Anti-stuck diaphragm for plunger oil pump and machining method of same

An oil pump and diaphragm technology, which is applied to the components of the pumping device for elastic fluid, pump components, variable displacement pump components, etc., can solve the problems of complex diaphragm processing technology, complex working environment, and narrow downhole space, etc. Achieve the effect of large overall deformation, simple production process and method, and long life of the diaphragm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

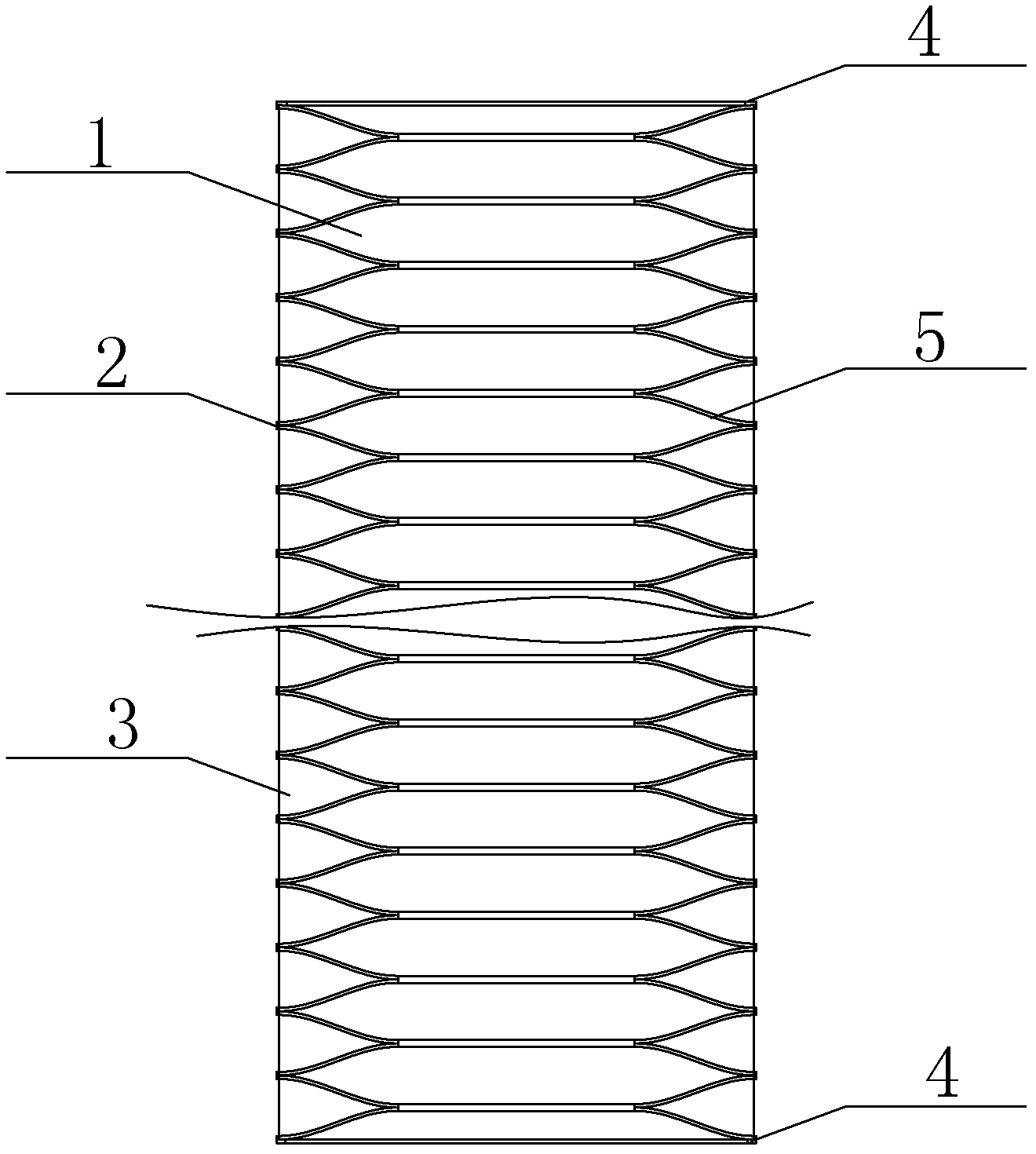

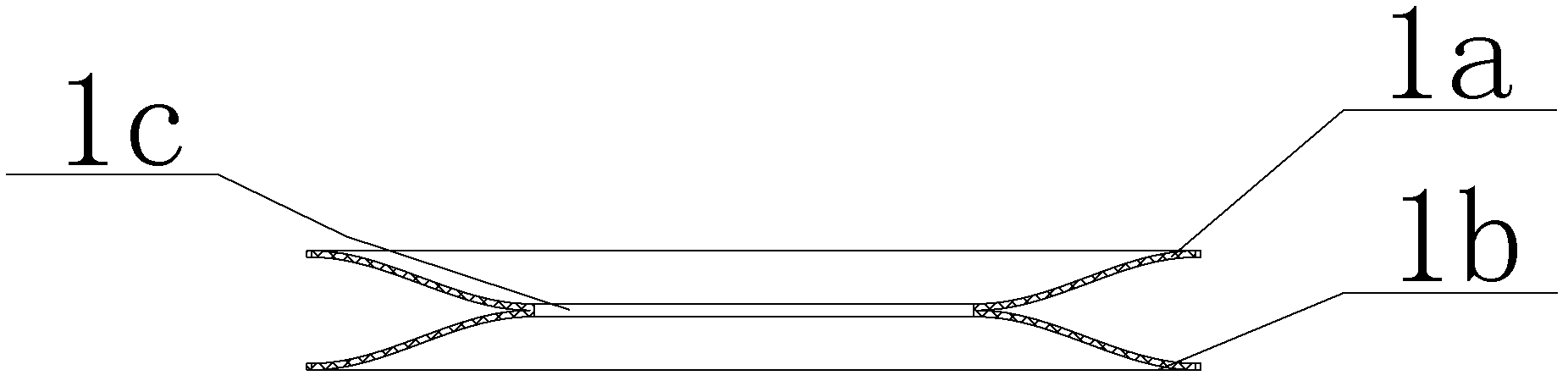

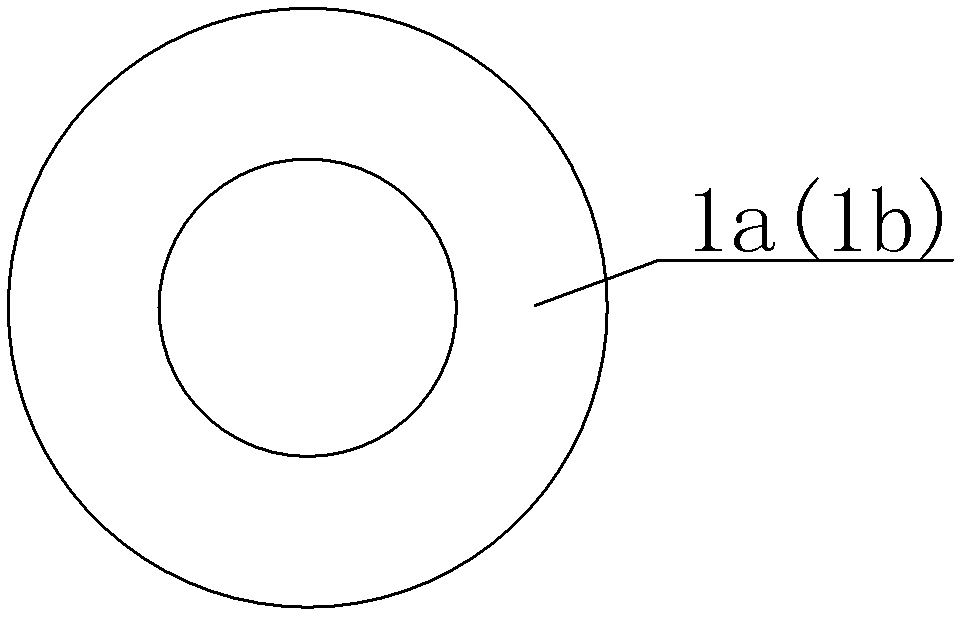

[0035] An anti-seize diaphragm for a plunger oil well pump, which is composed of a diaphragm assembly (1), a wear-resistant adapter ring (2), a pull wire (3), and a snap ring (4), and is characterized in that: the diaphragm The assembly (1) is composed of 100 to 1000 double-layer diaphragm units (5) whose inner and outer peripheral surfaces change to curved surfaces, extending in the shape of bellows through wear-resistant connecting rings (2); the outer diameter of the diaphragm assembly (1) 27.0mm to 95.3mm, the inner diameter is 13mm to 75.3mm; the double-layer diaphragm unit (5) includes an upper annular fluoroplastic material elastic layer (1a), a lower annular fluoroplastic material elastic layer (1b) and a ring clamp (1c ), the upper and lower annular fluoroplastic material elastic layers are hollow disk-shaped, and the small ends of the upper and lower annular fluoroplastic material elastic layers are symmetrically connected into one body through the ring clamp (1c); th...

