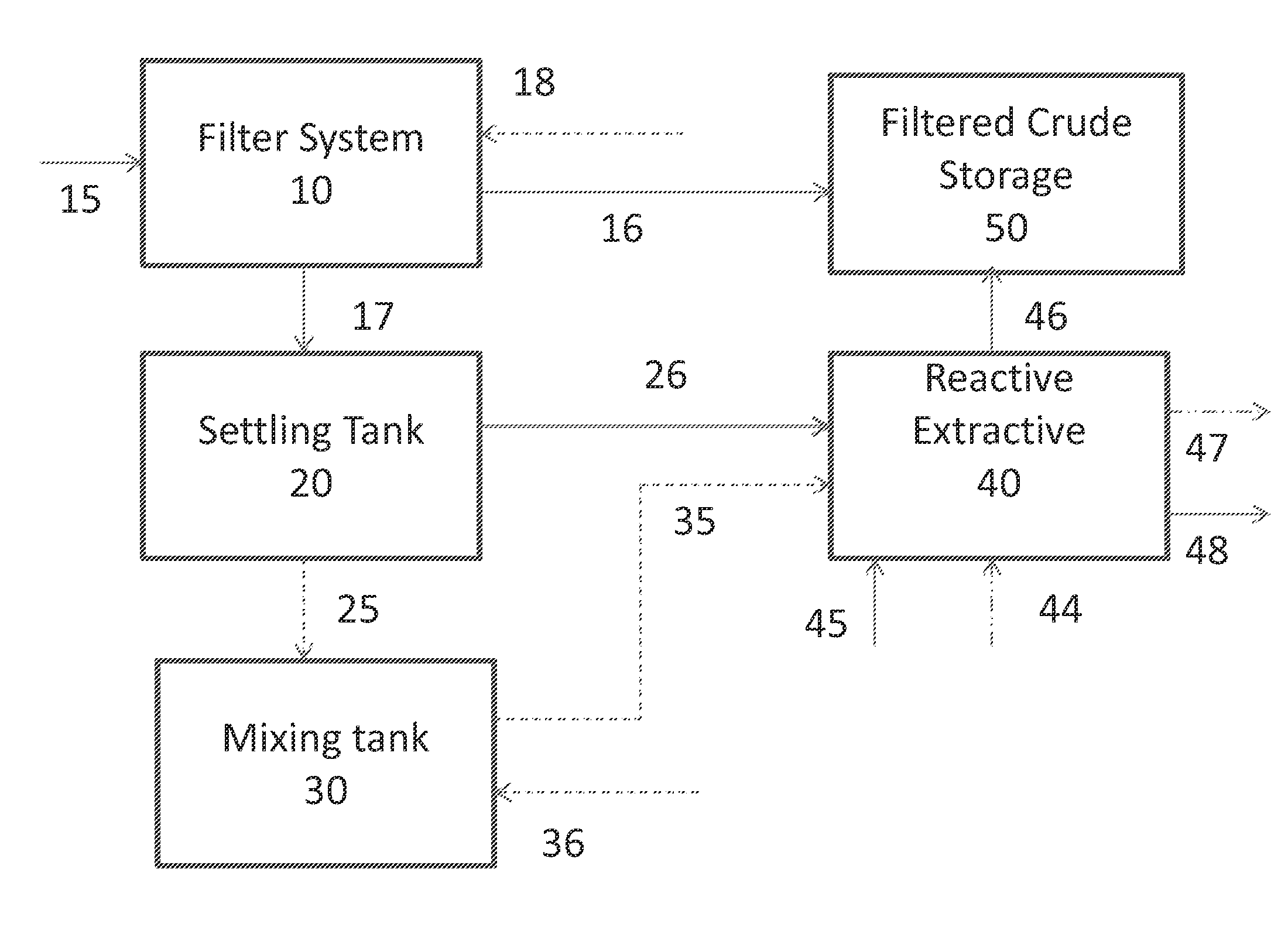

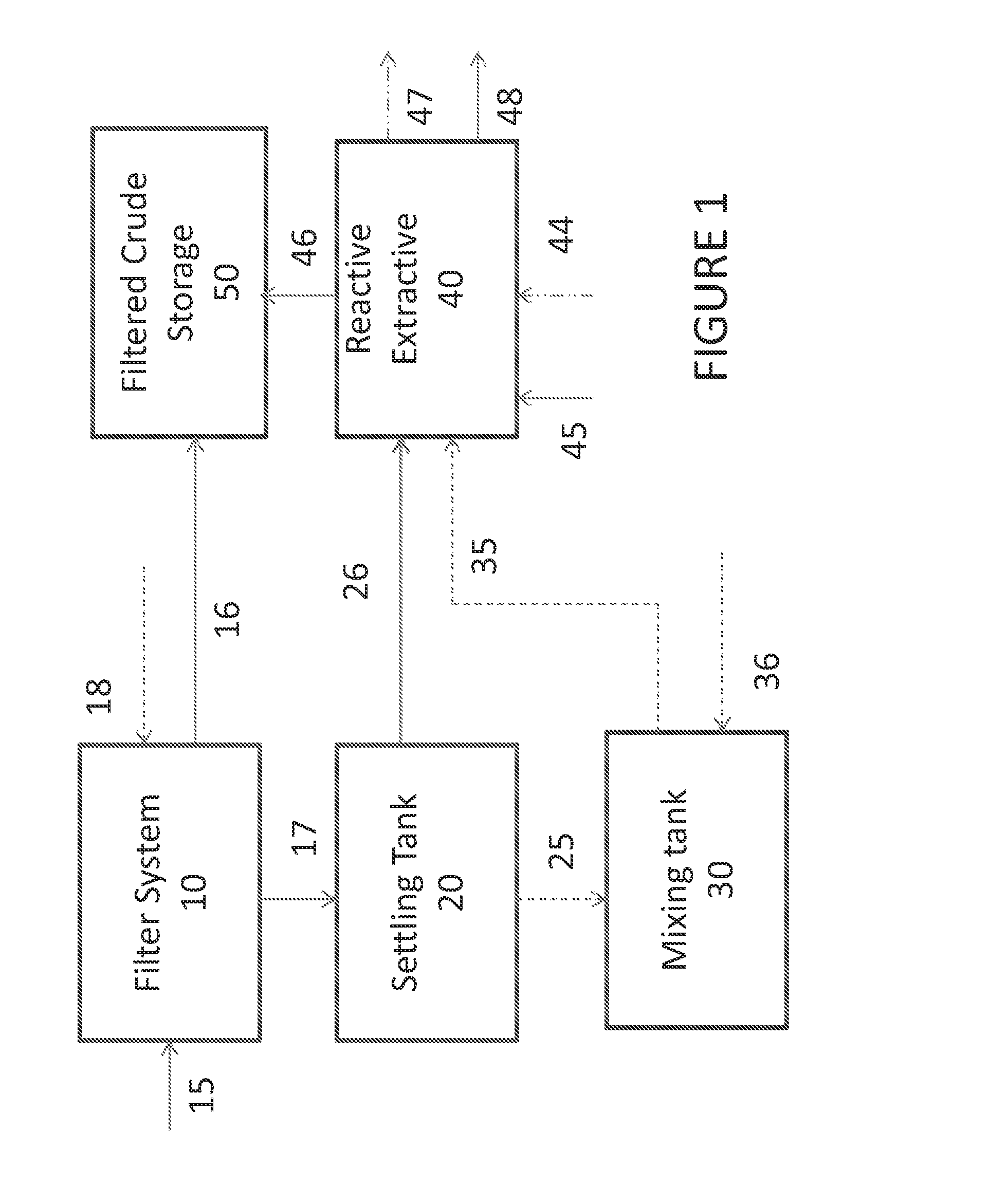

Process, Method, and System for Removing Heavy Metals from Fluids

ActiveUS20140262955A1Reduce its mercury concentrationRefining with non-metalsRefining with oxygen compoundsPhosphoniumFiltration

Trace element levels of mercury in crude oil are reduced by first passing the crude oil through a filtration device to generate filtered crude having a reduced concentration of mercury and a reject stream having a concentrated mercury level. In one embodiment, the filtration device is back-flushed to generate the reject stream. In another embodiment, the reject stream comprises a portion of the retentate from a cross-flow filter device. The reject stream is treated with an extractive agent selected from tetrakis(hydroxymethyl)phosphonium sulfate; tetrakis(hydroxymethyl) phosphonium chloride; an oxidizing agent; an organic or inorganic sulfidic compound to extract a portion of the mercury into a water phase for subsequent removal. In one embodiment, the extractive agent is a reductant to convert non-volatile mercury into volatile mercury.

