Patents

Literature

88results about How to "High scale inhibition rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-phosphorous environment-friendly composite corrosion and scale inhibitor

InactiveCN101746901AImprove toleranceGood dispersionScale removal and water softeningHigh concentrationTricarboxylic acid

The invention discloses a low-phosphorous environment-friendly composite corrosion and scale inhibitor that is used in a circulating cooling water system. The low-phosphorous environment-friendly composite corrosion and scale inhibitor comprises 2-phosphonic butane- 1,2,4 -tricarboxylic acid, plyaspartic acid or polyepoxysuccinic acid, maleic anhydride-acrylic acid copolymer, acrylic acid-2-acrylamide-2-methyl propanesulfonic acid or acrylic acid-acrylate-sulfonate, acrylic acid-acrylate-phosphonic acid-sulfonate quaternary copolymer, zinc salts (zinc sulfate or zinc chloride) or hydroxy benzotriazole. The invention is particularly suitable for the circulating cooling water system with high concentration multiple, which needs to control the phosphorous content (the total phosphorous content is lower than 0.5mg / l) due to environmental pressure.

Owner:成都澳贝龙科技发展有限公司

Scale inhibition antiscaling agent for oil-water well salt prevention and scale-inhibition operation and preparation process thereof

The invention relates to oil-water well salt prevention and scale-inhibition operation in the oil-field development process and a scale-inhibition agent used in a cooling circulation system, in particular to a scale inhibition antiscaling agent for oil-water well salt prevention and scale-inhibition operation and a preparation process thereof; the scale inhibition antiscaling agent is characterized in that: the scale inhibition antiscaling agent at least comprises 1) 2.0-2.5kg of ethanediamine tetramethylene phosphonate; 2) 4.5-5.0kg of polymaleic acid; 3) 4.5-5.0kg of sodium hexametaphosphate; 4) 6.5-7.0kg of triethanolamine; the preparation process of the scale inhibition antiscaling agent for oil-water well salt prevention and scale-inhibition operation is characterized in that: at normal temperature, 4.5-5.0kg of the sodium hexametaphosphate is dissolved by 30-35kg of clear water and is continuously stirred for 20-40 minutes, and then 6.5-7.0kg of the triethanolamine is slowly added in the mixture, after complete mixing, and 2.0-2.5kg of the ethanediamine tetramethylene phosphonate and 4.5-5.0kg of the polymaleic acid are slowly added continuously while stirring is carried out, so as to prepare the scale inhibition antiscaling agent; the scale inhibition antiscaling agent has hypersalinity resistance and high calcium ion resistance, takes alkalescence-neutrality, and has no strong corrosivity to injection-production equipment.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

Multifunctional sinking agent used in production of phosphoric acid by wet method

InactiveCN102219198AImprove settlement performanceGood anti-scaling effectPhosphorus compoundsFlocculationDiammonium phosphate

The invention relates to a multifunctional sinking agent used in production of phosphoric acid by a wet method. The multifunctional sinking agent is characterized by being prepared by mixing a non-ionic flocculating agent, a coagulation flocculation adsorbent and an anionic surfactant according to a mass ratio of 10-20:60-80:10-20. The invention provides a multifunctional sinking agent for removing impurities in coarse phosphoric acid in the process of producing phosphoric acid by a wet method. According to the invention, the multifunctional sinking agent can be completely settled; the height of base solution is low; the preparation method for the agent is simple; the cost is low; the agent has scale inhibition efficiency to the next procedure and can improve brightness and crystallization of diammonium phosphate granules to be produced.

Owner:HUBEI FORBON TECH

Efficient alkyl ether carboxylate type dirt dispersion agent and application thereof

InactiveCN103058399APromote hydrationGood dispersionScale removal and water softeningCarboxylic saltNuclear chemistry

The invention relates to an alkyl ether carboxylate type dirt dispersion agent. The dirt dispersion agent contains carboxyl and ether group functional groups. The invention aims to provide an application of the dirt dispersion agent disclosed by the invention to an industrial water treatment system, particularly a circulating cooling water system. The invention aims to provide an application method of the dirt dispersion agent disclosed by the invention; when being used, the dirt dispersion agent can be used separately and can also be compounded with other dirt dispersion agents or corrosion inhibitors to be used. According to the alkyl ether carboxylate type dirt dispersion agent, the alkyl ether carboxylate has very high tolerance on calcium and has a good dirt dispersion effect on difficultly-dissolved salts including calcium carbonate dirt, calcium sulfate dirt, calcium phosphate dirt and the like in the water under the conditions of high hardness, high alkali, high temperature and high pH (Potential of Hydrogen); and the alkyl ether carboxylate type dirt dispersion agent has the advantages of safety in use, low toxicity, easiness for biological degradation and environmental friendliness, is applicable to automatic medicine adding control, and is convenient to use, and so on.

Owner:NANJING YUSHUI SCI & TECH

Composite multi-component scale inhibitor for treating oil-field water and preparation thereof

ActiveCN101412567ALattice distortionHas a critical effectScale removal and water softeningChemistryEthylenediaminetetra(methylenephosphonic)acid

