Multi-joint universal sealing device for wellhead of oil well

A sealer, oil well technology, applied in sealing/isolation, wellbore/well components, drilling equipment, etc., can solve the problem of frequent replacement of sealing rings, achieve unaffected sealing effect, avoid oil well polished rod breaking, reduce Effects of replacement and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

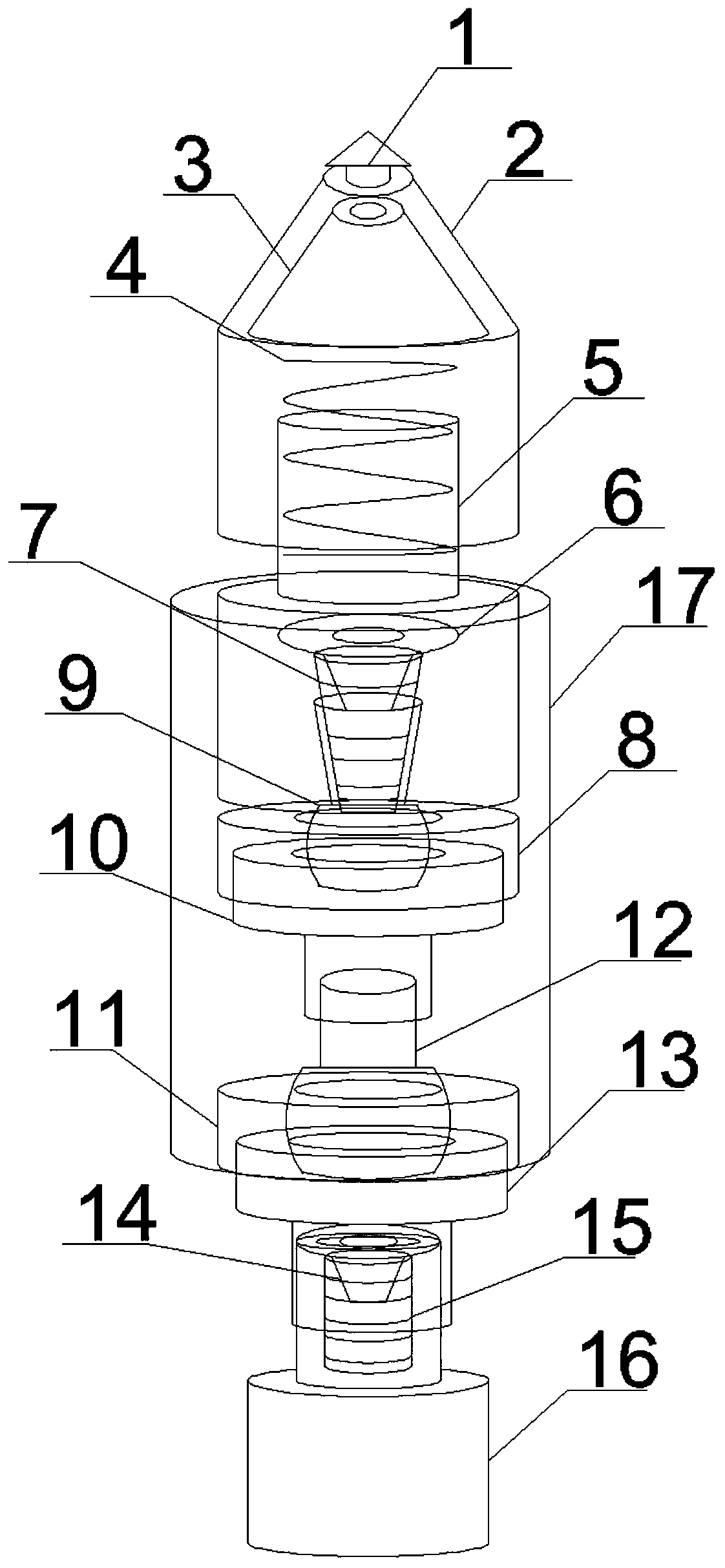

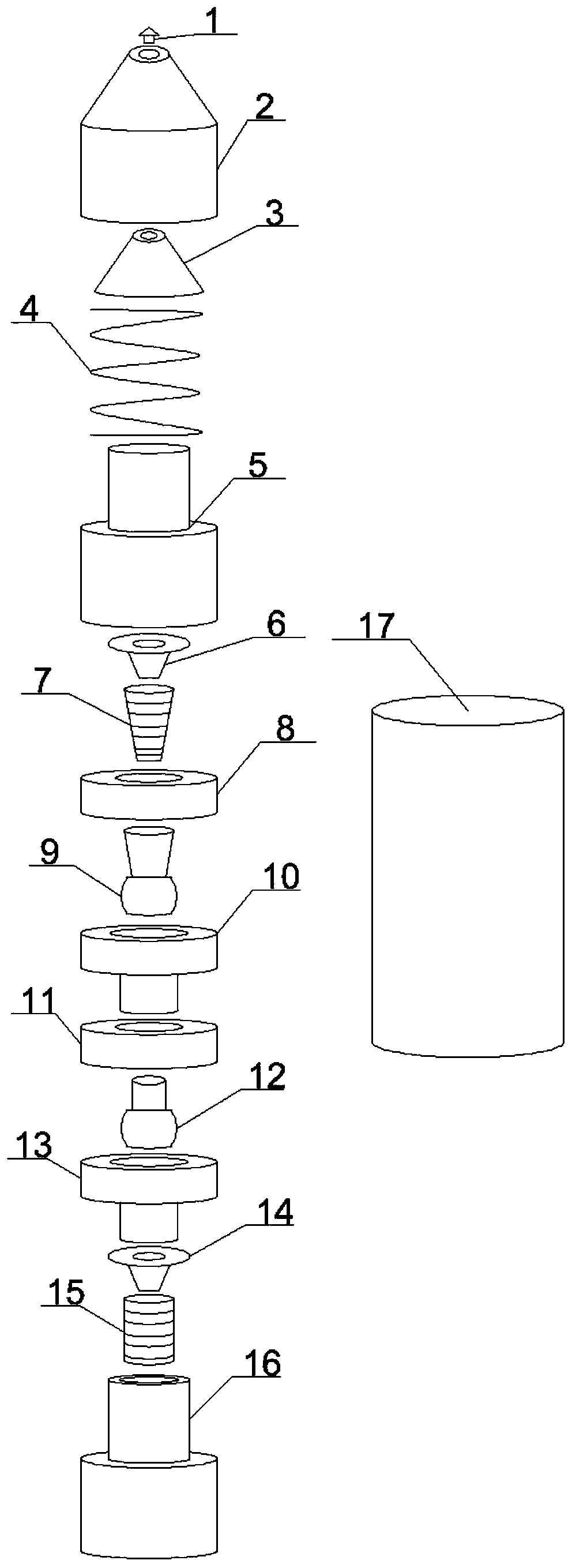

[0019] The multi-section universal sealer at the wellhead of the oil well of the present invention, such as Figure 1-2 As shown, it includes installation in the vertical direction, including the oil seal assembly at the top and the centralization assembly at the bottom; an outer protective sleeve 17 is connected between the oil seal assembly and the centralization assembly at the bottom; a first ball is installed inside the outer protective sleeve 17 component and the second ball component.

[0020] The oil seal assembly includes the top grease nipple 1, the bottom of the grease nipple 1 is connected to the tapered grease chamber wire cover 2, and the grease chamber sealing rubber ring 3 is arranged between the grease nipple 1 and the tapered grease chamber wire cover 2; the tapered grease chamber wire cover 2 Bottom connection seal assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com