Patents

Literature

52results about How to "Extension of Advanced Standing Period" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

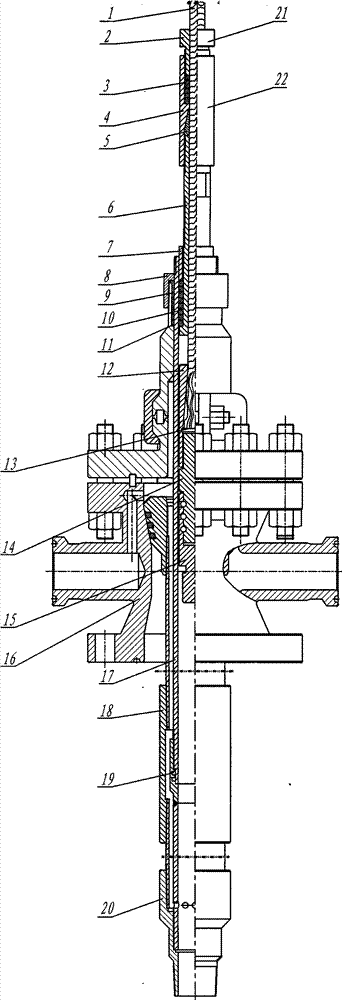

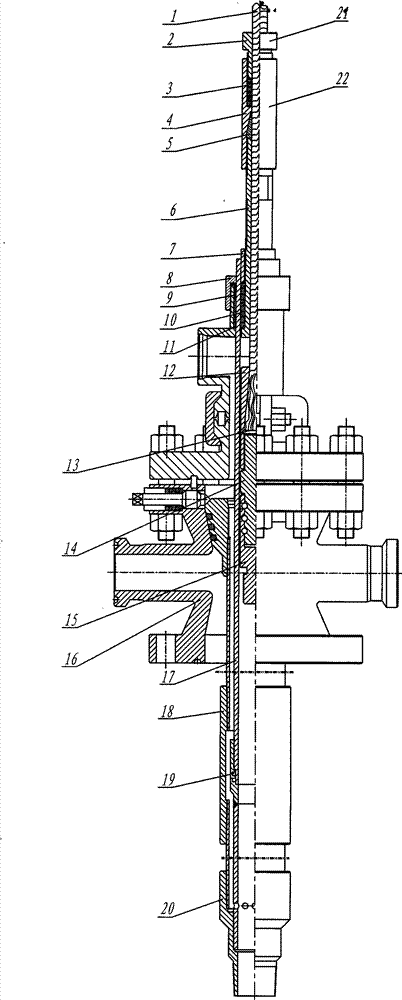

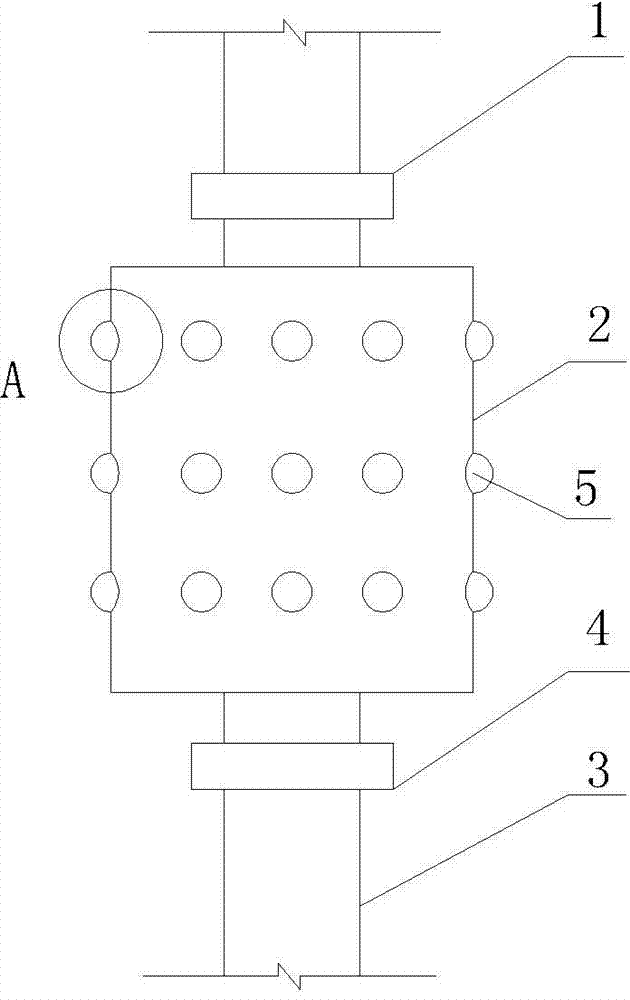

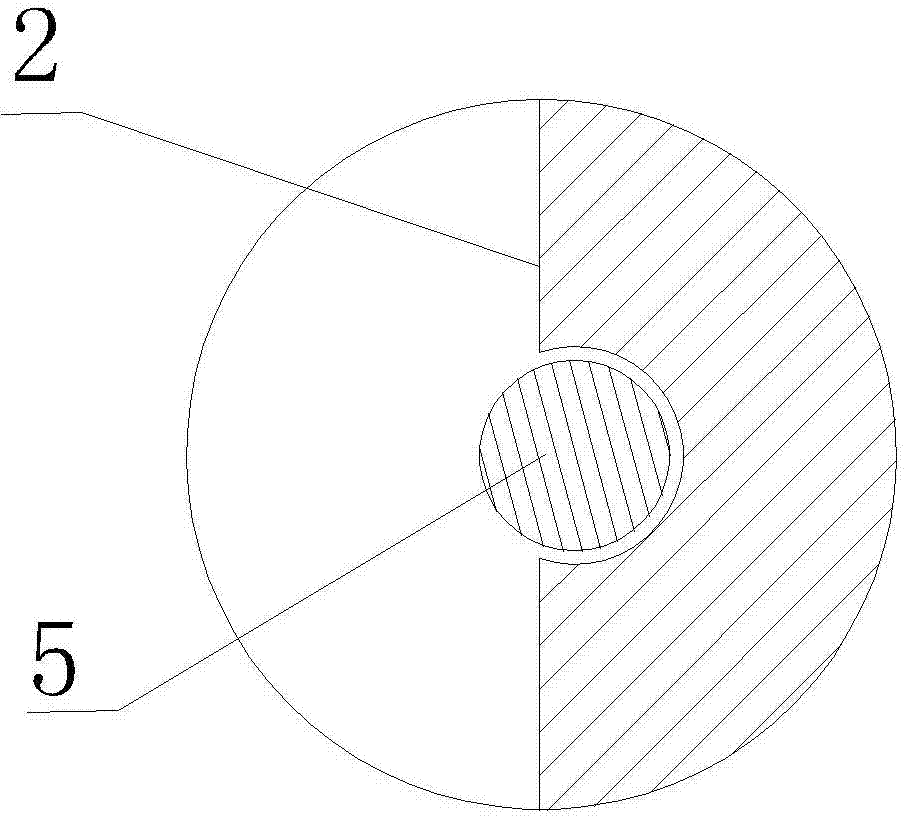

Intelligent synchronous testing and adjusting method capable of simultaneously infusing, testing and regulating

InactiveCN101672179AExtension of Advanced Standing PeriodImprove water injection efficiencySurveyFluid removalWater infusionBridge type