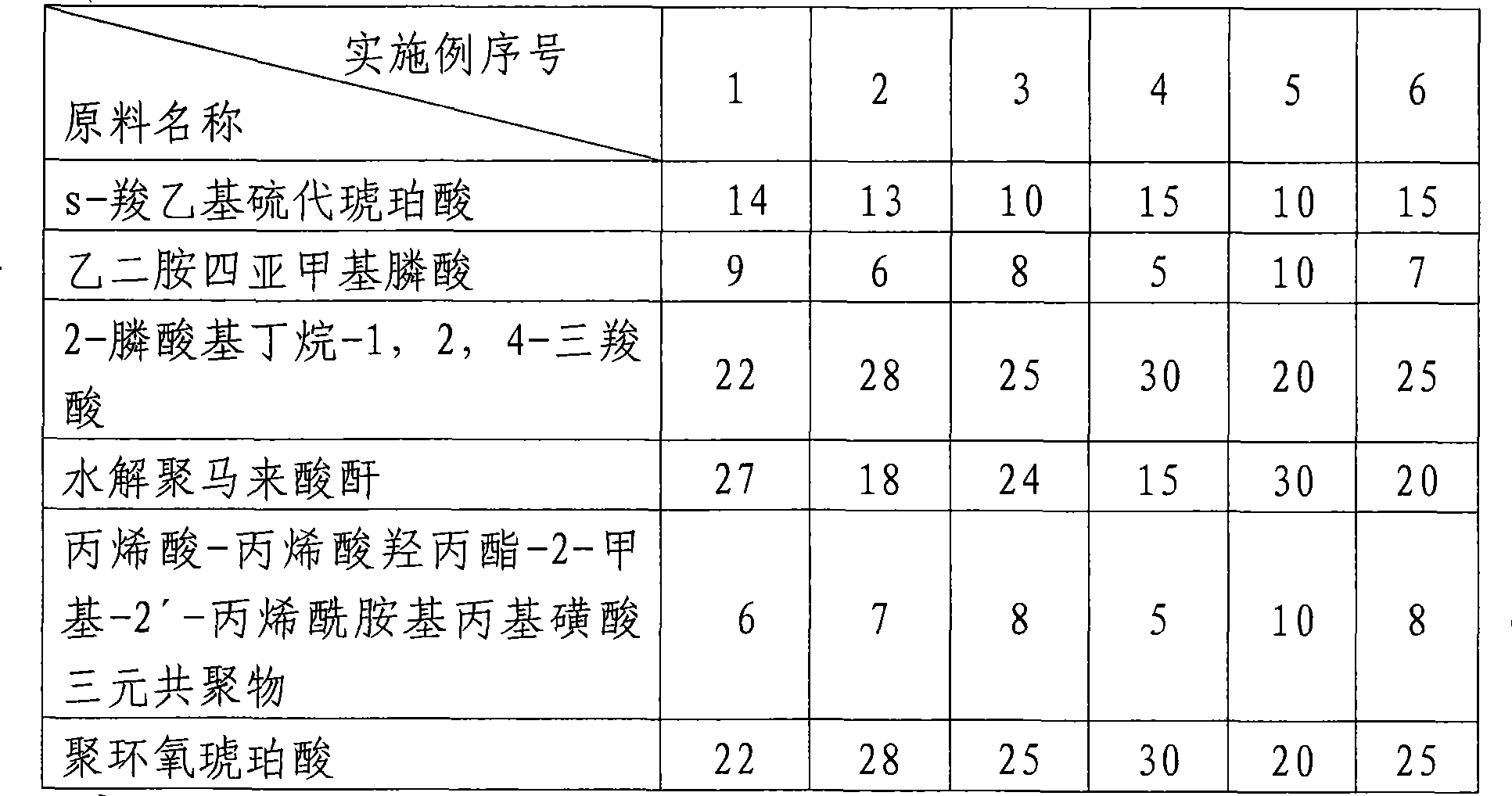

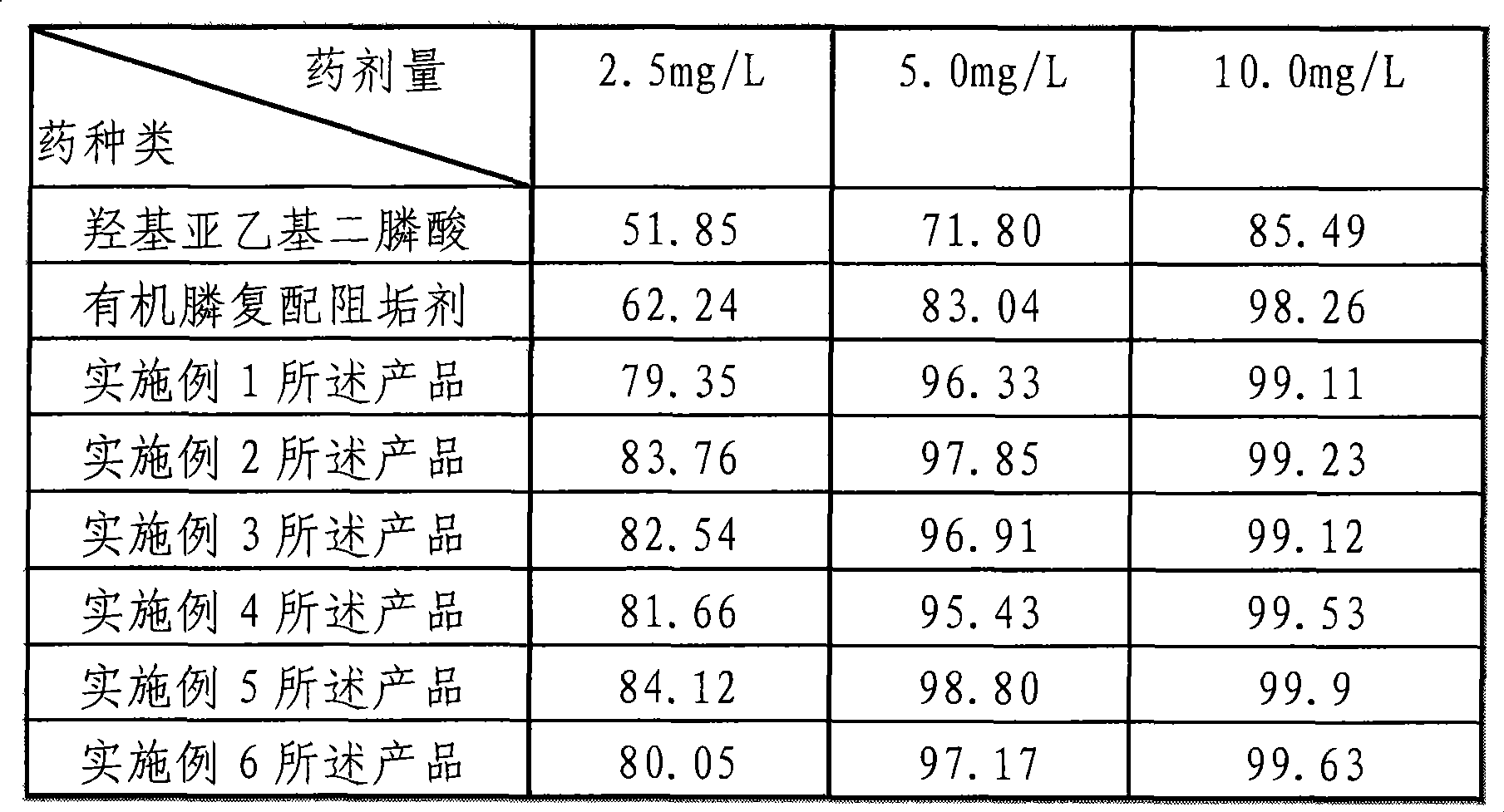

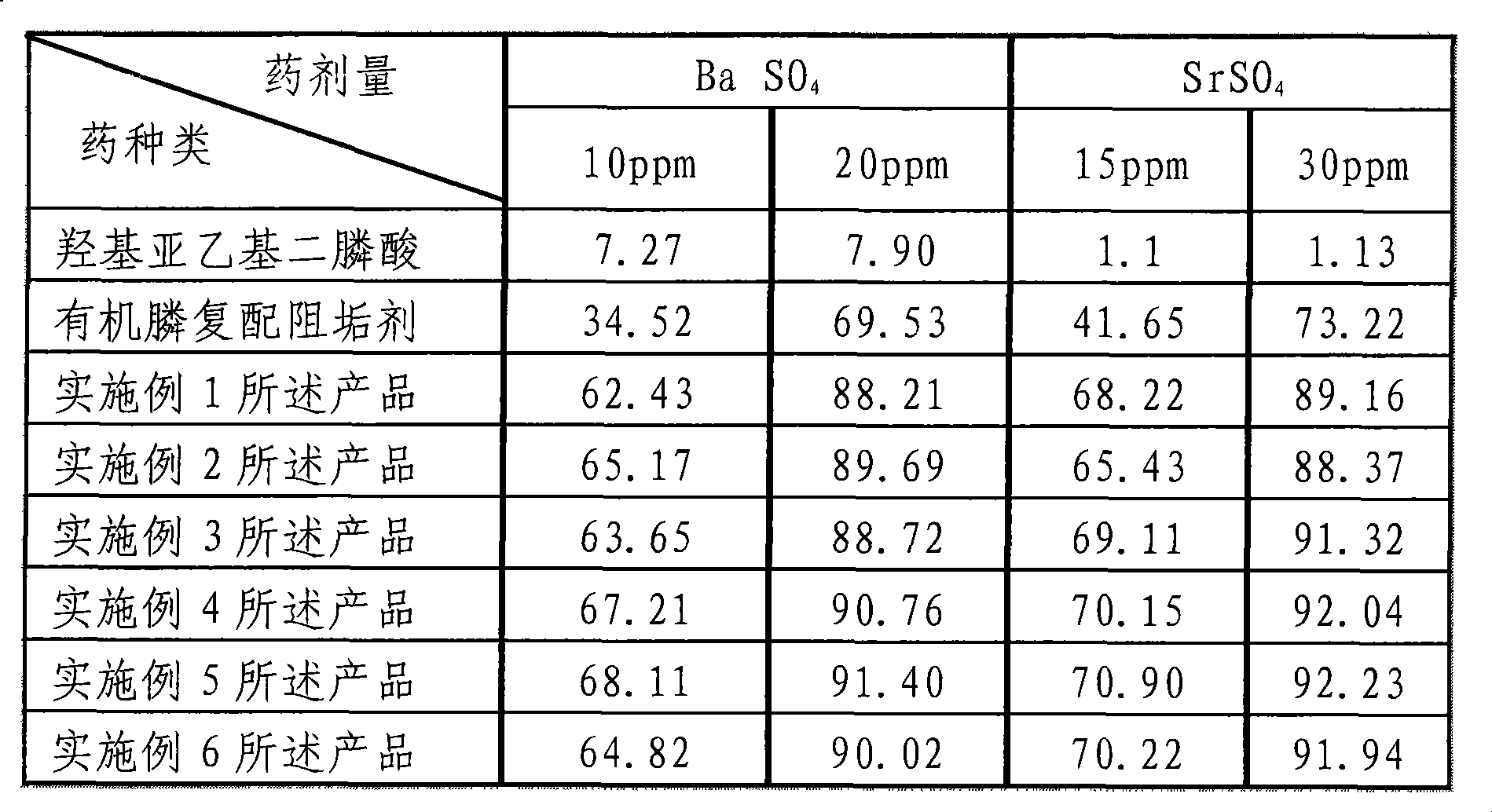

The invention relates to a composite multi-component scale inhibitor for oil field water treatment and a preparation method thereof. The composite multi-component scale inhibitor comprises s-propyloic sulpho succinic acid, tetramethylenediamine phosphonic acid, 2-phosphonic butane-1, 2, 4-tricarboxylic acid, hydrolyzed polymaleic anhydride, propenoic-hydroxypropyl acrylate-2-methyl-2'-acrylamide propyl sulphonic acid terpolymer, and polyepoxy succinic acid, which are mixed in weight portion, wherein active substances must reach standardized contents of the experiment. The preparation method comprises the following steps: adding the polyepoxy succinic acid into the 2-phosphonic butane-1, 2, 4-tricarboxylic acid; adding the tetramethylenediamine phosphonic acid into the hydrolyzed polymaleic anhydride; and preparing solutions of the propenoic-hydroxypropyl acrylate-2- methyl-2' -acrylamide propyl sulphonic acid terpolymer and the s-propyloic sulpho succinic acid by steps and mixing the solutions, stirring the solution evenly for 50 to 90 minutes and keeping a temperature range from 12 to 48 DEG C, and obtaining the composite multi-component scale inhibitor for oil field water treatment which has little dosage, wide application range, and can play excellent efficiency under the conditions of high alkali, high hardness and high temperature.

Owner:XINJIANG DELAND

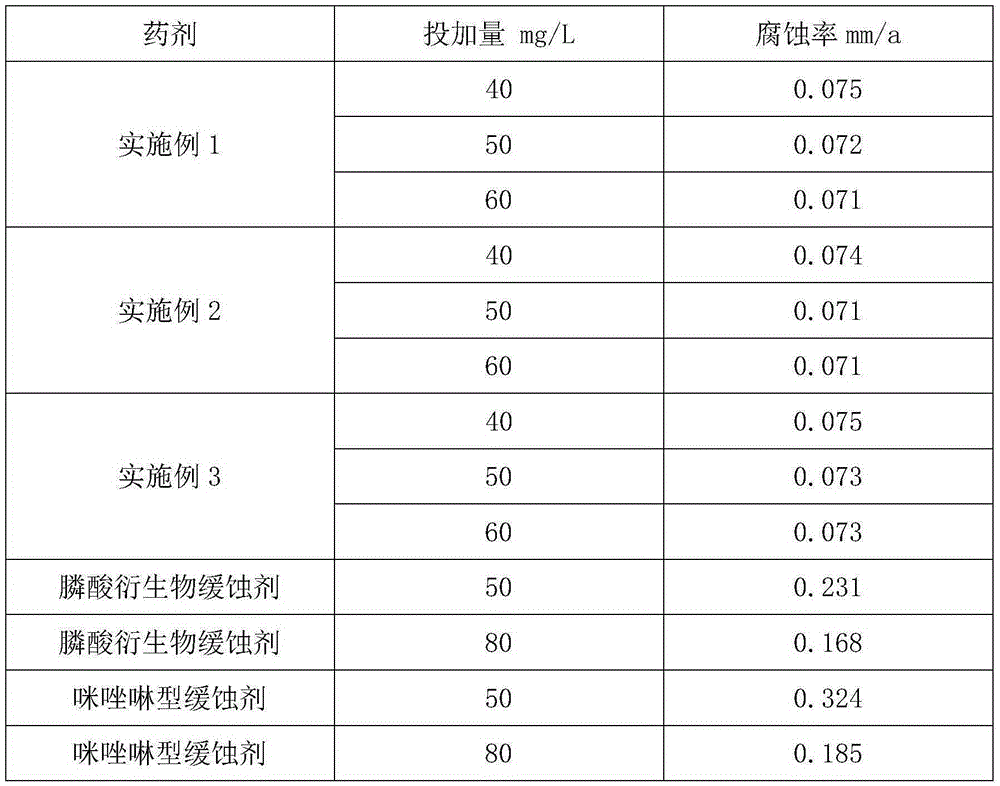

High-efficiency low-phosphorus corrosion and scale inhibiting dispersant and its preparation method

InactiveCN102745825AEasy to realize online automatic dosingImprove controllabilityScale removal and water softeningTungstateTurbidity

The invention discloses a high-efficiency low-phosphorus corrosion and scale inhibiting dispersant and its preparation method. The high-efficiency low-phosphorus corrosion and scale inhibiting dispersant comprises: 2%-12% of sodium benzoate, 1%-5% of molybdate (or tungstate), 1%-2% of thiazole, 3%-6% of anhydrous zinc chloride, 8%-18% of polyphosphonocarboxylate, 5%-15% of acrylic acid-2-methyl-2-acrylamido propane sulfonic acid copolymer, 3%-6% of a stabilizer, 3%-6% of a tracer, and the balance deionized water. The dispersant of the invention can be widely applicable to water quality treatment of circulating water with a sum of hardness and alkalinity of less than 1100mg / L, a chloride ion concentration of less than 1000mg / L, pH of 6.8-9.5, and turbidity of less than 20NTYU. The dispersant provided in the invention has scale and corrosion inhibiting performances able to meet the requirements of industrial circulating water design specifications and a wide source water quality application range, and has the advantages of low phosphorus, environmental protection, strong chlorine resistance, applicability for auto-medicating control, as well as convenient use, etc.