Owner:CHEVROU USA INC

Bleaching and brightness stabilization of lignocellulosic materials with water-soluble phosphines or phosphonium compounds

A method for the bleaching and brightness stabilization of lignocellulosic materials is described. The method involves the treatment of lignocellulosic materials, in particular, (a) wood pulps such as thermomechanical pulps (TMP) and chemithermomechanical pulps (CTMP), and (b) papers made from wood pulps, with a water-soluble phosphine or a phosphonium compound preferably containing at least one phosphorus hydroxyalkyl bond / linkage, for example a phosphorus hydroxymethyl bond / linkage (P-CH2OH). One example of such a water-soluble phosphine is the commercially available, tris(hydroxymethyl)phosphine (THP), P(CH2OH)3. One example of such a phosphonium compound is the commercially available, tetrakis(hydroxymethyl)phosphonium chloride (THPC), [P(CH2OH)4]Cl.

Owner:THE UNIV OF BRITISH COLUMBIA +1

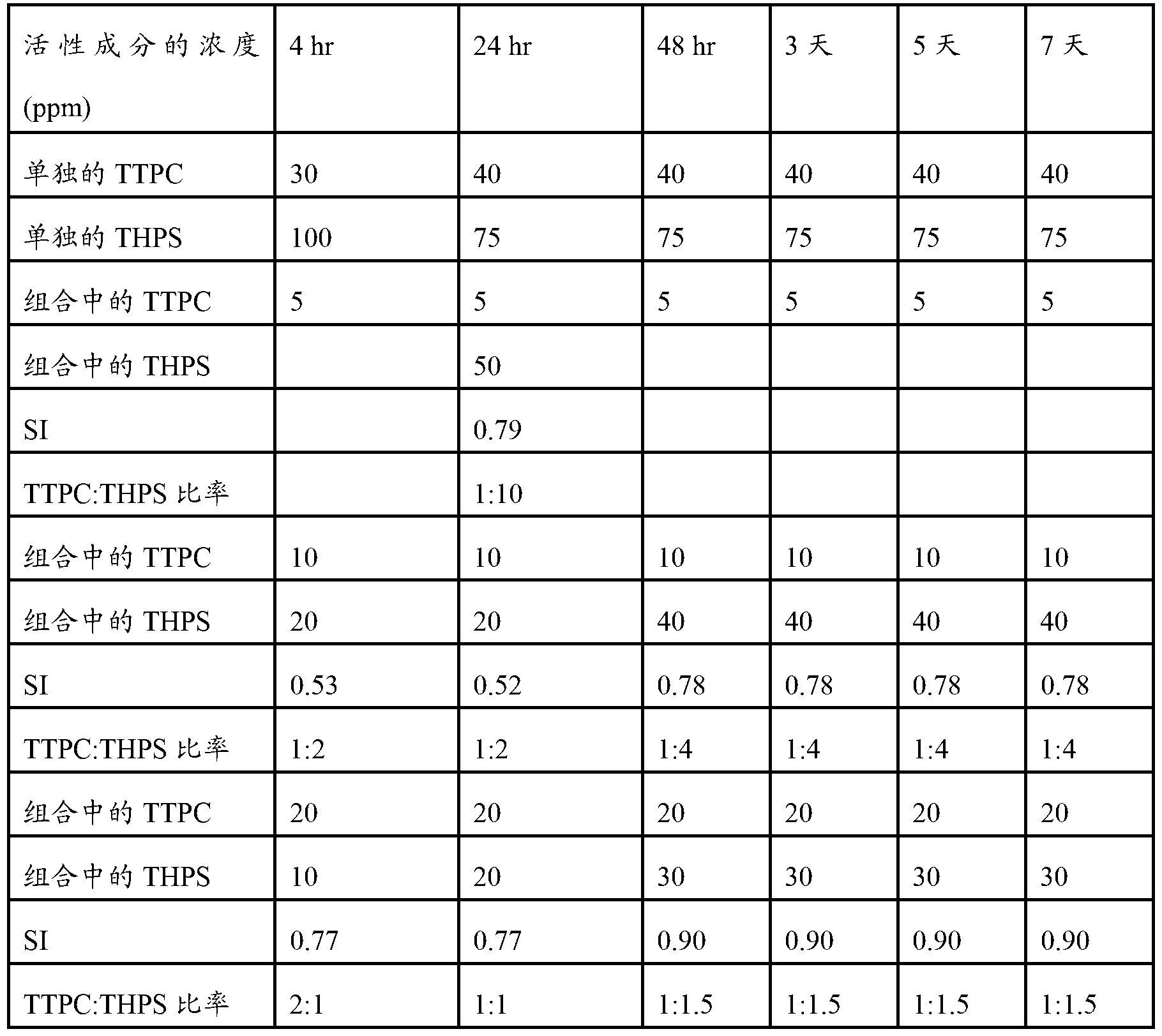

Biocidal composition

A biocidal composition comprising tributyl tetradecyl phosphonium chloride and tetrakis(hydroxymethyl)phosphonium sulfate at a weight ratio of 2:1 to 1:10, and its use for the control of microorganisms in aqueous and water-containing systems.

Owner:DOW GLOBAL TECH LLC

Co-antimicroorgan composition of peroxide acetic acid and phosphorous compounds

Synergistic antimicrobial combinations are disclosed comprising an effective amount of peracetic acid (PAA) and an effective amount of a phosphorus compound selected from the group consisting of tetrakis (hydroxy methyl) phosphonium sulfate (THPS), tetrakis (hydroxy methyl) phosphonium phosphate (THPP), and tetrakis (hydroxy methyl) phosphonium chloride (THPC). Methods for inhibiting microbial growth using these synergistic antimicrobial combinations are also disclosed.

Owner:CALGON CORP

Compound disinfectant for circulating water systems

InactiveCN101578997AImprove the bactericidal effectReduce use costBiocideDisinfectantsMicroorganismDisinfectant

The invention discloses a compound disinfectant for circulating water systems, comprising benzyltribenzyl phosphonium chloride, dithiocyano-methane and copper sulfate. When the compound disinfectant is used, if certain amount of penetrant is added, the synergistic effect among drugs can be brought into full play, and not only the antibacterial activity can be effectively improved but also microorganisms can be avoided from generating resistance to drugs due to long-term use of single variety of disinfectants. The compound disinfectant of the invention has good disinfection and algae elimination effects and low use cost, simultaneously solves the problem of resistance of bacteria to common disinfectants and is suitable for circulating cooling water systems, reclaimed water circulating systems, clean drainage recycling systems or other circulating water systems.

Owner:ZHEJIANG UNIV +2

Tannages and tanning material

A novel tannage comprises the reaction product of a quaternary phosphonium compound (e.g. tetrakis hydroxymcthyl phosphonium chloride or sulphate) with a vegetable tanning agent (e.g. mimosa, chestnut, wattle, tara, myrobolam or quebracho). There is also provided a method for the production of such a tannage.