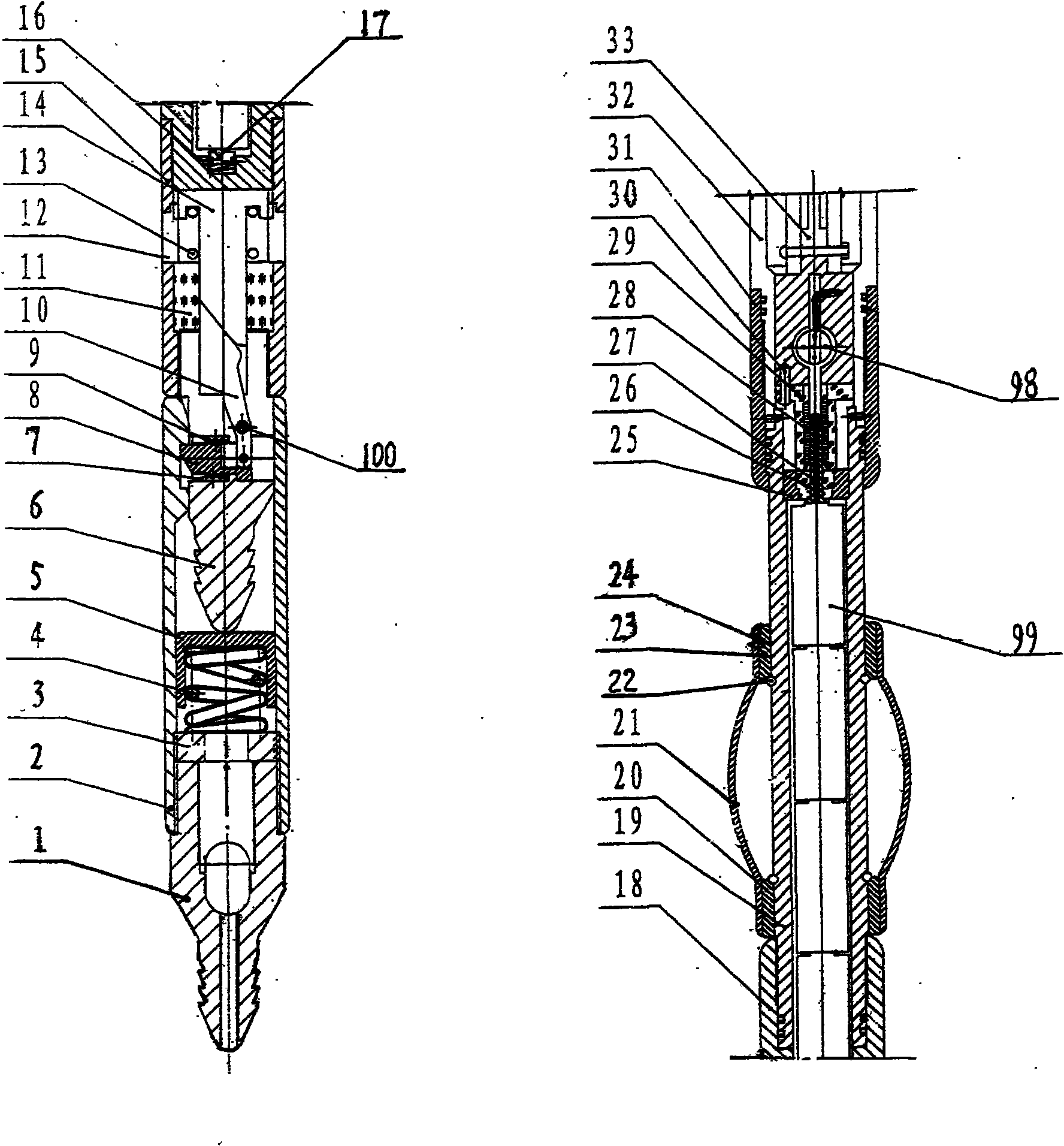

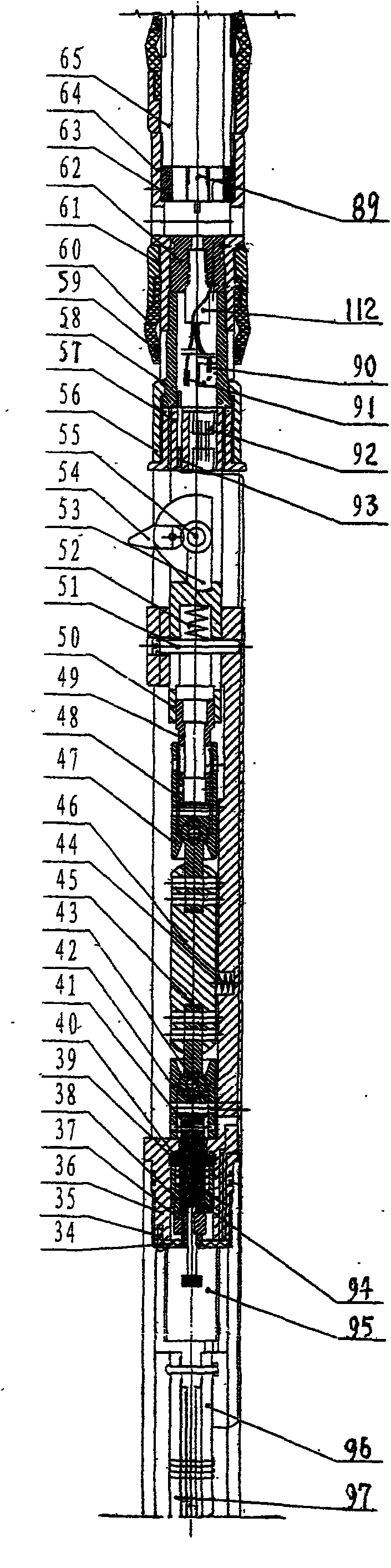

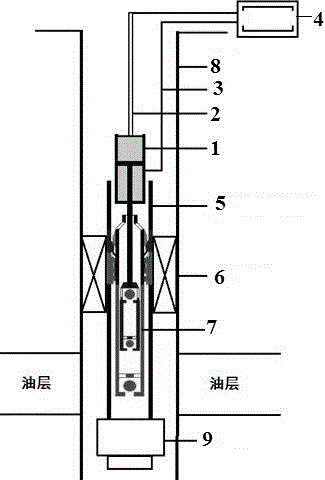

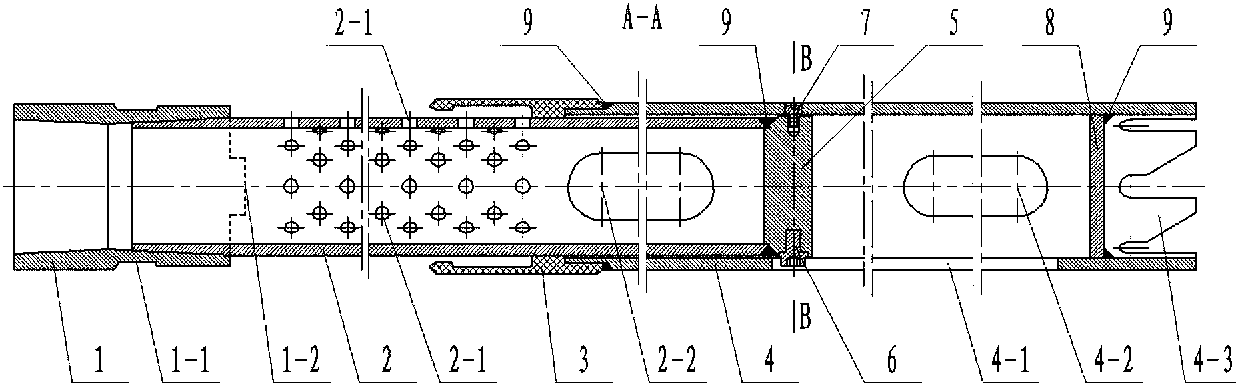

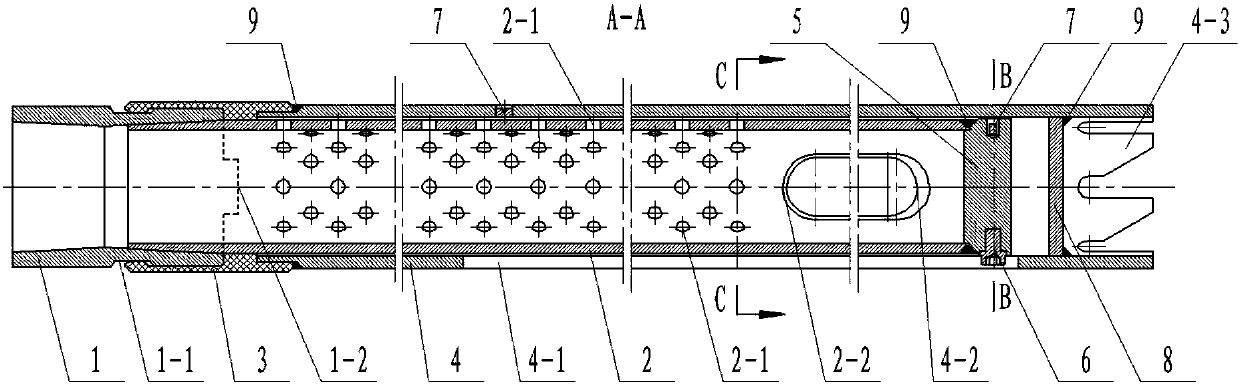

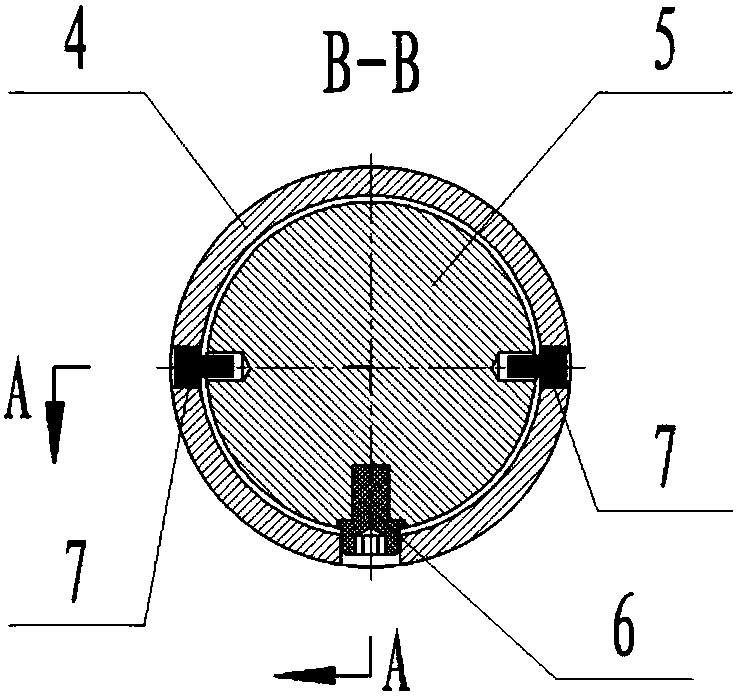

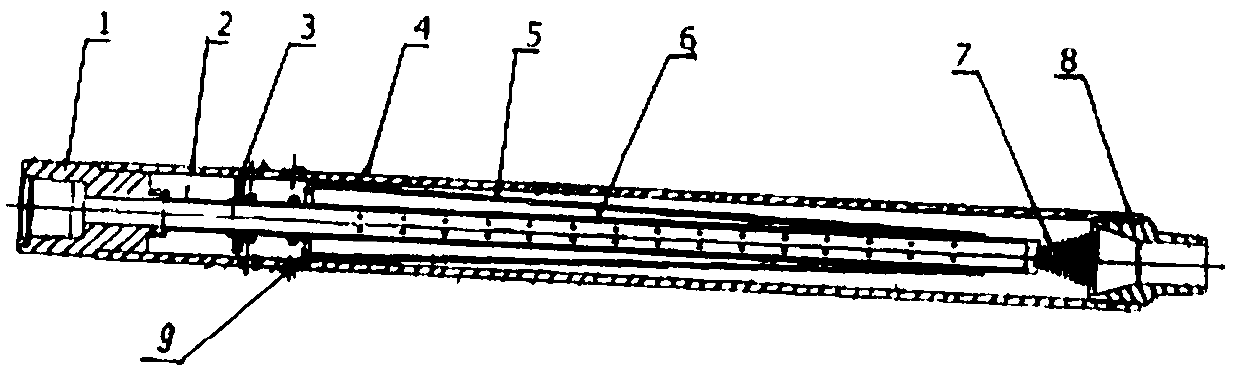

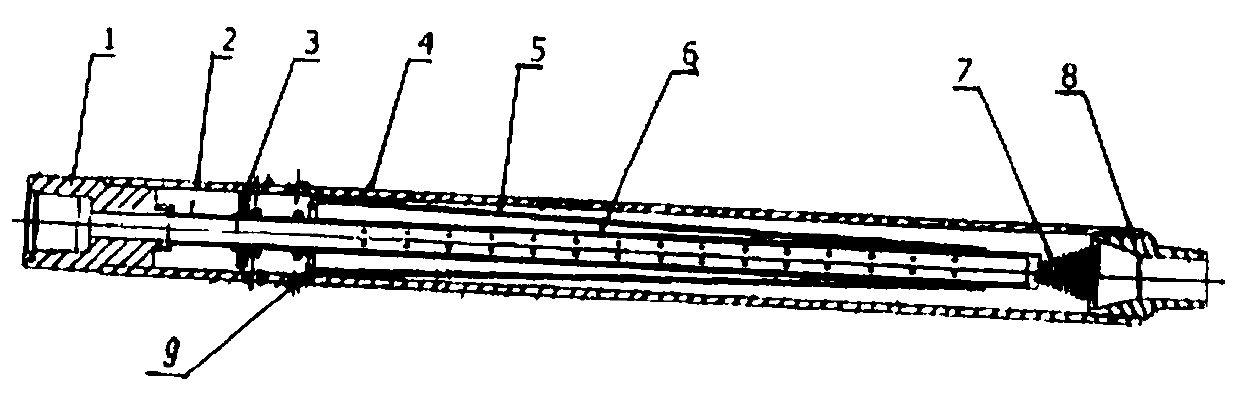

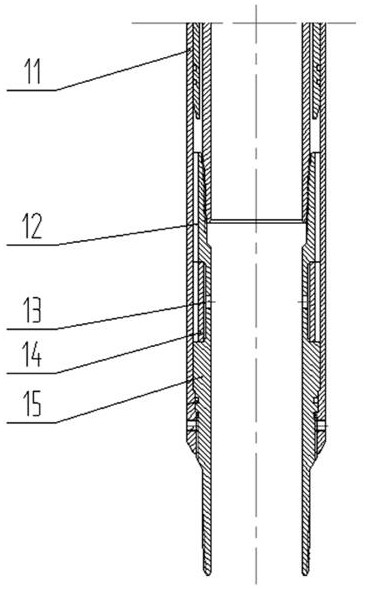

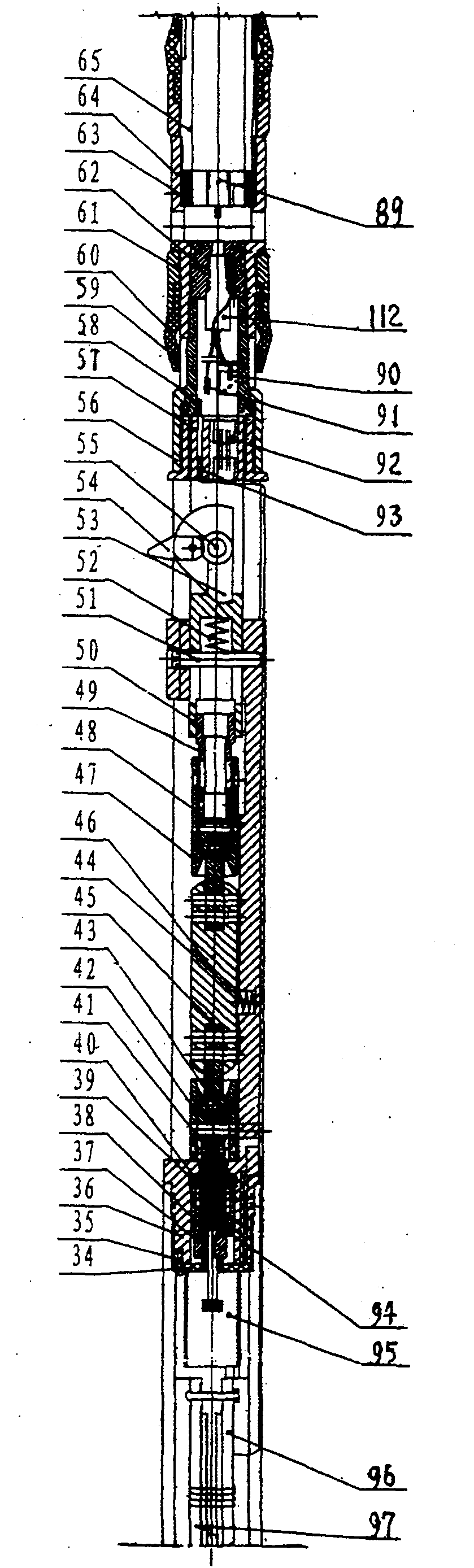

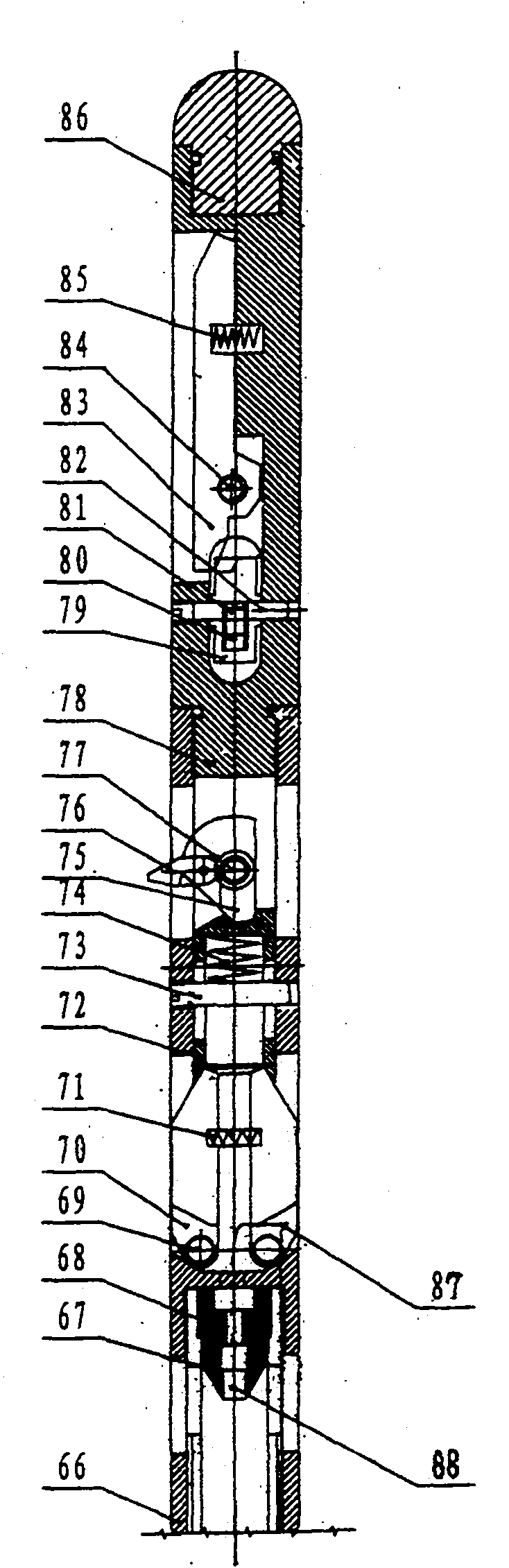

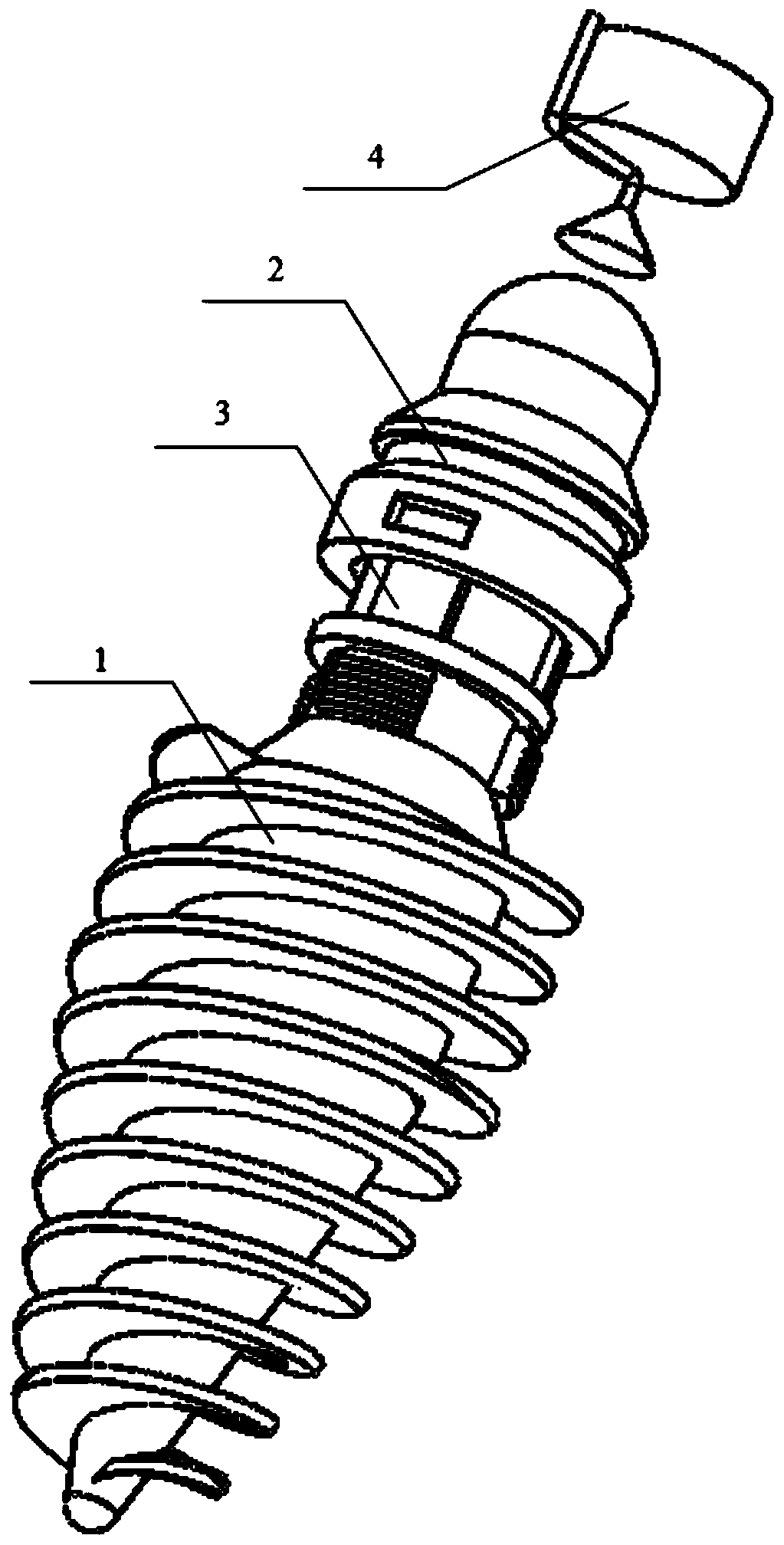

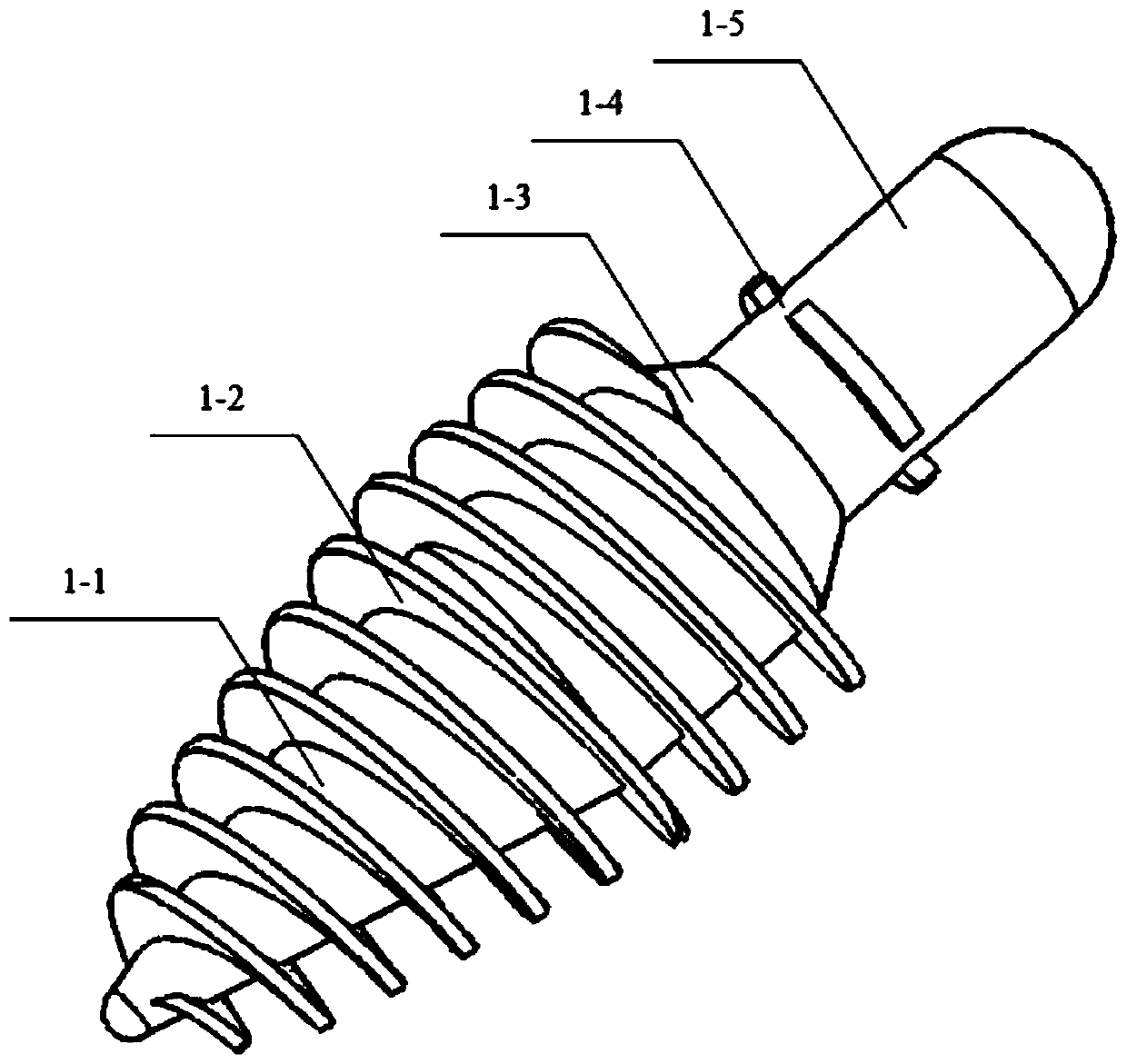

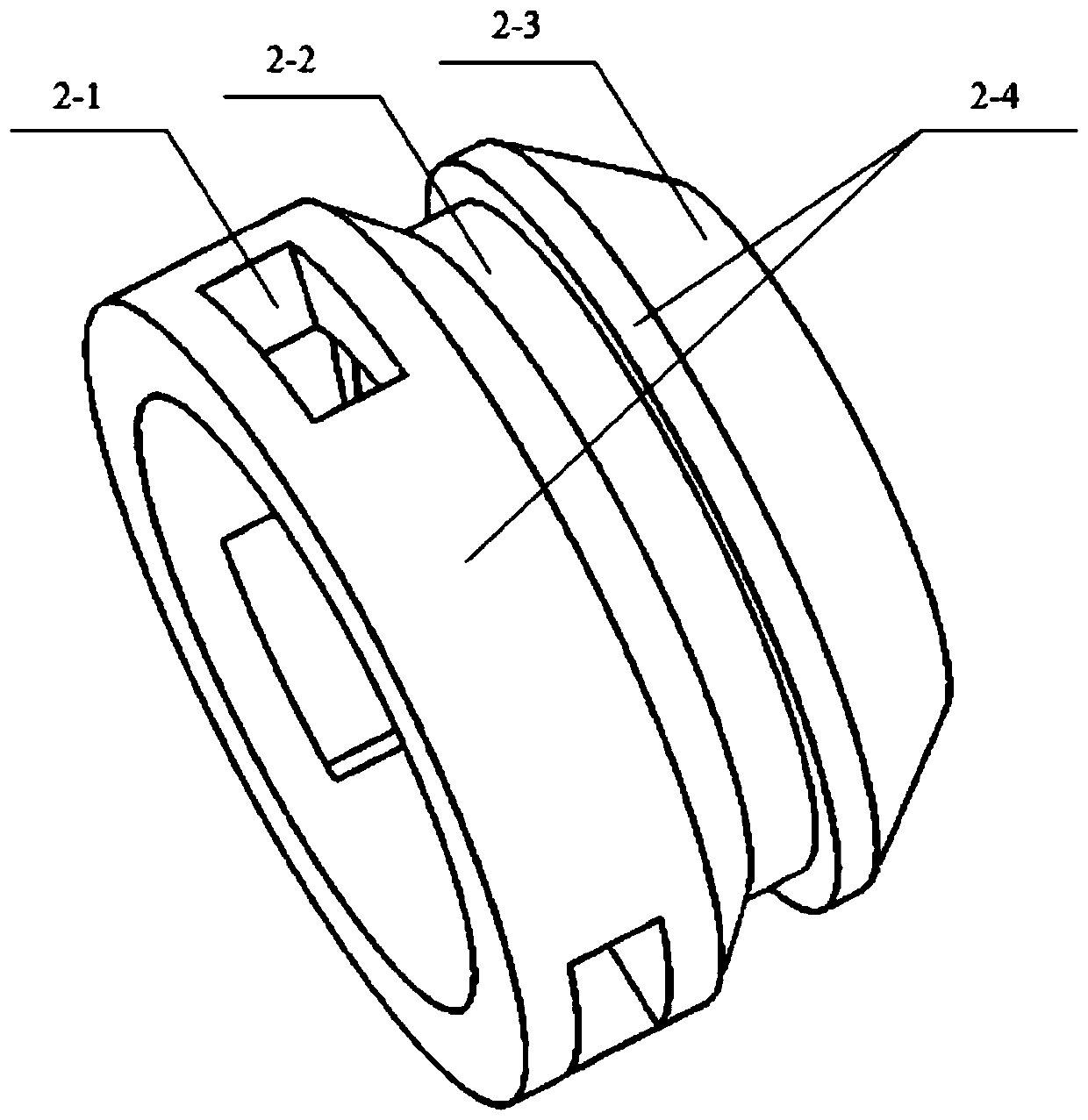

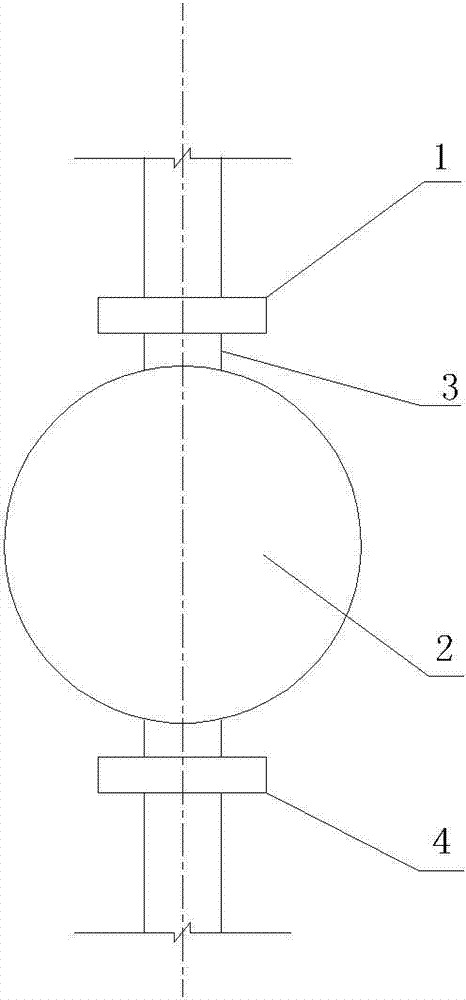

The invention relates to an intelligent synchronous testing and adjusting method capable of simultaneously infusing, testing and regulating, belonging to the field of oil extraction technologies in oil fields. A method of adopted equipment comprises the following steps: (1) a synchronous intelligent testing and adjusting device release part; (2) an intelligent testing and adjusting part; (3) a guiding part; and (4) an eccentric water distribution part. The adopted equipment is characterized in that the intelligent synchronous testing and adjusting method of the whole equipment comprises the following steps: descending into a well: using a steel wire to be suspended to descend into the well; placing the synchronous intelligent testing and adjusting device into a connected technological pipecolumn provided with an eccentric water distributor and a packer; and leading the adjustable blanking plug into an eccentric hole of the eccentric water distributor and releasing the adjustable blanking plug so that the adjustable blanking plug stays in the eccentric water distributor. The invention can realize the unchanged bridge type eccentric whole well working system, directly obtain the single-layer flow, achieve the simultaneous water infusion, testing and adjustment at multiple layers and enhance the work efficiency.