Owner:CHINA PETROLEUM & CHEM CORP +1

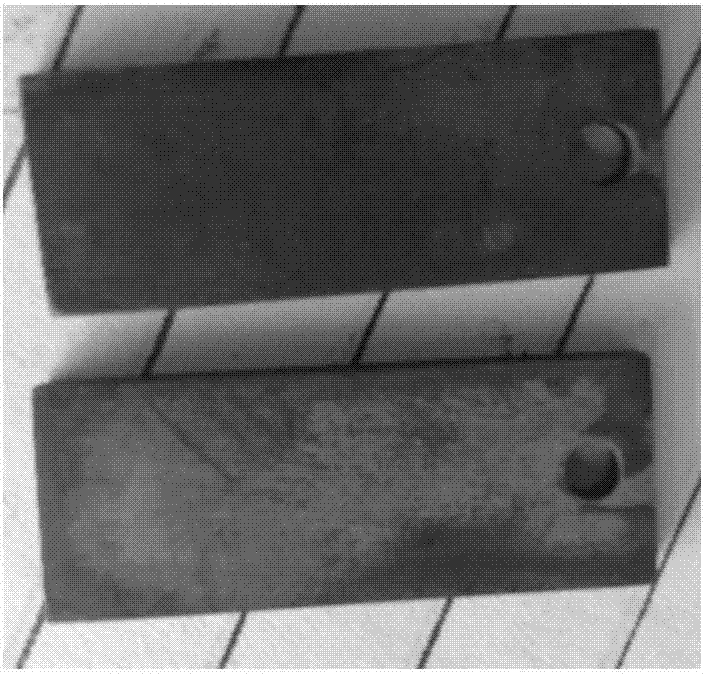

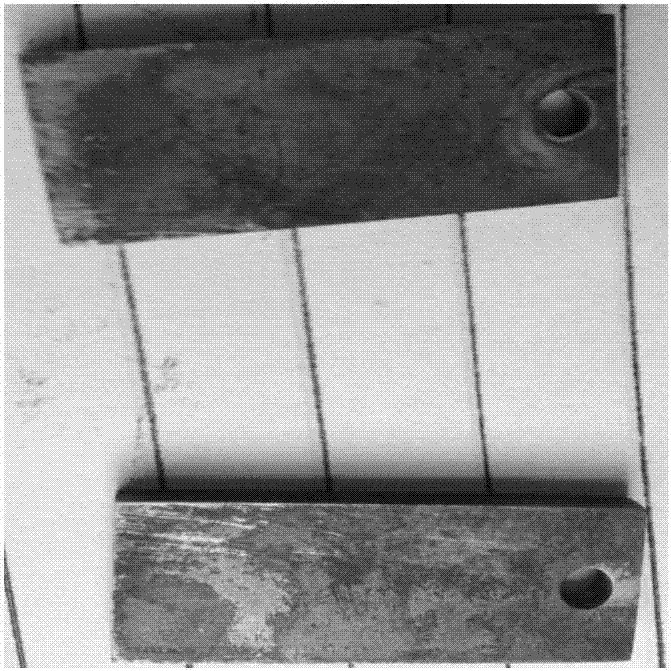

Scale inhibitor for oil refining equipment and preparation method of scale inhibitor

InactiveCN106701194AWide variety of sourcesInhibition of coking and foulingTreatment apparatus corrosion/fouling inhibitionDiimidePolyisobutylene succinimide

The invention discloses a scale inhibitor for oil refining equipment. The scale inhibitor is prepared from the following raw materials: purified water, polyisobutylene succinimide, N,N'-disalicylidene-promethylene diamine, calcium alkyl salicylate, heavy aromatics, hexadecyl dimethyl amine, 2,2,6,6-tetramethylpiperidinooxyl, toluene, sodium persulfate, hydrogen peroxide and potassium superphosphate. The scale inhibitor is used for inhibiting coking and scale deposition of various devices and equipment in petroleum refining and petrochemical processes, particularly for coking and scale deposition of hydrogenation process equipment; coking and scale deposition of heat exchangers and steam generators for catalytic cracking, delayed coking and crude oil distillation processes are inhibited; and a high scale inhibition rate is achieved with the filling amount of 80 to 100 [mu]m / g in a crude oil heat exchanger, a reactor and a heating furnace, and each component synergistically acts to achieve the carbon steel corrosion rate of 0.001 to 0.003 [mu]m*a<-1> and the calcium carbonate scale inhibition rate of 85 to 95 percent.

Owner:JIANGSU JINGWEI TECH INNOVATION CONSULTING CO LTD

Environment-friendly slow-release polymer scale inhibitor and preparation method thereof

ActiveCN107304078ABiodegradableWon't happenWaste water treatment from quariesWater treatment compoundsOil fieldRelease time

The invention discloses an environment-friendly slow-release polymer scale inhibitor, which is good in scale inhibition and slow release effects. The dosage of the scale inhibitor which needs to be added within a maintenance cycle can be estimated in advance according to the actual production condition of an oil well; the scale inhibitor is put into a sieve tube at the lower end of an oil-well pump of the oil well in regular repair and maintenance processes of an oil-well pipeline and a gathering pipeline; scale inhibition components are slowly dissolved and released to achieve the long-term scale inhibition effect through one-off addition when a produced liquid flows through the sieve tube, so that the long-term effective concentration can be maintained, the scale inhibiting ratio within the effective service cycle (about 90-120d) is greater than 85%, the effective release time can reach 90d or over, the protection period on the pipeline is long, and the production and maintenance cost of an oil field can be effectively reduced. The environment-friendly slow-release polymer scale inhibitor is nontoxic, harmless and degradable, and does not harm the formation and surrounding environment, and is environmentally friendly and suitable for popularization and application.

Owner:WUHAN UNIV OF TECH

Scale inhibitor and dispersant for wet process phosphoric acid filter system

The invention relates to a scale inhibitor and dispersant for a wet process phosphoric acid filter system. The scale inhibitor and dispersant is characterized by comprising the following raw material components in percentage by weight: 5%-15% of organic phosphoric acid, 40%-65% of phosphorus-containing polymer, 25%-40% of sulfonic acid copolymer, 0.05%-0.5% of aluminum slat and 4-10% of water. The adding amount of the scale inhibitor and dispersant is 0.005%-0.02% of wet process phosphoric acid; and the scale inhibitor and dispersant disclosed by the invention can effectively prevent the scale formation phenomenon of the filter system during the production of the phosphoric acid, has no influence on subsequent working sections and has good application prospects.

Owner:NANJING UNIV OF TECH

Washing liquid used for removing iron sulfides scale, and preparation method and applications thereof

ActiveCN107541198AImprove clearanceHigh scale inhibition rateDrilling compositionSodium saltBalance water

The invention discloses a washing liquid used for removing iron sulfides scale, and belongs to the field of chemical descaling. The washing liquid comprises 5 to 30% of an organic phosphorus chelatingagent, 1 to 6% of an ammonium salt chelating auxiliary agent, 2 to 8% of an inorganic oxidizing agent, 2 to 6% of a sulfur removing dispersant, and the balance water; the organic phosphorus chelatingagent is Tetrakis hydroxymethyl phosphonium sulfate and / or Tetrakis(hydroxymethyl)phosphonium Chloride. The sulfur removing dispersant is prepared via following steps: triazine, a polyol, and clear water are introduced into a reaction vessel, an obtained mixture is heated to 30 to 50 DEG C, and is reacted for 20 to 40min with stirring; Diethylenetriaminepenta(methylenephosphonicacid) sodium salt,an anionic surfactant, and clear water are added, the temperature is reduced to 25 to 35 DEG C, and stirring reaction is carried out under constant temperature conditions for 25 to 35min; wherein themass ratio of triazine, the polyol, and clear water is controlled to be 1:10-25:35-50, the mass ratio of the anionic surfactant, Diethylenetriaminepenta(methylenephosphonicacid) sodium salt, and clear water is controlled to be 1:1-4:10-24, and the mass amount of the anionic surfactant accounts for 0.5 to 4% of that of the sulfur removing dispersant. The washing liquid is high in clearing rate andscale inhibition rate, is safe, is friendly to the environment, and is high in biodegradability.

Owner:PETROCHINA CO LTD

Water-borne organic cold carrying/heat conduction medium and preparation method thereof

InactiveCN106701043AHigh scale inhibition rateAvoid corrosionHeat-exchange elementsTricarboxylic acidAdipic acid

The invention relates to a water-borne organic cold carrying / heat conduction medium and a preparation method. The water-borne organic cold carrying / heat conduction medium is prepared by the following steps of using propylene glycol, diethylene glycol, tri-ethylene glycol and deionized water as base liquids, and using succinic acid, adipic acid, tricarboxylic acid, diethanol amine, triethanolamine, tris(dimethylamino)phosphine, mercaptobenzothiazole, benzotriazole, tris(N,N-diethylamino)phosphine and polymaleic anhydride with polymerizing degree of 8000 as compound corrosion and scale inhibitors; respectively adding, heating by phases, stirring, and dissolving. The prepared water-borne organic cold carrying / heat conduction medium has the characteristics that the excellent corrosion and scale inhibition property is realized for a multi-metal system, and the electrochemical corrosion and heat corrosion are effectively prevented; the reserve alkalinity is more than 20ml, so that the medium has stable PH (potential of hydrogen) value, and the long-time effect of the medium property is guaranteed; the heat conduction coefficient is slightly better than the heat conduction coefficient of heat conduction oil, and the medium can normally work at the temperature range of -40 to 210 DEG C, can be used as a cold carrier and an anti-freezing agent at low temperature, and can also be used as a heat conduction liquid at high temperature; the property is stable at high temperature, the viscosity is low at low temperature, the corrosion and scale inhibition property is lasting, the environment-friendly effect is realized, and the heat conduction coefficient is good.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

