Ultra long stroke beam-pumping unit

A technology of ultra-long stroke and pumping unit, which is applied in the direction of production fluid, wellbore/well parts, earthwork drilling and production, etc. It can solve the problems of increasing oil production stroke, etc., and achieve the effect of reducing invalid stroke, saving steel, and maintaining safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

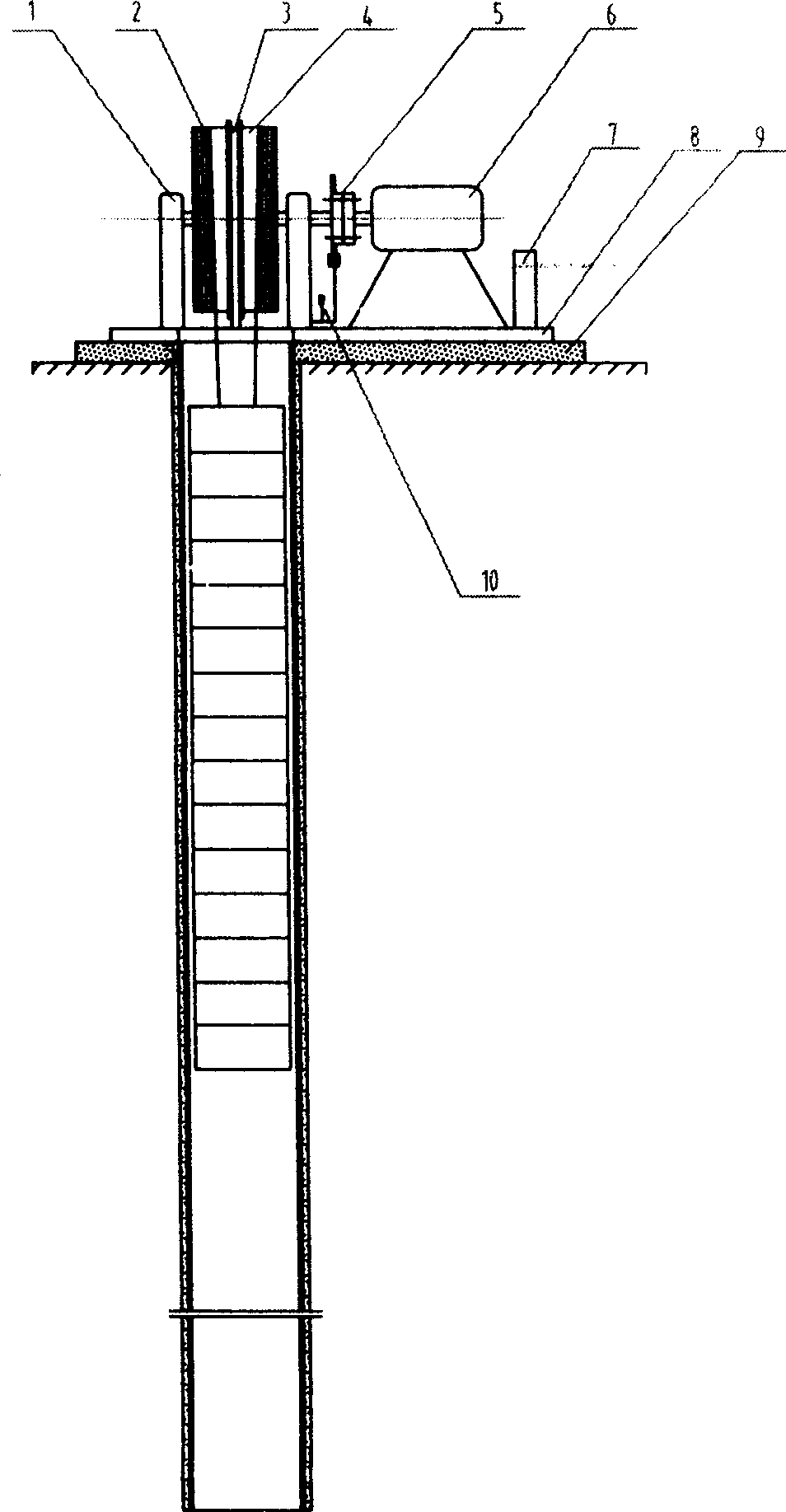

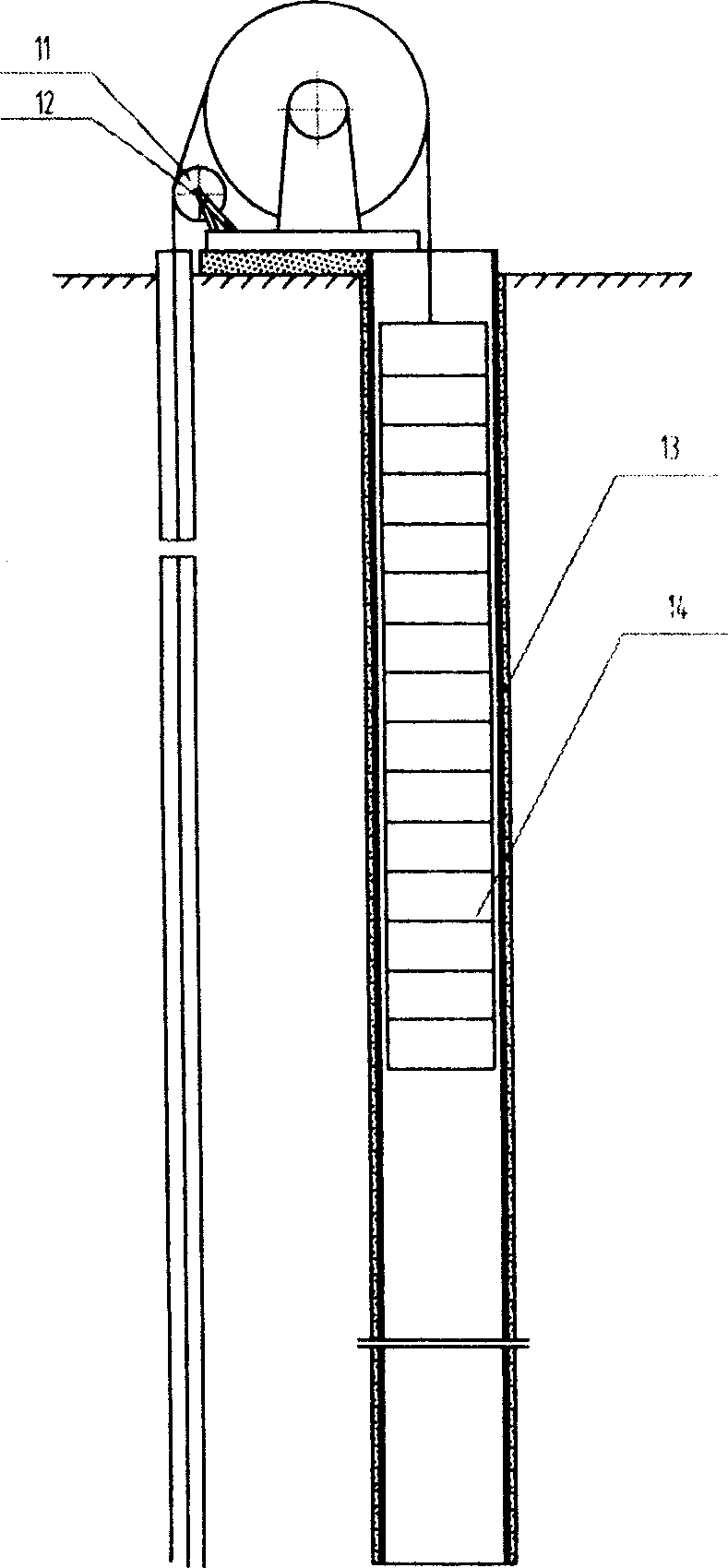

[0017] It can be seen from the figure that the two ends of the electric drum 4 are supported by the support 1, installed on the ground on the base 8 and connected with the motor installed on the base 8 through the coupling 5, and one end of the flexible sucker rod traction member 3 is fixed and wound on the electric drum 4. In the middle of the barrel, the other end is connected with the continuous sucker rod in the pumping well. One end of the counterweight traction member 2 is fixedly wound around the two ends of the barrel of the electric drum 4, and the other end is connected with the counterweight shaft 13 placed underground. The counterweight 14 links to each other, and the counterweight shaft 13 wellheads can be flush with the foundation 9 above the ground, and the counterweight shaft wall is formed by going into the forming pipe or steel pipe in the open hole and cementing with cement periphery. The expansion wheel 11 is supported and installed on the base by the expans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com