Owner:RHODIA CONSUMER SPECIALITIES LTD

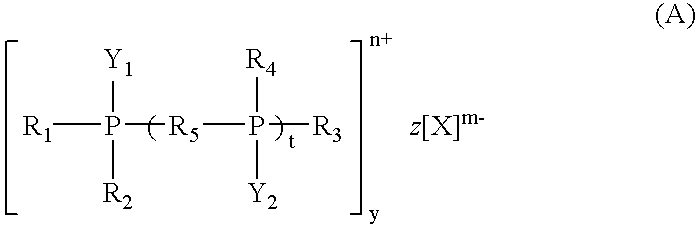

Process for the hydrogenation of imines

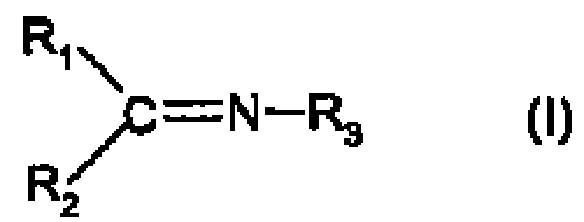

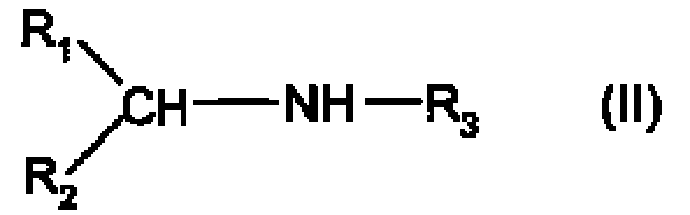

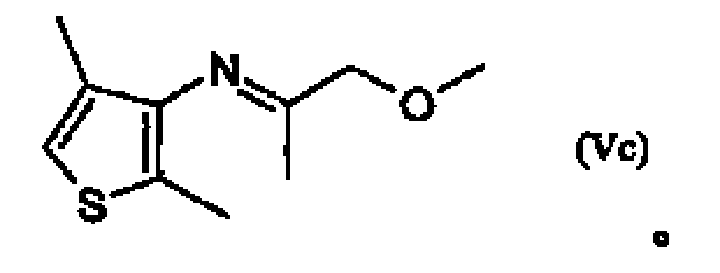

The present invention relates to a process for the hydrogenation of an imines with hydrogen in the presence of iridium catalysts. In particular, the present invention relates to a process for the hydrogenation of imines with hydrogen under elevated pressure in the presence of an iridium catalyst and with or without an inert solvent, wherein the reaction mixture comprises a phosphonium chloride, bromide or iodide in the presence of an acid, which can be an organic or inorganic acid soluble or insoluble in the reaction mixture. Suitable imines are especially those that contain at least one group. If the groups are substituted asymetrically and are thus compounds having a prochiral ketitine group, it is possible in the process according to the invention for mixtures of optical isomers or pure optical isomers to be formed if enantioselective or diastereoselective iridium catatalysts are used.

Owner:DEGUSSA AG

Washing liquid used for removing iron sulfides scale, and preparation method and applications thereof

ActiveCN107541198AImprove clearanceHigh scale inhibition rateDrilling compositionSodium saltBalance water

The invention discloses a washing liquid used for removing iron sulfides scale, and belongs to the field of chemical descaling. The washing liquid comprises 5 to 30% of an organic phosphorus chelatingagent, 1 to 6% of an ammonium salt chelating auxiliary agent, 2 to 8% of an inorganic oxidizing agent, 2 to 6% of a sulfur removing dispersant, and the balance water; the organic phosphorus chelatingagent is Tetrakis hydroxymethyl phosphonium sulfate and / or Tetrakis(hydroxymethyl)phosphonium Chloride. The sulfur removing dispersant is prepared via following steps: triazine, a polyol, and clear water are introduced into a reaction vessel, an obtained mixture is heated to 30 to 50 DEG C, and is reacted for 20 to 40min with stirring; Diethylenetriaminepenta(methylenephosphonicacid) sodium salt,an anionic surfactant, and clear water are added, the temperature is reduced to 25 to 35 DEG C, and stirring reaction is carried out under constant temperature conditions for 25 to 35min; wherein themass ratio of triazine, the polyol, and clear water is controlled to be 1:10-25:35-50, the mass ratio of the anionic surfactant, Diethylenetriaminepenta(methylenephosphonicacid) sodium salt, and clear water is controlled to be 1:1-4:10-24, and the mass amount of the anionic surfactant accounts for 0.5 to 4% of that of the sulfur removing dispersant. The washing liquid is high in clearing rate andscale inhibition rate, is safe, is friendly to the environment, and is high in biodegradability.

Owner:PETROCHINA CO LTD

Flame-retardant finishing method for polyester fabric

InactiveCN103789999AGood flame retardant durabilityDoes not affect colorFibre typesPolyesterWeather resistance

The invention discloses a flame-retardant finishing method for a polyester fabric. The method comprises the following steps: (1) mixing 1-2 parts of hydroxypropyl methyl cellulose, 8-9 parts of an aluminum zirconium coupling agent and 10-15 parts of tetrahydroxymethyl phosphonium chloride, simultaneously slowly adding 15-20 parts of cyclic phosphonate and 30-35 parts of zirconia, finishing batching within 15-20 minutes, and continuously mixing for 20-25 minutes to prepare a composite flame retardant; (2) impregnating the polyester fabrics in an impregnation solution containing 55-60 percent of composite flame retardant at the temperature of 60-65 DEG C for 1-2 hours; and (3) taking out the polyester fabric, and keeping the temperature of the polyester fabric to be 145-150 DEG C for 3-4 hours. The polyester fabric has high flame-retardant durability comprising washing resistance, resistance to dry cleaning and weather resistance, and color, appearance, handfeel and other physical and mechanical properties of the polyester fabric are not influenced.

