Preparation method for antisludging agent of central air-conditioning circulating water and application thereof

A technology for central air conditioning and circulating water, applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

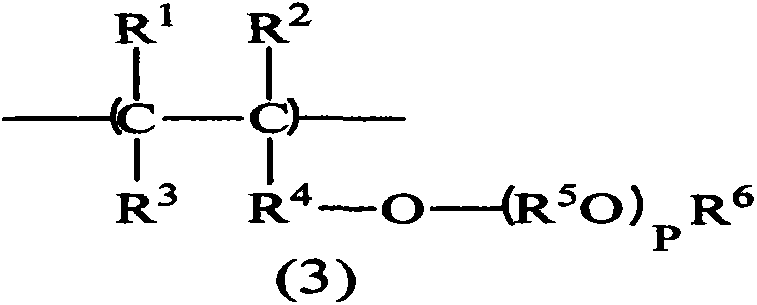

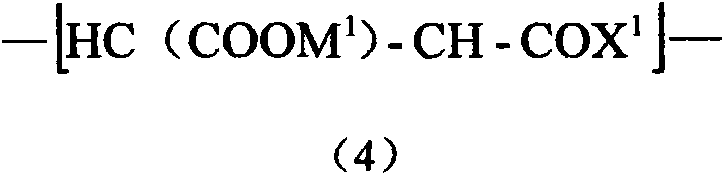

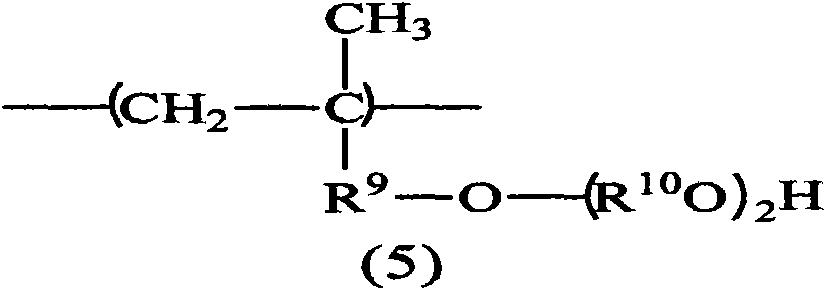

Method used

Image

Examples

Embodiment 1

[0048] Example 1: Production of antiscalant X for central air-conditioning circulating water

[0049]In a 1 ton enamel reactor, add 50kg distilled water, 350kg by the unsaturated alcohol that 35 mole oxirane and 3-methyl-3-buten-1-alcohol addition reaction make, 200kg maleic anhydride, The temperature of the reactor was raised to 60 °C. Within 240min, 25kg of distilled aqueous solution dissolved with 1.0kg of sodium persulfate was dropped into the reaction kettle. Maintain the temperature in the reactor at 60° C. for 60 minutes to complete the polymerization reaction, and obtain a polymer that is an aqueous solution of a scale inhibitor for central air-conditioning circulating water. The polymer has a weight-average molecular weight of 35,000.

Embodiment 2

[0050] Example 2: Production of scale inhibitor Y for central air-conditioning circulating water

[0051] Add 130kg ion-exchanged water, 400kg in a one ton reactor, the unsaturated alcohol that 35 mole oxirane and 3-methyl-3-butene-1-alcohol addition reaction make, 220kg maleic anhydride, The temperature of the reactor was raised to 65°C. Within 200 minutes, 50 kg of ion-exchanged aqueous solution in which 1.0 kg of sodium persulfate was dissolved was dropped into the reaction kettle. The temperature in the reactor was maintained at 65° C. for 60 minutes to complete the polymerization reaction, and a polymer was obtained, which was an aqueous solution of a scale inhibitor for central air-conditioning circulating water. The weight-average molecular weight of the polymer was 25,000.

Embodiment 3

[0052] Embodiment 3: experimental medium: 80 ℃ tap water and preparation water: adjust the pH value of aqueous solution with NaOH and HCl; Use analytical pure CaCl 2 Regulates Ca in solution 2+ content. The chemical composition of tap water is: pH7.6, Ca 2+ 67mg / L, Mg 2+ 28mg / L, Cl-15mg / L, SiO 2 18mg / L.

[0053] Comparison of Antiscalant Effects

[0054] Static antiscaling method was used to study the antiscaling effects of X and Y two high temperature antiscalants at a concentration of 5 mg / L in tap water and prepared water at 70°C. The results are shown in Table 1.

[0055] Table 1 Scale inhibition rate / % of scale inhibitors in water at 100°C

[0056]

[0057] It can be seen from Table 1 that the scale inhibition rate of X is better than that of Y in tap water and prepared water. This is because the high-temperature stability of the Y complex is not as high as that of X, and the hydrolysis occurs, which reduces its scale inhibition ability.

[0058] And X not on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com