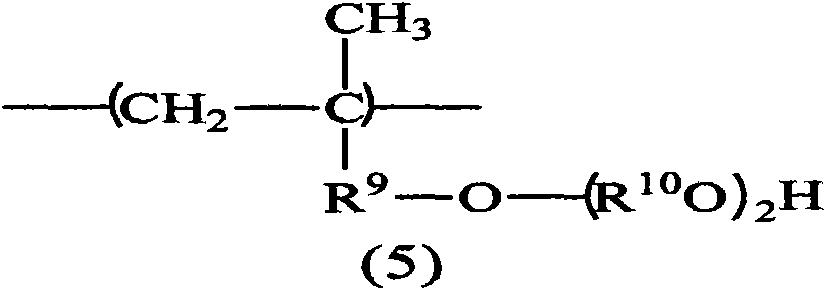

Preparation method for antisludging agent of central air-conditioning circulating water and application thereof

InactiveCN103420495AHigh scale inhibition rateImprove stabilityScale removal and water softeningWater qualityGlycol ethers

The invention provides a preparation method for an antisludging agent of central air-conditioning circulating water and application thereof. A copolymer (A), a copolymer (B) or a copolymer (C), which is used as a necessary component of the antisludging agent of the central air-conditioning circulating water, is a copolymer having certain weight-average molecular weight, and is gained by polymerizing certain mass of alkyl glycol ether, maleic anhydride and other monomers capable of being copolymerized. The antisludging property of the central air-conditioning circulating water can be provided by copolymer (A), copolymer (B) or copolymer (C) individually, and when the copolymer (A), copolymer (B) or copolymer (C) is in combined utilization, the antisludging property can be improved to a certain extent. The antisludging agent can enable the air-conditioning circulating water to be good in water quality stability property under the condition of air conditioning running temperature, and the acquired stable property cannot be lost along with time within a longer time.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY +2

Hydrogenation scale inhibitor and preparation method thereof

ActiveCN107177379AReduce Chloride ContentGood effectTreatment apparatus corrosion/fouling inhibitionOrganic solventClearing Agent

The invention discloses a hydrogenation scale inhibitor. The hydrogenation scale inhibitor is prepared from components in percentage by weight as follows: 10%-30% of a clearing agent, 5%-10% of an antioxidant, 0.5%-2% of a passivator, 0.5%-2% of an antirust agent, 1%-2% of a cosolvent and 50%-70% of an organic solvent, wherein the clearing agent is Mannich amine. The invention further provides a preparation method of the hydrogenation scale inhibitor. According to the preparation method, the raw materials are taken in a ratio of the components and are mixed and stirred uniformly at normal temperature and normal pressure. Mannich amine is adopted to replace other amines, so that the hydrogenation scale inhibitor is better in high-temperature stability, excellent in scale inhibition performance and low in cost and has a better cleaning function for high-temperature parts such as an air inlet valve, a nozzle and the like, and tail gas emission can be reduced.

Owner:金浦新材料股份有限公司

Water treatment pharmaceutical composition and application thereof

InactiveCN104556430AGood scale inhibitionGood corrosion inhibitionSpecific water treatment objectivesScale removal and water softeningAntibiotic YTetracycline antibiotics

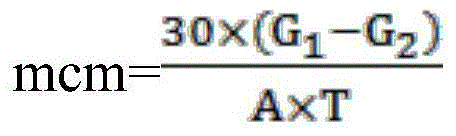

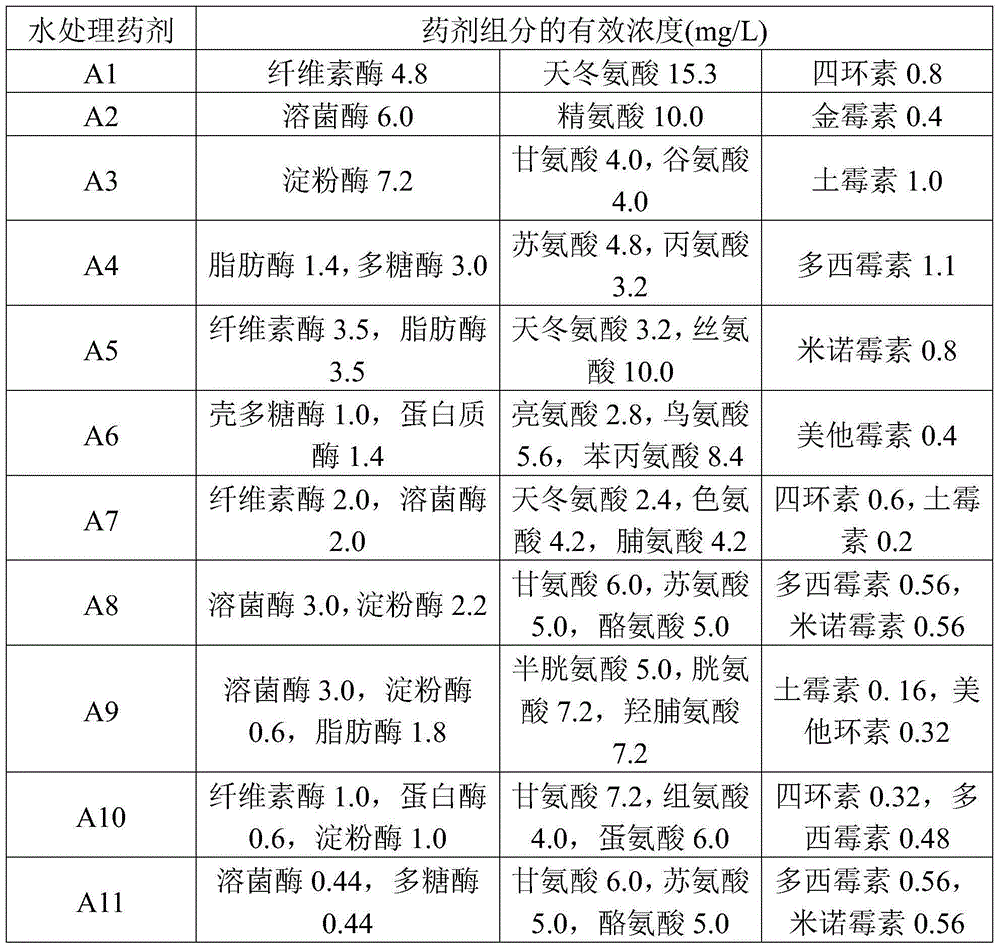

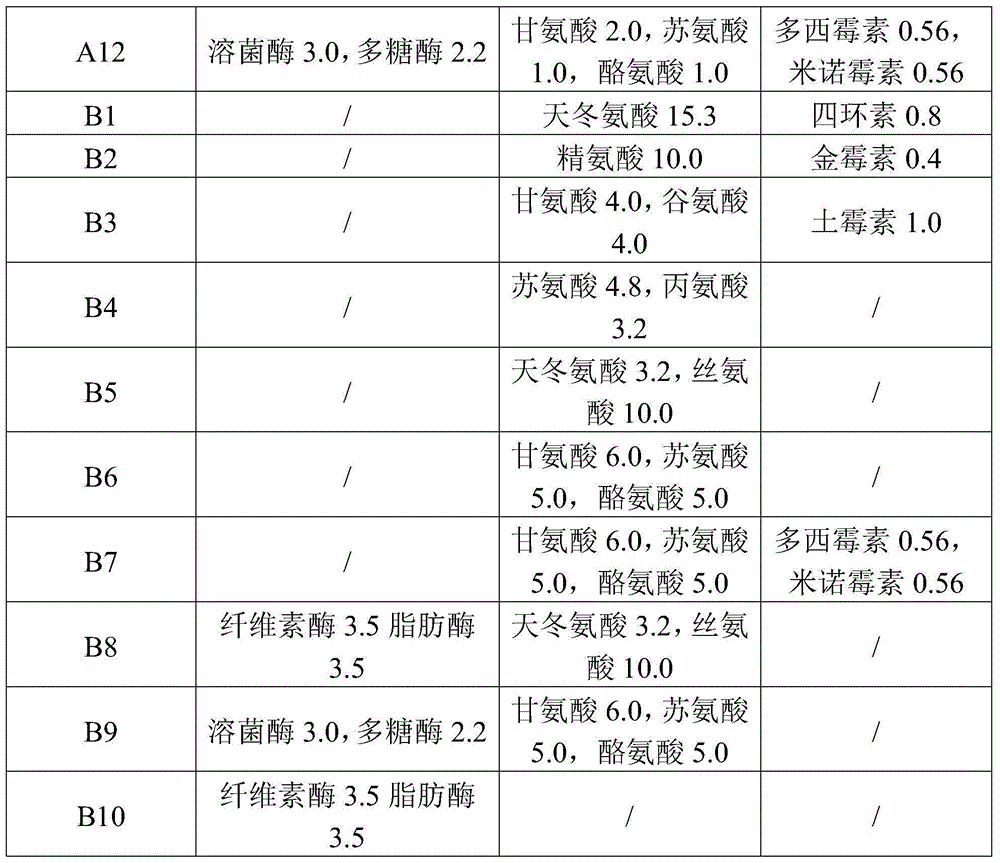

The invention discloses a water treatment pharmaceutical composition and an application thereof. The water treatment pharmaceutical composition contains amino acids having a scale and corrosion inhibition function, tetracycline antibiotics having sterilization functions, and an enzyme for playing a synergistic effect on the amino acids and antibiotics. The invention further discloses an application of the water treatment pharmaceutical composition in water treatment. A performance estimation result of the pharmaceutical composition indicates that the scale inhibition rate of calcium carbonate scale inhibition is larger than 99%, the corrosion rate of a dynamic simulation test is 0.024 mm / a, and the minimum number of heterotrophic bacteria within 72h can reach 1.4*10<2> pieces / ml. The water treatment pharmaceutical composition is low in dosage, free of phosphorus, strong in scale inhibition ability, good in corrosion inhibition, good in sterilization effect and long in duration.

