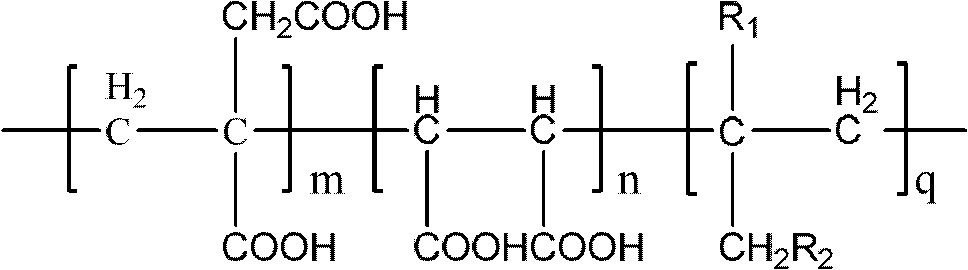

Itaconic acid copolymer antisludging agent and microwave synthetic method thereof

A synthesis method and antiscalant technology are applied in the field of novel itaconic acid copolymer antiscalant and its microwave synthesis, which can solve the problems of increasing the production cost of the copolymer, hindering industrial production, and the high price of acrylic acid, so as to avoid water body enrichment. Troubleshooting problems, fast synthesis speed, and high scale inhibition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: (according to every part of 1 / 10g meter in parts by mass)

[0033] In there-necked flask, add 6.0g itaconic acid, 0.9g maleic anhydride, and a certain amount of sodium propylene sulfonate, the stoichiometric ratio of each component is shown in Table 1 (the proportioning of these three kinds of raw materials is monomer proportioning), Dissolve in 10mL of deionized water, add 0.1g of catalyst ferrous ammonium sulfate, place it under a microwave field of 2450MHz (XH-100A computer microwave catalytic / synthetic extraction instrument), microwave power is 700W, slowly drip at a certain rate Add 0.5g initiator (mass ratio is the mixture of 1: 1 hydrogen peroxide (30%) and sodium bisulfite (30%)) and 1.5g chain transfer agent isopropanol, apply microwave synthesis technology, stir, reflux, The microwave irradiation time was 30 min, and the reaction temperature was 70° C. to obtain a pale yellow transparent solution. Add 150 mL of acetone to the product and wash it...

Embodiment 2

[0038]Embodiment 2: (according to every part of 1 / 10g of mass parts)

[0039] Add 6.0g of itaconic acid, 0.9g of maleic anhydride and 1.0g of sodium methylpropene sulfonate into a three-necked flask, dissolve them in 10mL of deionized water, add 0.1g of catalyst ferrous ammonium sulfate, and place it in a microwave at 2450MHz Under the field (same as above), the microwave power is 700W, and a certain amount of initiator (a mixture of hydrogen peroxide (30%) and sodium bisulfite (30%) with a mass ratio of 1:1) and 1.2 g chain transfer agent isopropanol, the amount of initiator added is shown in Table 2, using microwave synthesis technology, stirring, reflux, microwave irradiation time is 40min, reaction temperature is 80°C, and a light yellow transparent solution is obtained. Add 100 mL of acetone to the product and wash it 4 times, then distill under reduced pressure to separate the remaining part of the chain transfer agent, cool to room temperature and discharge to obtain th...

Embodiment 3

[0044] Embodiment 3: (according to every part of 1 / 10g meter in parts by mass)

[0045] Add 6.0g of itaconic acid, 0.9g of maleic anhydride and 1.0g of sodium ethyl propylene sulfonate to a three-necked flask, dissolve them in 10mL of deionized water, add 0.1g of catalyst ferrous ammonium sulfate, and place it in a microwave at 2450MHz Under the field (same as above), the microwave power is 800W, and the initiator (mass ratio is 1: 1 mixture of hydrogen peroxide (30%) and sodium bisulfite (30%)) and A certain amount of chain transfer agent isopropanol, the amount of chain transfer agent added is shown in Table 3, using microwave synthesis technology, stirring, reflux, microwave irradiation time is 50min, reaction temperature is 60°C, and a light yellow transparent solution is obtained. Add 150 mL of acetone to the product and wash it 3 times, then distill under reduced pressure to separate the remaining part of the chain transfer agent, cool to room temperature and discharge t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com