Preparation method and application method of multifunctional polyepoxysuccinic acid derivative scale inhibitor

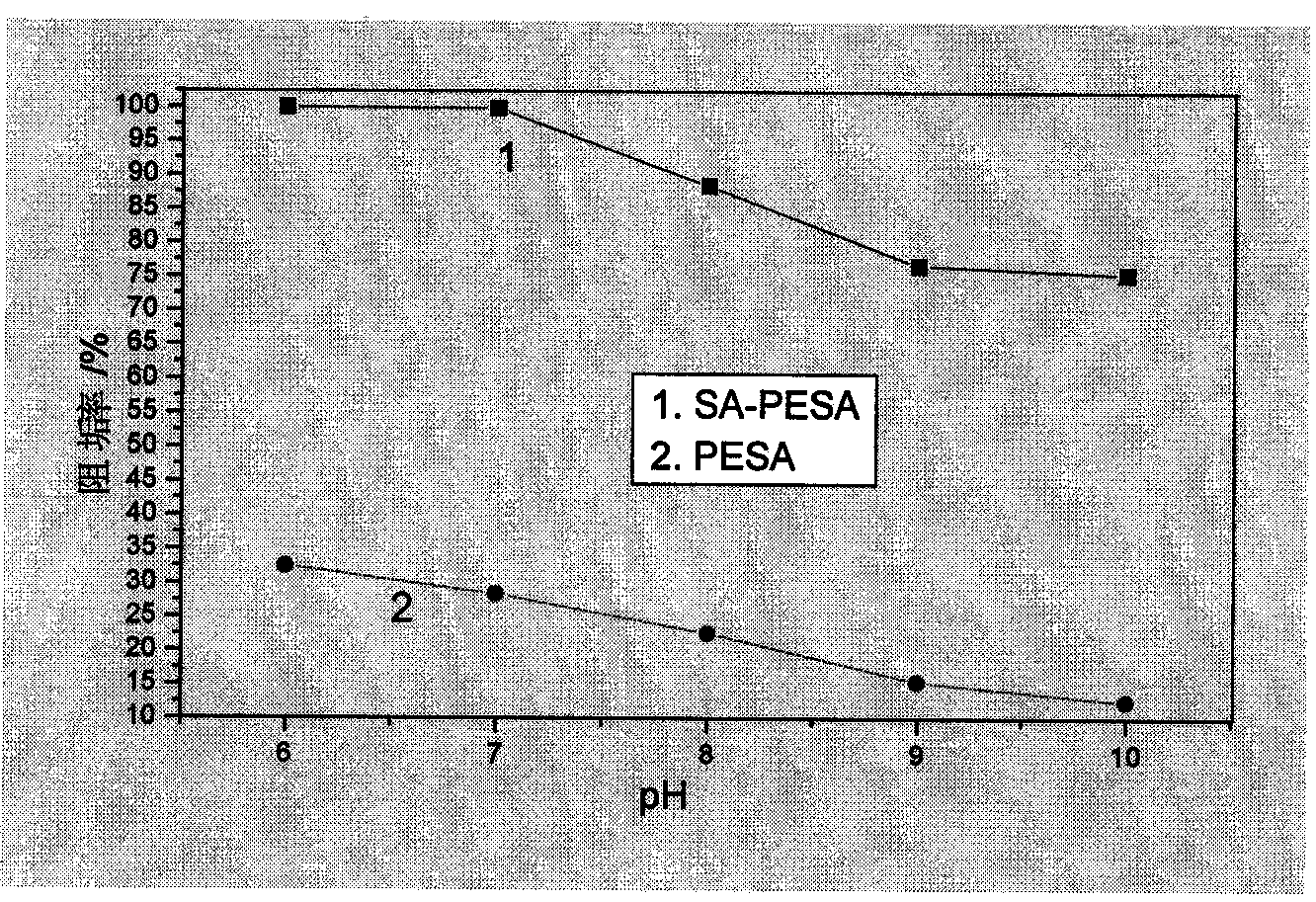

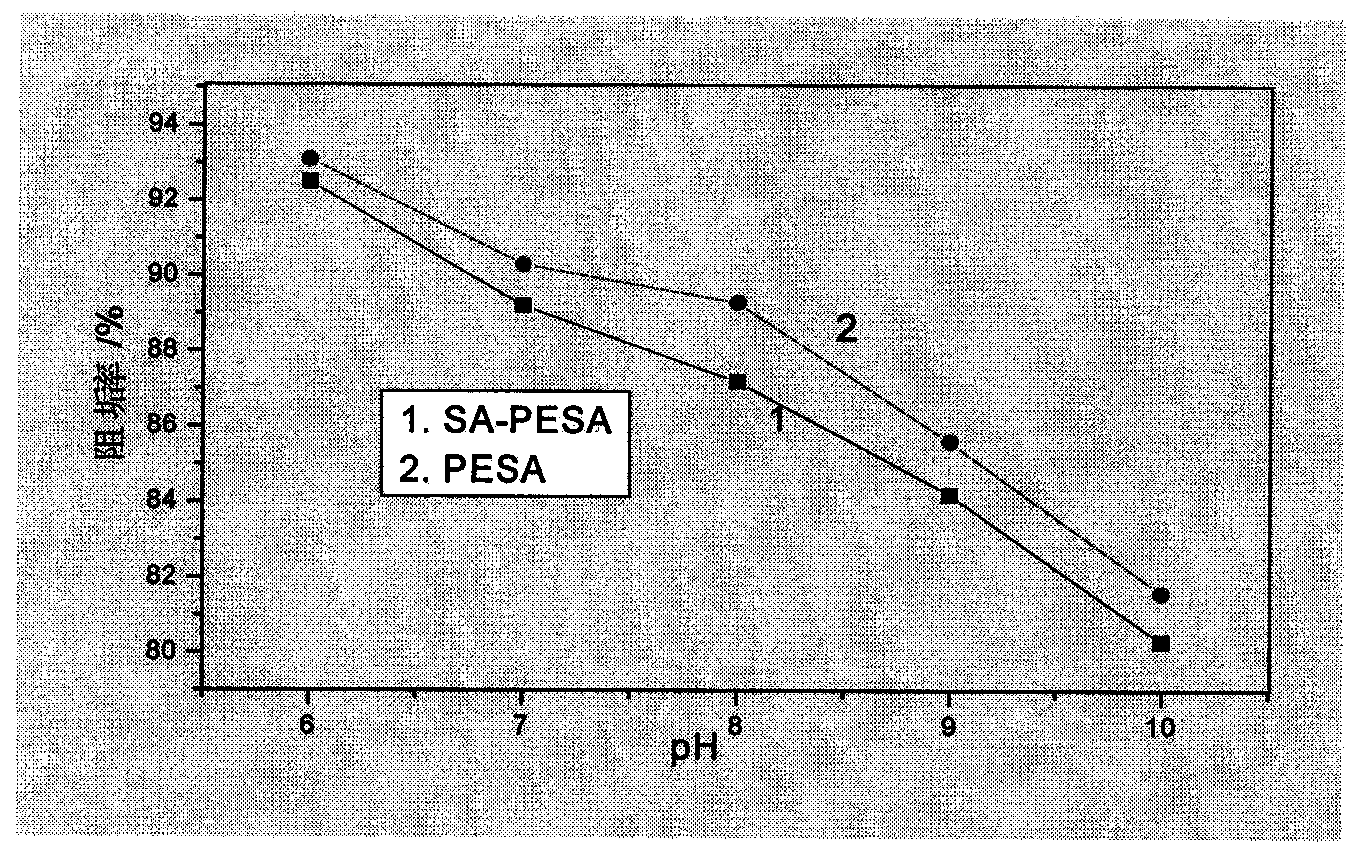

A technology of polyepoxysuccinic acid and sodium epoxysuccinate, applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc. The problem of high cost of use of scale agents can improve the scale inhibition rate, good scale inhibition and increase the dispersion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A. Cyclization reaction and purification of cyclization products

[0022] aAdd 15g of NaOH and 33ml of water into the three-necked flask, put the three-necked flask into a magnetic stirring water bath, fully dissolve under magnetic stirring, then add 19.6g of maleic anhydride, while the temperature of the water bath is raised to 55°C. After the water bath was heated to 55°C, the catalyst 1.2gNa was added 2 WO 4 . Finally, raise the temperature of the water bath to 70°C. After the temperature stabilizes, use a separatory funnel to evenly add 24ml of hydrogen peroxide dropwise within 35 minutes. Mixed crude products were obtained after 1.5 hours of reaction.

[0023] b product purification: the mixed crude product of step a is heated with an electric heating mantle, and vacuumized simultaneously for distillation under reduced pressure. When the remaining liquid after evaporation is 1 / 2 of the volume of the original solution, stop the vacuum distillation. Pour the sol...

Embodiment 2

[0029] A. Cyclization reaction and purification of cyclization products