Owner:CHANGSHU YAOU IMPORTS & EXPORTS TRADE

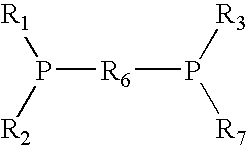

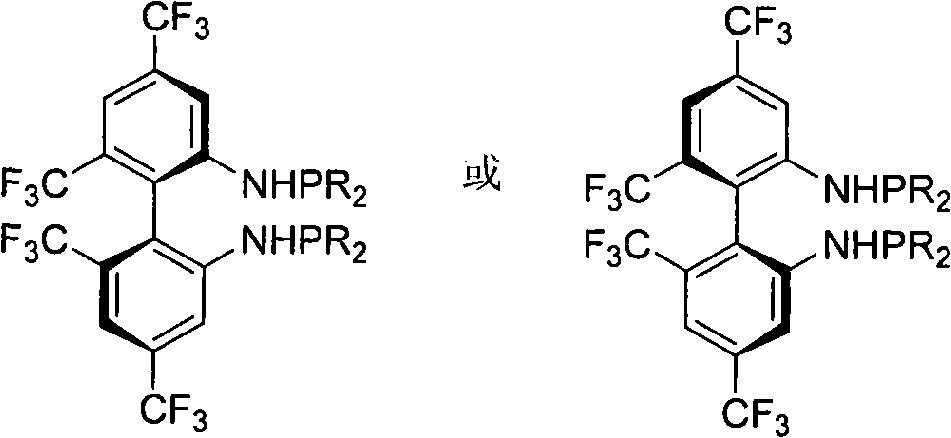

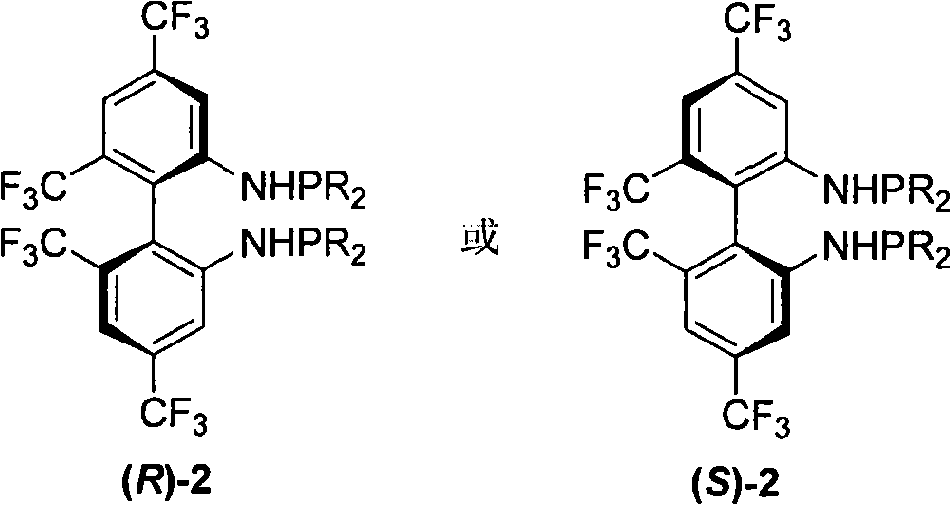

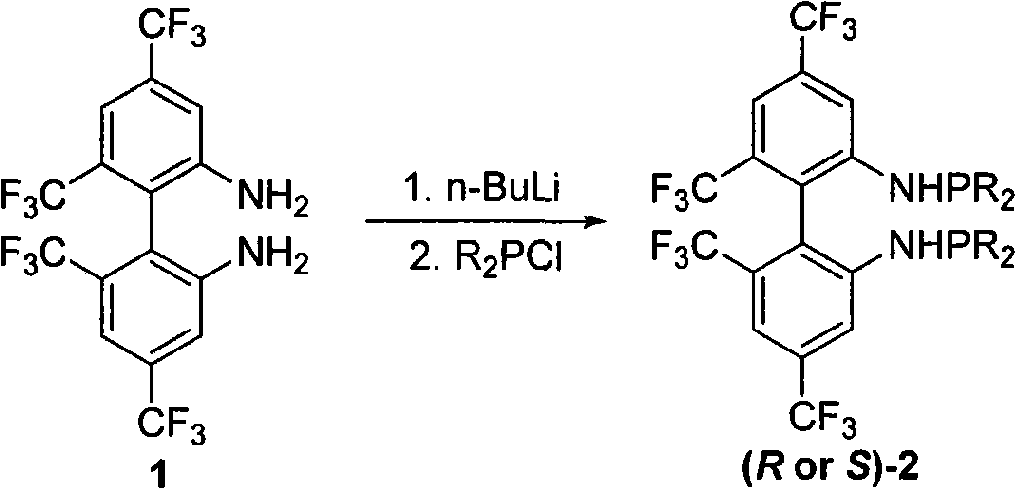

Phosphoramidite type diphosphine ligand, preparation method and application thereof

InactiveCN101333230AEasy to synthesizeOrganic compound preparationGroup 5/15 element organic compoundsEnantiomerDiphosphines

The invention provides a novel pure enantiomer amide type phosphinidene bidentate phosphine ligand with the structural formula shown on the right, wherein, the substituent R on the phosphorus atom of the bidentate phosphine ligand is alkyl or aryl. The synthetic methodsynthesis method is as follows: 4,4',6,6' -quadra (trifluoromethyl) biphenyl -2,2'- diamine is lithiated with n-butyllithium at -40 DEG C to 0 DEG C; then the lithiated 4,4',6,6' -quadra (trifluoromethyl) biphenyl-2,2'-diamine is reacted with dialkyl phosphonium chloride or diaryl phosphonium chloride, and heated naturally to room temperature and reacted for 12-24 hours to get the bidentate phosphine ligand through column chromatography. The invention takes chiral 4,4',6,6'-quadra(trifluoromethyl) - biphenyl -2,2'- diamine and various dialkyl phosphine chlorides or diphenyl(or substituted diphenyl group) phosphine chlorides as raw materials to prepare the amide type phosphinidene bidentate phosphine ligand. The invention enables the pure enantiomer amide type phosphinidene bidentate phosphine ligand to be applied to Rh-catalyzed ene amide and asymmetric hydrogenation of alpha-dehydro amino acid esters and achieves very good results, with the product enantioselectivity up to 99%.

Owner:WUHAN UNIV

Durable flame resistance, electric conduction and ash black dyeing one-step processing method of cotton fabric

ActiveCN108611880ATightly boundRealize the grafting reactionHeat resistant fibresDyeing processEpoxyPhosphonium

The invention discloses a durable flame resistance, electric conduction and ash black dyeing one-step processing method of cotton fabric. According to the method, a flame retardant tetrakis hydroxymethyl phosphonium chloride (THPC) or tetrakis hydroxymethyl phosphonium hydroxide (THPOH) is reacted with graphene oxide (GO), and the hydroxymethyl of the flame retardant is reacted with the hydroxyl or epoxy group of the GO, so that a multifunctional finishing agent with flame resistance, electric conduction and dyeing functions is formed. The multifunctional finishing agent, urea, magnesium chloride and hexamethylolmelamine are prepared into a finishing liquor, the cotton fabric is subjected to padding of the finishing liquor, and the multifunctional finishing agent is subjected to drying andammonia finishing and is firmly fixed on the cotton fabric, so that the durable flame resistance, electric conduction and ash black dyeing cotton fabric is obtained. Flame resistance, electric conduction and ash black dyeing one-step processing method of the cotton fabric is realized through the method, the time is saved, the production efficiency is improved, and the multifunctional finishing agent is tightly combined with the cotton fabric, and the wash resistance is excellent.

Owner:新乡市新科防护科技有限公司

Process for finishing knitted fabrics

InactiveCN107142726AExcellent flame retardantGood antibacterialBiochemical fibre treatmentLiquid/gas/vapor removalTime of useSorbitan

The invention discloses a process for finishing knitted fabrics. The process comprises the following steps: adding 1-5 parts by mass of hydroxypropyl methyl cellulose, 3 parts by mass of guanidine bactericide, 5 parts by mass of polyoxyethylene polyamine, and 2 parts by mass of nano-scale magnesium hydroxide into 20-50 parts by mass of deionized water, and mixing and stirring the components uniformly; slowly adding 1 parts by mass of sorbitan fatty acid ester, 2 parts by mass of schizonepeta volatile oil, 3 parts by mass of tetrakis hydroxymethyl phosphonium chloride, and 1 part by mass of barbaloin at the same time, and performing stirring continuously until the components are mixed fully and uniformly to prepare a finishing solution; and then performing antibacterial treatment. By use of the process for final finishing of knitted fabrics for hats, a finished fabric has excellent flame-retardant, antibacterial, anti-wrinkle and antistatic properties, and is strong in washing resistance; and the process can improve the antibacterial property of the fabrics, so that the fabrics are good in antibacterial effect and long in service time.

