Passive type multifunctional well head backflow dredging compensating device

A compensating device and multi-functional technology, applied in the fields of production fluids, wellbore/well components, earthwork drilling, etc., can solve problems such as increased operating costs, cavitation, mechanical wear of electric pumps, etc., and save operating costs and operating time. , Guarantee the separation effect, improve the effect of displacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

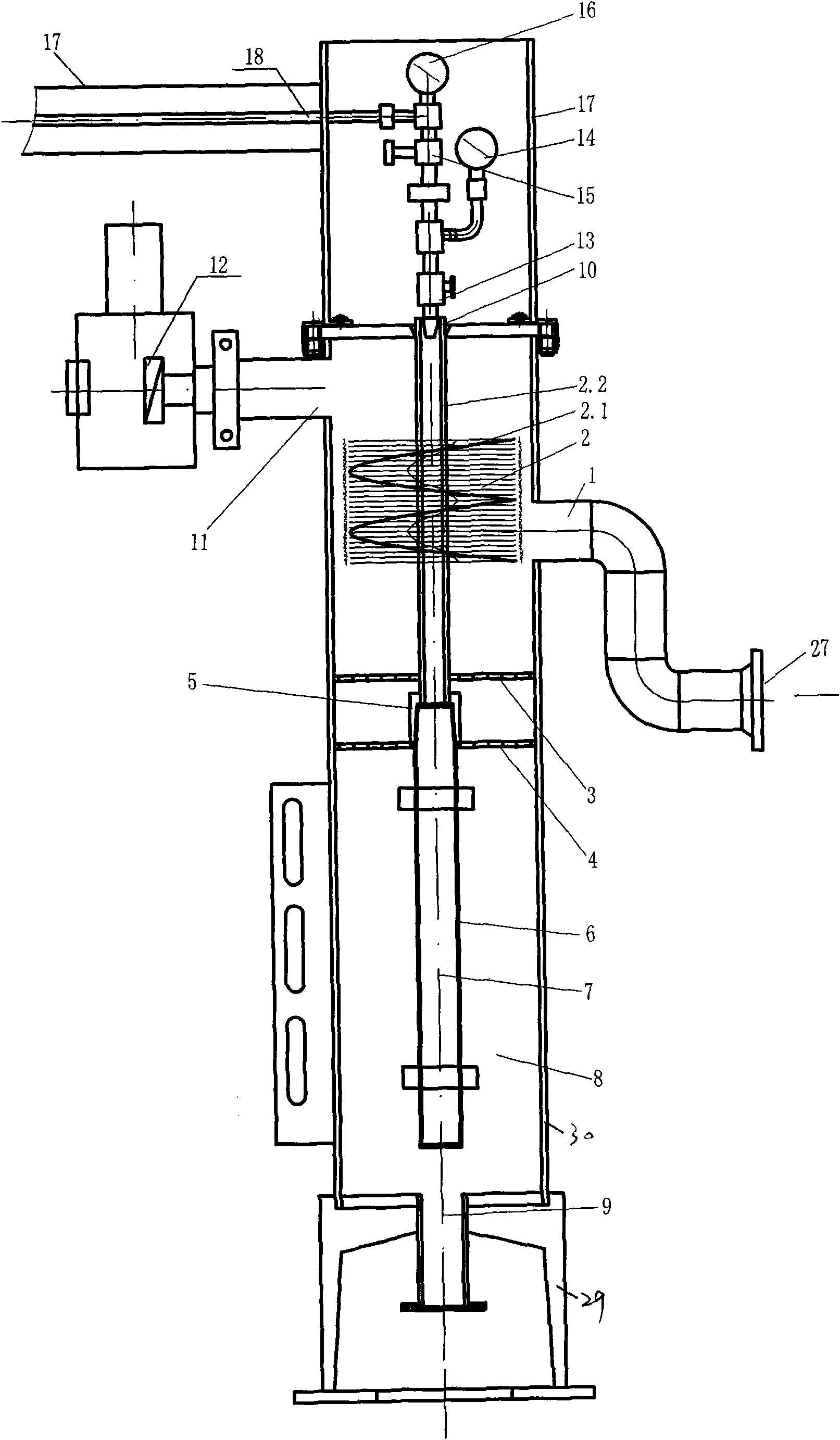

