Intelligent control system of pumping unit and its intelligent control method for pumping

A technology of intelligent control system and pumping unit, which is applied in earth-moving drilling, fluid production, wellbore/well components, etc., can solve the problems of reducing equipment service life, damage to oil production equipment, shortening wire rope life, etc., to ensure stability and reliability, increased automation, and enhanced overall balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

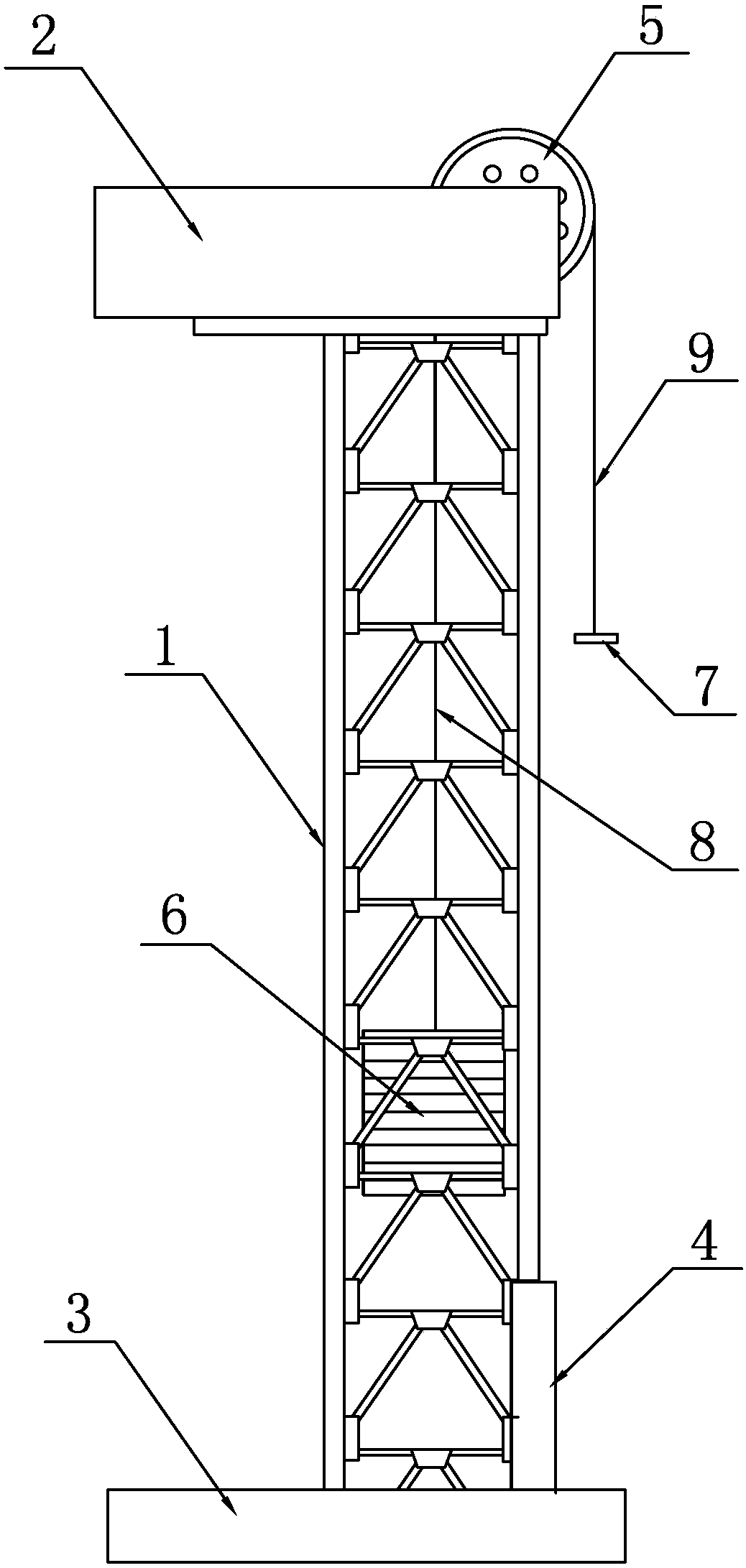

