Cross-flow filter device and filter assembly for cross-flow filter device

A technology for cross-flow filtration and filter components, which is applied in the fields of filtration and separation, fixed filter element filters, chemical instruments and methods, etc., can solve the problems of poor sealing reliability, inability to accurately determine the leaking parts of filter components, and low sealing reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

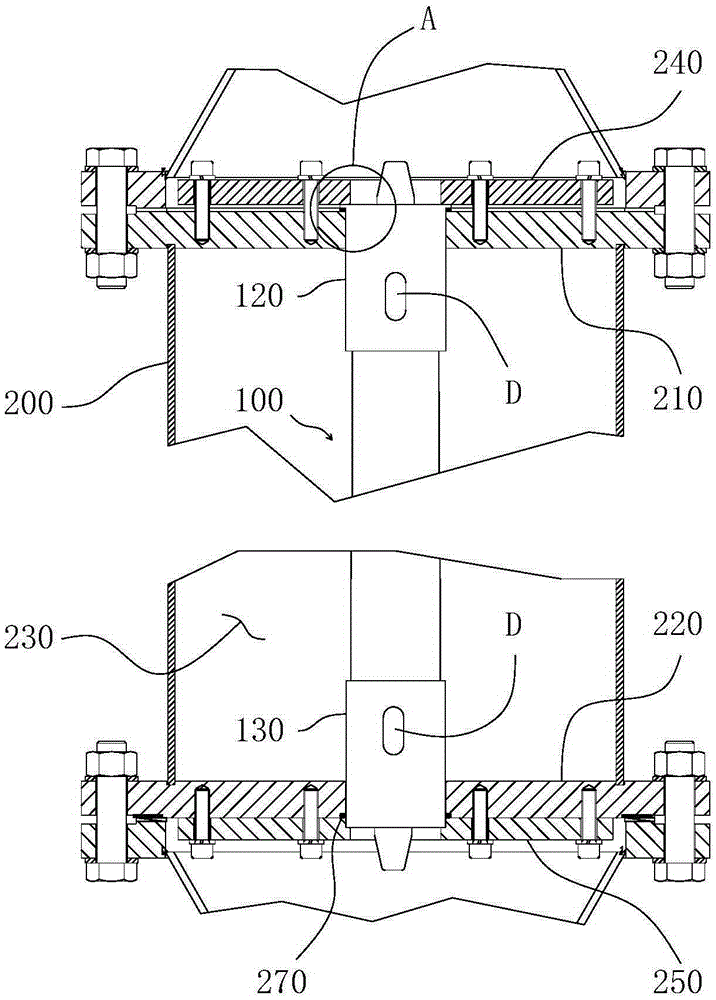

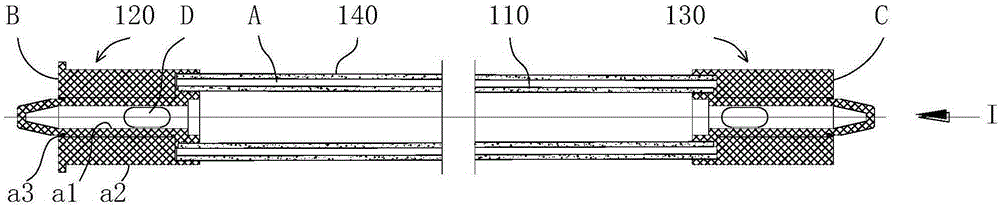

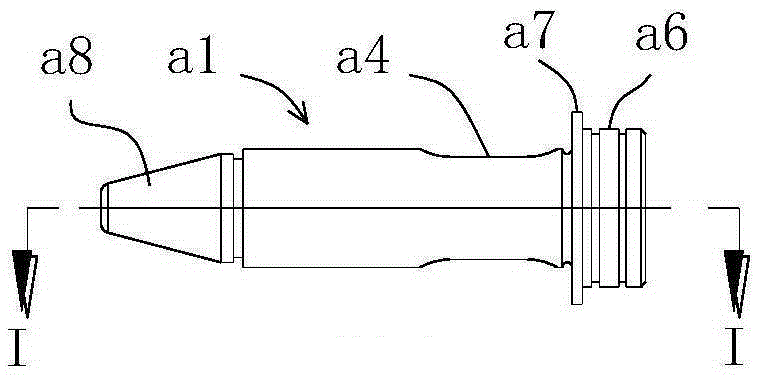

[0020] Such as Figure 2-7 As shown, the filter assembly includes an inner filter tube 110 and an outer filter tube 140 that is sleeved on the outside of the inner filter tube 110 and maintains a relative position with the inner filter tube 110 through an upper end joint 120 and a lower end joint 130. The channel A to be filtered is formed between the inner tube walls of the outer filter tube 140, the upper joint 120 is provided with an unfiltered output channel B which is connected to one end of the channel A to be filtered, and the lower joint 130 is provided with a The other end of the filter channel A is connected to the input channel C to be filtered. The upper joint 120 and the lower joint 130 are respectively provided with the inner filter tube 110 lumen and are used to export the filtered matter in the lumen to the inner filter tube 110. The filtered material output channel D of the filter assembly, the upper end joint 120 and the lower end joint 130 respectively have ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com