A reverse osmosis antiscalant

A reverse osmosis and antiscalant technology, applied in the field of water treatment, can solve the problems of poor antiscaling effect and achieve high antiscaling rate, strong antiscaling and dispersion effect, and high tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

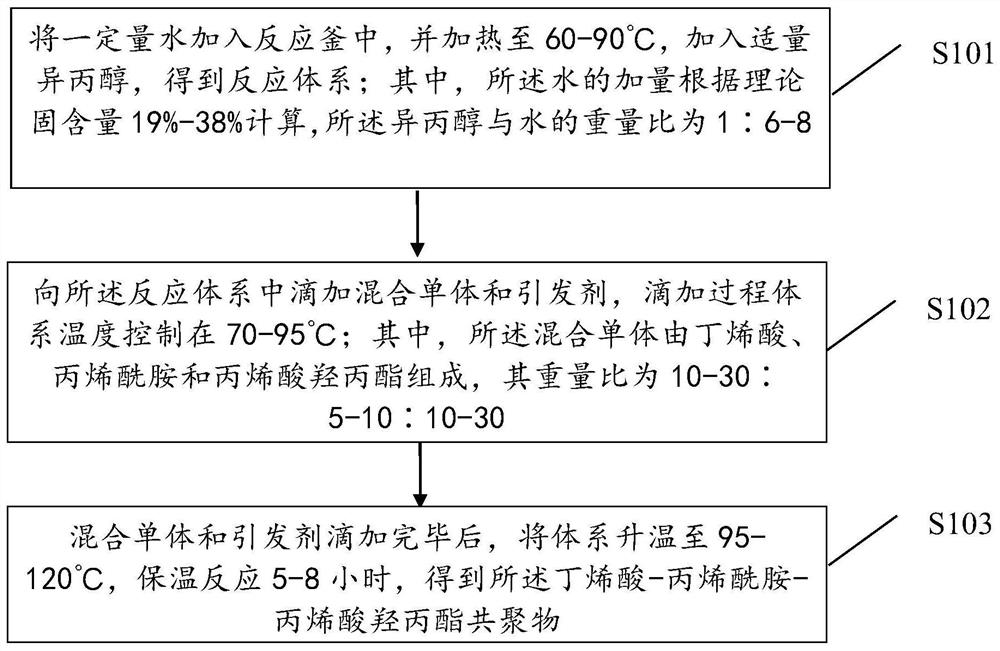

[0029] see figure 1 , in an embodiment of the present invention, the preparation method of the crotonic acid-acrylamide-hydroxypropyl acrylate copolymer comprises the following steps:

[0030] S101: add a certain amount of water into the reaction kettle, heat it to 60-90° C., add an appropriate amount of isopropanol to obtain a reaction system; The weight ratio of isopropanol and water is 1:6-8;

[0031] Wherein, water is the solvent of the polymerization reaction, and isopropanol is used to adjust the molecular weight of the polymer.

[0032] S102: drop the mixed monomer and the initiator into the reaction system, and control the temperature of the dropwise process system at 70-95 °C; wherein, the mixed monomer is composed of crotonic acid, acrylamide and hydroxypropyl acrylate, Its weight ratio is 10-30:5-10:10-30;

[0033] S103: After the dropwise addition of the mixed monomer and the initiator, the temperature of the system is raised to 95-120° C., and the reaction is m...

Embodiment 1

[0040] S1: Preparation of crotonic acid-acrylamide-hydroxypropyl acrylate copolymer:

[0041] 105g of water was added to the reactor, heated to 60°C, and 17.5g of isopropanol was added to obtain a reaction system;

[0042] The mixed monomer and ammonium persulfate aqueous solution were added dropwise to the reaction system, and the temperature of the system during the dropwise addition was controlled at 70°C; wherein, the mixed monomer was composed of 10 g of crotonic acid, 5 g of acrylamide and 10 g of hydroxypropyl acrylate , the dosage of ammonium persulfate is 0.125g;

[0043] After the dropwise addition of the mixed monomer and the initiator, the temperature of the system was raised to 95° C., and the reaction was maintained for 8 hours to obtain the crotonic acid-acrylamide-hydroxypropyl acrylate copolymer.

[0044] S2: Weigh 35g polyaminopolyether-based methylenephosphonic acid (PAPEMP), 40g crotonic acid-acrylamide-hydroxypropyl acrylate copolymer, 5g ethylenediaminet...

Embodiment 2

[0049] S1: Preparation of crotonic acid-acrylamide-hydroxypropyl acrylate copolymer:

[0050] 150g of water was added to the reactor, heated to 70°C, and 25g of isopropanol was added to obtain a reaction system;

[0051] The mixed monomer and ammonium persulfate aqueous solution were added dropwise to the reaction system, and the temperature of the system during the dropwise addition was controlled at 80°C; wherein, the mixed monomer was composed of 30 g of crotonic acid, 5 g of acrylamide and 15 g of hydroxypropyl acrylate , the dosage of ammonium persulfate is 0.5g;

[0052] After the dropwise addition of the mixed monomer and the initiator, the temperature of the system was raised to 100° C., and the reaction was maintained for 6 hours to obtain the crotonic acid-acrylamide-hydroxypropyl acrylate copolymer.

[0053] S2: Weigh 45g of polyaminopolyether methylenephosphonic acid (PAPEMP), 35g of crotonic acid-acrylamide-hydroxypropyl acrylate copolymer, 5g of ethylenediaminet...

PUM

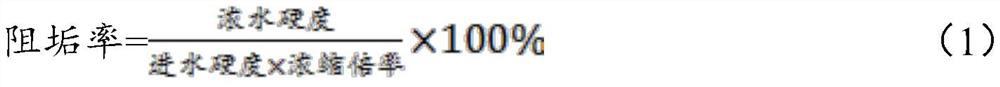

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com