Owner:FUXIN CITY GASOLINEEUM TOOL FACTORY

Scale inhibition antiscaling agent for oil-water well salt prevention and scale-inhibition operation and preparation process thereof

The invention relates to oil-water well salt prevention and scale-inhibition operation in the oil-field development process and a scale-inhibition agent used in a cooling circulation system, in particular to a scale inhibition antiscaling agent for oil-water well salt prevention and scale-inhibition operation and a preparation process thereof; the scale inhibition antiscaling agent is characterized in that: the scale inhibition antiscaling agent at least comprises 1) 2.0-2.5kg of ethanediamine tetramethylene phosphonate; 2) 4.5-5.0kg of polymaleic acid; 3) 4.5-5.0kg of sodium hexametaphosphate; 4) 6.5-7.0kg of triethanolamine; the preparation process of the scale inhibition antiscaling agent for oil-water well salt prevention and scale-inhibition operation is characterized in that: at normal temperature, 4.5-5.0kg of the sodium hexametaphosphate is dissolved by 30-35kg of clear water and is continuously stirred for 20-40 minutes, and then 6.5-7.0kg of the triethanolamine is slowly added in the mixture, after complete mixing, and 2.0-2.5kg of the ethanediamine tetramethylene phosphonate and 4.5-5.0kg of the polymaleic acid are slowly added continuously while stirring is carried out, so as to prepare the scale inhibition antiscaling agent; the scale inhibition antiscaling agent has hypersalinity resistance and high calcium ion resistance, takes alkalescence-neutrality, and has no strong corrosivity to injection-production equipment.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

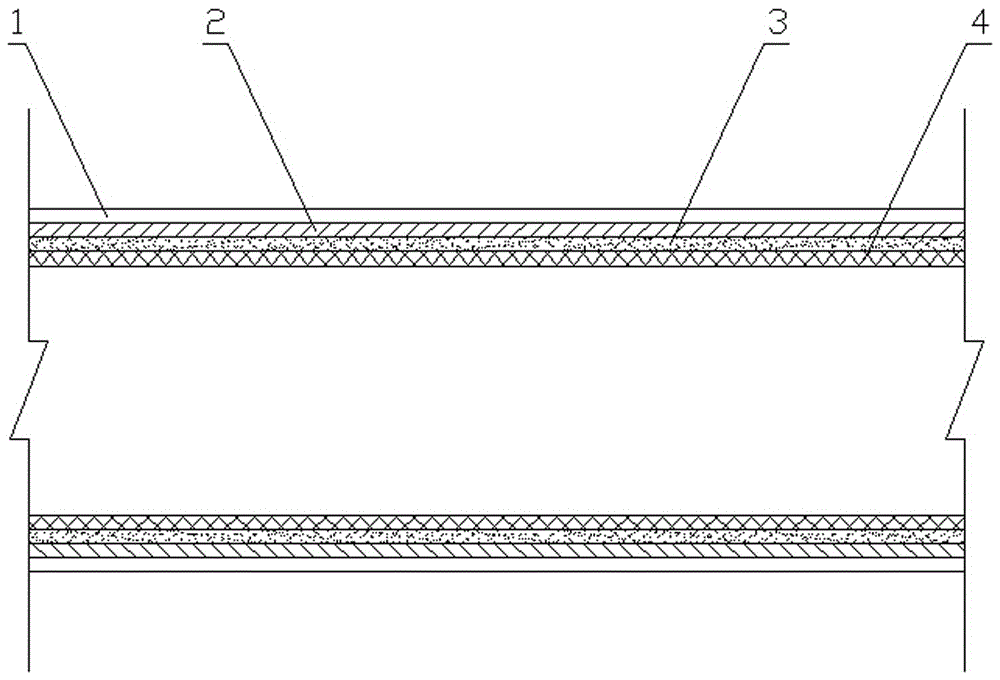

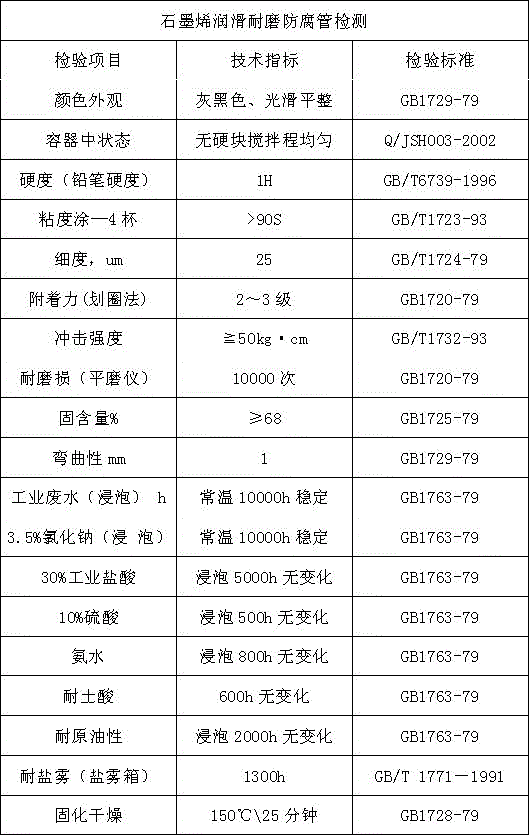

Lubricant, wear-resistant and anti-corrosion graphene pipe and preparation process thereof

InactiveCN106337977AExcellent chemical corrosion resistanceStrong adhesionPretreated surfacesSpecial surfacesAdhesive cementGraphene

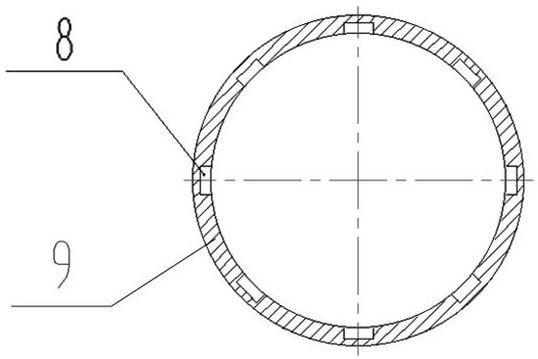

The invention provides a lubricant, wear-resistant and anti-corrosion graphene pipe and a preparation process thereof and relates to the technical field of petroleum equipment. The pipe comprises an oil pipe, a lubricant, wear-resistant and anti-corrosion layer, an adhesive layer and a protecting layer, wherein the oil pipe is in a hollow cylindrical structure, the inner wall of the oil pipe is sprayed with the lubricant, wear-resistant and anti-corrosion layer, the adhesive layer and the protecting layer from outside to inside sequentially by a high-pressure gas-free spraying system in a hot-air curing manner. The lubricant, wear-resistant and anti-corrosion layer is made of lubricant, wear-resistant and anti-corrosion powder, and the thickness of the lubricant, wear-resistant and anti-corrosion layer is larger than 100um; the adhesive layer consists of an adhesive, and the thickness of adhesive layer is 120-260 mum; the protecting layer consists of graphene, and the thickness of the protecting layer is 0. 5-3.7 mum. The graphene lubricant, anti-wear and anti-corrosion pipe reduces conveying resistance to the oil pipe, and when the pipe is applied as a gas field well pipe is used to improve gas well productivity, reduce corrosion of inner wall of gas field pipeline, reduce the number of pigging and prolong service life of gas field pipeline.

Owner:大庆市盛日石油技术开发有限公司

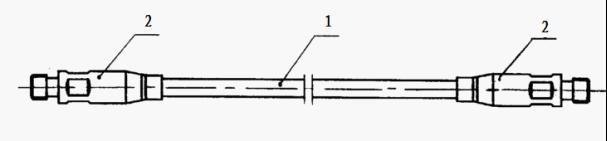

Novel carbon fiber sucker rod and manufacturing method thereof

The invention relates to a novel carbon fiber sucker rod and a manufacturing method thereof. The sucker rod in the invention consists of a rod body and rod joints, wherein the rod body is prepared from carbon fiber composite, the both ends of the rod body are connected with the rod joints; the rod joints are prepared from carbon fiber composite; and the rod joints are machined on the rod body directly and integrated with the rod body. The sucker rod is prepared from the main raw materials comprising T300 carbon fiber-12K, epoxy resin, Me-THPA, accelerator and release agent through the pultrusion technology. According to the invention, as the sucker rod is corrosion-resistant, is difficult to break and has light weight, the time of downhole operations in a pumped well is reduced, the maintenance-free period is prolonged, and the downhole operation cost and the material cost for changing the sucker rod are saved. By adopting the carbon fiber composite sucker rod disclosed by the invention, the transportation is convenient, the installation speed is high, the time and the labor are saved and the operation is safe and reliable.

Owner:DALIAN CHUANGDA TECH TRADE MARKET

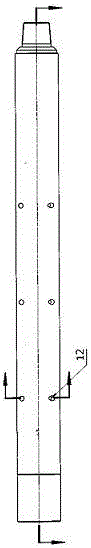

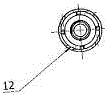

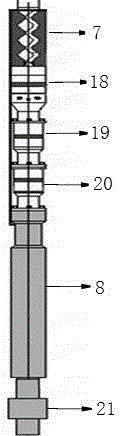

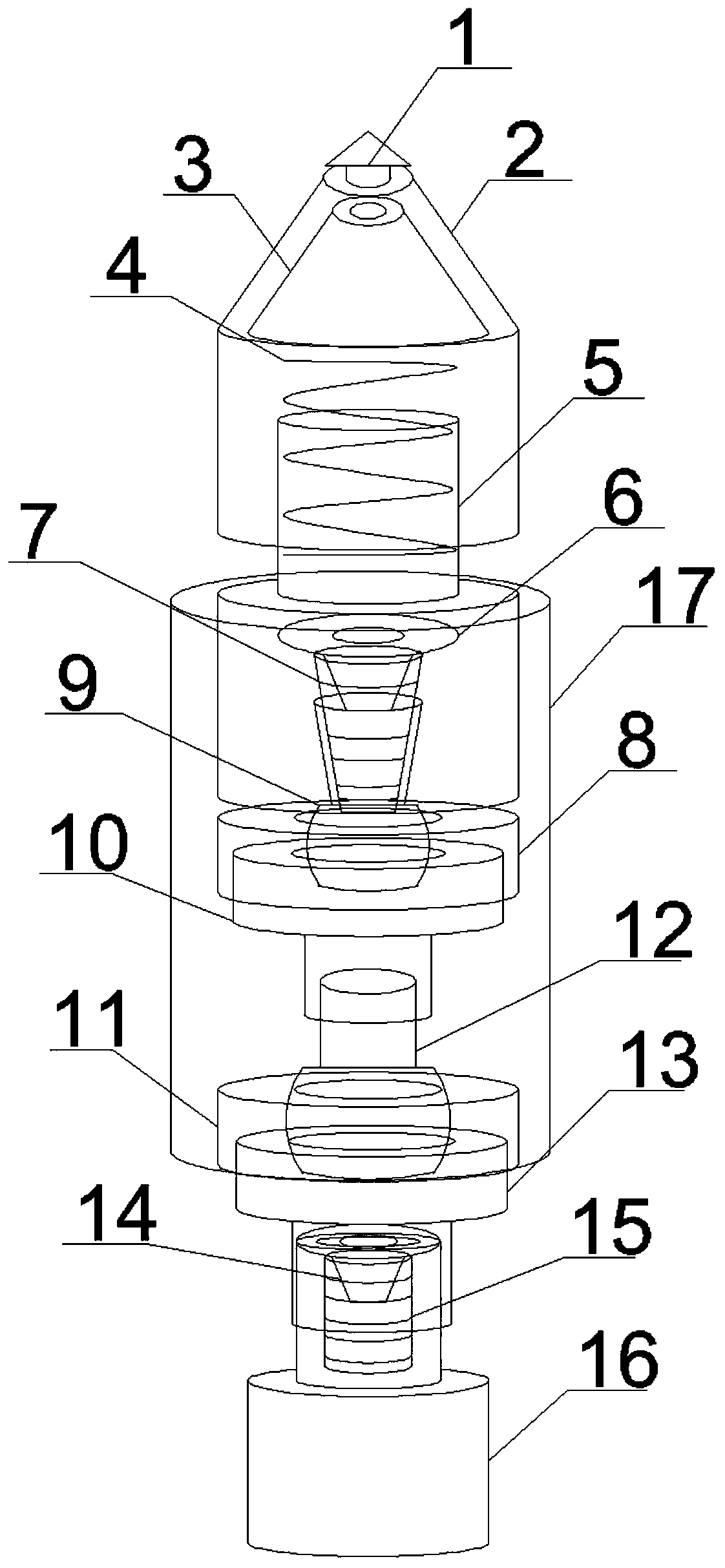

High-efficient multi-stage cyclone self-cleaning separator and application method

ActiveCN105756657AAvoid easy cloggingAvoid adsorptionFluid removalMembrane filtersEngineeringOil well

The invention discloses a high-efficient multi-stage cyclone self-cleaning separator and an application method, relates to the sand control technique of oil well pumps and solves the problems in the prior art. The structural relationship of the separator lies in that an upper connector is connected to the upper end of an outer tube, and a lower connector is connected to the lower end of the outer tube; an inner tube is arranged in the middle of the outer tube; spring supports are respectively fixed on the periphery of the inner tube; big ends of springs are fixed on the spring supports; small ends of the springs are fixed on upper fixed rings, slip rings are arranged on the periphery of the inner tube, filter screens are arranged at the outer ends of the springs, the upper ends of the filter screens are fixed on the peripheries of the slip rings by filter screen small hoop rings, and the lower ends of the filter screens are fixed on the peripheries of the spring supports by filter screen large hoop rings.

