Anti-blocking sieve tube column integrating oil collection and sand flushing

A sand washing and anti-blocking technology, applied in the direction of production fluid, drill pipe, casing, etc., can solve the problems of pipe string failure, high operating cost, and prolonged well occupation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

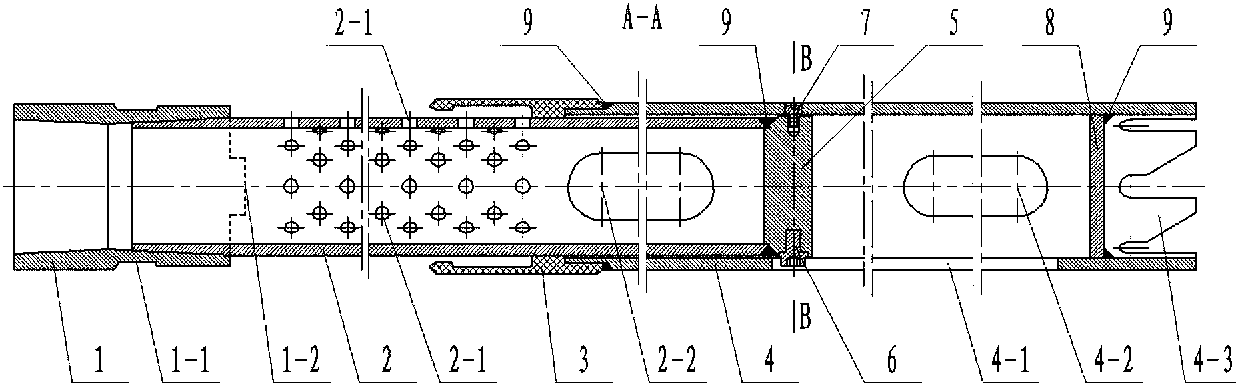

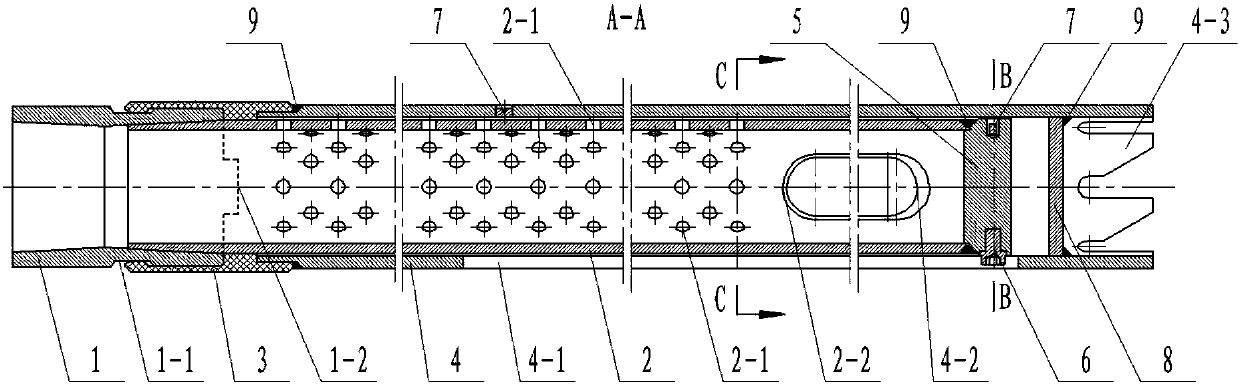

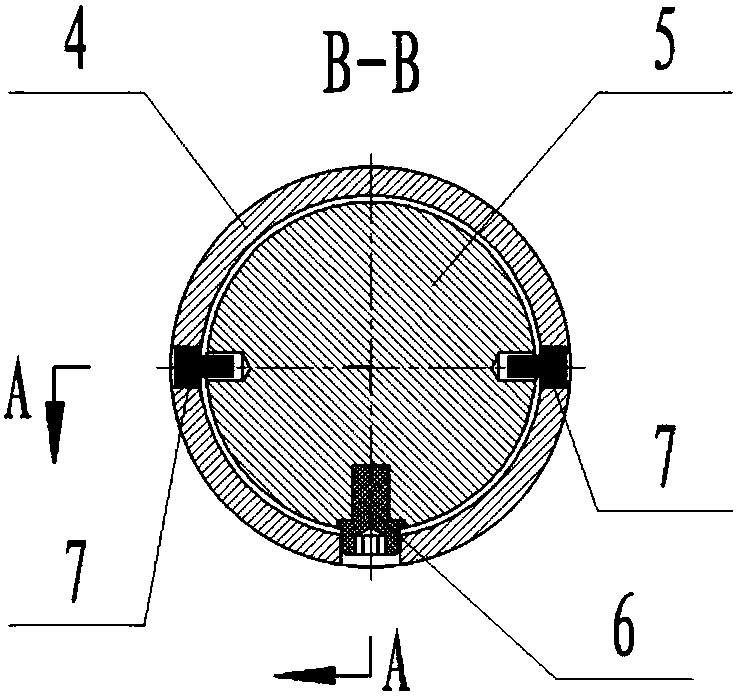

[0028] The present invention will be further described below in conjunction with accompanying drawing.

[0029] Such as Figure 1-5 As shown, this embodiment provides an anti-blocking screen string integrating oil production and sand washing, including a coupling 1, a screen 2, and a sand washing pipe 4. There are multiple rows of screen holes 2-1 on the screen pipe, and the meshes of adjacent rows are staggered to increase the strength of the screen pipe. The upper end of the screen pipe 2 is connected with the coupling 1 through threads, and its lower end The inner blind plate 5 is closed, the lower end of the screen pipe 2 is sleeved in the sand washing pipe 4, the inner blind pipe 5 is fixed on the sand washing pipe 4 by the shear pin 7, and an axial sliding mechanism is connected between the two. On the screen pipe 2, a waist-shaped inner sand-washing hole 2-2 is provided below the screen mesh, and a locking device is provided at the upper end of the sand-washing pipe 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com