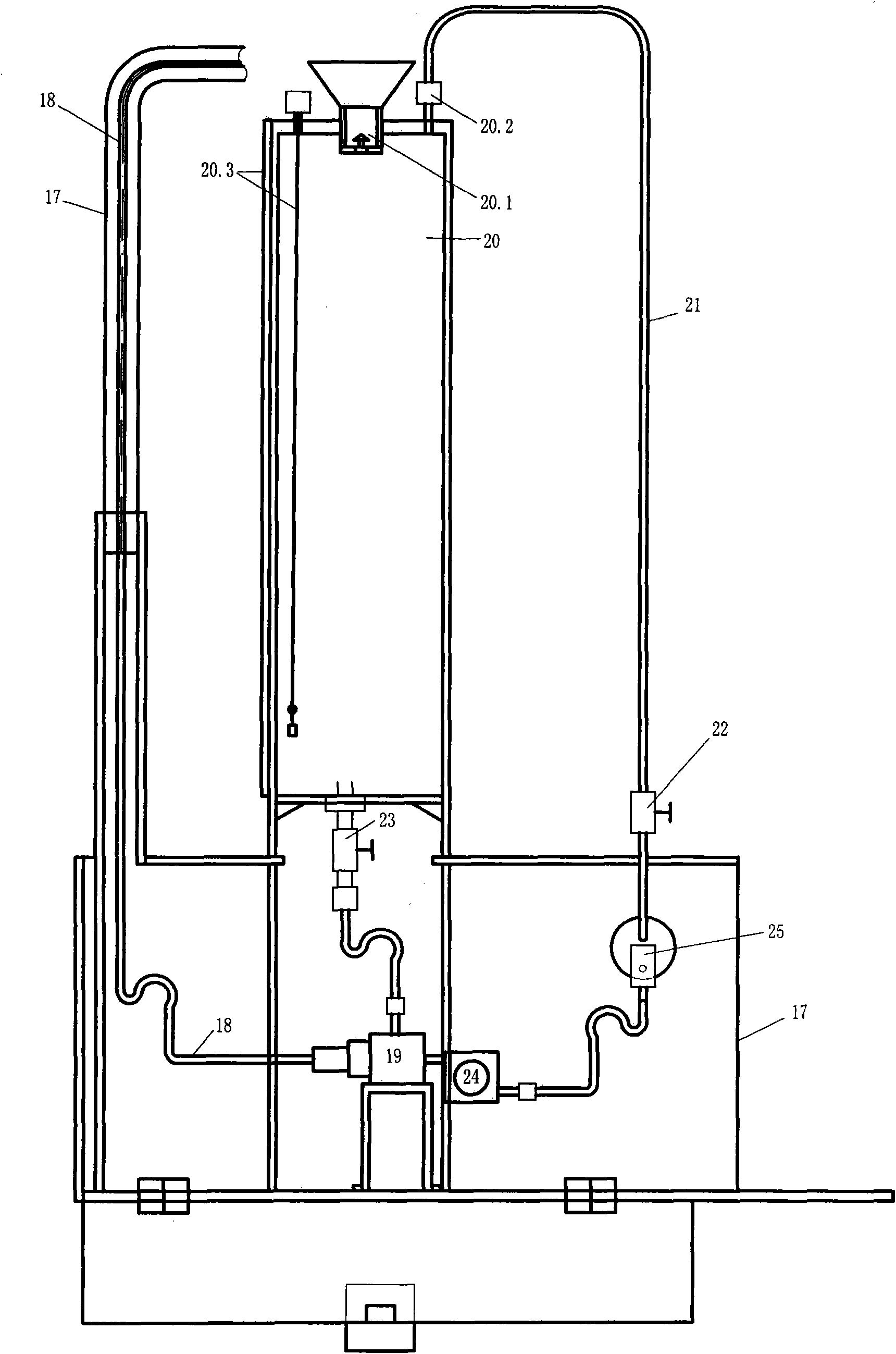

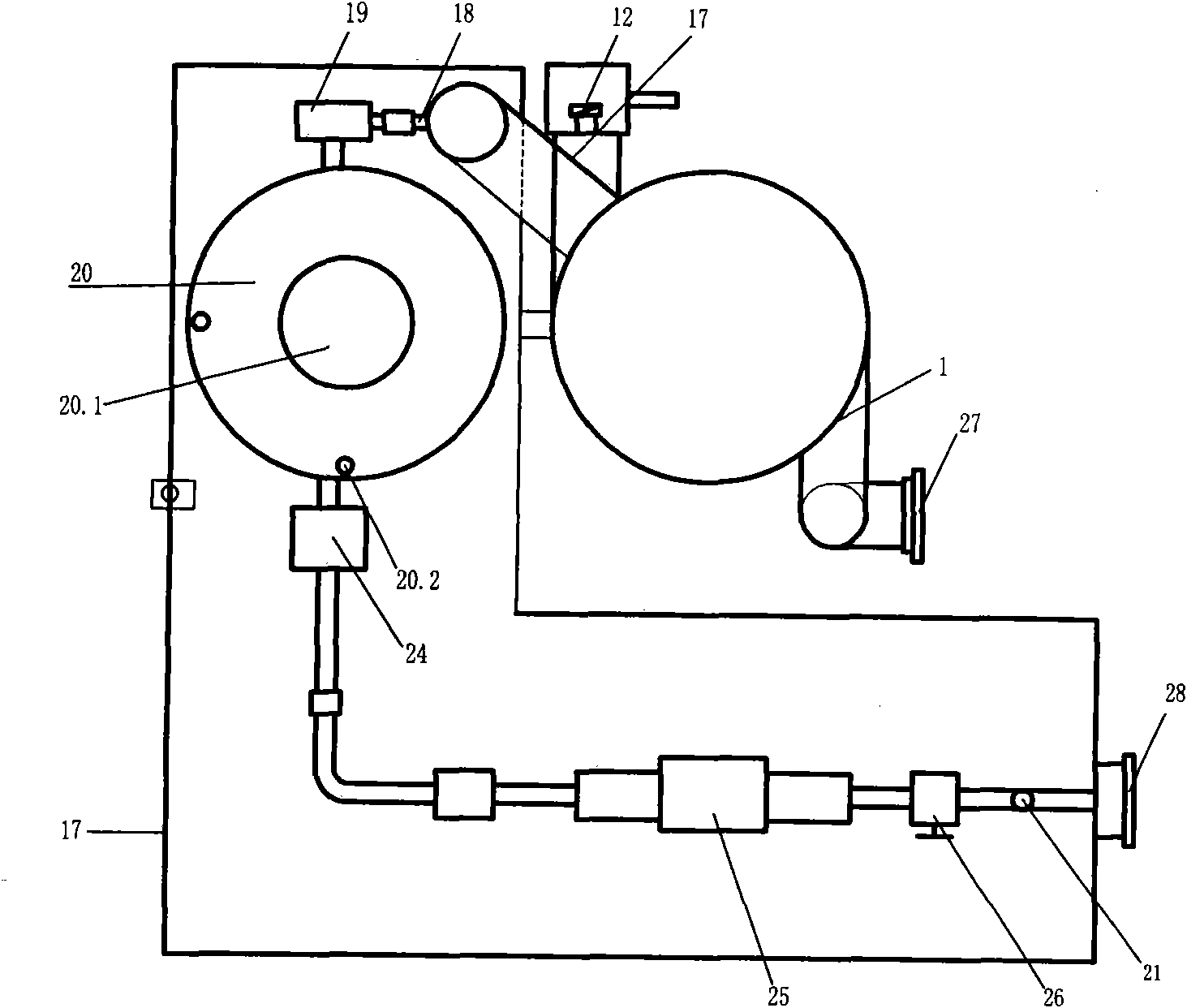

[0028] combined with Figure 1-4 , to further describe the present invention:

[0029] The present invention mainly consists of a well fluid inlet 1, a honeycomb spiral track separation tower 2, a honeycomb first-stage oil-blocking plate 3, a honeycomb-type secondary oil-blocking centralizing plate 4, and a well fluid outlet 11 to form a well fluid separation unit. The well fluid inlet 1 is located at The middle part of the well fluid separation unit and the well fluid outlet 11 are located at the upper part of the well fluid separation unit, and are respectively connected with the well fluid separation unit along the tangential direction of the outer wall of the well fluid separation unit; device; the space below the honeycomb secondary oil-resistance centralizing plate 4 and the filter constitutes a sand storage water storage chamber 8; it consists of a return liquid stop valve 13, a partial pressure gauge 14, a flow regulating valve 15, a return pressure gauge 16, and a ret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com