Owner:HENAN DONGFANGLONG MACHINE MFR

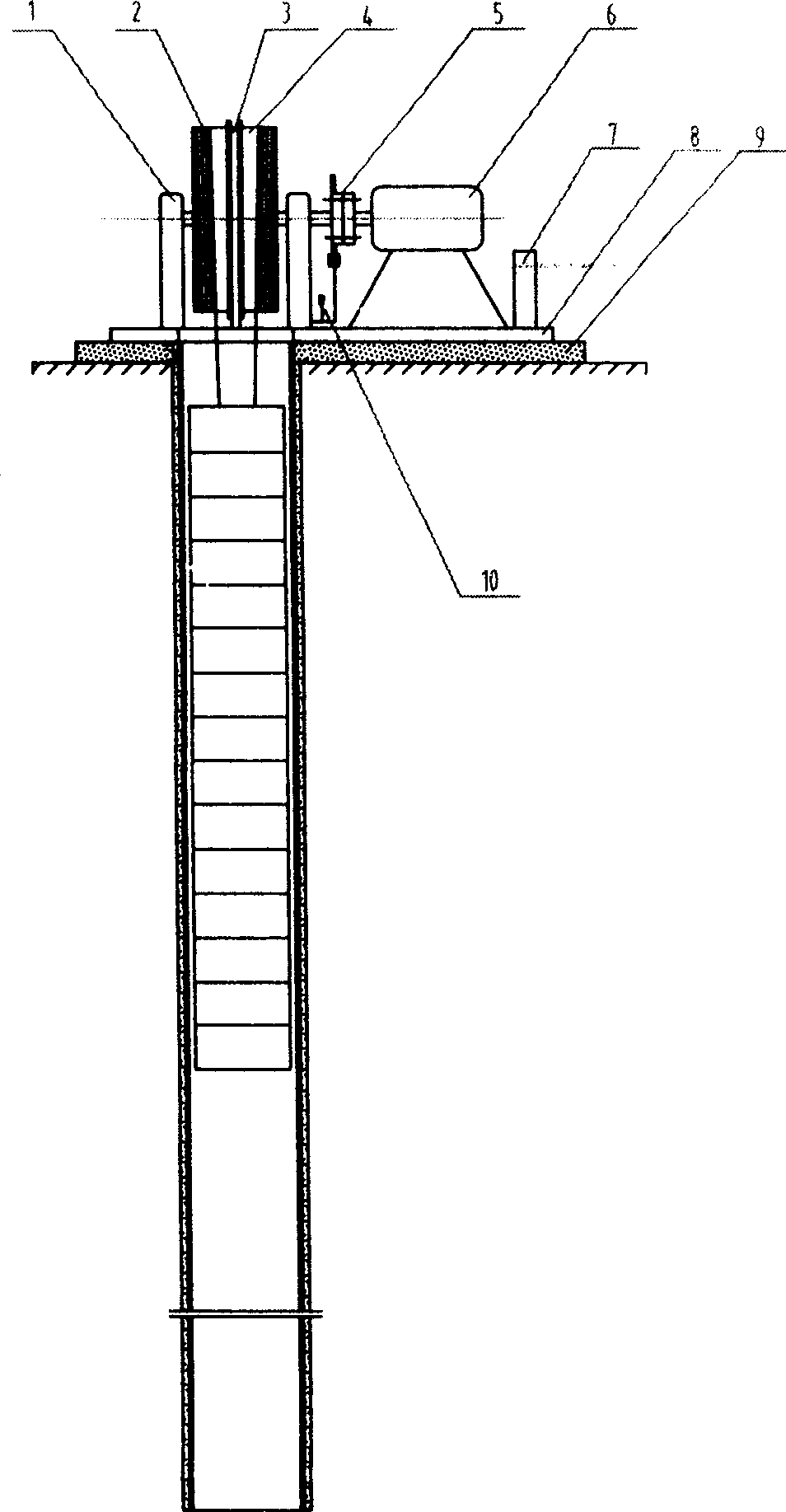

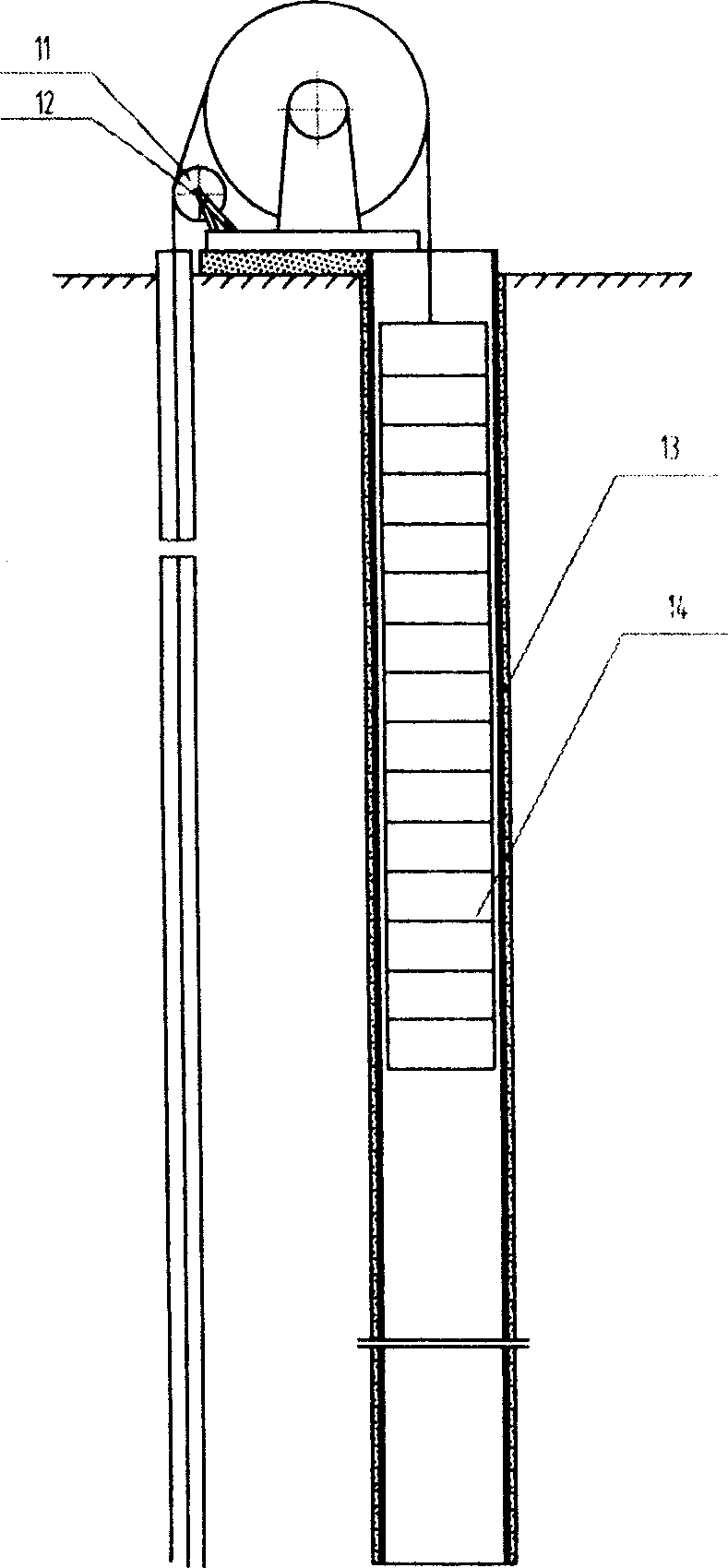

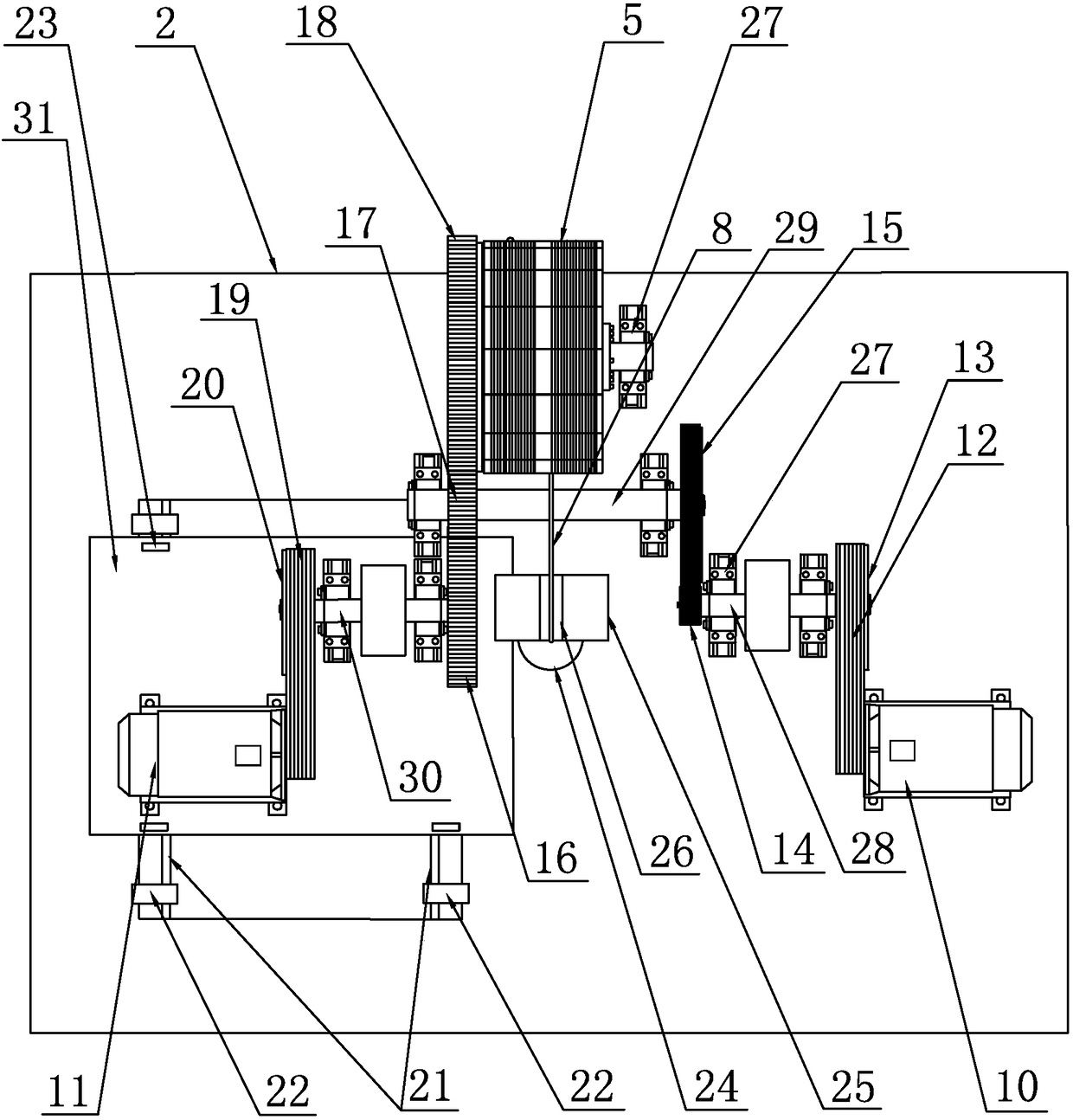

Ultra long stroke beam-pumping unit

The invention is an ultra-long stroke oil pumping machine, comprising supporting seat, balance weight dragging piece, flexible oil pumping rod dragging piece, reducing power-driven roller, shaft coupler, electric motor, intelligent control cabinet, base, foundation, braking system, swelling wheel, swelling wheel stand, balance weight shaft, and balance weight, and characterized in that two ends of the power driven roller are supported by the supporting seat and connected with the electric motor on the base through the shaft coupler, one end of the flexible oil pumping rod dragging piece is fixedly wound in the middle of the power-driven roller body and the other end is connected with an oil pump through a continuous oil pumping rod in the oil pumping well, the balance weight dragging piece is composed of two steel wire ropes and nonmetallic rope, one end of each of them is fixedly wound at one end of the reducing power-driven roller body, and the other end is connected with the balance weight placed in an underground balance weight shaft, the swelling wheel is installed on the front-side base by the swelling wheel stand, it can make the flexible oil pumping rod aligned with the well mouth by adjusting the swelling wheel stand, the braking system and the intelligent control cabinet are installed on the base and the base is installed on the foundation.

Owner:山东创新石油技术有限公司

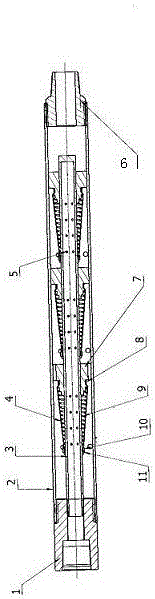

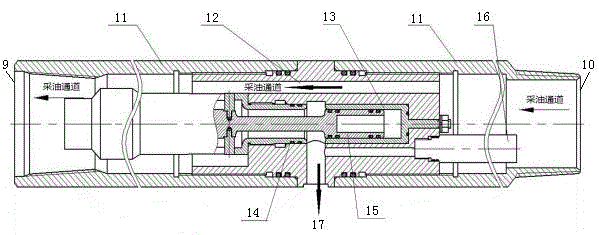

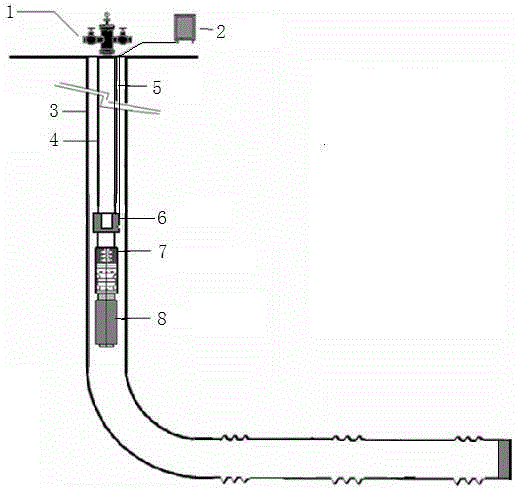

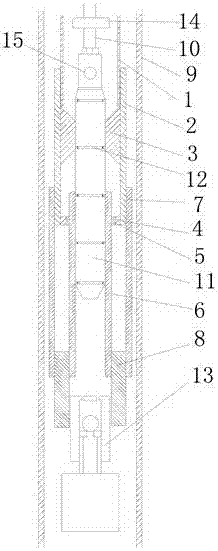

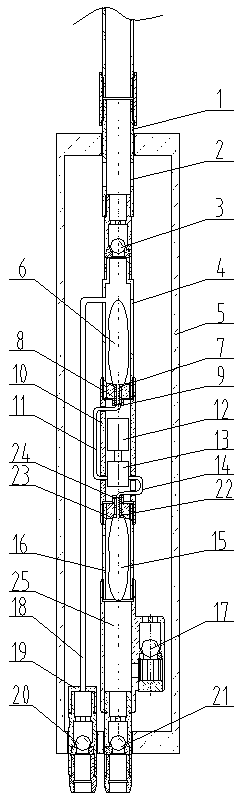

Huff-and-puff oil production device with submersible directly-driven screw pump

ActiveCN105422053AOptimize work processImprove construction efficiencyFluid removalWell/borehole valve arrangementsMarine engineeringElectric machinery

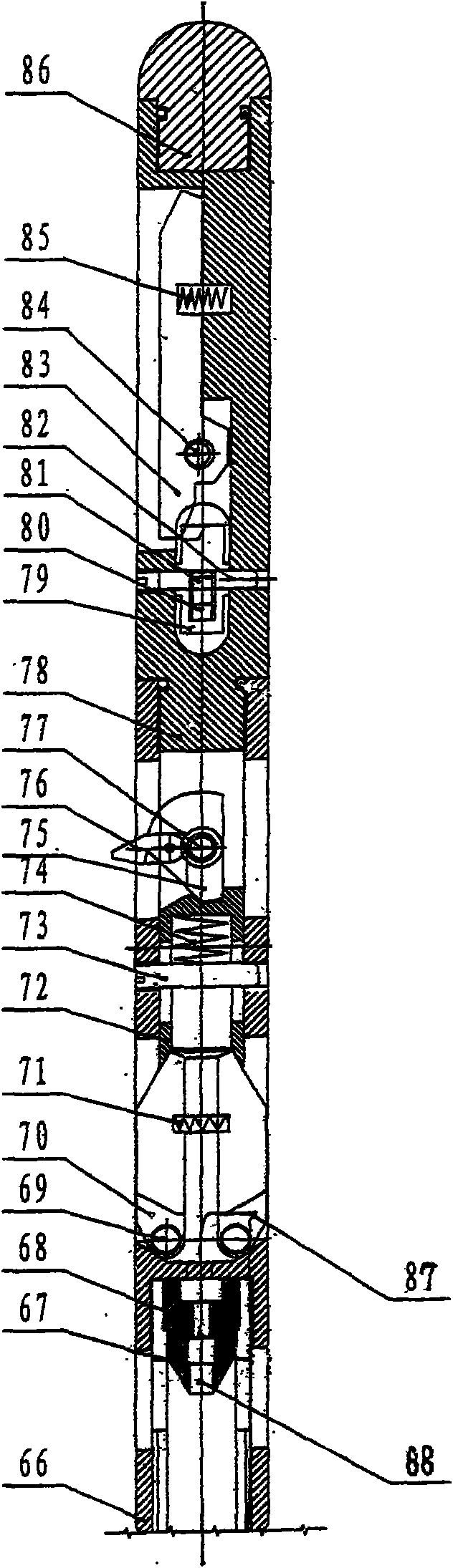

The invention provides a huff-and-puff oil production device with a submersible directly-driven screw pump. The huff-and-puff oil production device comprises an underground automatic water injection switch for realizing water injection and oil production channel switching and a submersible directly-driven screw pump, wherein a liquid outlet in the upper end of the underground automatic water injection switch is connected with an oil pipe, and a liquid inlet in the lower end of the underground automatic water injection switch is connected with an oil outlet in the upper end of the submersible directly-driven screw pump through the oil pipe; the submersible directly-driven screw pump comprises a screw pump, a flexible shaft, an upper protect tor, a lower protector, a submersible motor and a centralizer which are non-coaxially connected from top to bottom; the upper end of the screw pump is connected with the lower end of the underground automatic water injection switch; and the screw pump and the submersible motor are respectively electrically connected to a submersible cable outside a wellhead. The huff-and-puff oil production device is free of repeatedly tripping and has the characteristics of simple and convenient operation flow, high construction efficiency, safety, environment friendliness, low risk and the like; and due to the adoption of the lifting way, the huff-and-puff oil production device has the characteristics of low rotating speed and large torque and is suitable for a well with low liquid quantity, the eccentric wear of pipe poles is eliminated, the maintenance-free period of an oil well is prolonged, and the economic benefit can be effectively increased.

Owner:PETROCHINA CO LTD

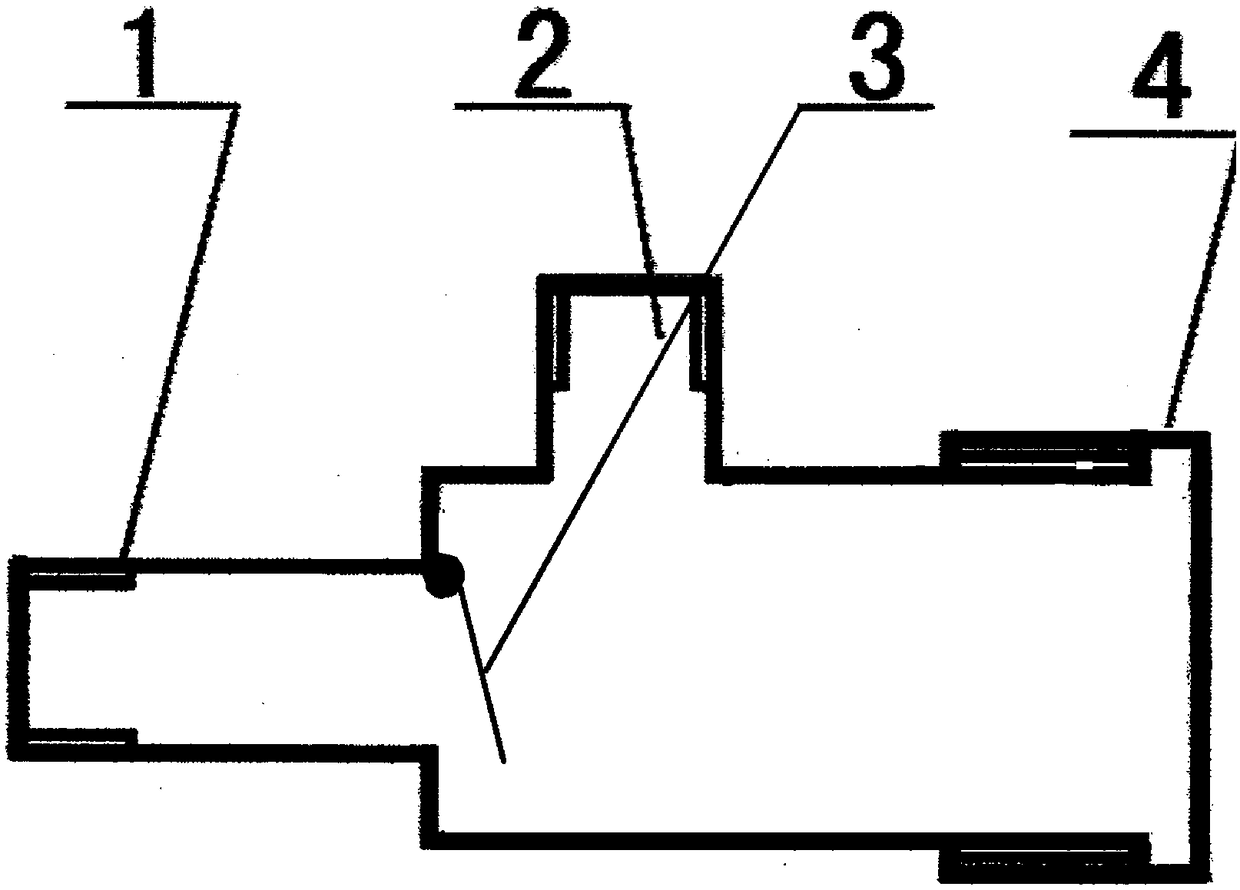

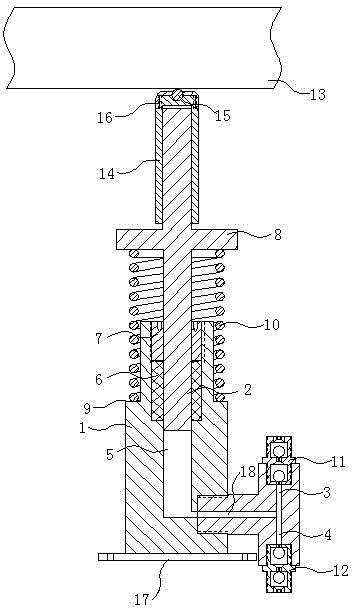

Suspension type underground hydraulic rod type pumping production device

InactiveCN105464628AEliminate partial wearExtension of Advanced Standing PeriodFluid removalHydraulic cylinderHydraulic pump

The invention provides a suspension type underground hydraulic rod type pumping production device which comprises a hydraulic cylinder, a hydraulic pipe communicated with the hydraulic cylinder, a hydraulic control cabinet and a rod type oil-well pump. A hollow sucker rod is communicated to the upper end of the hydraulic cylinder. The hollow sucker rod and the other end of the hydraulic pipe are connected with the hydraulic control cabinet. The rod type oil-well pump is connected with the hydraulic cylinder. The rod type oil-well pump is arranged in an oil pipe. The hydraulic cylinder is arranged above the oil pipe. The lower portion of the oil pipe is provided with a supporting slip. The oil pipe is sleeved with a packer. Pipe rod eccentric wear is eliminated, and the oil well maintenance-free period can be prolonged; the hollow sucker rod is adopted as a hydraulic transmission pipe, the heat of high-temperature hydraulic oil can be transferred to a well shaft, and paraffinning is effectively prevented. The device adopts a casing pipe oil extraction mode, only one or two oil pipes are needed, the operation process is simplified, and the operation cost is reduced.