Owner:CHINA PETROLEUM & CHEM CORP +1

Reverse-osmosis scale inhibitor

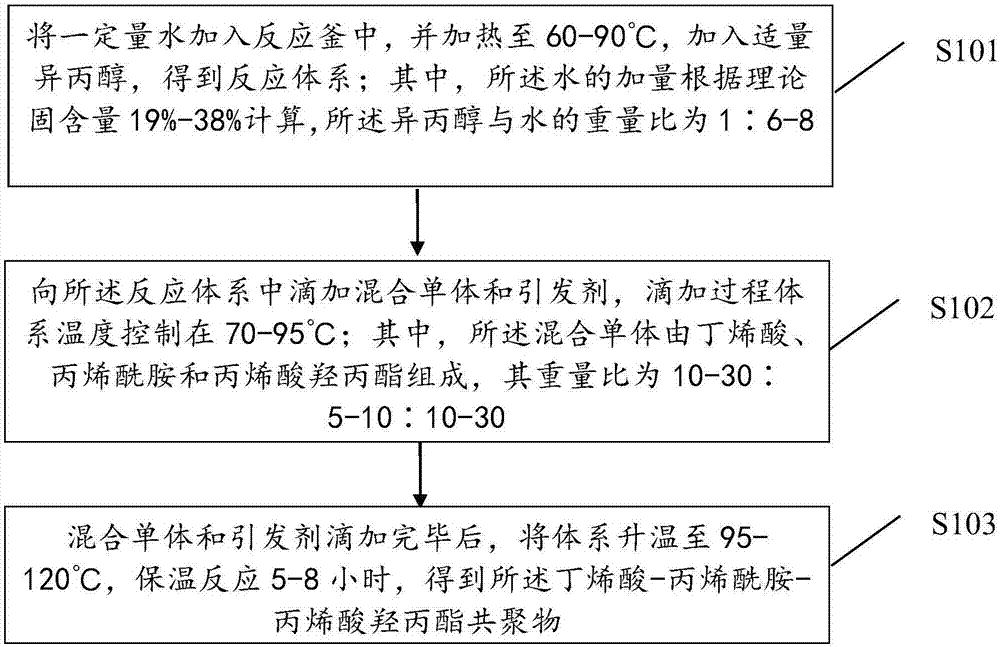

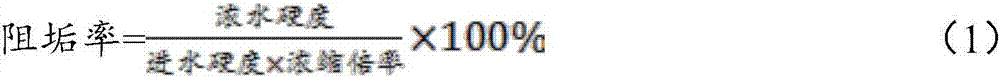

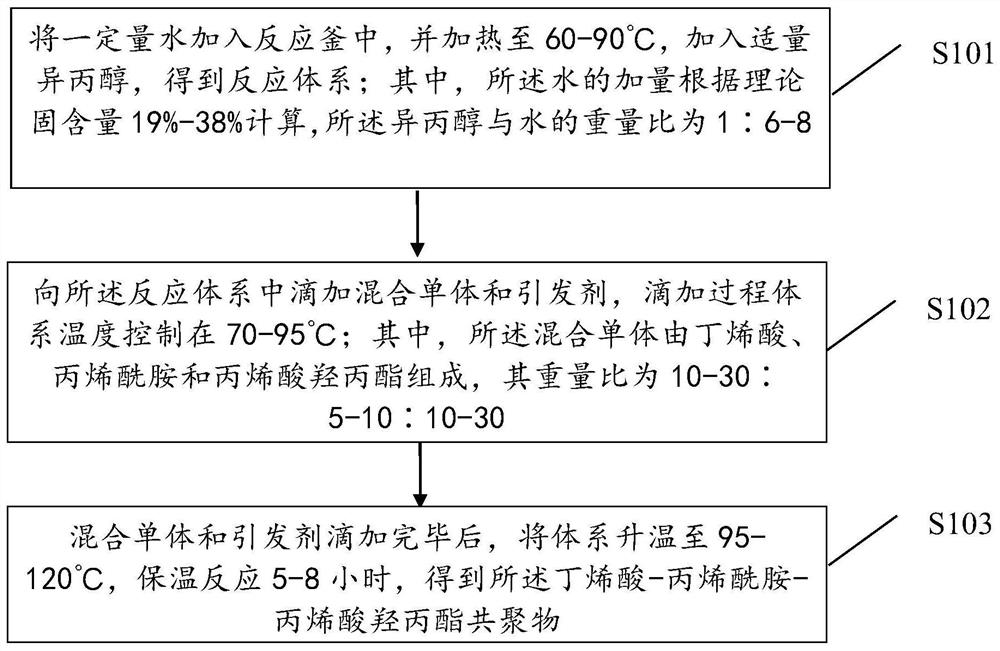

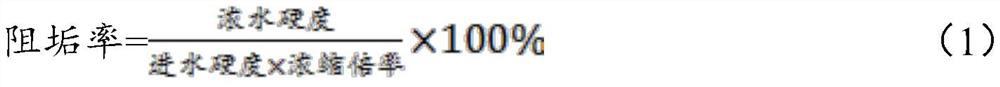

ActiveCN107261855ANot blocked by pollutionImprove utilizationReverse osmosisWater/sewage treatment bu osmosis/dialysisSulfateWater quality

The invention discloses a reverse-osmosis scale inhibitor and belongs to the technical field of water treatment. Based on 100 parts by weight of the reverse-osmosis scale inhibitor, the reverse-osmosis scale inhibitor comprises 30 to 50 parts by weight of polyamino polyether methylene phosphonate, 30 to 60 parts by weight of a butenoic acid-acrylamide-hydroxypropyl acrylate copolymer, 3 to 5 parts by weight of ethylenediaminetetra(methylenephosphonic acid) and 10 to 20 parts by weight of water. According to the reverse-osmosis scale inhibitor disclosed by the invention, all components in a formula have a synergistic effect and the technical problem of an existing reverse-osmosis scale inhibitor that the scale inhibition effect on water quality with high rigidity and high sulfate concentration is poor is solved; and the reverse-osmosis scale inhibitor is suitable for a reverse-osmosis desalting system for the water quality with the high rigidity and high sulfate concentration and is used for preventing a condition that salt in the water is enriched to form scale and a reverse-osmosis membrane is polluted and blocked.

Owner:SHOUGANG CORPORATION

Scale inhibitor for oilfield water injection

InactiveCN106396141AChemically stableExcellent corrosion and scale inhibitionTreatment using complexing/solubilising chemicalsEthylene diaminePolyaspartic acid

The invention belongs to the technical field of oilfield water treatment and relates to a scale inhibitor for oilfield water injection. The technical scheme includes that the scale inhibitor for oilfield water injection is characterized by being prepared from, by weight, 1-3 parts of amino trimethylene phosphonic acid, 1-2 parts of etidronic acid, 2-4 parts of ethylenediamine tetra(methylene phosphonic acid) sodium, 4-8 parts of ammonium molybdate, 6-10 parts of EDTA (ethylene diamine tetraacetic acid), 6-10 parts of polyaspartic acid, 1-3 parts of chitosan and 20-35 parts of water. The scale inhibitor for oilfield water injection is environment friendly.

Owner:WEIHAI YUNRUI INFORMATION TECH CO LTD

Coal gasification ash water scale inhibitor and preparation method thereof

ActiveCN108439618AHigh scale inhibition rateScale removal and water softeningPolymer modifiedMaleopimaric acid

The invention provides a preparation method of a coal gasification ash water scale inhibitor. The preparation method comprises the following steps: carrying out oxidization and sulfonation on a natural polymer to obtain a sulfonation modified product; carrying out amination on 10 weight percent to 20 weight percent of the sulfonation modified product to obtain an amination modified product; enabling 40 weight percent to 60 weight percent of the amination modified product to be subjected to copolymerization reaction with one or more of acrylic acid and maleic acid under the action of an initiator, so as to obtain a copolymerized product; mixing 20 weight percent to 50 weight percent of the sulfonation modified product, the amination modified product and the copolymerized product to obtain the coal gasification ash water scale inhibitor. According to the preparation method provided by the invention, the sulfonation modified product obtained by carrying out the oxidization and sulfonationon the natural polymer, the amination modified product obtained by carrying out the amination on the sulfonation modified product and the copolymerized product are mixed and have a cooperative effectto be commonly used as the coal gasification ash water scale inhibitor; a high molecular polymer modified through oxidization and degradation, sulfonation, selective amination, grafting and copolymerization and the like and the finally obtained coal gasification ash water scale inhibitor has a high scale inhibition rate.

Owner:兖矿水煤浆气化及煤化工国家工程研究中心有限公司 +2

Green and environment-friendly corrosion and scale inhibitor

InactiveCN112607874AGood anti-scaling effectIt has the effect of green environmental protectionScale removal and water softeningAlcoholEnvironmental engineering

The invention relates to the field of water treatment chemicals, and particularly discloses a green and environment-friendly corrosion and scale inhibitor. The environment-friendly corrosion and scale inhibitor is prepared from modified polyepoxysuccinic acid, an amino acid corrosion inhibitor, water and the like, and the preparation method of the modified polyepoxysuccinic acid comprises the following steps: adding chitosan with the deacetylation degree of 70-85% into a citric acid solution, and stirring until the chitosan is dissolved to obtain a chitosan citric acid solution; the preparation method comprises the following steps: adding absolute ethyl alcohol into a chitosan citric acid solution, uniformly stirring, heating and refluxing for 1-2h, cooling to 40-50 DEG C, adding polyepoxysuccinic acid, uniformly stirring, carrying out ultrasonic treatment for 2-4h, cooling to room temperature, and finally adjusting the pH value to 5.5-7.0, thereby obtaining the modified polyepoxysuccinic acid. The green and environment-friendly corrosion and scale inhibitor prepared by the invention still has good scale inhibition performance in a high-temperature state, does not bring in phosphorus, and has a green and environment-friendly effect.

Owner:广州市粤新工程技术有限公司

A reverse osmosis antiscalant

ActiveCN107261855BNot blocked by pollutionImprove utilizationReverse osmosisWater/sewage treatment bu osmosis/dialysisSulfate radicalsReverse osmosis

The invention discloses a reverse-osmosis scale inhibitor and belongs to the technical field of water treatment. Based on 100 parts by weight of the reverse-osmosis scale inhibitor, the reverse-osmosis scale inhibitor comprises 30 to 50 parts by weight of polyamino polyether methylene phosphonate, 30 to 60 parts by weight of a butenoic acid-acrylamide-hydroxypropyl acrylate copolymer, 3 to 5 parts by weight of ethylenediaminetetra(methylenephosphonic acid) and 10 to 20 parts by weight of water. According to the reverse-osmosis scale inhibitor disclosed by the invention, all components in a formula have a synergistic effect and the technical problem of an existing reverse-osmosis scale inhibitor that the scale inhibition effect on water quality with high rigidity and high sulfate concentration is poor is solved; and the reverse-osmosis scale inhibitor is suitable for a reverse-osmosis desalting system for the water quality with the high rigidity and high sulfate concentration and is used for preventing a condition that salt in the water is enriched to form scale and a reverse-osmosis membrane is polluted and blocked.

