Intelligent synchronous testing and adjusting method capable of simultaneously infusing, testing and regulating

An intelligent, measuring and adjusting technology, which is applied in the directions of surveying, earthwork drilling, mining fluid, etc., can solve the problems that the measuring and adjusting process cannot be adapted, and the requirement of validity period is shortened.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

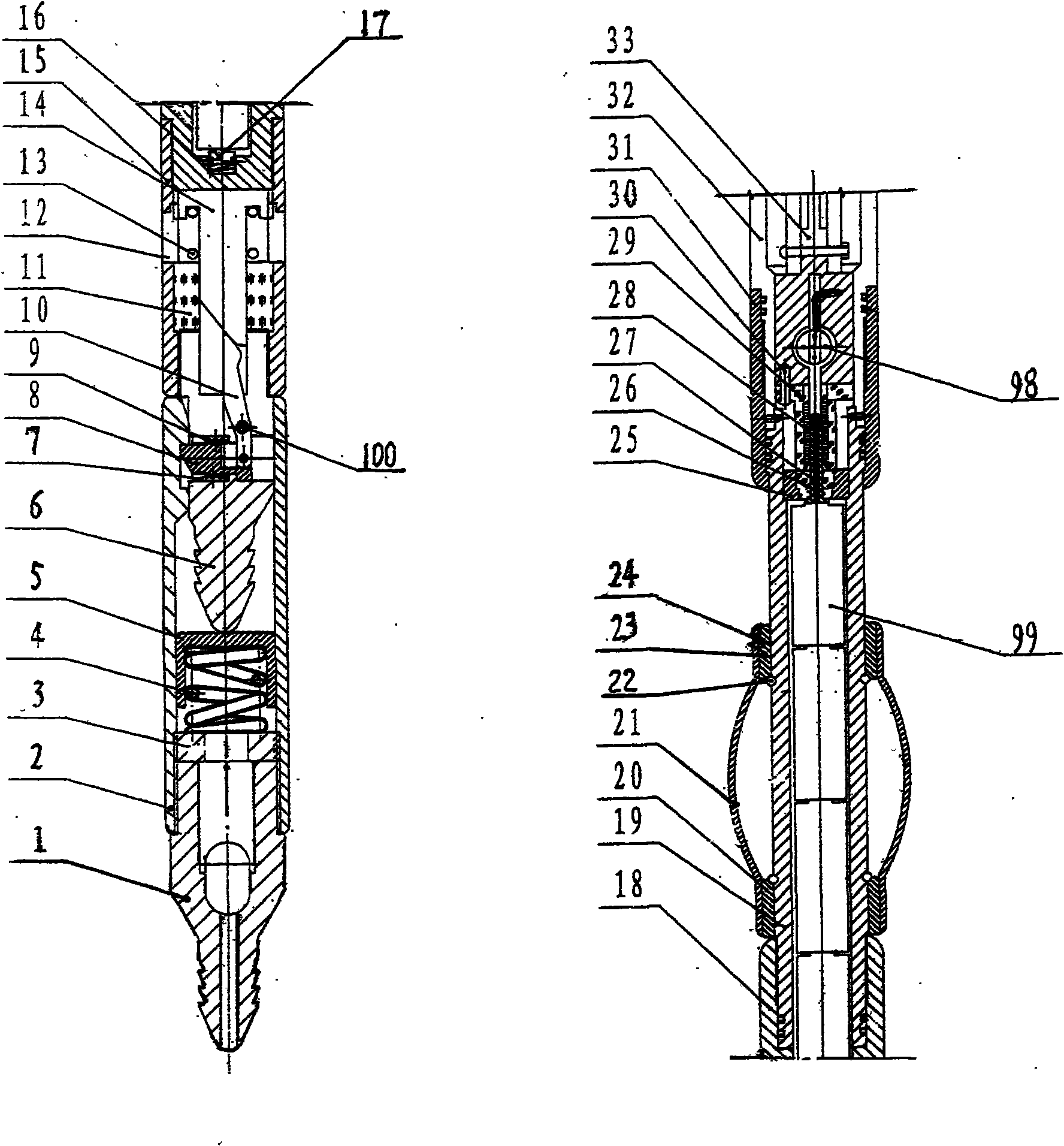

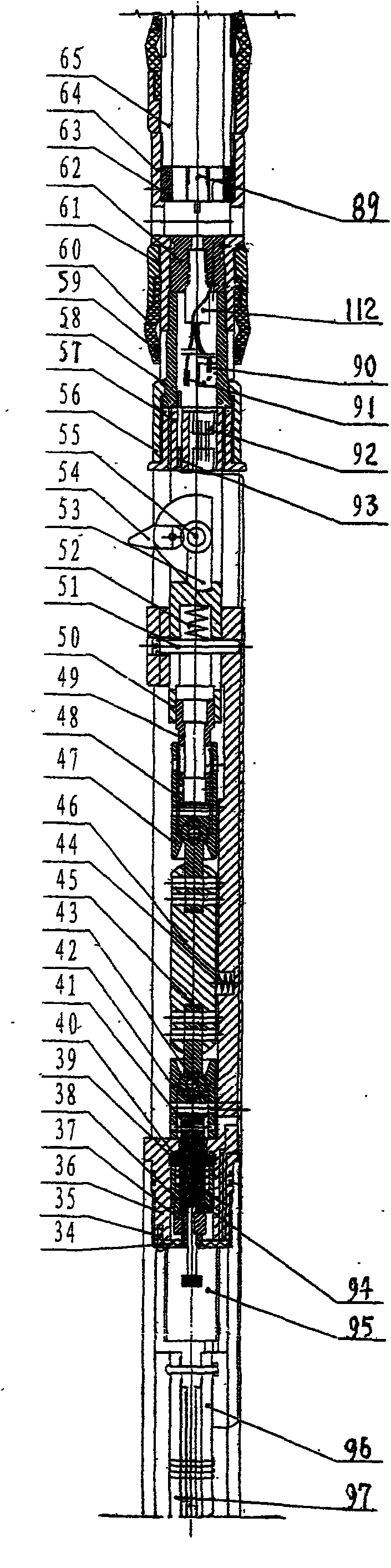

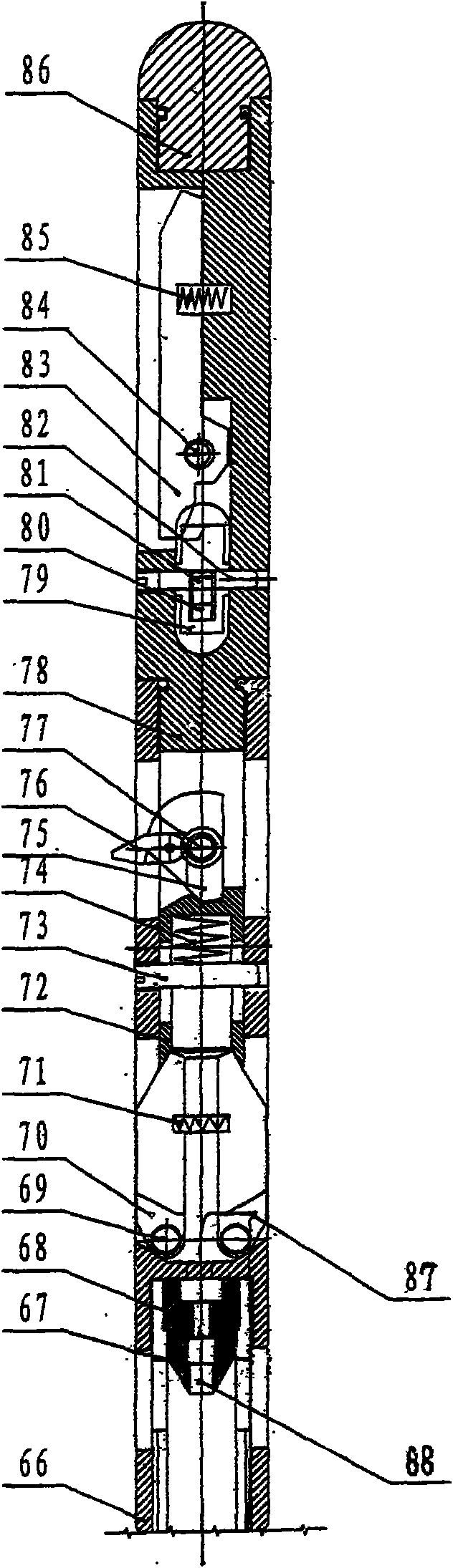

[0011] Examples, see attached Figure 1~4 , The intelligent synchronous measurement and adjustment method includes the device drop part, the intelligent measurement and adjustment part, the guiding part and the eccentric water distributor part. Refer to attached figure 1 , The throwing part is connected by the following parts, the rope cap 1 is threaded with the throwing short 2, the inner thread of the throwing short 2 is connected with barrier five lakes, and the cylindrical helical compression spring 4 and the guide cap 5 are arranged in the throwing short 2 at the same time. The electronic throwing part is contained in the throwing short circuit 2, and the electronic throwing is composed of a fishing head 6, an electronic lock cap 7, an electronic dead bolt 8 and an electronic lock spring 9. The electronic lock tongue 8 is connected with the pull rod 10 through the lock pin 100 . Electromagnetic coil 11 is contained in the protective cover 15, and iron rod 14 is housed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com