Owner:PETROCHINA CO LTD

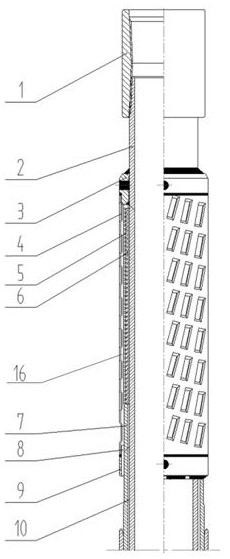

Anti-blocking sieve tube column integrating oil collection and sand flushing

PendingCN107725008AExtension of Advanced Standing PeriodImprove work efficiencyDrilling rodsFluid removalBlood collectionCoupling

The invention discloses an anti-blocking sieve tube column integrating oil collection and sand flushing. The column includes a coupling, a sieve tube and a sand flushing tube, the top of the sieve tube is connected with the coupling, the bottom of the sieve tube is connected with an inner blind plate and sleeved in the sand flushing tube, the blind plate at the bottom of the sieve tube is fixed tothe sand flushing tube through shearing pins, and an axial sliding mechanism is connected between the blind plate and the sand flushing tube; the lower end of the sieve tube is provided with an innersand flushing hole, a locking device is arranged at the upper end of the sand flushing tube, an outer sand flushing hole is formed in the lower end, the tube column body is pressed appropriately, andafter the shearing pins are cut off, the blind plate and the sand flushing tube move oppositely through the axial sliding mechanism; the locking device of the sand flushing tube is connected with thecoupling to tightly lock the sand flushing tube with the coupling, and the inner sand flushing hole is correspondingly communicated with the outer sand flushing hole. By adopting the anti-blocking sieve tube column, one tube can be used for two use purposes, the functions of the sieve tube is integrated with the functions of the sand flushing tube, and meanwhile, the tube column has a liquid inlet overflowing anti-blocking advantage, that is to say that when sieve holes are blocked or bonded, a normal liquid feeding and producing function of the sieve holes can be recovered in time, the maintenance-free period of an oil well is finally prolonged, and the working efficiency is further improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

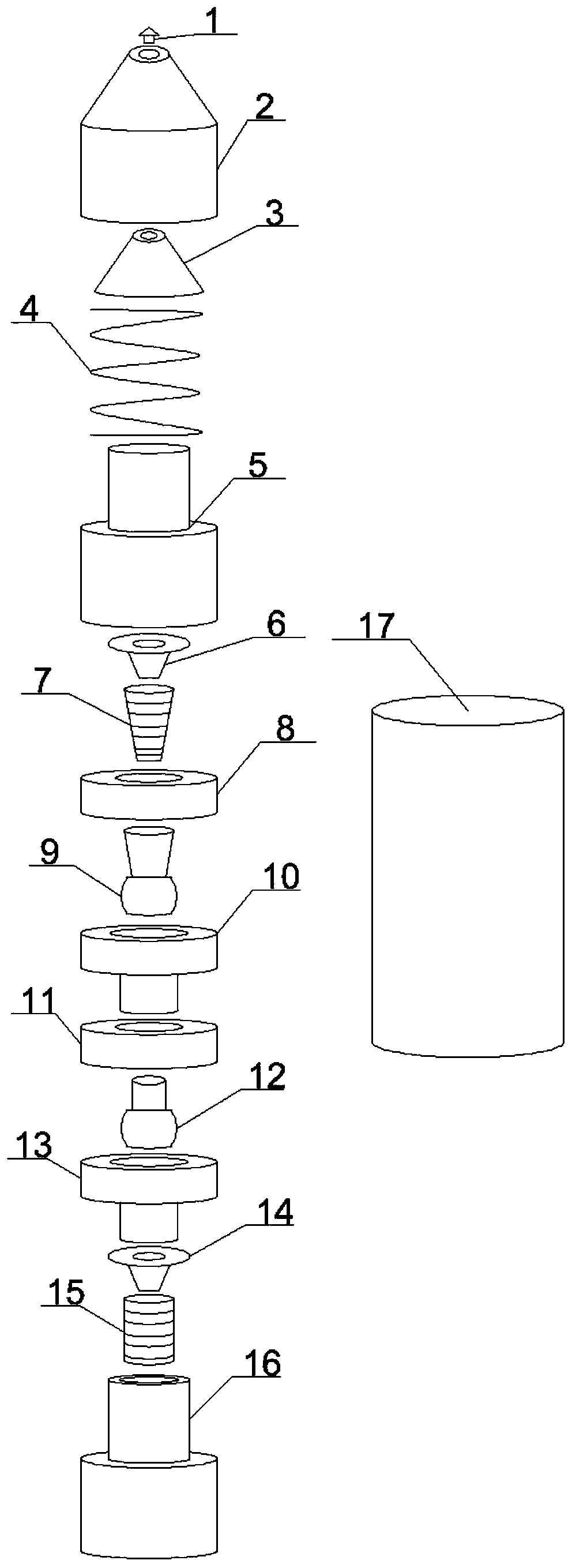

Efficient elastic filter screen vibration separation device and application method

The invention discloses an efficient elastic filter screen vibration separation device and an application method, and relates to a sand prevention technology for an oil well pump. The efficient elastic filter screen vibration separation device and the application method solve the problems in the prior art. The efficient elastic filter screen vibration separation device is structurally characterized in that an upper joint and a lower joint are arranged at the two ends of an outer pipe separately, an inner pipe is located in the middle of the outer pipe, the lower end of the inner pipe is connected to a conical vibrating spring, the outer edge of the inner pipe is sleeved with a conical sand-proof filter screen, the lower end of a centralizing vibrating spring is connected to the inner pipe,the upper end of the centralizing vibrating spring is connected to a corrugated pipe, the upper end of the corrugated pipe is connected to the upper joint, the conical sand-proof filter screen is conical, the conical caliber of the upper part is large, the conical caliber of the lower part is small, the taper is 10 degrees, the bore diameter of the conical sand-proof filter screen is 180 meshes,the top end of the conical sand-proof filter screen is connected to the upper end of the inner pipe, a gap between the outer wall of the top end of the conical sand-proof filter screen and the inner wall of the outer pipe is 5 mm, and the bottom end of the conical sand-proof filter screen is connected to the lower end of the inner pipe.

Owner:HENAN DONGFANGLONG MACHINE MFR

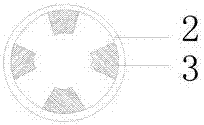

Downhole gas slow-release device

InactiveCN109113645AGuarantee normal productionRealize dynamic controlWell/borehole valve arrangementsSealing/packingPressure differenceLiquid surfaces

The invention discloses a downhole gas slow-release device which comprises a shell. An inlet and an outlet are formed in the shell, a baffle is arranged at the inlet and mounted on the inner wall of the inlet through hinges, and the baffle is matched with the inlet. The situations that the oil well sleeve pressure is excessively high, consequently the dynamic liquid surface is dropped, the pump efficiency is lowered, and oil well production is abnormal are eliminated, dynamic control over the oil well sleeve pressure is achieved, and normal production of an oil well is guaranteed. The situation that sleeve gas is manually released, consequently drop of the downhole flow pressure is excessively fast, the formation instantaneous production pressure difference is excessively large, an oil well sand prevention process is damaged, and consequently the well lying phenomenon is caused by formation excited sand discharging are avoided, the oil well exemption period is prolonged, and the crudeoil yield is increased.

Owner:SHAANXI XINGCHEN PETROLEUM TECH

Anti-blocking water control screen pipe

The invention discloses an anti-blocking water control screen pipe. The anti-blocking water control screen pipe comprises a base pipe, a wire winding screen sleeve and a slotted screen sleeve sequentially sleeve the base pipe from inside to outside, a supporting sleeve is connected to the lower end of the wire winding screen sleeve, a filtrate channel is formed between the supporting sleeve and the base pipe, and a sand passing channel is formed between the wire winding screen sleeve and the slotted screen sleeve. An upper end ring and a lower end ring are correspondingly arranged on the basepipe; a plurality of shakeout grooves are formed in the lower end ring in the circumferential direction, and the shakeout grooves communicate with the sand passing channel; a sheath is hermetically connected with the lower end of the supporting sleeve, a valve seat is installed at the lower end of the base pipe in a threaded mode, a water control valve is installed on the valve seat, and a liquidflow channel communicating with the filtrate channel is formed between the valve seat and the sheath; and the water control valve comprises a liquid inlet, a rotational flow cavity and a liquid outlethole, and the liquid inlet is streamlined and forms a tangential motion trail with the inner wall of the rotational flow cavity. The self-cleaning capacity and the anti-blocking performance can be improved while oil field effluent is controlled, the water content of an oil field is greatly reduced, the service life of a sand filter pipe is prolonged, and the oil yield and the recovery ratio of anoil well are improved.

Owner:山东普瑞思德石油技术有限公司 +1

Passive type multifunctional well head backflow dredging compensating device

InactiveCN101608536AReduce resistancePrevent reverse accessFluid removalSealing/packingWater storageElectricity

The invention relates to a passive type multifunctional well head backflow dredging compensating device for petroleum industry, mainly comprising a separating backflow assembly and a medicament carrying unit, wherein the separating backflow assembly mainly comprises a well fluid separating unit, a filter, a sand and water storage chamber and a backflow flow rate control unit; the medicament carrying unit mainly comprises a medicament carrier, a medicament can and an air balancing connection pipe, wherein the medicament carrier is respectively communicated with a fluid returning pipe and the medicament can; and after well fluid is separated and filtered by the separating backflow assembly, a part of polluted water enters the medicament carrier through a well fluid backflow pipe column along the fluid returning pipe and is mixed with medicament inside the medicament can by a water power spray principle to flow back to a passage dredging submergence depth air in an oil sleeve ring in the air. The invention reduces the resisting force of the air which upwards flows from submergence depth, prevents the air reversely entering an electric pump, ensures the separating effect of an electric pump separator, prolongs the exemption period of an electric pump well and saves a great amount of operation expense and operation time.

Owner:SHENGLI OILFIELD SANLI GASOLINEEUM TECH DEV

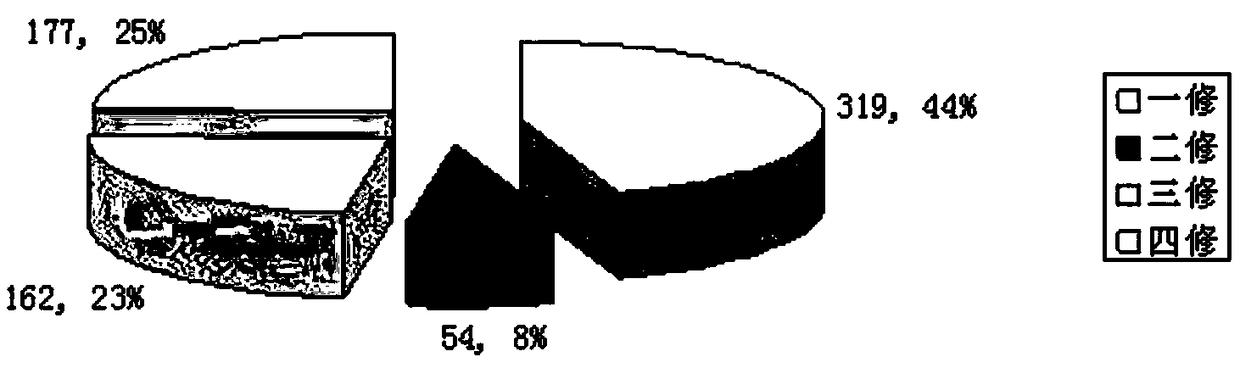

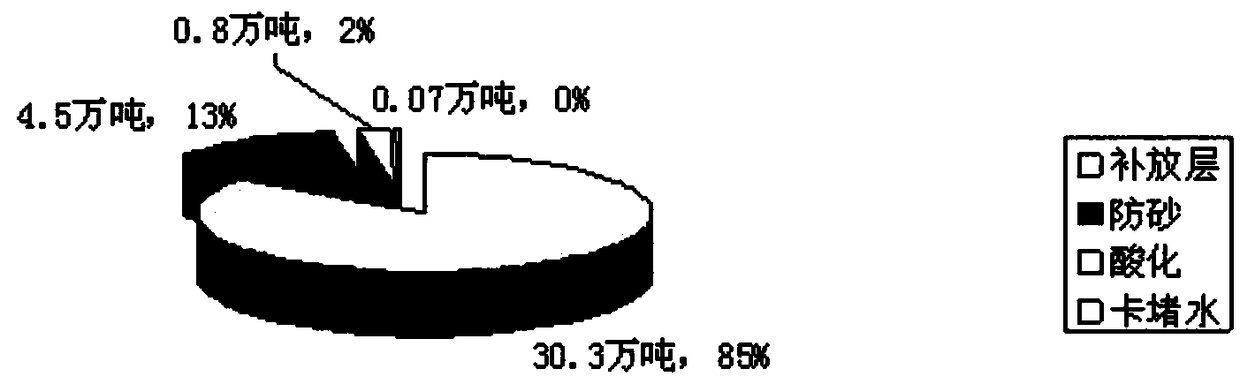

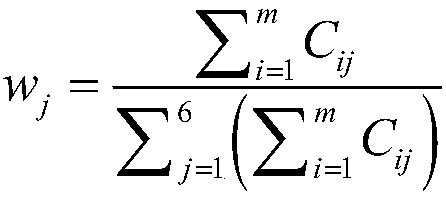

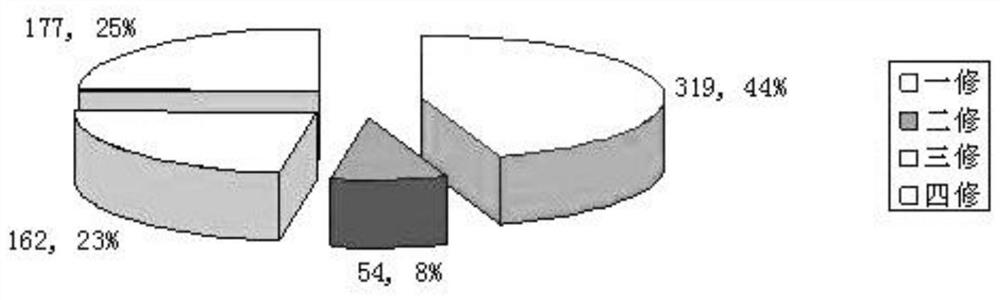

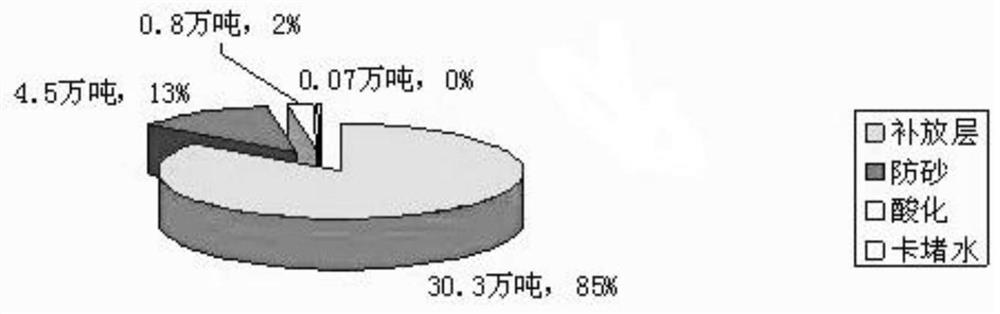

Method for evaluating construction effect of remedial operation in underground workover operation

ActiveCN109083641AExtension of Advanced Standing PeriodImproving the Quality of Workover OperationsDesign optimisation/simulationResourcesOil waterWorkover

The invention discloses a method for evaluating the construction effect of remedial operation in underground workover operation. The method comprises the steps that (a) an evaluating index set U of the remedial operation is determined; an evaluating set V of the operation effect is determined; the weight W of each evaluating index is determined; evaluation matrixes R and Ri are given, wherein R= (R1, R2, R3, R4, R5, R6T), and Ri= (ri1, ri2, ri3, ri4, ri5); a fuzzy evaluation model is established; an evaluating index value B is calculated and normalized; and according to a maximum subordinationprinciple, a comprehensive evaluation result is obtained. The purpose of the invention is to provide a method for evaluating the construction effect of the remedial operation in the underground workover operation to overcome the above defects of an evaluation method of the remedial underground operation in the prior art, improve the workover operation quality, prolong the maintenance-free periodof an oil-water well, timely know and grasp the workover operation effect and influencing factors, improve the quality of the remedial operation, thereby achieving the purpose of trying to avoid unnecessary overhaul and complex operation.

