Suspension type underground hydraulic rod type pumping production device

A technology of oil production device and hydraulic rod, which is applied in the field of mechanical oil production, can solve the problems of long operation period, complicated operation procedures, wellbore wax deposition, etc., and achieve the effect of reducing operation cost, simplifying operation process and improving maintenance-free period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

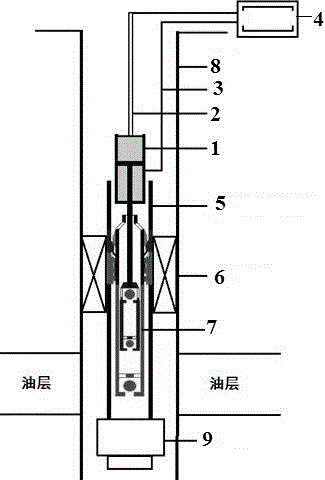

[0018] This embodiment provides a suspended downhole hydraulic rod pump oil extraction device, which includes a hydraulic cylinder 1, a hydraulic pipe 3 communicating with the hydraulic cylinder 1, a hydraulic control cabinet 4 and a rod pump 7, and the upper end of the hydraulic cylinder 1 communicates with There is a hollow sucker rod 2, the other end of the hollow sucker rod 2 and the hydraulic pipe 3 are connected to the hydraulic control cabinet 4, the rod type oil pump 7 is connected to the hydraulic cylinder, and the rod type oil pump 7 is set on the oil pipe 5, the hydraulic oil cylinder is set above the oil pipe 5, the lower part of the oil pipe 5 is provided with a support slip 9, and the oil pipe 5 is provided with a packer 6.

[0019] Before going into the well, connect the hydraulic cylinder 1 with the hydraulic pipe 3 and the hollow sucker rod 2, and debug the hydraulic control cabinet 4 to ensure that the direction of the liquid drive device is sensitive; 1. Aft...

Embodiment 2

[0023] On the basis of embodiment 1, this embodiment provides a kind of figure 1 In the suspended downhole hydraulic rod pump oil production device shown, the hydraulic control cabinet 4 includes an electrical control box and a heating control box, and the electrical control box is mainly used to control the starting of the motor and the reversing of the liquid drive device; Hydraulic oil, the heat is transferred to the hollow sucker rod 2 and then to the wellbore along with the hydraulic oil, which can effectively prevent the wellbore from waxing.

[0024] In this embodiment, the packer 6 is a KZ311 packer, which adopts a two-stage sealing method of expansion and self-sealing, and the hollow sucker rod 2 completes the sealing and unsealing to realize the casing 8 oil production.

[0025] The thrust of the hydraulic cylinder 1 is 0-1.5m, the rated thrust can reach 25000-35000N, and the medium temperature meets 0-150°C. The hydraulic pipe 3 is made of 316L stainless steel, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com