Owner:NANTONG SANJIANG TEXTILE CO LTD

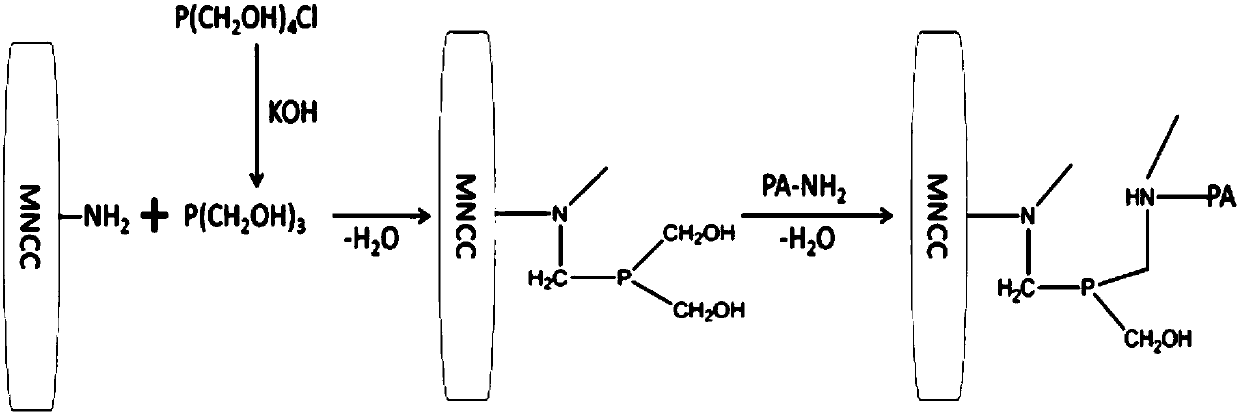

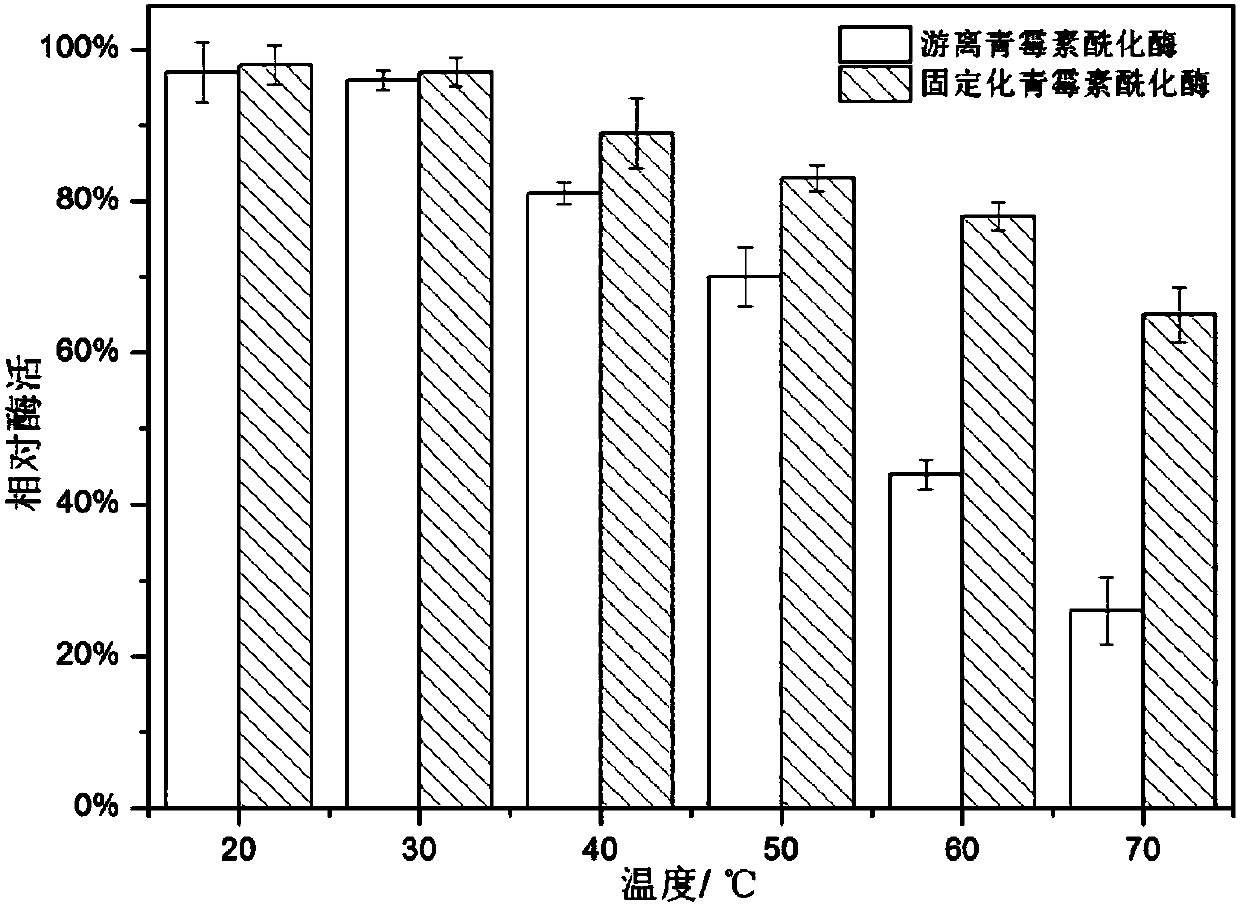

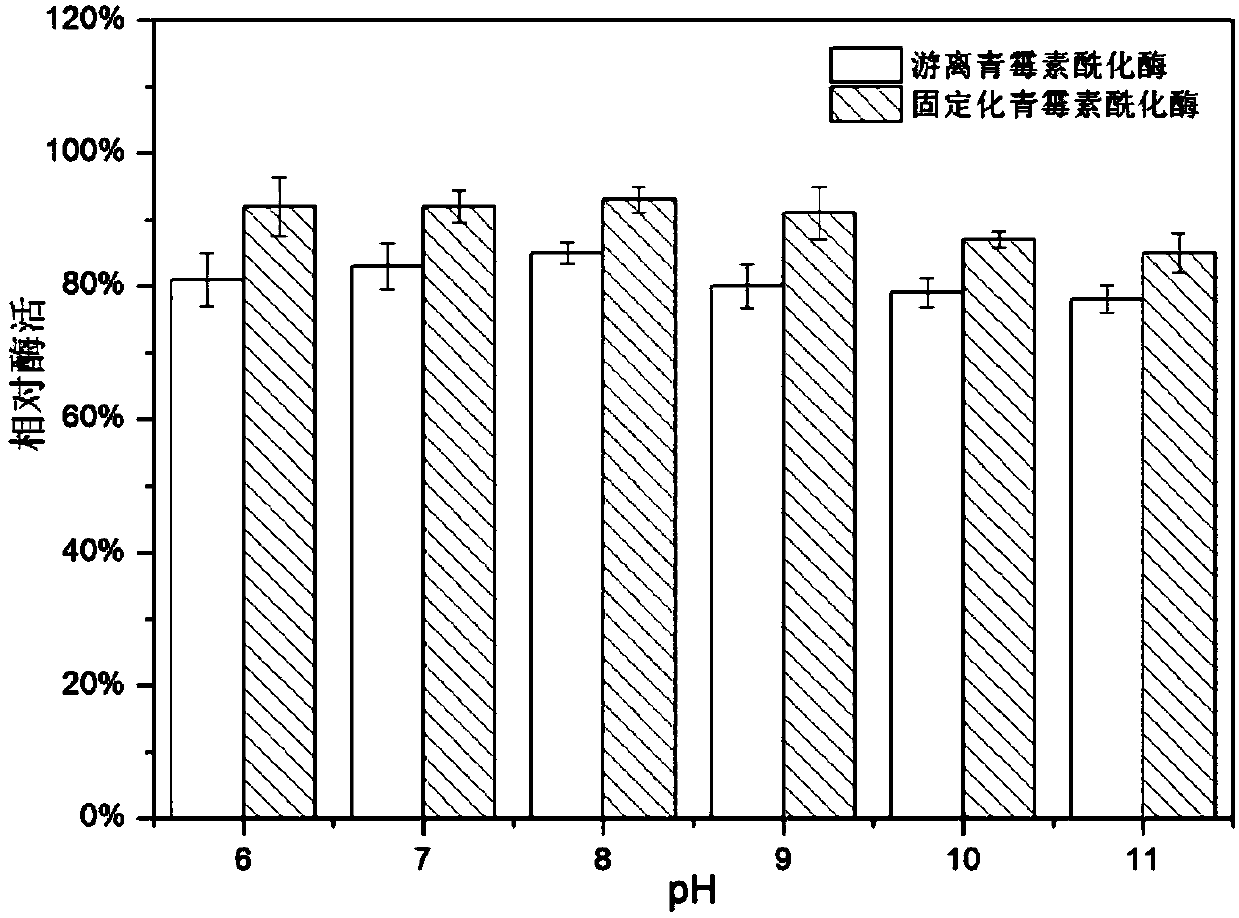

Penioillin acylase preparation and immobilization method

ActiveCN107746840ALow priceReduce manufacturing costHydrolasesOn/in organic carrierCelluloseTetrakis(hydroxymethyl)phosphonium chloride

The invention belongs to the technical field of a material, and discloses a penioillin acylase preparation and an immobilization method. The immobilization method comprises the following steps of (1)under the conditions of stirring at room temperature, dripping a potassium hydroxide water solution into a tetrakis hydroxymethyl phosphonium chloride solution to obtain a mixed solution containing trisphosphine oxide; (2) adding magnetic cellulose nanometer crystals into the mixed solution containing trisphosphine oxide in the step (1); performing stirring for 1 to 30min at room temperature; performing centrifugal washing to obtain the treated magnetic cellulose nanometer crystals; (3) diluting the penioillin acylase into a buffer solution with the pH being 6 to 11 to obtain an enzyme solution; (4) adding the treated magnetic cellulose nanometer crystals into the enzyme solution; performing curing at room temperature to obtain the immobilized penioillin acylase, i.e., the penioillin acylase preparation. The method is simple; the cost is low; the enzyme activity recovery rate of the prepared immobilized penioillin acylase preparation is high; the enzyme loading rate is high; meanwhile,the stability is high.