Owner:SOUTHWEST PETROLEUM UNIV

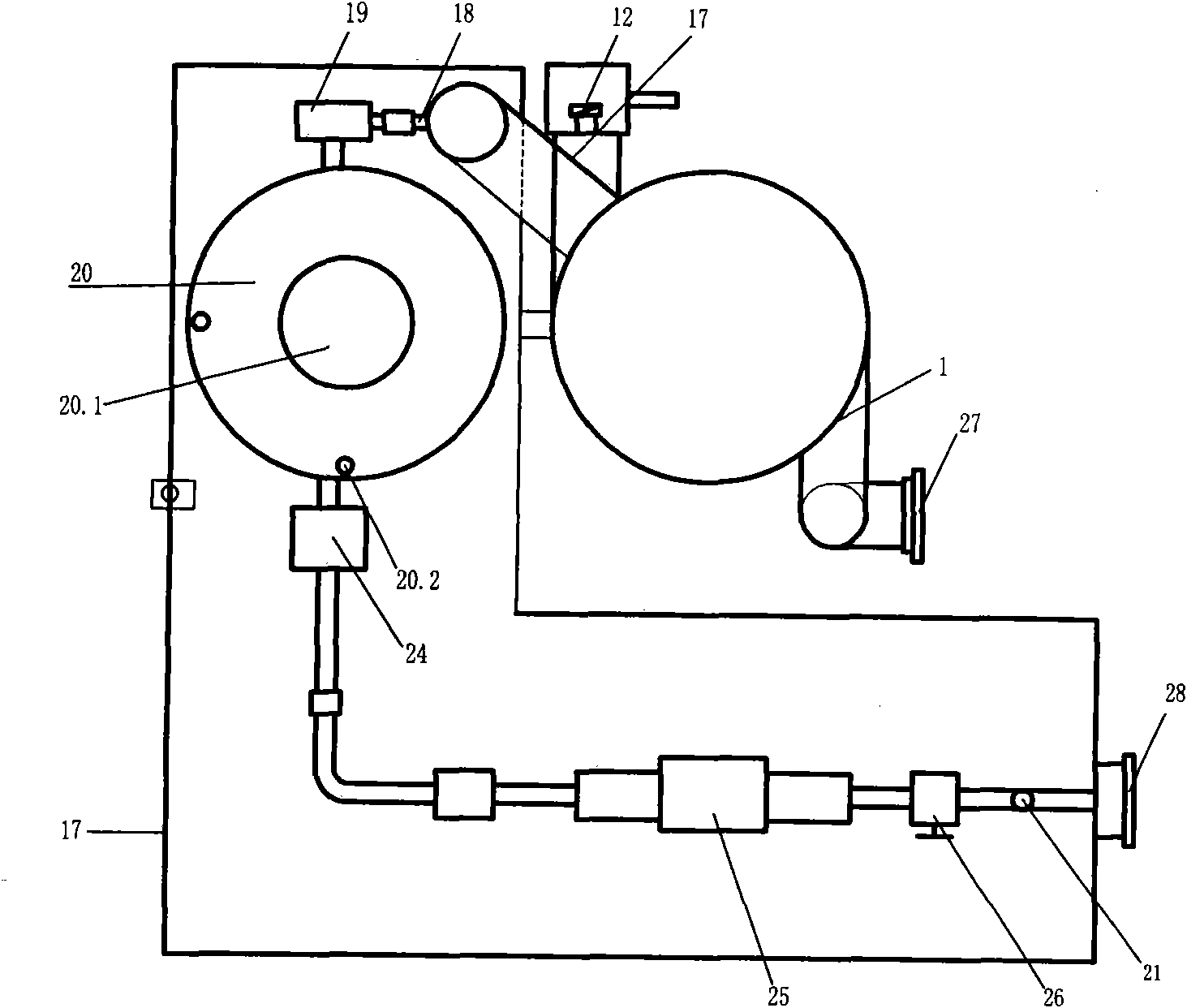

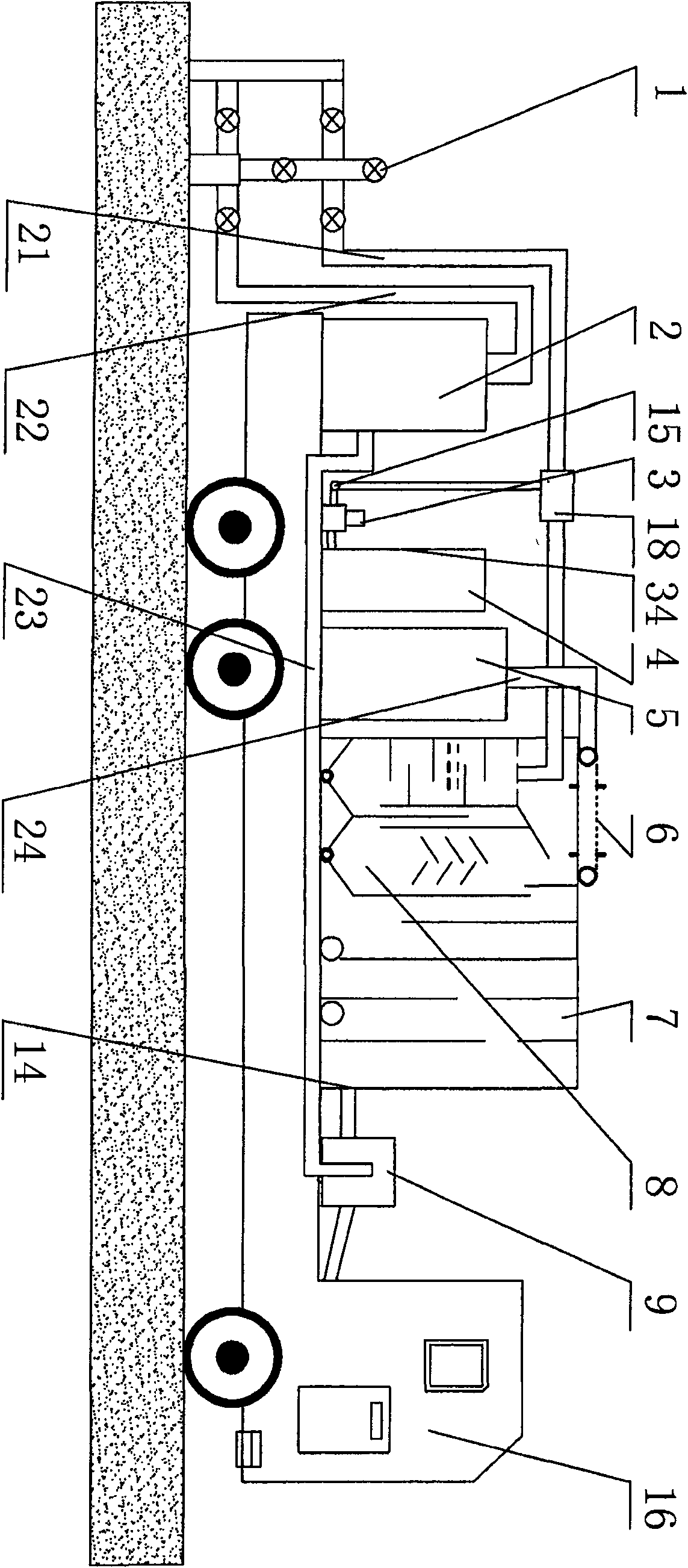

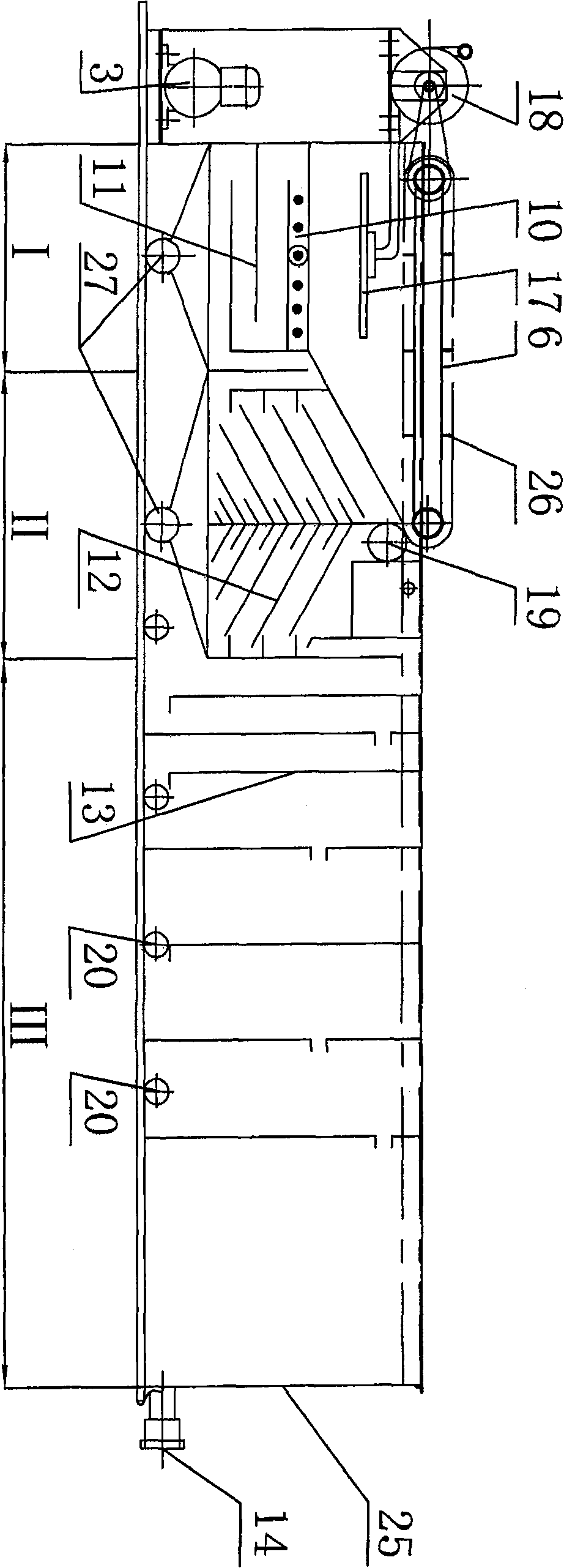

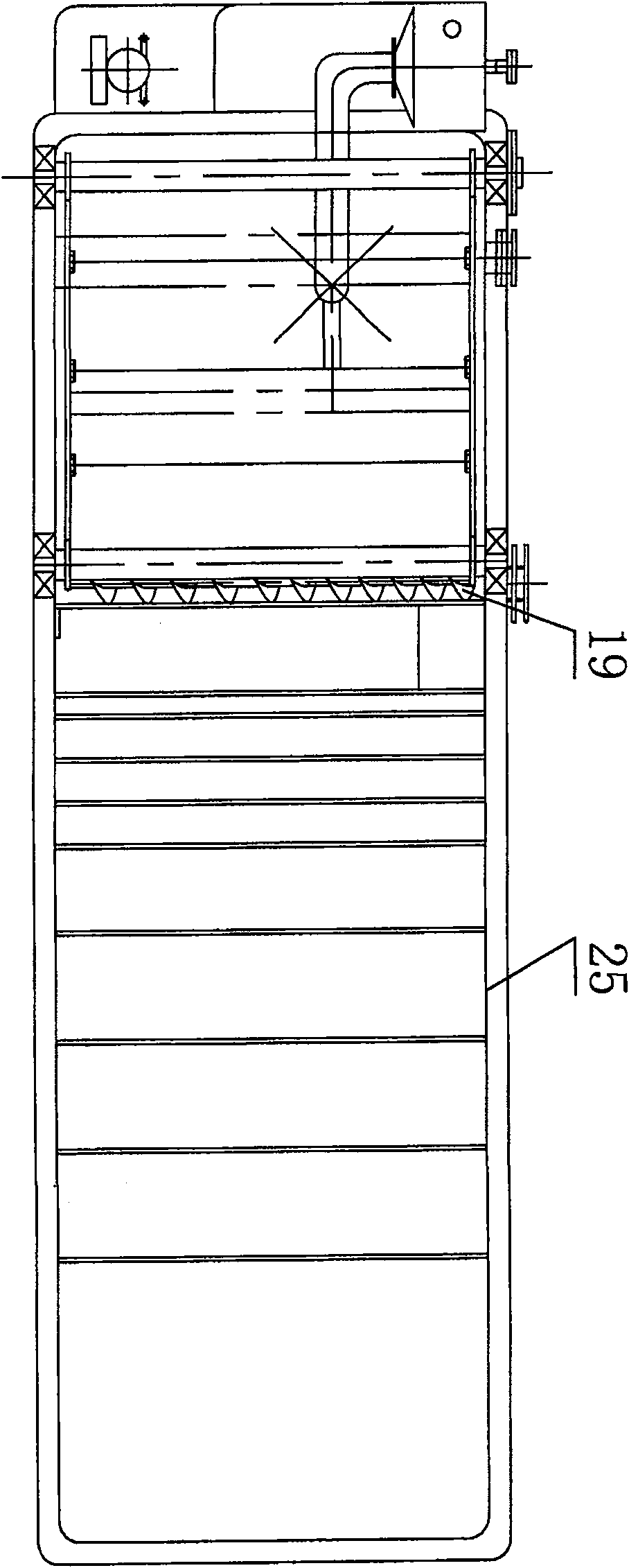

Vehicular flushing liquid closed cycle dirty oil and water treatment system for water injection well

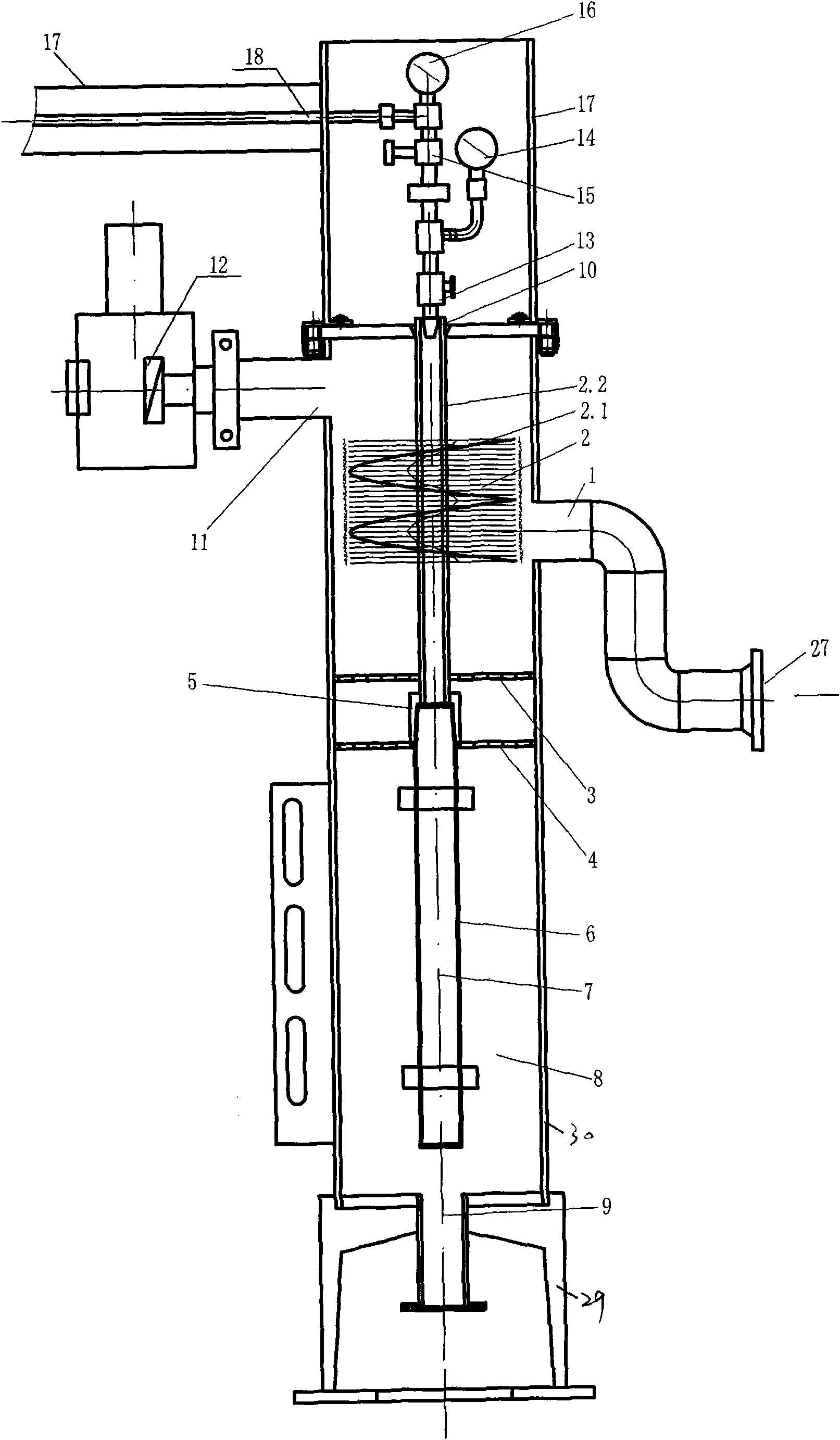

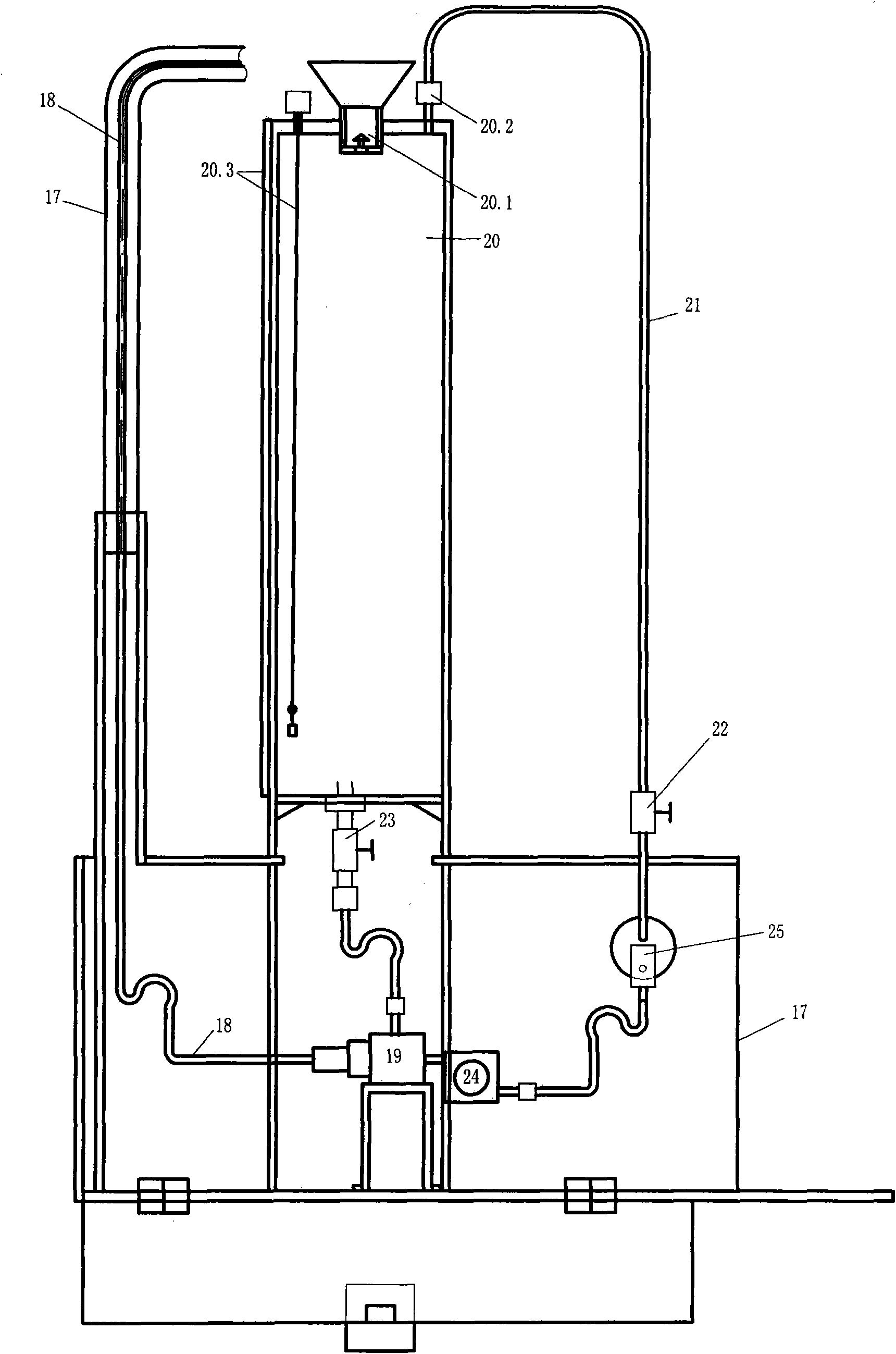

ActiveCN100572295CImprove well cleaning qualityExtension of Advanced Standing PeriodWater/sewage treatment using germicide/oligodynamic-processNon complianceWater turbine

The utility model relates to a vehicle-mounted water injection well flushing fluid closed circuit sewage oil water treatment system, which relates to a treatment system for oilfield water injection well flushing fluid. The invention effectively solves the problems of low working efficiency of the well washing operation of the water injection well, inability to continuously circulate the well washing, and the water quality of the well washing not up to the standard. The well flushing fluid return circulation pipe (21) is connected with the water turbine (18), the outlet of the water turbine (18) is connected with the drip dosing device (34) through the flow divider (15), and the well flushing fluid return circulation pipe (21) is connected with the unpowered oil-water The separator (7) is connected, the dirty oil tank (5) is connected with the unpowered oil-water separator (7) through the sewage pipe (24), and the treatment liquid outlet (14) of the unpowered oil-water separator (7) is connected with the circulation pump (9) connected, the circulation pump (9) communicates with the water inlet (31) of the fine filter device (2) through the well flushing fluid return pipe (23), and the water outlet (33) of the fine filter device (2) communicates with the water injection pipe (22) . The invention has the advantages of convenient operation and water resource saving in the well washing process.