Embodiment 2

[0040] An anti-jamming diaphragm for a plunger oil well pump, the difference from Example 1 is that there is no pull wire (3) to carry the tension, and at this time only 2-8 wear-resistant rings of the wear-resistant adapter ring are provided for The axial through groove (2d) for liquid circulation, the diaphragm assembly itself is in a compressed state or a naturally stretched state during the movement of the plunger, and the diaphragm bears a certain tension in the stretched state.

Embodiment 3

[0042] A processing method for an anti-jamming diaphragm of a plunger oil well pump mainly includes the following steps:

[0043] 1. Make wear-resistant adapter ring (2) and double-layer diaphragm unit (5) respectively, described wear-resistant adapter ring (2) comprises annular connection clamp (2a) and wear-resistant ring (2b), described double-layer diaphragm unit (5) The inner peripheral surface is curved, including the upper annular fluoroplastic material elastic layer (1a), the lower annular fluoroplastic material elastic layer (1b) and the ring clip (1c), the upper and lower annular fluoroplastic material elastic layers are both Hollow disc shape, the small ends of the upper and lower annular fluoroplastic material elastic layers are symmetrically connected into one body through the ring clip (1c); the wear-resistant connecting ring (2) includes a wear-resistant Ring (2b) and an annular connecting clip (2a) for connecting each double-layer diaphragm unit (5); the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com