Owner:SHOUGANG CORPORATION

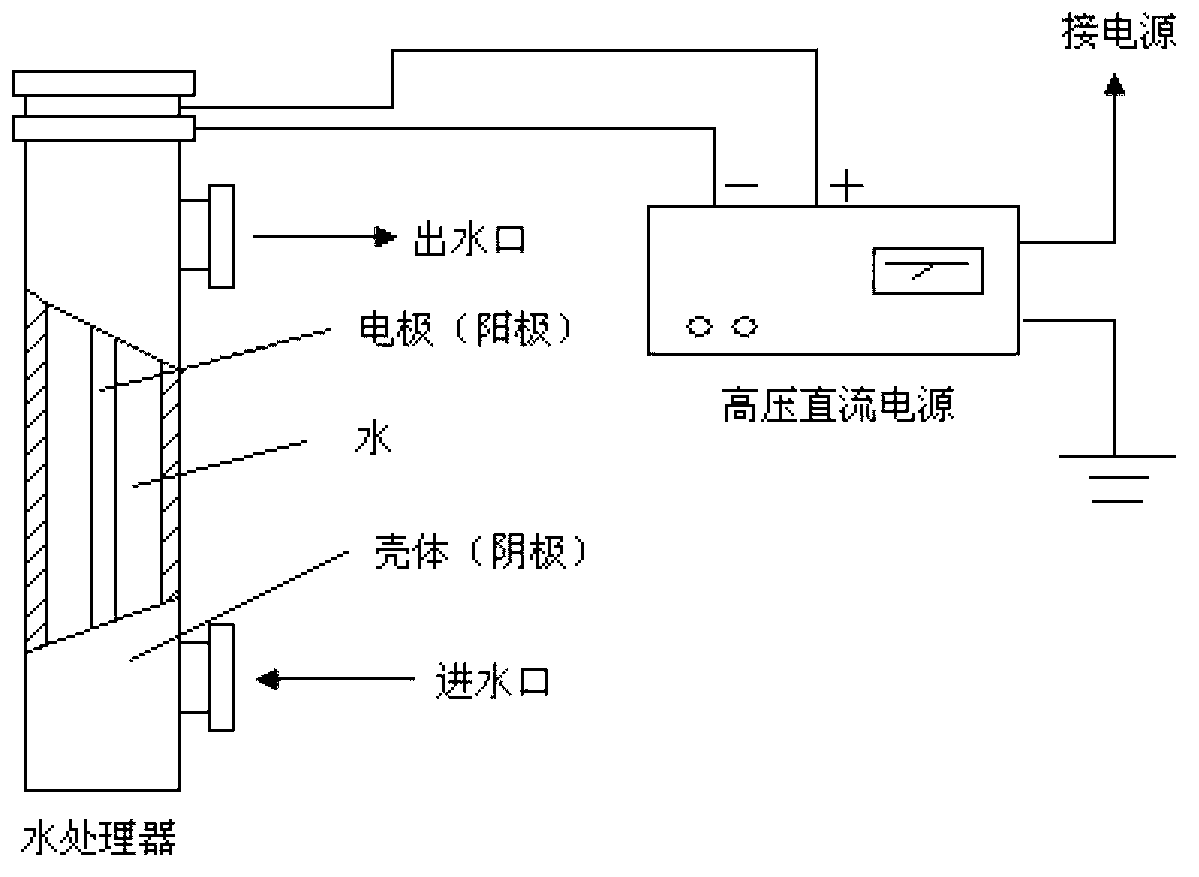

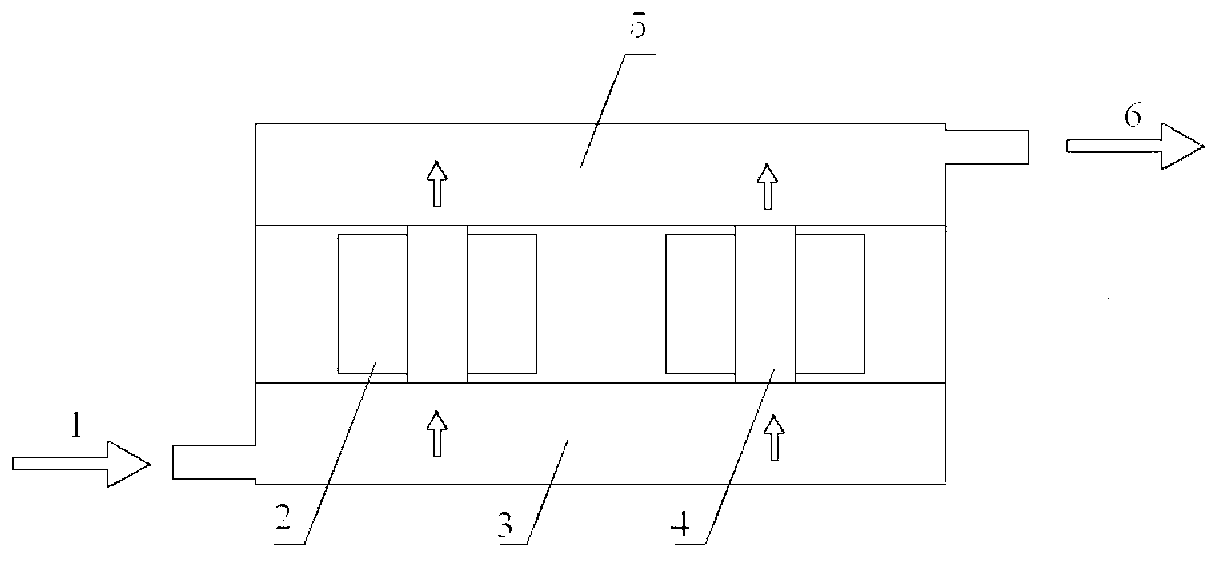

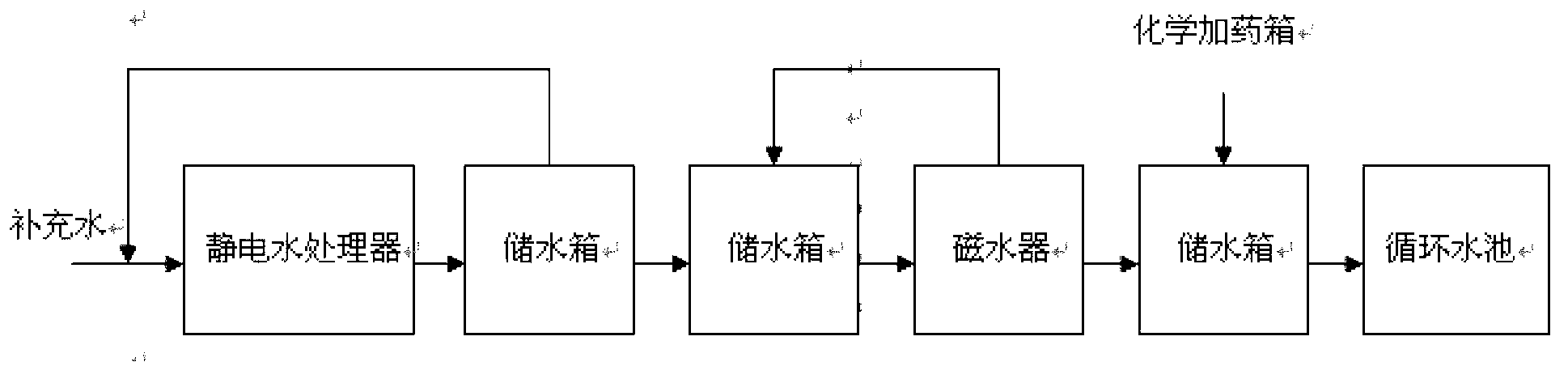

Static, magnetic filed and chemical dosing united water treatment novel method

InactiveCN103058445AReduce the amount addedHigh scale inhibition rateScale removal and water softeningMultistage water/sewage treatmentCalcium biphosphateWater flow

The invention discloses a static, magnetic filed and chemical dosing united water treatment novel method. The method comprises the following steps: firstly, treating raw water by virtue of a static water processor for a period of time to obtain static water; in the process, carrying out static water treatment by using different static water treatment time, different water flows by the static water processor and different static voltages; and then, treating the static water by utilizing a water magnetizer, magnetizing the water by using different magnetizing time, different magnetizing water flows and different intensities of the magnetic fields, and then, adding different ESA / AMPS copolymers for scale inhibition test research to calcium carbonate and calcium phosphate. The scale inhibition rate of the ESA / AMPS copolymer obtained is the scale inhibition rate coordinated by static, magnetic filed and ESA / AMPS copolymers.

Owner:ENERGY RESOURCES INST HEBEI ACADEMY OF SCI

Scale inhibitor applied in petroleum processing course and preparation method of scale inhibitor

InactiveCN104479657AHigh scale inhibition rateDrilling compositionTreatment apparatus corrosion/fouling inhibitionSodium phosphatesChloride sodium

The invention discloses a scale inhibitor applied in a petroleum processing course and a preparation method of the scale inhibitor. The scale inhibitor is prepared from the following raw materials in parts by weight: 35-60 parts of octyl acetate, 25-55 parts of butyl acetate, 12-45 parts of triethyl phosphate, 12-25 parts of tri-iso-octyl phosphate, 12-30 parts of dioctyl succinate, 8-25 parts of sodium chloride, 8-20 parts of ammonium nitrate, 8-20 parts of citric acid, 12-30 parts of sodium pyrophosphate and 30-65 parts of water. The scale inhibitor disclosed by the invention is applicable to the petroleum processing course, and the scale inhibitor is convenient to use, safe, durable, practical and long-acting.

Owner:SUZHOU YOUJUN ENVIRONMENTAL SCI & TECH

Environment-friendly corrosion and scale inhibitor for boiler and preparation method of environment-friendly corrosion and scale inhibitor

InactiveCN106554096AExtended service lifeEasy to useSpecific water treatment objectivesScale removal and water softeningHeat exchangerAmmonium chloride mixture

The invention discloses an environment-friendly corrosion and scale inhibitor for a boiler. The environment-friendly corrosion and scale inhibitor is prepared from deionized water, sodium sulfonate, potassium sulfonate, benzotriazole, 2-acrylamide-2-methyl propane sulfonic acid, dodecyl dimethyl benzyl ammonium chloride, methyl alcohol, alkylphenol polyoxyethylene, hexamine, sodium tungstate and lignin sulfonate. The environment-friendly corrosion and scale inhibitor is applicable to dealing with scaling and corrosion problems of heat equipment such as the boiler; the phosphorus value in discharged water is 0.1 to 0.3 mg / L, appear of calcium phosphate scale precipitates can be prevented, the risk of eutrophication of water is reduced, the quality is reliable, and the tolerance is high; the inhibitor is high in applicability and can be prevented from being deposited on a high-temperature heat exchanger, and the service life of the boiler can be greatly prolonged; with the advantages of low dosage, efficiency and energy conservation, the inhibitor can be used in water with high alkalinity, high hardness, high pH value and high concentration multiple; all the components generate the synergistic effect; and the corrosion rate to carbon steel is 0.001 to 0.003 mm a<-1>, and the scale inhibition rate is 98.5 percent to 99.5 percent.