Owner:SOUTH CHINA UNIV OF TECH

Flame-retardant knitted fabric

InactiveCN104047092AFeel comfortableImprove flame retardant performanceFibre treatmentWoven fabricsCarboxymethyl celluloseTetrakis(hydroxymethyl)phosphonium chloride

The invention discloses a flame-retardant knitted fabric. The warp of the fabric is DTY150D / 48F, and the weft of the fabric is ATY320D / 96F; the fabric is soaked in steeping liquid containing 35%-40% composite finishing agent at the temperature ranging from 70 DEG C to 75 DEG C for five hours to six hours and then is placed at the constant temperature ranging from 155 DEG C to 160 DEG C for five hours to seven hours after being taken out. The composite finishing agent is prepared with the following methods that 2 parts to 3 parts of carboxymethyl cellulose, 4 parts to 5 parts of vinyl trimethoxy silane, 8 parts to 9 parts of tetrakis hydroxymethyl phosphonium chloride, 1 part to 2 parts of phosphorous ester and three parts to four parts of triethoxy ethyl silane are mixed, then, 7 parts to 8 parts of cyclic phosphonate ester and 6 parts to 7 parts of molybdenum trioxide are synchronously and slowly added, material feeding is completed within eight minutes to ten minutes, continuous mixing lasts for ten minutes to fifteen minutes, and the composite flame-retardant agent is prepared. The flame-retardant knitted fabric has excellent flame-retardant performance.

Owner:JIANGSU JINHONG KNITTING

Method for preparing tetrakis(hydroxymethyl)phosphonium chloride from phosphine generated in sodium hypophosphite production

ActiveCN101143878ASmall doseSmall foamingGroup 5/15 element organic compoundsHypophosphorous acidToxic gasAbsorption column

The present invention relates to a method which uses the phosphine generated in the process of producing sodium hypophosphite to prepare tetrakis (hydroxymethyl) phosphonium chloride. From the waste gas generated in the process of producing the sodium hypophosphite, the phosphine is collected and stored; aqueous solution is prepared with formaldehyde and hydrochloric acid according to the molar ratio of 4.05 to 4.15:1; the aqueous solution is pumped into an absorption column by an erosion-resistant pump and is sprayed down from the top of the column, the phosphine gas in a gas vessel is pumped into the absorption column by a gas pump, a synthesis reaction is carried out under the condition of temperature between 40 DEG C and 50 DEG C, the reaction formula is 4HCHO plus HCL plus PH3=(HOCH2)4PCL, and finally, the tetrakis (hydroxymethyl) phosphonium chloride is prepared. The prepared tetrakis (hydroxymethyl) phosphonium chloride is a quaternary alkylphosphonium salt bactericidal algicide, which does not pollute environment. The formaldehyde and the hydrochloric acid can thoroughly absorb the phosphine, thus realizing zero emission of toxic gas. The present invention resolves the problem of environmental pollution caused by the waste gas generated in the process of producing sodium hypophosphite.

Owner:江苏和纯化学工业有限公司

Comprehensive filtering wave compensation controller

InactiveCN104449099AExtended service lifeWith heat insulationAnti-corrosive paintsElectrically-conductive paintsEmulsionCresol

The invention discloses a comprehensive filtering wave compensation controller which comprises a shell, wherein the shell is coated with a protecting layer; the protecting layer is prepared according to the following steps: 1) feeding the following components in parts by weight into 12.6 parts of deionized water: 2.6 parts of modified styrene-acrylic emulsion, 1.8 parts of dimethyl cresol, 2.1 parts of triphenyl(phenylmethyl)-phosphonium chloride and 0.9 part of benzotriazole, and uniformly stirring, thereby obtaining a primer protecting coating; 2) feeding the following components in parts by weight into 11.3 parts of deionized water: 1.6 parts of amino resin, 2.4 parts of polydimethylsiloxane, 0.7 part of titanium dioxide and 1.9 parts of isopropanolamine, and uniformly stirring, thereby obtaining a surface protecting coating; 3) firstly, spraying the primer protecting coating on the surface of the shell, and curing and drying; and 4) further spraying the surface protecting coating, and curing and drying. As the shell of the comprehensive filtering wave compensation controller is coated with the protecting layer, the service life of the comprehensive filtering wave compensation controller is prolonged.