Owner:DAQING OILFIELD CO LTD +1

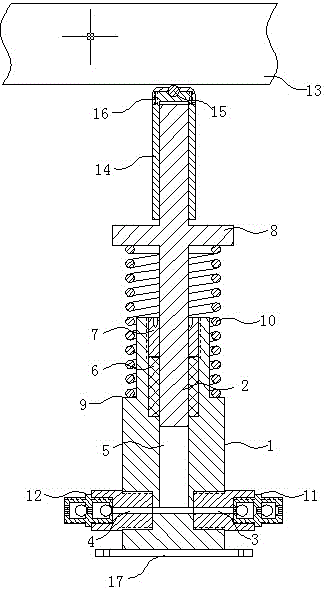

Energy consumption-free liquid charge pump for jack well

ActiveCN103557134AReduce loadExtension of Advanced Standing PeriodFluid removalPumpsRest energyEngineering

The invention relates to liquid charge pumps, in particular to an energy consumption-free liquid charge pump for a jack well. The liquid charge pump is formed by a pump body, a plunger, a liquid inlet and a liquid outlet; the liquid inlet is formed in one side of the lower part of the pump body, and the liquid outlet is formed in the other side of the pump body; one end of the plunger is arranged in the inner cavity of the pump body; the upper part of the inner cavity is fixed by a gland of which the packing is connected to the top of the pump body by a screw port; a platen is fixed at the upper part of the other end of the plunger; a spring is arranged between an annular boss at the upper part of the pump body and the platen; the upper screw port of the liquid inlet is connected with a liquid inlet check valve body, and the screw port of the liquid outlet is connected with a liquid outlet check valve body; the top of the plunger is slidably connected with a walking beam in the jack well. The liquid charge pump is powered and connected by the vertical reciprocation of the walking beam on a pumping unit, certain electric-driven supporting facilities are saved, and the energy consumption-free liquid charge pump has the characteristics that the size is small, the weight is light, the structure is simple, the flow is precisely adjusted by the rest energy of the pumping unit without consuming electric energy in the operation process, the cost is low and the like.

Owner:杨庆祝

Double-sealing packing box for oil field wellhead and wellhead double-sealing method

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

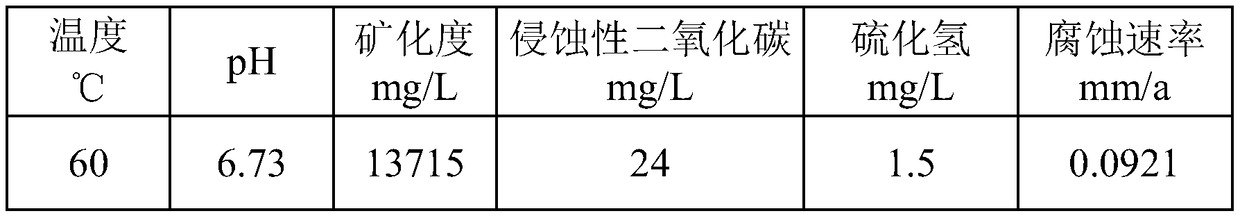

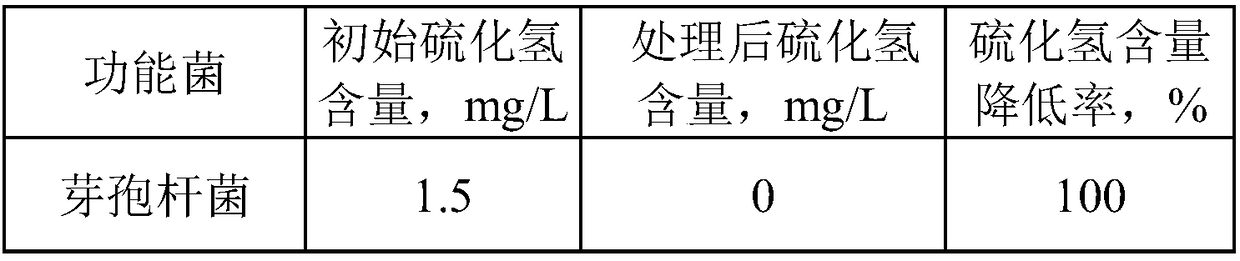

Method for controlling corrosion of acidic produced liquid of oil field

InactiveCN109336260AReduce dosageSolving Corrosion ProblemsWaste water treatment from quariesBiological water/sewage treatmentSludgeWater quality

The invention discloses a method for controlling the corrosion of an acidic produced liquid of an oil field and belongs to the technical field of oil field sludge treatment and corrosion control. Themethod specifically comprises the following steps: analyzing the water quality of the produced liquid; screening the produced liquid; screening desulfurization and corrosion inhibition functional bacteria; determining a modifier; determining a dirt dispersion agent; determining an on-site implementation process; and carrying out on-site implementation and effect evaluation. By combining a biological desulfurization process with a modified process, the corrosion rate of the produced liquid is reduced effectively and the maintenance free period of the oil field is prolonged effectively. The corrosion rate of the produced liquid reaches over 80%, and the maintenance free period of the oil field is prolonged by over 50%. Moreover, the method has the characteristics of being simple in implementation process, high in pertinence and operability and good in on-site test effect, so that the method can be widely applied to treatment of the acidic produced liquid of the oil field.

Owner:CHINA PETROLEUM & CHEM CORP +1

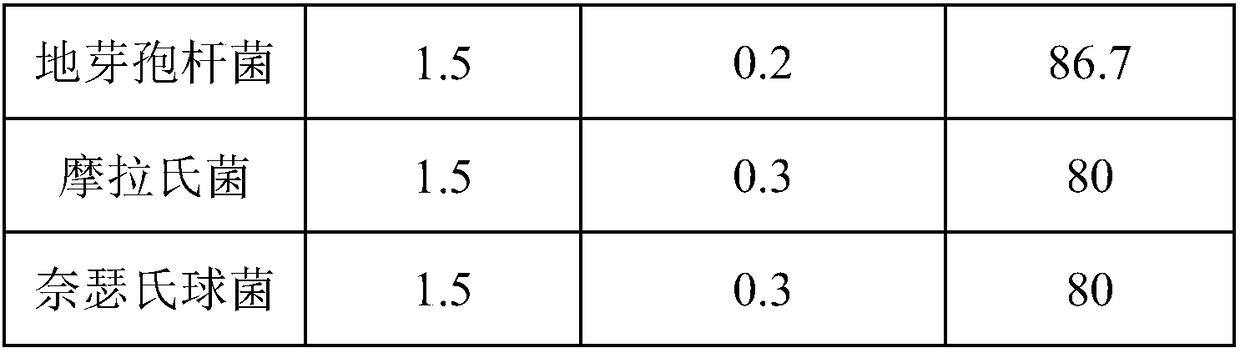

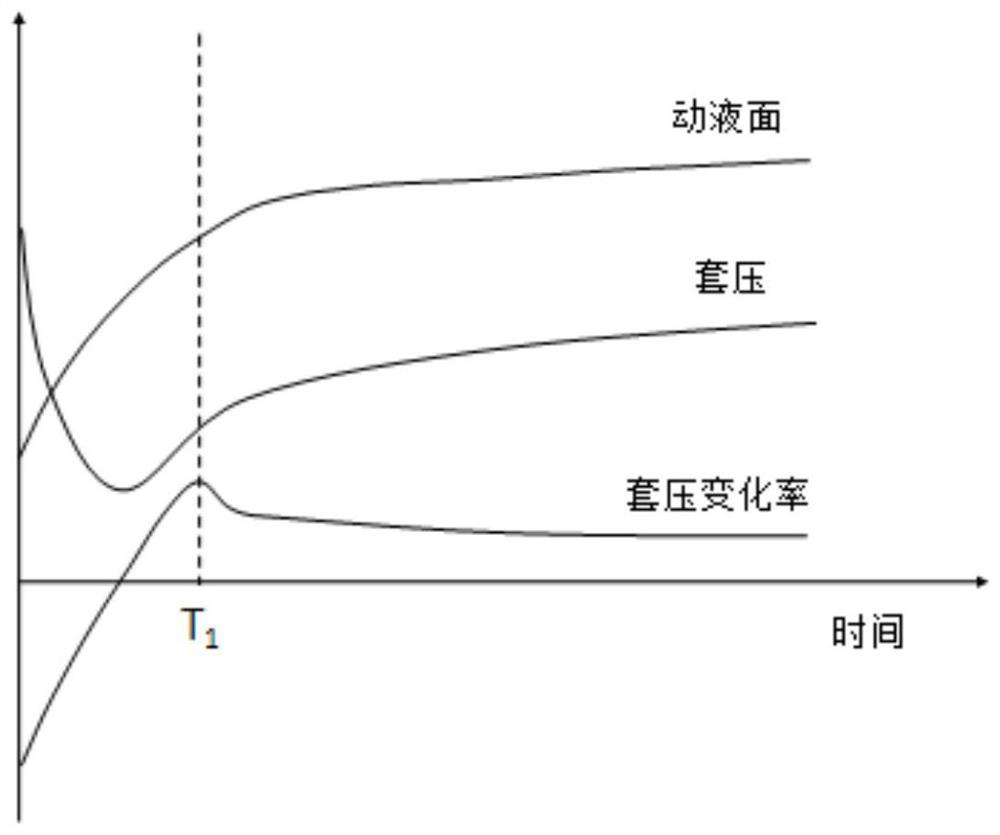

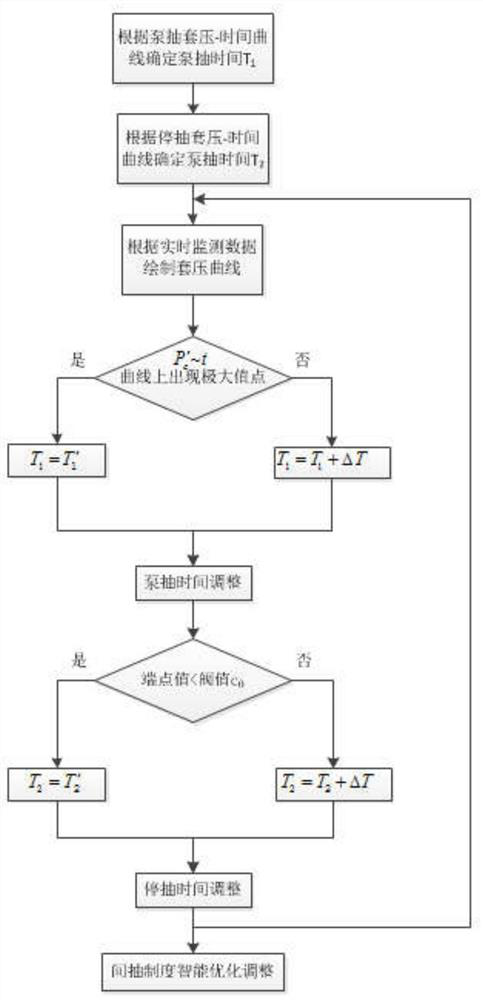

Intelligent interval pumping control method based on casing pressure test analysis

ActiveCN109882137BReasonable yield productionRealize automatic collectionSurveyConstructionsControl engineeringTest analysis

The invention relates to an intelligent intermittent pumping control method based on casing pressure well test analysis. According to the casing pressure-time relationship curve during the pumping period, the casing pressure change rate-time curve is drawn; the pumping time is determined as T 1 ; According to the casing pressure recovery curve during the withdrawal period, draw the casing pressure change rate-time curve; determine the withdrawal stop time as T 2 ; Oil well according to the interval pumping period T 1 +T 2 Run, draw the casing pressure-time relationship curve and casing pressure change rate-time curve during pumping period and stop pumping period respectively; update pumping time and stop pumping time according to the curve. The invention continuously monitors the casing pressure of the oil well, draws the casing pressure-time curve and the casing pressure change rate time curve, analyzes the variation law of the casing pressure and the dynamic liquid level, and determines the reasonable opening time and closing time; According to the production status, real-time optimization and adjustment of the pumping system is carried out to realize the intelligent control of low-yield and low-efficiency wells. While giving full play to the production potential of low-yield wells, the purpose of saving energy and reducing consumption and reducing the loss of pumping units and their equipment is achieved. .

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Anti-clamping oil well pump

InactiveCN107165813AGuarantee normal workAvoid stuck pump failurePositive displacement pump componentsFlexible member pumpsPistonOil well

The invention discloses an anti-clamping oil well pump. The anti-clamping oil well pump comprises an oil pipe, a correcting joint hoop, correcting bodies, a pump barrel, an outer desilting pipe, a casing pipe, an oil rod, a piston, a pump seat and the like. The oil pipe is arranged in the casing pipe. The lower end of the oil pipe is connected with the outer desilting pipe trough the correcting joint hoop. The correcting bodies are arranged in the correcting joint hoop. The lower end of the correcting joint hoop is connected with the upper portion of the pump barrel through the connecting bodies and a fixing ring. The lower end of the pump barrel and the lower end of the outer desilting pipe are connected with a double-wire joint. An inner thread of the lower end of the double-wire joint is connected with the pump seat. The piston and the oil rod are arranged in the pump barrel. The lower end of the outer desilting pipe is connected with an outer thread of the double-wire joint. The pump barrel is connected with an inner thread of the double-wire joint. A piston cap is arranged on the oil rod. The anti-clamping oil well pump has the beneficial effects that scrap iron and sediment are guided into an annular space between the pump barrel and the outer desilting pipe through the piston cap, the normal work of the oil well pump can be guaranteed, the scrap iron and sediment can be collected effectively, the stuck pump fault is avoided, and the service life of the oil well pump is prolonged.

Owner:YANCHANG OIL FIELD

Intelligent synchronous testing and adjusting method capable of simultaneously infusing, testing and regulating

InactiveCN101672179BExtension of Advanced Standing PeriodImprove effective water injection timeSurveyFluid removalWater infusionBridge type

The invention relates to an intelligent synchronous testing and adjusting method capable of simultaneously infusing, testing and regulating, belonging to the field of oil extraction technologies in oil fields. A method of adopted equipment comprises the following steps: (1) a synchronous intelligent testing and adjusting device release part; (2) an intelligent testing and adjusting part; (3) a guiding part; and (4) an eccentric water distribution part. The adopted equipment is characterized in that the intelligent synchronous testing and adjusting method of the whole equipment comprises the following steps: descending into a well: using a steel wire to be suspended to descend into the well; placing the synchronous intelligent testing and adjusting device into a connected technological pipecolumn provided with an eccentric water distributor and a packer; and leading the adjustable blanking plug into an eccentric hole of the eccentric water distributor and releasing the adjustable blanking plug so that the adjustable blanking plug stays in the eccentric water distributor. The invention can realize the unchanged bridge type eccentric whole well working system, directly obtain the single-layer flow, achieve the simultaneous water infusion, testing and adjustment at multiple layers and enhance the work efficiency.

Owner:FUXIN CITY GASOLINEEUM TOOL FACTORY

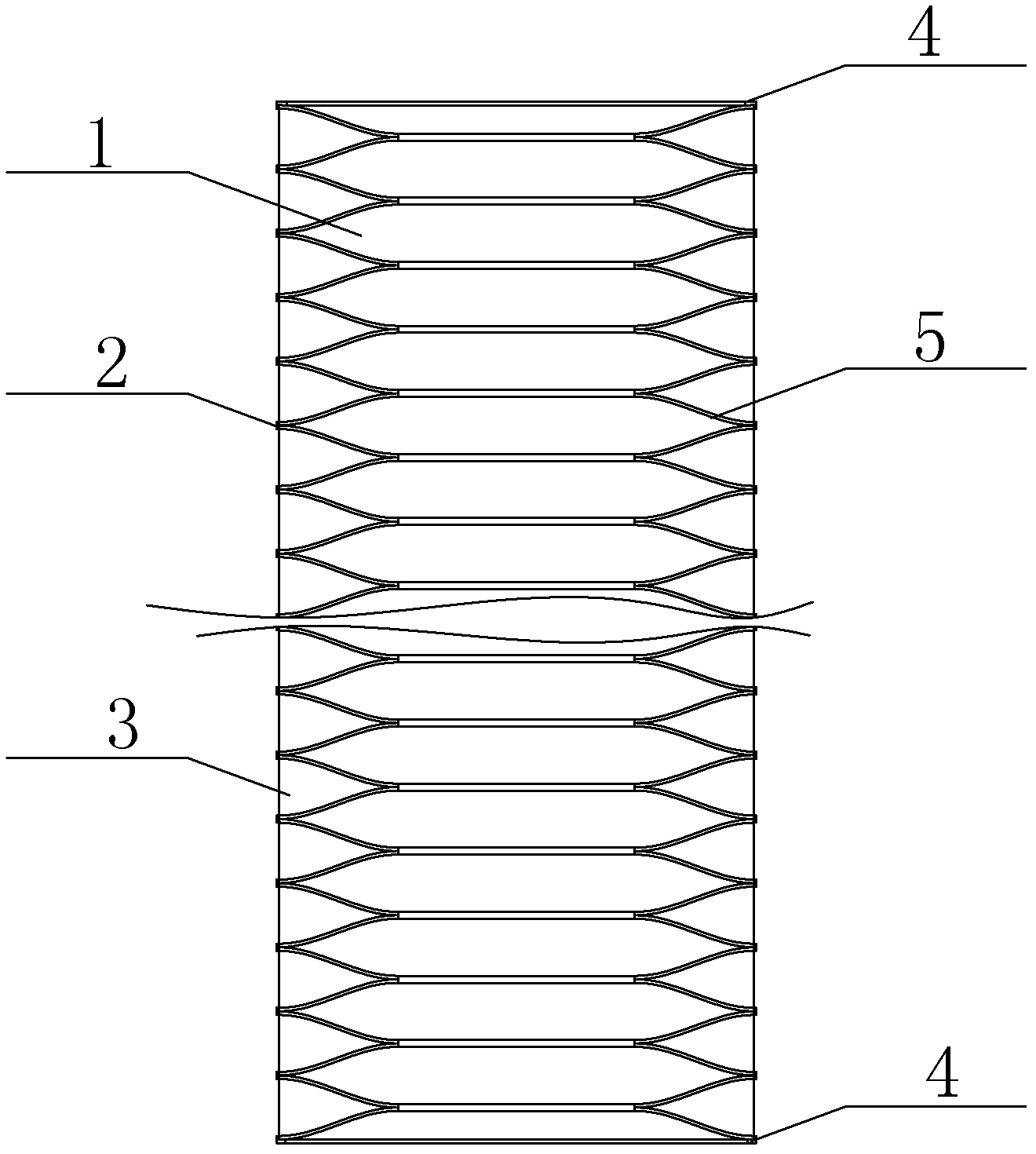

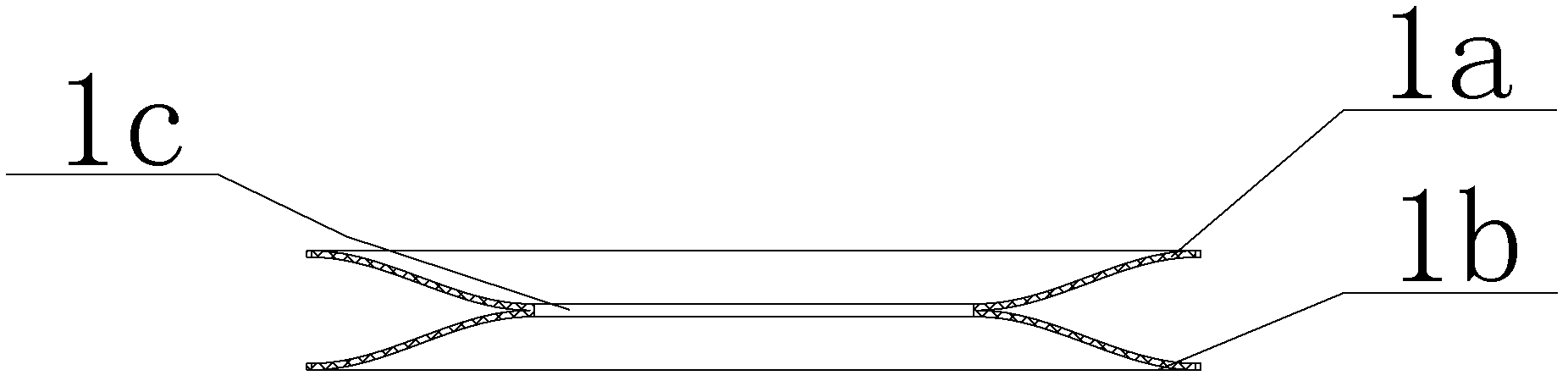

Anti-stuck diaphragm for plunger oil pump and machining method of same

ActiveCN102207079BSmall amount of local deformationLarge amount of deformationPositive displacement pump componentsLiquid fuel engine componentsPull forceWear resistant

The invention relates to an anti-seize diaphragm for a plunger oil pump and a processing method thereof, which is composed of a diaphragm assembly, a wear-resistant connecting ring, a pull wire, a snap ring, etc. It is composed of two double-layer diaphragm units and wear-resistant connecting rings, and the double-layer diaphragm units are connected by wear-resistant connecting rings. The two ends of the diaphragm assembly are snap rings, and the pull wire passes through the wear-resistant connecting rings and snap rings to the diaphragm assembly. connected into a whole. In the present invention, the local deformation is small during the working process of the oil well pump. After each double-layer diaphragm unit returns to elastic deformation, it relies on the pull wire to bear the tension during the continuous stretching movement. The outer peripheral part of the ring is a wear-resistant ring, and the life of the diaphragm is long; the overall deformation of the diaphragm is large, and it can realize normal stretching and contraction. It is suitable for the isolation and sand prevention of the pumping channel at the contact point between the pump barrel and the plunger of various stroke conventional oil well pumps. And can effectively reduce wear and improve pump efficiency.