Owner:WUXI LONGYING ENVIRONMENTAL PROTECTION TECHCO

Scale and corrosion inhibitor for oilfield reinjection water and preparation method thereof

InactiveCN104528961AExcellent anti-corrosion and corrosion inhibitionEasy to prepareWaste water treatment from quariesSpecific water treatment objectivesPolyacrylamideEnvironmental geology

The invention relates to a scale and corrosion inhibitor for oilfield reinjection water and a preparation method thereof, and belongs to the technical field of petroleum additives. The scale and corrosion inhibitor is prepared from the following components in parts by weight: 4-15 parts of laurylamine polyoxyethylene ether, 1-2 parts of polyepoxysuccinic acid, 6-11 parts of 2-acrylamide-2-methylpropyl sulfonic acid, 10-18 parts of molybdate, 4-9 parts of imidazoline, 1-6 parts of polyacrylamide, 4-8 parts of sodium sulfate, 3-6 parts of sodium citrate, 2-6 parts of sodium gluconate, 10-20 parts of ethyl acetate, 10-16 parts of ethanol and 26-30 parts of water. The scale and corrosion inhibitor can be effectively chelated with salt in produced water, has a scale inhibition rate of 99.9 percent, has an excellent antiseptic corrosion inhibition effect, cannot cause secondary injury on pipelines after being used, and has a corrosion inhibition rate of 96 percent.

Owner:JIANGSU JIANSHEN BIOLOGY AGROCHEM

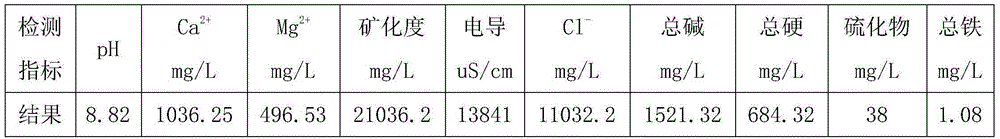

Special antisludging agent for saline-alkali soil bitter desalting plant and preparation method therefor

ActiveCN105016491AHigh scale inhibition rateReduce corrosion rateTreatment using complexing/solubilising chemicalsSulfonateChlorogenic acid

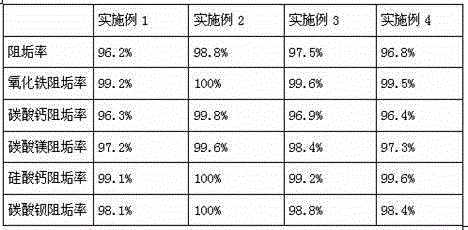

The invention provides a special antisludging agent for saline-alkali soil bitter desalting plant and a preparation method therefor. The antisludging agent comprises the following components in parts by weight: 30-34 parts of chlorogenic acid, 8-9 parts of sodium lignin sulfonate, 8-10 parts of citric acid, 7-9 parts of malic acid, 2-4 parts of gallotannic acid, 3-4 parts of polyepoxysuccinic acid, 1-2 parts of dimethyl sulfoxide, 2-4 parts of tetradecyl dimethyl benzyl ammonium, 0.5-1.5 parts of allyl polyether and 48-50 parts of deionized water. The preparation method of the antisludging agent comprises the step of chlorogenic acid dissolution: adding chlorogenic acid into deionized water, stirring for dissolution, enabling the rotation speed to be 80 rpm, and stirring for 12-15 minutes. The preparation method of the antisludging agent also comprises the steps of melting sodium lignin sulfonate and allyl polyether: enabling the melting temperature of sodium lignin sulfonate and allyl polyether to be 70-80 DEG C. The scale inhibiting ratio is 96.2% to 98.8% by adopting the antisludging agent.

Owner:WEIFANG YOURONG IND

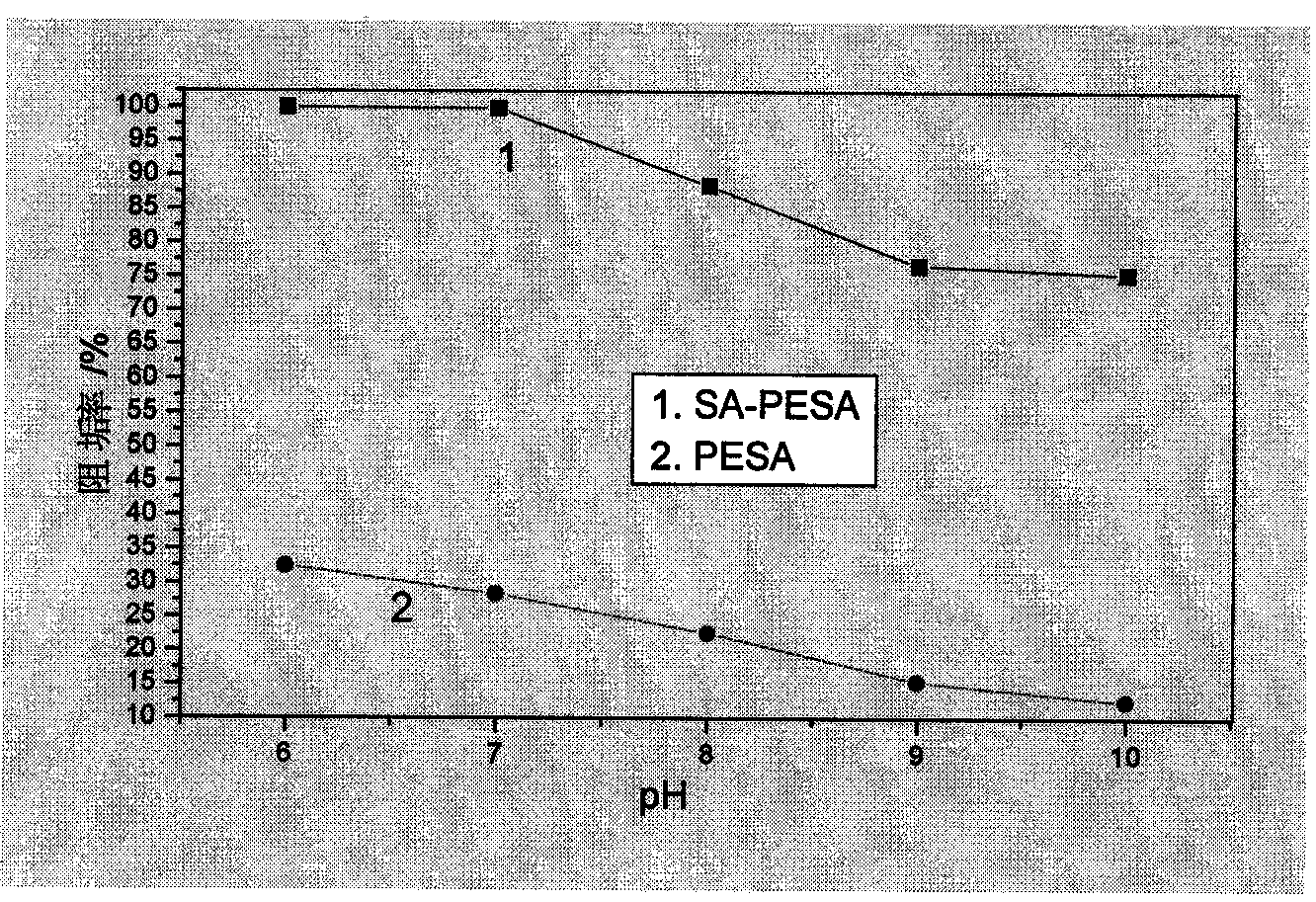

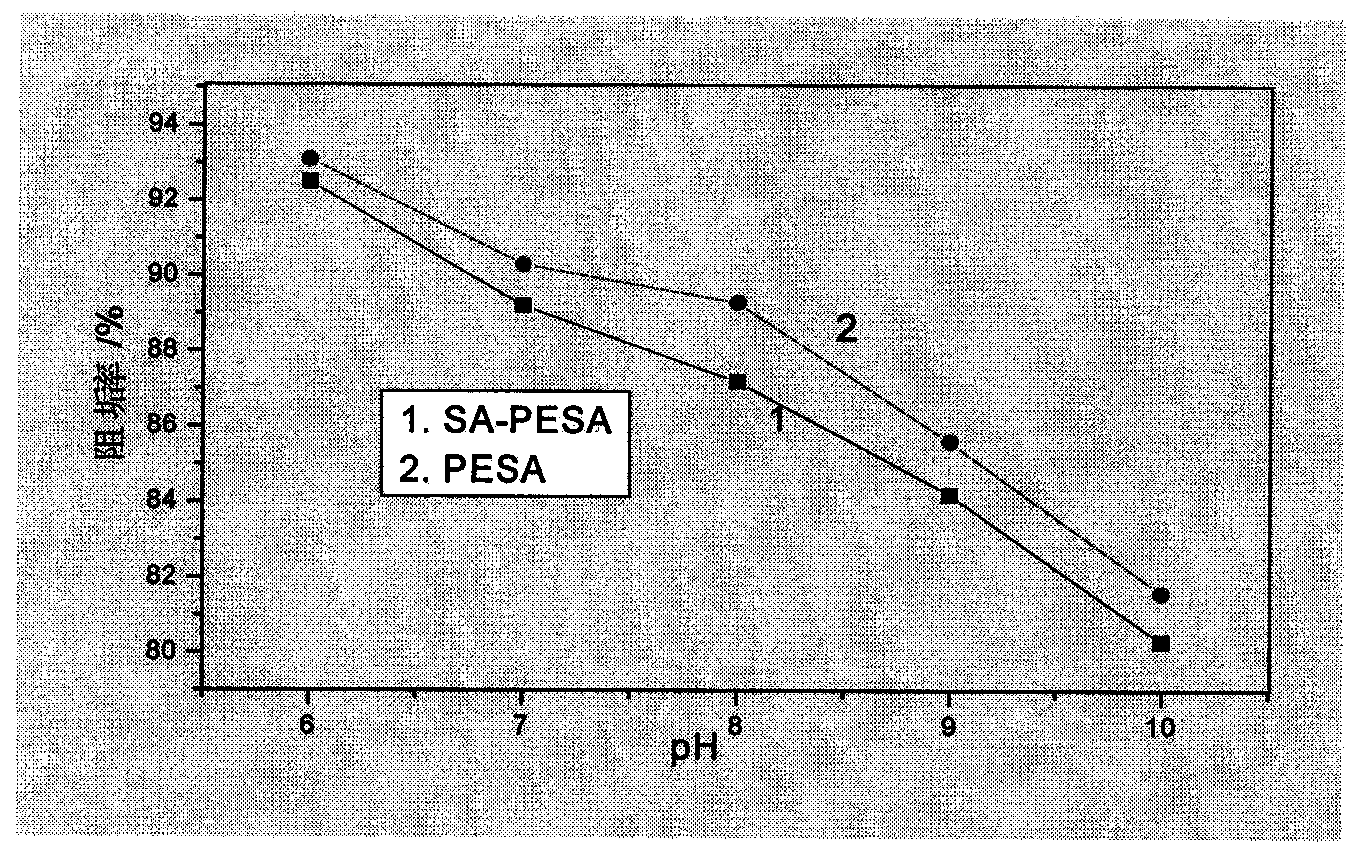

Preparation method and application method of multifunctional polyepoxysuccinic acid derivative scale inhibitor

