Downhole gas slow-release device

A slow-release device and gas technology, which is applied in the field of automatic control of oil well casing gas pressure release, can solve the problems of unfavorable stable production of oil wells, inconvenient production management, and sand production in formations, so as to avoid excessive drop of bottom-hole flow pressure and ensure Normal production and elimination of the effect of fluid level drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings.

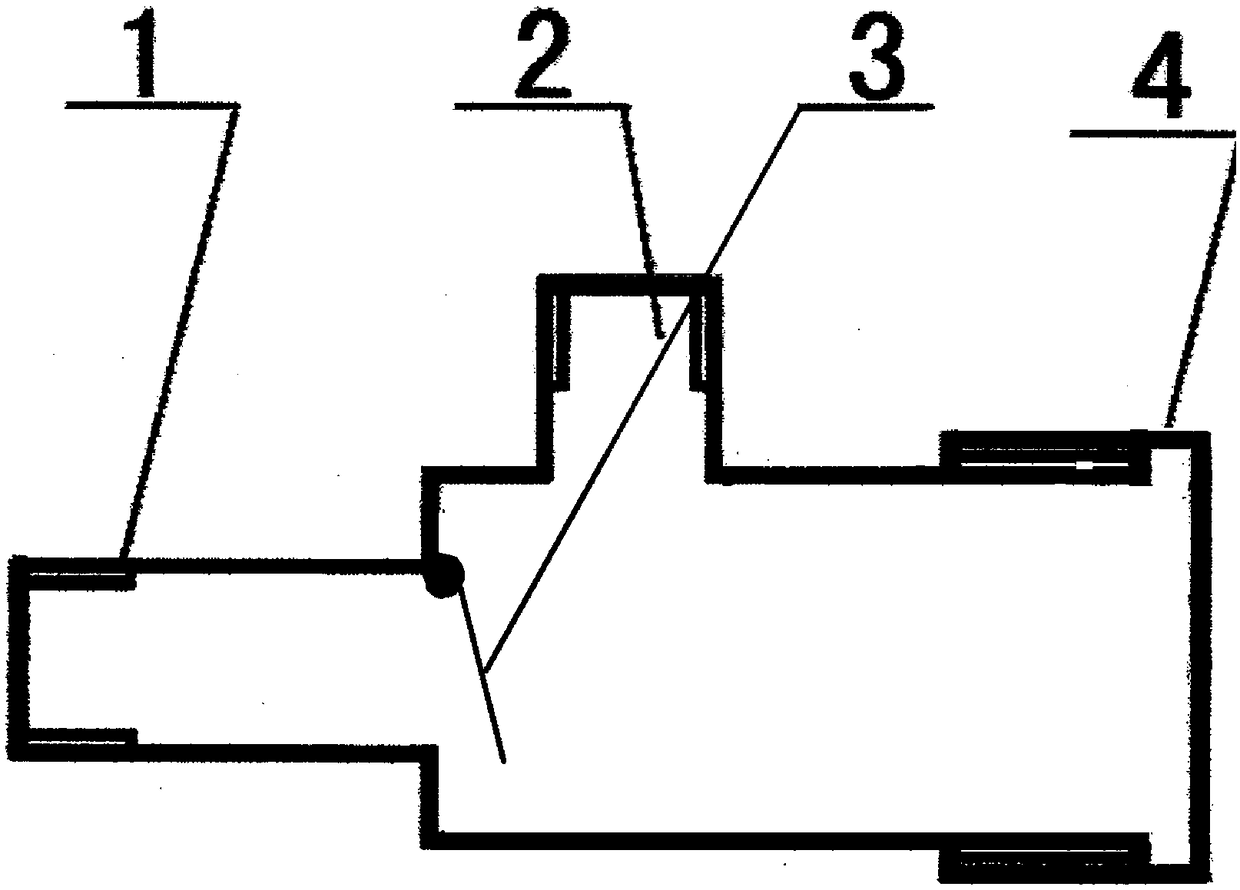

[0012] Such as figure 1 As shown, the present invention provides a downhole gas slow release device, comprising: a housing 4, an inlet 1 and an outlet 2 are arranged on the housing 4, a baffle 3 is arranged at the inlet 1, and the baffle 3 passes through The hinge is installed on the inner wall of the inlet, and the baffle plate 3 matches the inlet 1. The inlet 1 and the outlet 2 are arranged vertically, and the edge of the baffle plate 3 is provided with a sealing strip.

[0013] Working principle: The casing gas enters the downhole gas slow release device from the inlet. When the pressure is lower than the yield stress of the spring, the baffle is tightly pressed against the inner port of the casing gas inlet, and the casing gas cannot be released and is temporarily collected in the casing. The valve The body is in the closed state; when the casing gas pressure c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com