Anti-clamping oil well pump

An oil pump and anti-seize technology, which is applied in the direction of pumps, pump components, variable capacity pump components, etc., can solve the problems of unusable percussion oil drains, environmental pollution, hidden safety hazards, etc., to extend the repair-free period of oil wells and avoid The effect of stuck pump failure and guaranteeing normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

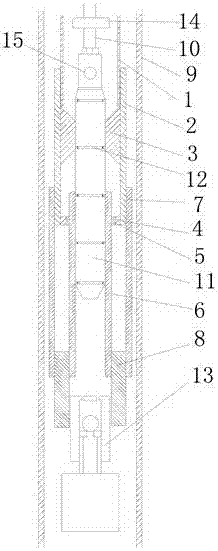

[0017] Embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings.

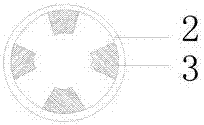

[0018] Depend on figure 1 An anti-seize oil well pump shown in —3 includes an oil pipe 1 arranged in the casing 9, an outer dust pipe 7 connected by a centralizing joint 2 and a piston cap 14 installed on the oil rod 10. The piston cap can be used Made of metal materials or plastics and rubber, four centralizers 3 are arranged in the centralizer hoop 2 connected to the lower part of the oil pipe 1, and its function is to center the piston 11 while ensuring that iron filings and sediments can be discharged smoothly. Through; the lower end of the righting section hoop 2 is provided with four connecting bodies 4, which are used to connect the fixed ring 5. The function of the fixed ring 5 is to fix the pump barrel 6 and prevent it from swinging wantonly under the action of the pressure difference, but it does not require sealing; 4. A connecting body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com