Anticorrosive antiscale agent for saline-alkali soil sprinkler irrigation equipment and preparation method therefor

A scale inhibitor and technology for saline-alkali soil, applied in the field of special anti-corrosion and scale inhibitor for sprinkler irrigation equipment in saline-alkali soil and its preparation field, can solve the problems of short life, low scale inhibition rate, easy corrosion of sprinkler irrigation equipment, etc., to prolong the service life and reduce corrosion. The effect of speed and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

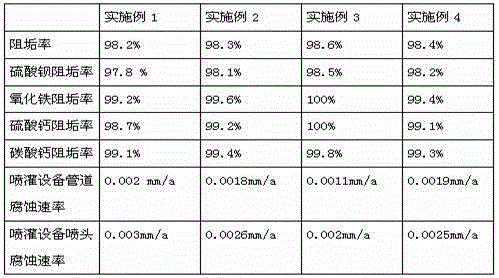

Embodiment 1

[0024] Example 1 A special anti-corrosion and scale inhibitor for sprinkler irrigation equipment in saline-alkali land

[0025] The weight ratio of each component of the anticorrosion and scale inhibitor is:

[0026] 24 parts of citric acid, 21 parts of tannic acid, 4 parts of glycine dimethyl phosphonic acid, 9 parts of polyepoxysuccinic acid, 6 parts of oxaloacetic acid, 1.5 parts of polyoxyethylene alkyl alcohol ether, 1 part of N-vinylpyrrolidone , 6 parts of sodium lignosulfonate, 3 parts of potassium sorbate, 40 parts of water.

[0027] Described citric acid purity: 99%;

[0028] Described tannic acid purity: 85%;

[0029] Described water is distilled water.

Embodiment 2

[0030] Example 2 A special anti-corrosion and scale inhibitor for sprinkler irrigation equipment in saline-alkali land

[0031] The weight ratio of each component of the anticorrosion and scale inhibitor is:

[0032] 25 parts of citric acid, 22 parts of tannic acid, 5 parts of glycine dimethylene phosphonic acid, 10 parts of polyepoxysuccinic acid, 7 parts of oxaloacetic acid, 2 parts of polyoxyethylene alkyl alcohol ether, 1 part of N-vinylpyrrolidone , 7 parts of sodium lignosulfonate, 3 parts of potassium sorbate, 45 parts of water.

[0033] Described citric acid purity: 99%;

[0034] Described tannic acid purity: 85%;

[0035] Described water is distilled water.

Embodiment 3

[0036] Example 3 A special anti-corrosion and scale inhibitor for sprinkler irrigation equipment in saline-alkali land

[0037] The weight ratio of each component of the anticorrosion and scale inhibitor is:

[0038] 25 parts of citric acid, 23 parts of tannic acid, 5 parts of glycine dimethylene phosphonic acid, 9 parts of polyepoxysuccinic acid, 8 parts of oxaloacetic acid, 2.2 parts of polyoxyethylene alkyl alcohol ether, 1 part of N-vinylpyrrolidone , 9 parts of sodium lignosulfonate, 4 parts of potassium sorbate, and 48 parts of water.

[0039] Described citric acid purity: 99%;

[0040] Described tannic acid purity: 85%;

[0041] Described water is distilled water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com