Owner:苏州菲斯特电力科技有限公司

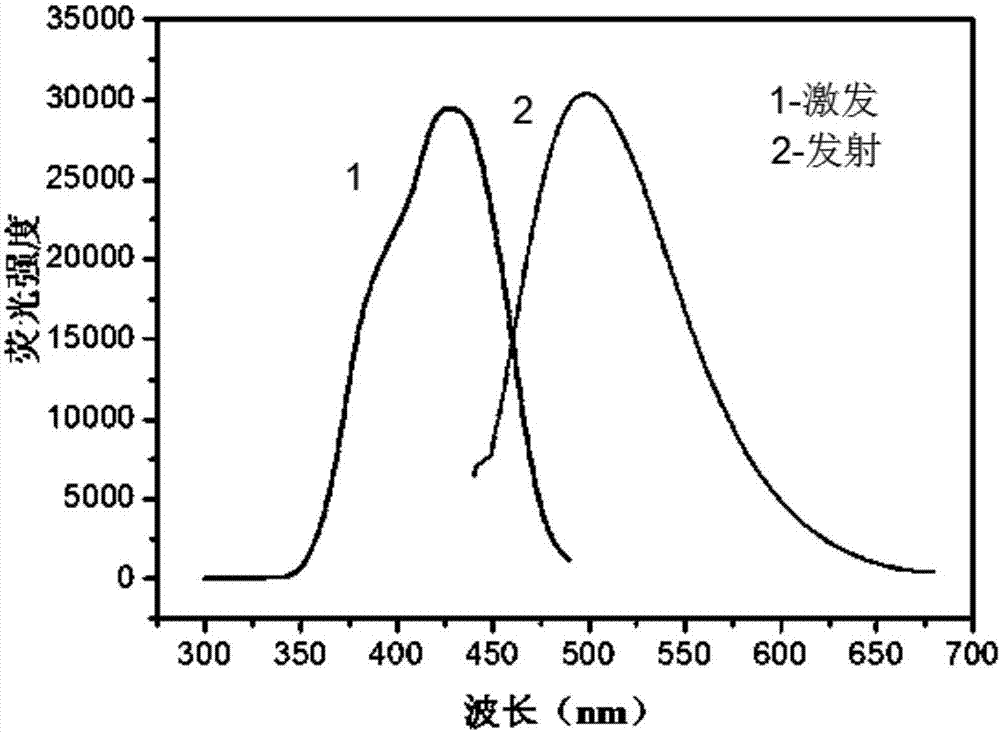

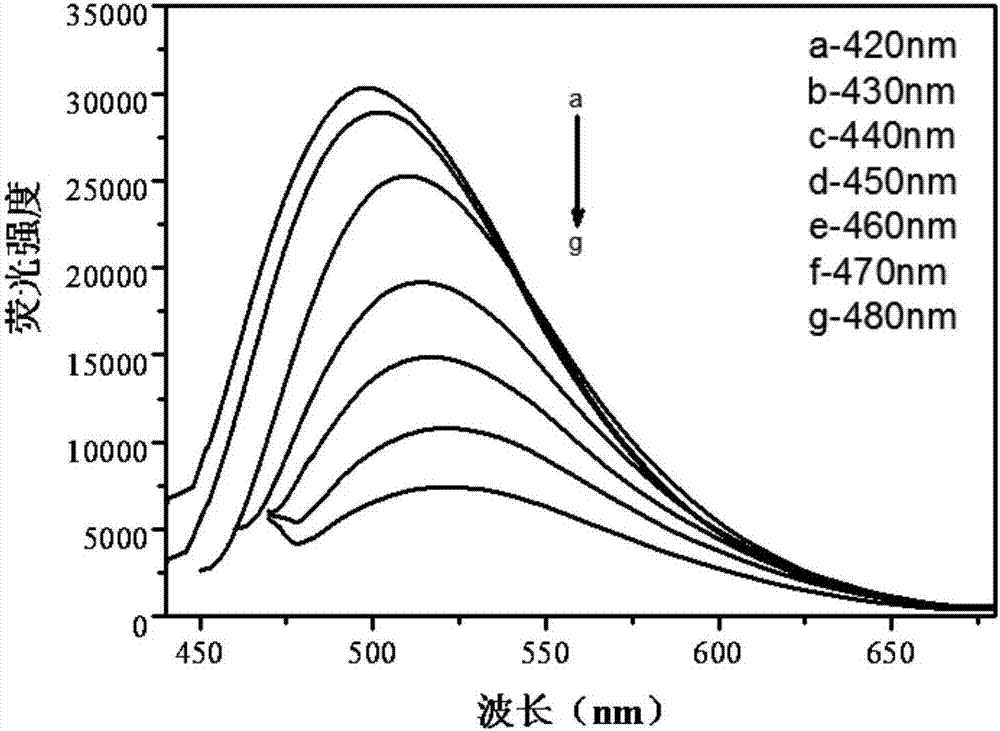

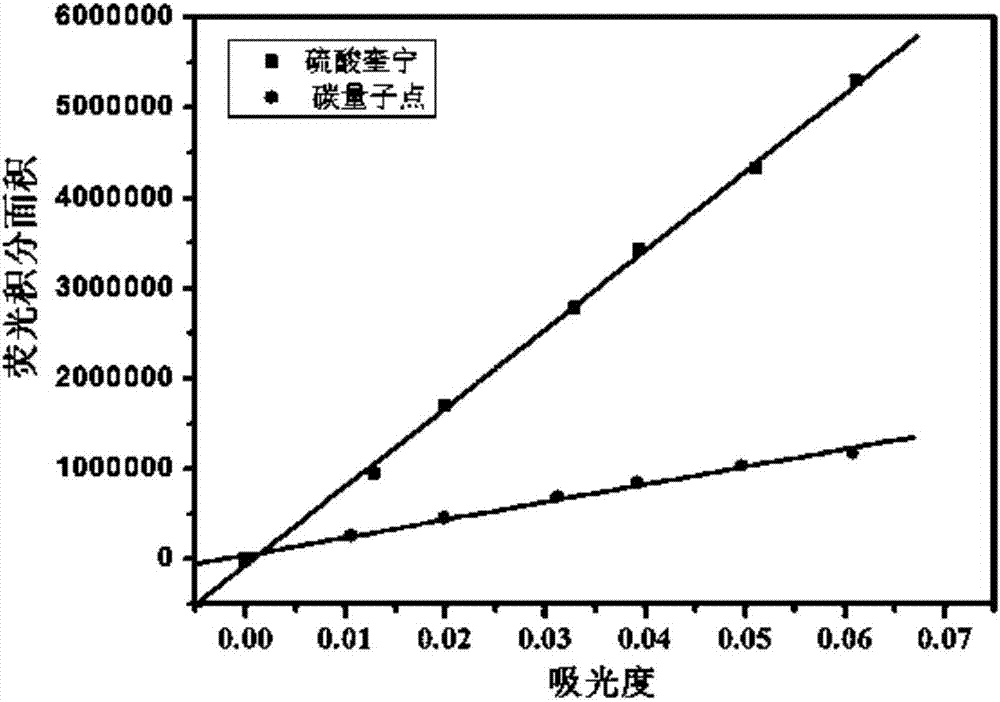

Preparation method of water-soluble N-P-codoping carbon dot

InactiveCN107312526ACarbon richCarbon savingLuminescent compositionsUltrapure waterPhosphonium chloride

The invention discloses a preparation method of a water-soluble N-P-codoping carbon dot. The preparation method comprises the following steps of (1) dissolving sulfanilic acid into ultrapure water to prepare a precursor solution, and uniformly mixing tetrahydroxymethyl phosphonium chloride and the precursor solution according to the volume ratio of 1:(10 to 20) to obtain a mixed solution; (2) carrying out hydrothermal reaction on the mixed solution prepared in the step (1), and thus obtaining the water-soluble N-P-codoping carbon dot. According to the preparation method of the water-soluble N-P-codoping carbon dot provided by the invention, the water-soluble N-P-codoping carbon dot is prepared by adopting a one-step hydrothermal method, the carbon source is rich and cheap, the preparation process is simple and easy, the whole preparation process is free of pollution and toxicity, and is green and environmentally friendly, and preparation in large scale can be realized.

Owner:GUANGXI TEACHERS EDUCATION UNIV

Automobile coating

InactiveCN103131314AStrong covering powerStrong adhesionPolyurea/polyurethane coatingsFreeze thawingSodium thiocyanate

The invention discloses an automobile coating. The automobile coating comprises, by mass, 1-2 parts of trifluoro-acetylacetone europium, 1-3 parts of tetrahydrofuran, 3-5 parts of 3-propargyl chloride, 2-4 parts of benzyl trimethyl ammonium tribromide, 1-3 parts of ferricyanate, 3-6 parts of polyurethane resin, 1-4 parts of tetrabutyl phosphonium chloride, 2-3 parts of sodium thiocyanate, 2-6 parts of hexabromocyclododecane, 2-5 parts of diethylene glycol butyl ether, and 4-7 parts of deionized water. The automobile coating has the advantages of being good in covering capacity, adhesive force, viscosity and fineness, pollution-resisting, freeze-thawing-resisting, brushing-resisting, aging-resisting, alkali-resisting, full in coating film, gorgeous and soft in luster, good in distinctness of image, safe, and non-poisonous.