Owner:SINOPEC OILFIELD EQUIP CORP +1

Scale inhibition antiscaling agent for oil-water well salt prevention and scale-inhibition operation and preparation process thereof

The invention relates to oil-water well salt prevention and scale-inhibition operation in the oil-field development process and a scale-inhibition agent used in a cooling circulation system, in particular to a scale inhibition antiscaling agent for oil-water well salt prevention and scale-inhibition operation and a preparation process thereof; the scale inhibition antiscaling agent is characterized in that: the scale inhibition antiscaling agent at least comprises 1) 2.0-2.5kg of ethanediamine tetramethylene phosphonate; 2) 4.5-5.0kg of polymaleic acid; 3) 4.5-5.0kg of sodium hexametaphosphate; 4) 6.5-7.0kg of triethanolamine; the preparation process of the scale inhibition antiscaling agent for oil-water well salt prevention and scale-inhibition operation is characterized in that: at normal temperature, 4.5-5.0kg of the sodium hexametaphosphate is dissolved by 30-35kg of clear water and is continuously stirred for 20-40 minutes, and then 6.5-7.0kg of the triethanolamine is slowly added in the mixture, after complete mixing, and 2.0-2.5kg of the ethanediamine tetramethylene phosphonate and 4.5-5.0kg of the polymaleic acid are slowly added continuously while stirring is carried out, so as to prepare the scale inhibition antiscaling agent; the scale inhibition antiscaling agent has hypersalinity resistance and high calcium ion resistance, takes alkalescence-neutrality, and has no strong corrosivity to injection-production equipment.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

Borehole fluid lifting device and method

PendingCN111287714AAvoid safety accidents caused by overturningAvoid corrosion and wear phenomenaFluid removalWell/borehole valve arrangementsGear pumpInlet valve

The invention discloses a borehole fluid lifting device and method. Two tubular column inlet channels are arranged for stratum output liquid, one channel is that when a lower bag shrinks, borehole fluid enters a production tubular column through a lower tubular column liquid inlet valve; when the lower bag is increased, the borehole fluid enters an airtight annular space formed by closely connecting an upper short section, an upper tubular column liquid inlet valve and the lower tubular column liquid inlet valve through a lower liquid discharging valve, and then the borehole fluid enters the tubular column through a tubular column liquid inlet. The other channel is that when an upper bag shrinks, the borehole fluid enters the upper tubular column liquid inlet valve, and then enters an upper bag short section along an upper tubular liquid inlet channel; and when the upper bag is increased, output liquid is squeezed to the upper tubular column by an upper liquid discharging valve. The borehole fluid is only in touch with the outer surface of a bag, the exterior of a motor, the exterior of a gear pump and the like during application, cannot enter important movement parts such as the gear pump, and thus the influence of oil well corrosion and sand production on liquid yield equipment is thoroughly avoided.

Owner:CHINA PETROLEUM & CHEM CORP +1

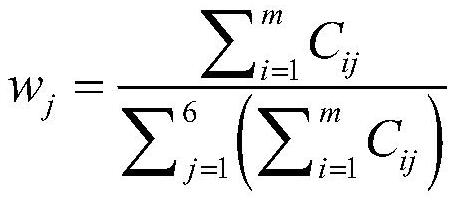

A Method for Evaluating Construction Effect of Measure Operation in Downhole Workover Operation

ActiveCN109083641BExtension of Advanced Standing PeriodImproving the Quality of Workover OperationsDesign optimisation/simulationResourcesEvaluation resultWater well

The invention discloses a method for evaluating construction effects of measure operations in downhole workover operations: (a) determining the evaluation index set U of measure operations; determining the evaluation set V of operation effects; determining the weight W of each evaluation index; giving the evaluation Matrix R=(R 1 , R 2 , R 3 , R 4 , R 5 , R 6 T ), R i =(r i1 ,r i2 ,r i3 ,r i4 ,r i5 ); establish a fuzzy evaluation model; calculate the evaluation index value B and normalize it; obtain the comprehensive evaluation result according to the principle of maximum membership. The purpose of the present invention is to provide a method for evaluating the construction effect of measure operations in downhole workover operations, so as to solve the above-mentioned defects in the evaluation methods for measure downhole operations in the prior art, improve the quality of workover operations, and prolong the maintenance-free period of oil and water wells. In order to keep abreast of the effects of workover operations and their influencing factors in a timely manner, the purpose of improving the quality of workover operations is to avoid unnecessary overhaul and complex operations as much as possible.

Owner:SOUTHWEST PETROLEUM UNIV

Pumping well anti-eccentric device based on ball face abrasion-proof body

InactiveCN104712262AAvoid wear and tearExtended service lifeDrilling rodsDrilling casingsStructural engineeringMechanical engineering

The invention relates to a pumping well anti-eccentric device based on a ball face abrasion-proof body. During a site using process of a sucker rod anti-eccentric device, anti-eccentric effect is not obvious, and accordingly a sucker rod and an oil pipe are damaged and fall off. The pumping well anti-eccentric device is provided with a center rod. The cylindrical abrasion-proof body is arranged on the center rod in a sleeved mode. A plurality of sphere grooves are evenly formed in the outer wall of the abrasion-proof body. Sphere balls are embedded into the sphere grooves. Small part ball crowns of the balls are placed out of the sphere grooves. Upper limiting rings and lower limiting rings which are fixed on the center rod are arranged on the center rod and on the upper side and the lower side of the abrasion-proof body. Gaps exist between the upper limiting rings, the lower limiting rings and the abrasion-proof body. The pumping well anti-eccentric device based on a ball face abrasion-proof body is long in wear-resistant time, direct contact of the sucker rod and the oil pipe is avoided, so that abrasion is avoided, the service life of the sucker rod and the oil pipe is prolonged, and oil well normal production is kept.

Owner:XIAN XIDIAN SOFTWARE

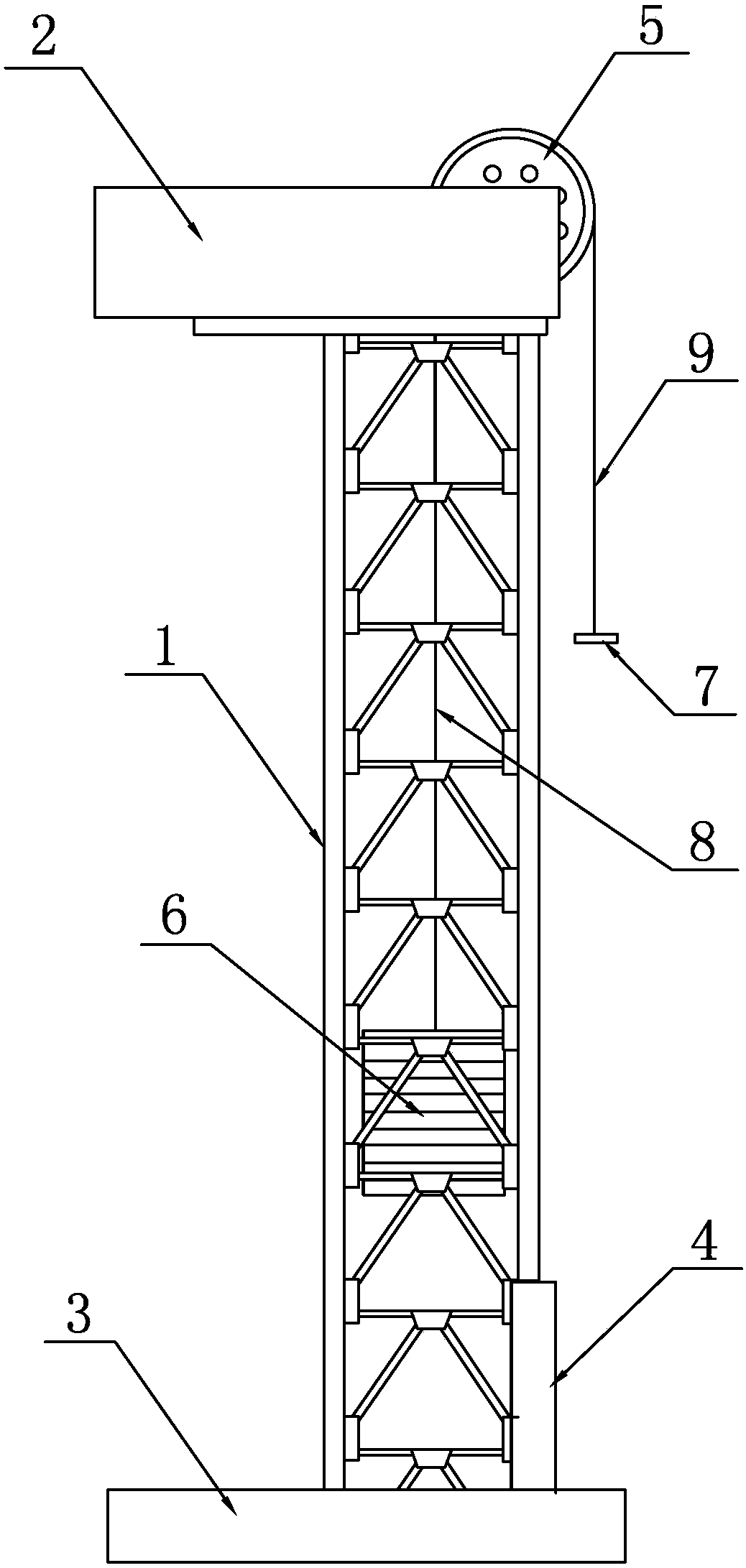

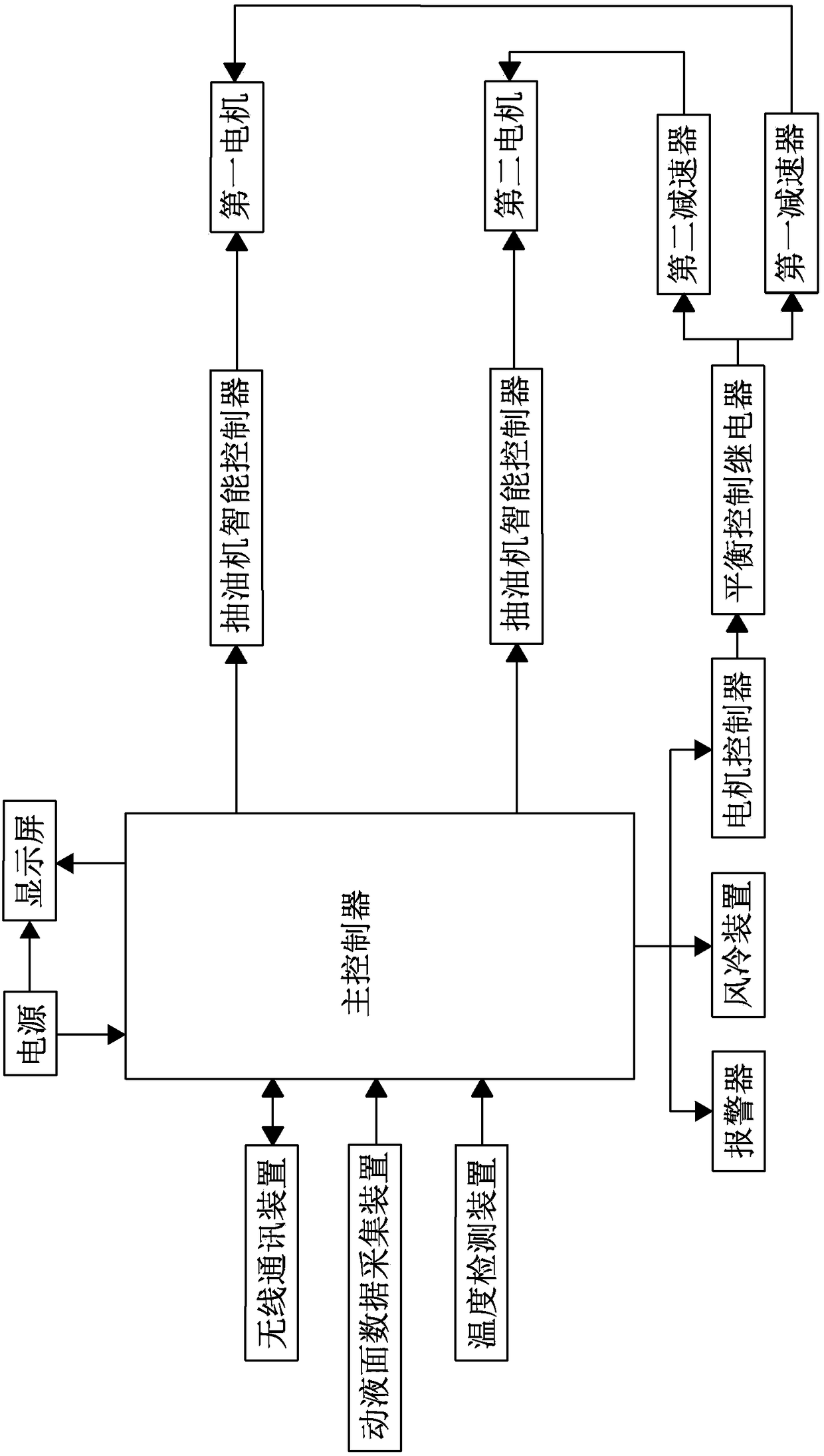

Intelligent control system of pumping unit and its intelligent control method for pumping

ActiveCN105863572BImprove stabilityGuaranteed stabilityFluid removalMotor controllerMaster controller

The invention relates to an intelligent control system of a pumping unit and an intelligent oil pumping control method of the intelligent control system. The aim that the intelligent control system of the pumping unit and the intelligent oil pumping control method of the intelligent control system are low in energy consumption, high in intelligent degree and high in work efficiency is achieved. The intelligent control system comprises a tower, an operating platform and a transmission device. The operating platform is arranged at the top end of the tower, the transmission device is arranged on the operating platform, the transmission device is overall arranged at the top end of the operating platform in a triangular structure, and a weight is clamped in the middle of the operating platform. A control cabinet is arranged at the bottom end of the tower, a master controller, a wireless communication device and a motor controller are arranged in the control cabinet, the work process of the pumping unit is controlled through the master controller, and the master controller is connected with a wireless network through the wireless communication device. In the work process, the output power of a motor in each stroke process is monitored, and if the output power of the motor is reduced, the speed of the motor is reduced, and the stroke frequency is reduced; if the output power of the motor rises, the speed of the motor is increased, and the stroke frequency is increased.

Owner:北京高和华泰节能环保科技有限公司 +1

Multi-joint universal sealing device for wellhead of oil well

InactiveCN111594086AReduce eccentric wearReduce manufacturing costDrilling rodsSealing/packingRubber ringOil well

The invention discloses a multi-joint universal sealing device for a wellhead of an oil well. The multi-joint universal sealing device for the wellhead of the oil well is mounted in the vertical direction and comprises an oil sealing component at the top and a strengthening component at the bottom; an outer protective sleeve is connected between the oil sealing component and the bottom strengthening component; and a first spherical component and a second spherical component are mounted in the outer protective sleeve. Eccentric wear of a polished rod is lightened by utilizing the parts, such asa strengthening rubber ring, a strengthening rubber ring box and a strengthening rubber ring pressing sleeve; the increase of the oil well maintenance operation and the production cost caused by theeccentric wear of the polished rod of the wellhead is reduced; the production cost is reduced; and the maintenance free period of the oil well is prolonged.

Owner:延长油田股份有限公司定边采油厂

Gas-liquid separation device and separation method for electric submersible pump

ActiveCN108317091BReduce energy consumptionSolve the free gas contentPump componentsFluid removalEngineeringFishing

The invention discloses a gas-liquid separation device and a separation method for a submersible electric pump, wherein the gas-liquid separation device comprises a separator main body, a slip, a fishing mechanism and a gas collecting mechanism, wherein the separator main body comprises a mandrel, a conical seat and a central pipe from top to bottom. The central tube is further provided with blades, a spiral channel extending spirally in the vertical direction is formed between the blades and the outer wall surface of the central tube, and the central tube is provided with a constant diameterportion and a gradual contractile portion connected with the lower end of the constant diameter portion. The cross-sectional area of the constant diameter portion is constant, and the cross-sectionalarea of the gradual contractile portion gradually decreases from top to bottom. The slip can fit with the conical seat, the mandrel is sleeved with the fishing mechanism, and a diversion channel whichis in communication with the spiral channel is arranged between the fishing mechanism and the mandrel. A collecting opening of the gas collecting mechanism is adjacent to the upper portion of the mandrel, and is isolated from an inlet of the submersible electric pump. The gas-liquid separation device and the separation method for the submersible electric pump have better performance.

Owner:PETROCHINA CO LTD

Pumping well anti-eccentric wear device with spherical wearproof body

InactiveCN104712264AAvoid wear and tearExtended service lifeDrilling rodsDrilling casingsEngineeringMechanical engineering

The invention relates to a pumping well anti-eccentric wear device with a spherical wearproof body. In the field use process of a pumping rod anti-eccentric wear device, the anti-eccentric wear effect is not obvious, and a pumping rod and an oil pipe are prone to being damaged and broken off. The device is provided with a center rod, and the center rod is sleeved with the spherical wearproof body; an upper limiting ring and a lower limiting ring which are fixed on the center rod are arranged at the upper side and the lower side of the wearproof body on the center rod respectively, and gaps exist between the upper limiting ring and the wearproof body and between the lower limiting ring and the wearproof body. The pumping well anti-eccentric wear device with the spherical wearproof body is long in wearproof time, and capable of preventing the pumping rod and the oil pipe from directly making contact to generate wear, prolonging the service life of the pumping rod and the oil pipe and maintaining the normal production of a pumping well.

Owner:XIAN XIDIAN SOFTWARE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com