Efficient elastic filter screen vibration separation device and application method

A separation device and filter screen technology, applied in the direction of earthwork drilling, mining fluid, wellbore/well components, etc., can solve the problem of reducing the filter area of the sand control filter, increasing the suction force of the sand control filter, losing the filtering effect of the filter, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

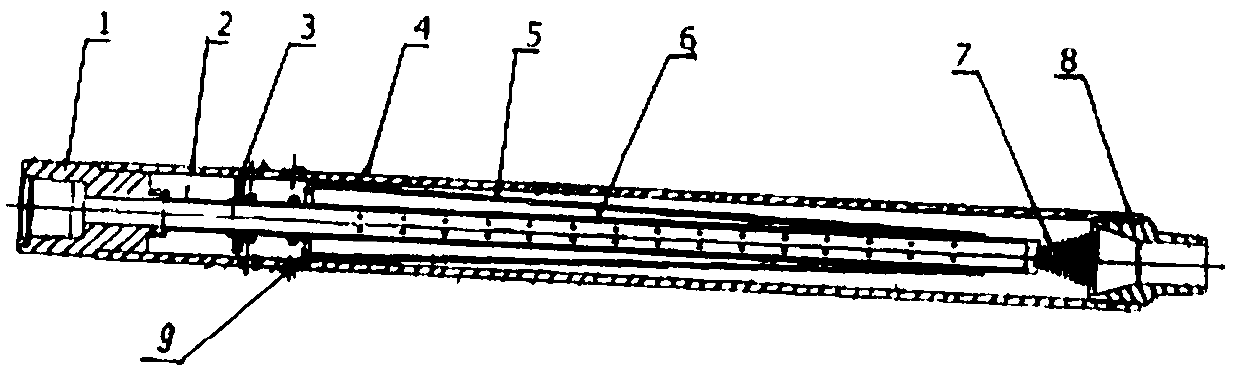

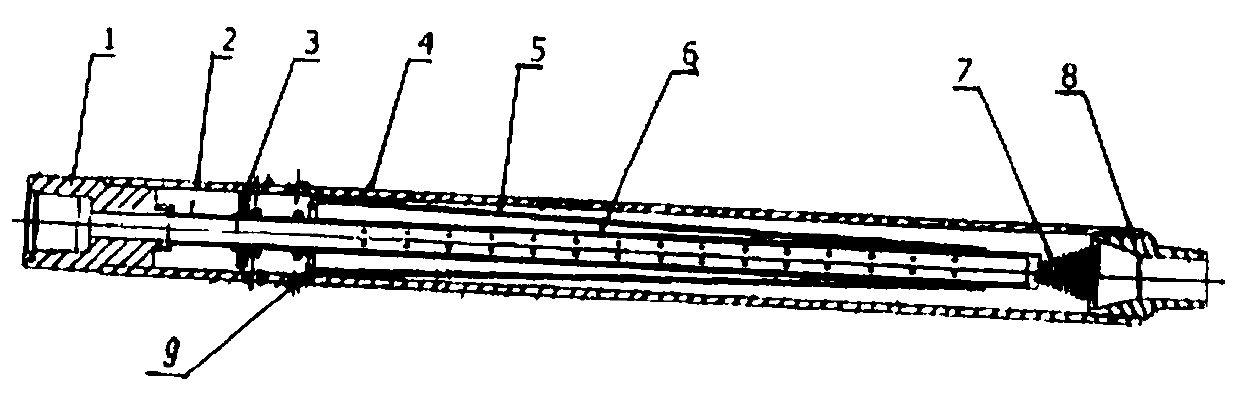

[0015] Embodiment 1. The present invention includes an upper joint 1, a bellows 2, a righting vibration spring 3, an outer tube 4, a conical sand control filter 5, an inner tube 6, a conical vibration spring 7, and a lower joint 8. The upper joint 1 , lower joints 8 are respectively installed at the two ends of the outer pipe 4; the inner pipe 6 is located in the middle of the outer pipe 4, the lower end of the inner pipe 6 is connected to the conical vibrating spring 7, and the outer edge of the inner pipe 6 is covered with a conical sand control Filter screen 5 ; the lower end of the righting vibration spring 3 is connected with the inner pipe 6 , the upper end is connected with the bellows 2 , and the upper end of the bellows 2 is connected with the upper joint 1 .

Embodiment 2

[0016] Embodiment 2, the conical sand control filter screen 5 is conical, the conical caliber is large and the bottom is small, the taper is 10 degrees, the aperture of the conical sand control filter screen 5 is 180 mesh, and the top of the conical sand control filter screen 5 is connected On the upper end of the inner pipe, the top outer wall of its conical sand control filter screen 5 and the outer pipe 4 inwall gaps are 5mm, and the bottom end of the conical sand control screen 5 is connected to the lower end of the inner pipe.

Embodiment 3

[0017] Embodiment 3. The vibrating spring 7 is conical, the upper part is smaller and the lower part is larger, and the bottom end of the vibrating spring 7 is fixed on the lower joint 8 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com