Owner:NANTONG HAISHUN CHEM

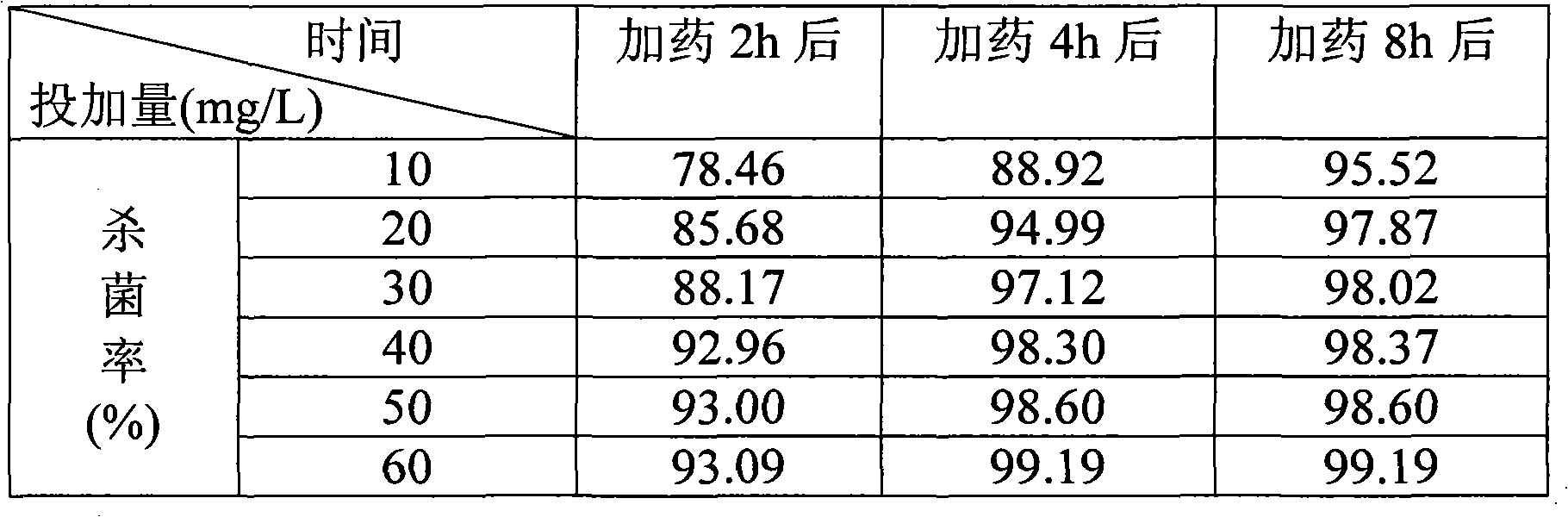

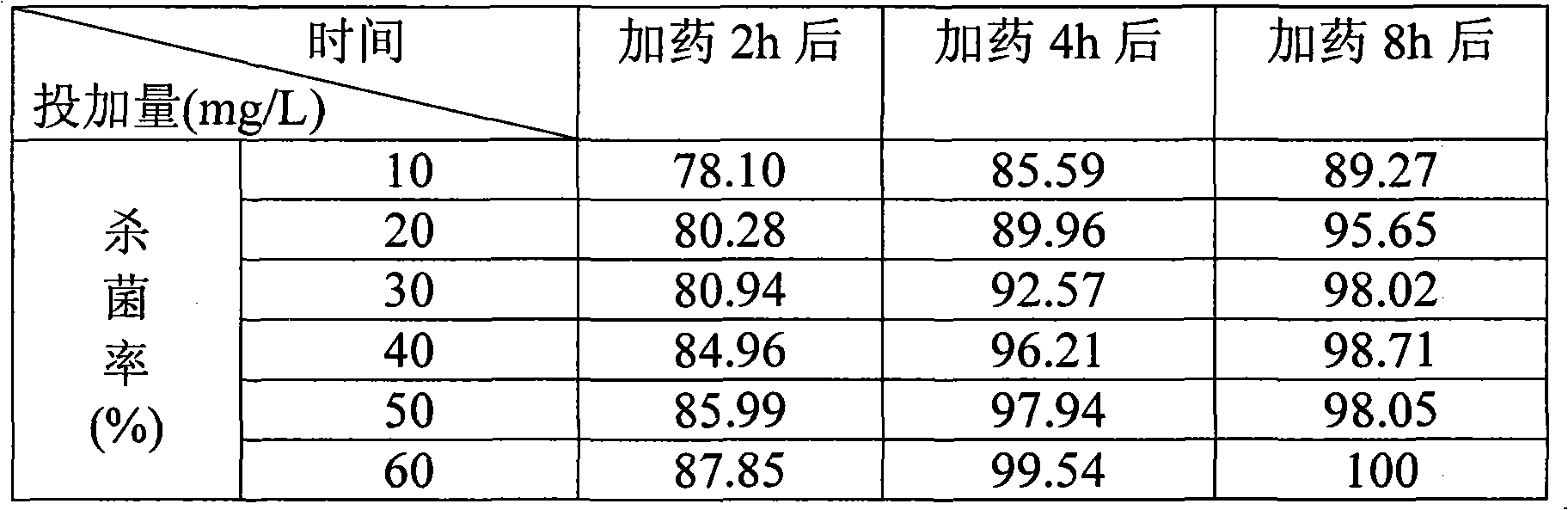

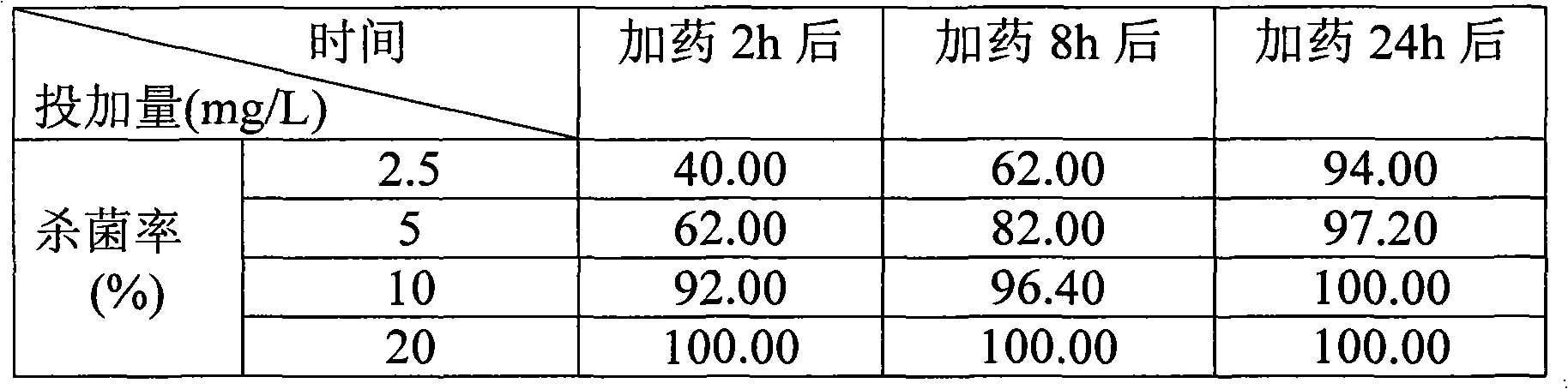

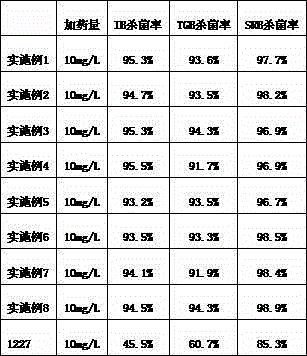

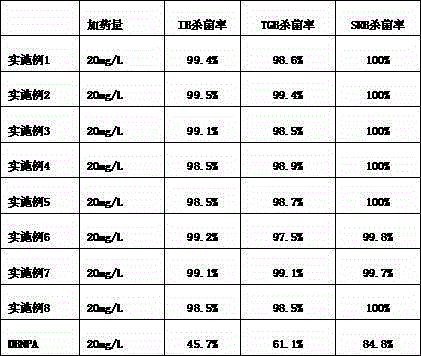

Fungicide for compound oilfield reinjection water, and preparation method therefor

ActiveCN105104420AReduce dosageThe dosage is lower than that of domestic existing oil field reinjection water fungicidesWaste water treatment from quariesBiocidePhosphonium saltBiology

The present invention relates to a treatment medicament for oilfield reinjection water, and particularly to a fungicide for compound oilfield reinjection water, and a preparation method therefor. A technical scheme of the invention is: a fungicide for compound oilfield reinjection water is prepared by quaternary phosphonium salt, dibromo nitrilo propionamide, 50% glutaraldehyde solution, and water, wherein the mass ratio of the quaternary phosphonium salt, the dibromo nitrilo propionamide, the 50% glutaraldehyde solution, and the water is 20-30: 10-20: 10-20: 30-60. The quaternary phosphonium salt is one of tetrakis hydroxymethyl phosphonium chloride and tetrakis hydroxymethyl phosphonium sulfate. The present invention provides a highly efficient fungicide for compound oilfield reinjection water.

Owner:WEIHAI XIANGYU TECH

Process for the hydrogenation of imines

The present invention relates to a process for the hydrogenation of imines with hydrogen in the presence of iridium catalysts. In particular the present invention relates to a process for the hydrogenation of imines with hydrogen under elevated pressure in the presence of an iridium catalysts and with or without an inert solvent, wherein the reaction mixture comprises a phosphonium chloride, bromide or iodide in the presence or in the absence of an acid, which can be an organic or inorganic acid, soluble or insoluble in the reaction mixture. Suitable imines are especially those that contain at least one (Formula I) group. If the groups are substituted asymmetrically and are thus compounds having a prochiral ketimine group, it is possible in the process according to the invention for mixtures of optical isomers or pure optical isomers to be formed if enantioselective or diastereoselective iridium catalysts are used.

Owner:EVONIK DEGUSSA GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com