InactiveCN104072749AGood anti-scaling effectGood dispersionScale removal and water softeningSolubilityCalcium biphosphate

The invention relates to the preparation and application field of a multifunctional polyepoxysuccinic acid derivative scale inhibitor and in particular relates to a preparation method and application method of the multifunctional polyepoxysuccinic acid derivative scale inhibitor which has good biodegradability and water solubility and can be applied to a water treatment agent. The preparation method comprises the following steps: carrying out cyclization reaction and purifying a cyclization product, preparing a polyepoxysuccinic acid product, and preparing the multifunctional polyepoxysuccinic acid derivative. The multifunctional polyepoxysuccinic acid derivative scale inhibitor is applied when the pH value is 6.0-10.0, blocking calcium carbonate scale inhibition rate is in a range of 85%-90% and blocking calcium phosphate scale inhibition rate is in a range of 40%-80%. By utilizing the multifunctional polyepoxysuccinic acid derivative scale inhibitor, the multifunctional scale inhibition capacity of original polyepoxysuccinic acid is improved and purpose of improving the scale inhibition efficiency is finally achieved. Only a small molecule material is added into synthesis to achieve the purpose of increasing the multifunctional scale inhibition capacity of the polyepoxysuccinic acid without changing other process conditions.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

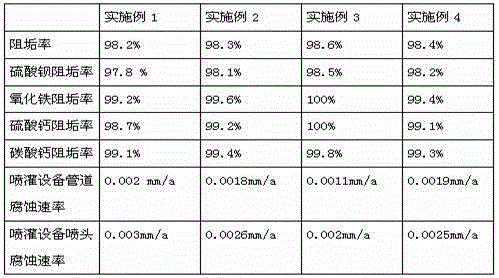

Anticorrosive antiscale agent for saline-alkali soil sprinkler irrigation equipment and preparation method therefor

ActiveCN105000686AHigh scale inhibition rateReduce corrosion rateScale removal and water softeningAlkali soilPyrrolidinones

The invention provides an anticorrosive antiscale agent for saline-alkali soil sprinkler irrigation equipment and a preparation method therefor. The anticorrosive antiscale agent comprises the following components in parts by weight: 24-26 parts of citric acid; 21-24 parts of tannin; 4-6 parts of glycine di(methylene phosphonic acids); 9-11 parts of polyepoxysuccinic acid; 6-8 parts of oxaloacetic acid; 1.5-2.5 parts of polyoxyethylene alkyl alcohol ether; 1-2 parts of N-vinyl pyrrolidone; 6-9 parts of sodium lignin sulfonate; 3-4 parts of potassium sorbate; and 40-50 parts of water. The preparation method of the anticorrosive antiscale agent comprises a step of preparing a citric acid aqueous solution: adding citric acid to weighted water, and stirring for 12 to 15 minutes at a rotational speed of 100 rpm under a condition of 20 to 70 DEG C. The anticorrosive antiscale agent of the invention has a scale inhibition rate of 98.2 to 98.6%.

Owner:WEIFANG YOURONG IND

Preparation method of slow-release scale inhibitor

InactiveCN110937697AOvercoming the problem of continuous dosingReduce replacement rateTreatment using complexing/solubilising chemicalsBiochemical engineeringProcess engineering

The invention provides a preparation method of a slow-release scale inhibitor. The invention overcomes problems in continuous dosing of a liquid scale inhibitor and also overcomes the defects of poormechanical strength, non-uniform surface area, difficulty in control of release speed and the like of irregular solid scale inhibitors in the prior art. When the slow-release scale inhibitor is applied to scale inhibition of domestic purified water, the scale inhibitor is non-toxic and harmless, has a high scale inhibition rate, and can reduce the replacement rate of a filter element and prolong the service life of the filter element.

Owner:OCHEMATE MATERIAL TECH CO LTD

Corrosion and scale inhibitor for reinjection water of oil field and preparation method of corrosion and scale inhibitor

ActiveCN105254040AGuarantee normal operationReduce dosageTreatment using complexing/solubilising chemicalsIndustrial water treatmentGlycerol

The invention provides a corrosion and scale inhibitor, which belongs to the technical field of industrial water treatment. The corrosion and scale inhibitor is prepared from the following raw materials in parts by weight: 30 to 50 parts of calendic acid, 18 to 35 parts of glycerol, 12 to 25 parts of epoxysuccinic acid, 10 to 20 parts of acrylic acid, 5 to 15 parts of initiator, 30 to 50 parts of phosphono carboxylic acid copolymer and 5 to 10 parts of dodecyl dimethyl benzyl ammonium chloride. According to the corrosion and scale inhibitor, a corrosion and scale inhibiting effect for a reinjection water system under environments of high temperature, high mineralization degree and high corrosion can be effectively realized, and normal operation of water injection equipment and pipelines is guaranteed.

Owner:XINJIANG DELAND

Preparation method of polyaspartic acid scale inhibitor

InactiveCN103524736AHigh scale inhibition rateScale removal and water softeningSal ammoniacMaleic anhydride

The invention relates to a preparation method of a descaling matter. A preparation method of a polyaspartic acid scale inhibitor comprises the following steps: mixing maleic anhydride and distilled water in a molar ratio of 1:1.5-2.5, performing water bath of 55 DEG C and stirring, dissolving completely, and cooling to room temperature; slowly dropping aqua ammonia into the solution, keeping the temperature no greater than 25 DEG C; after finishing dropping of the aqua ammonia, heating up to 80 DEG C, reacting at a constant temperature for 6h, cooling to the room temperature to obtain a colorless transparent glass-like liquid; drying the liquid at 100-110 DEG C to obtain white solid powder; heating the white solid powder by oil bath of 220-260 DEG C for 3-7 h, cooling to obtain a red brown brittle solid, adding the red brown brittle solid into a sodium hydroxide solution with the mass fraction of 10%, adjusting the pH to 9 to obtain a polyaspartic acid scale inhibitor solution. The polyaspartic acid scale inhibitor has a high scale inhibiting ratio, and is suitable for low-mineralization-degree industrial circulating cooling water and oilfield reinjection water.

Owner:SHAANXI SHENGMAI PETROLEUM

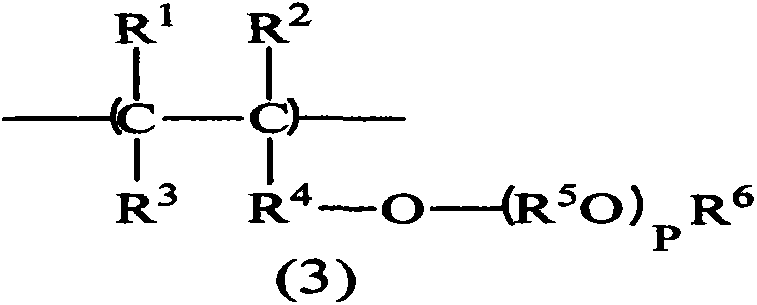

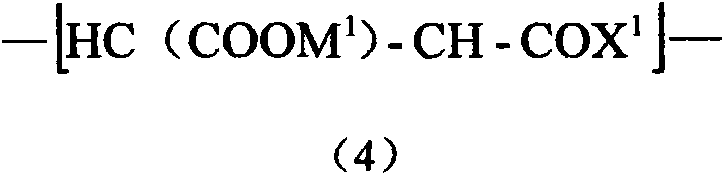

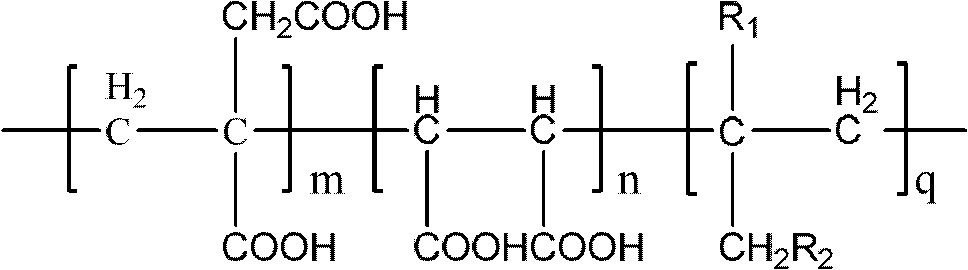

Itaconic acid copolymer antisludging agent and microwave synthetic method thereof

InactiveCN101830571BHigh scale inhibition rateImprove toleranceScale removal and water softeningMicrowaveItaconic acid

The invention discloses a novel itaconic acid copolymer antisludging agent and a microwave synthetic method thereof. The antisludging agent comprises a chain link structure shown in the formula [I]. The synthetic method comprises the following steps of: using the itaconic acid as a main raw material; and carrying out copolymerization on the itaconic acid, maleic anhydride, sulfonate and the like in the presence of an initiator to prepare a terpolymer. The molecular weight of the itaconic acid copolymer prepared by the invention is 2,000-3,000, and the color of the copolymer is light yellow orbrown yellow. The novel itaconic acid copolymer antisludging agent belongs to an environment-friendly chemical-industrial product, and can be used as an antisludging agent, an anti-corrosion agent, adispersing agent and the like. The invention has the advantages of simple process, high synthesis speed, low energy consumption and less pollution.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com