[0030] a Add 13g of NaOH and 35ml of water into the three-necked flask, put the three-necked flask into a magnetic stirring water bath, fully dissolve under magnetic stirring, add 18g of maleic anhydride, and raise the temperature of the water bath to 52°C. After the temperature of the water bath was raised to 52°C, the catalyst 1gNa was added 2 WO 4 . Finally, raise the temperature of the water bath to 65°C. After the temperature is stable, use a separatory funnel to evenly add 20ml of hydrogen peroxide dropwise within 30 minutes. At this point, 1:1 hydrochloric acid solution was used to adjust the pH to 6-7, and the mixed crude product was obtained after 1 hour of reaction.

[0031] b product purification: the mixed crude product of step a is heated with an electric heating mantle, and vacuumized simultaneously for distillation under reduced pressure. When the remaining liquid after evaporation is ...

Embodiment 3

[0037] A. Cyclization reaction and purification of cyclization products

[0038] a Add 18g of NaOH and 38ml into the three-necked flask, put the three-necked flask into a magnetic stirring water bath, fully dissolve under magnetic stirring, add 20g of maleic anhydride, and raise the temperature of the water bath to 58°C. After the temperature of the water bath was raised to 58°C, 1.5g of Na2WO4 catalyst was added, and then the temperature of the water bath was raised to 75°C. After the temperature stabilized, 26ml of hydrogen peroxide was evenly added dropwise within 40min with a separatory funnel. At this point, 1:1 hydrochloric acid solution was used to adjust the pH to 7, and the mixed crude product was obtained after 2 hours of reaction.

[0039]b product purification: the mixed crude product of step a is heated with an electric heating mantle, and vacuumized simultaneously for distillation under reduced pressure. When the remaining liquid after evaporation is 1 / 2 of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com