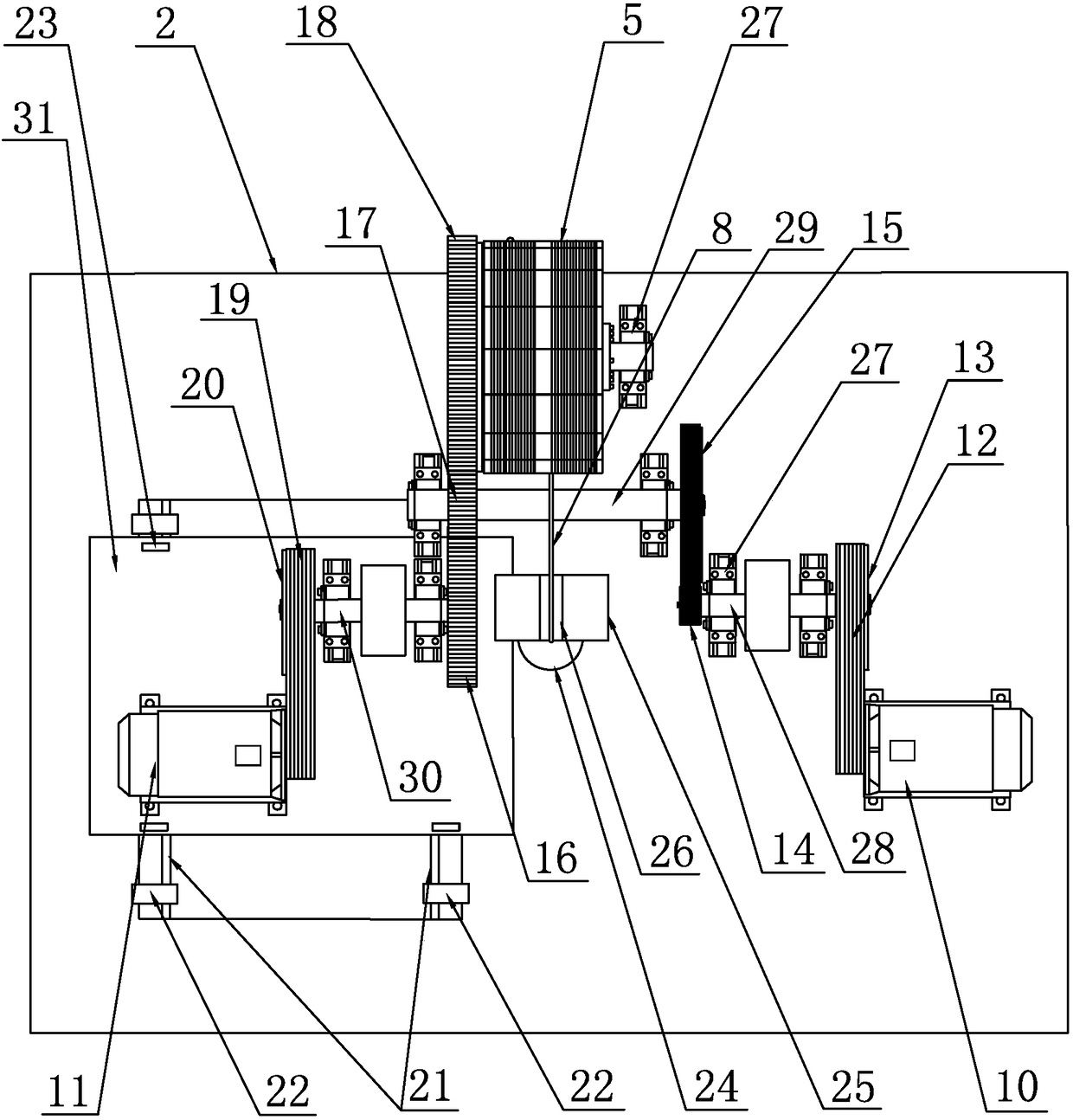

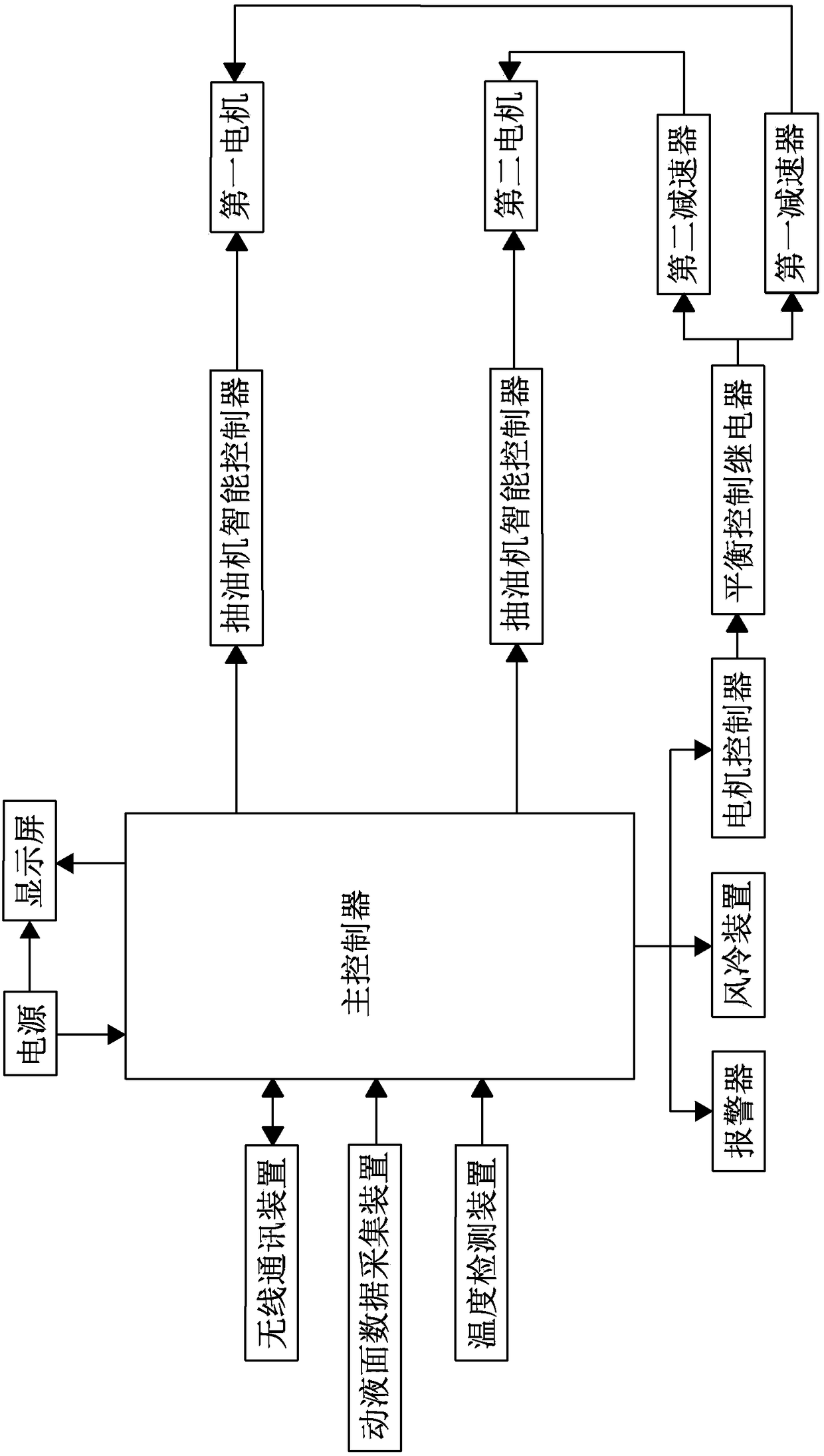

[0025] like figure 1 As shown, it is a front view of the intelligent control system of the pumping unit of the present invention, including a tower 1 , an operating platform 2 , a transmission device and a control cabinet 4 . The tower frame 1 is placed above the wellhead, a base 3 is added at the bottom of the tower frame 1, a control cabinet 4 is installed on the base, an operation platform 2 is arranged on the top of the tower frame 1, and a transmission device is arranged on the operation platform 2. like figure 2 As shown, it is a top view of the operating platform in the intelligent control system of the pumping unit of the present invention. The transmission device includes a primary belt transmission device, a secondary gear transmission device, a tertiary gear transmission device, an additional belt transmission device and an external gear transmission device. The first-stage belt transmission device includes the first motor 10, the first transmission shaft 28, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com