Lubricant, wear-resistant and anti-corrosion graphene pipe and preparation process thereof

A preparation process, a technology for a wear-resistant and anti-corrosion layer, applied in the field of graphene lubricated wear-resistant anti-corrosion pipes and preparation processes, can solve the problems of limited coating technical conditions, surface abrasion, etc., and achieve investment cost saving, strong waterproof performance, curing short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

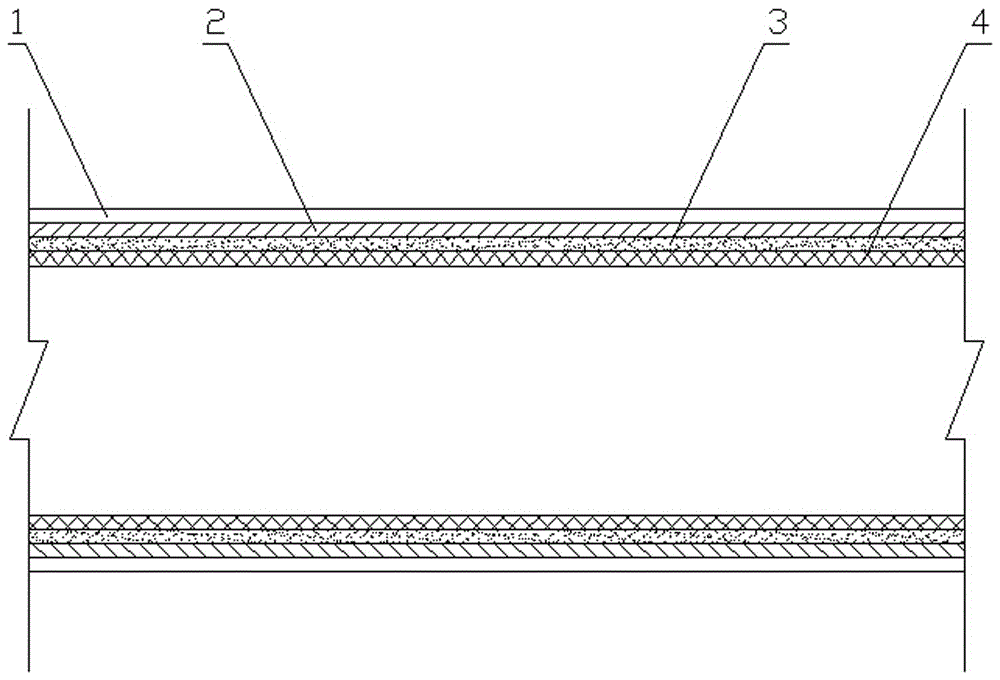

[0029] refer to figure 1 , a graphene lubricated wear-resistant anti-corrosion pipe and its preparation process, comprising oil pipe 1, lubricating wear-resistant anti-corrosion layer 2, adhesive layer 3 and protective layer 4, the oil pipe 1 is a cylindrical hollow structure, and the inner wall of the oil pipe 1 is sequentially arranged from outside to inside Attach the lubricating, wear-resistant and anti-corrosion layer 2, the adhesive layer 3 and the protective layer 4, the lubricating, wear-resistant and anti-corrosion layer 2 is composed of lubricating, wear-resistant and anti-corrosion powder, and the thickness of the lubricating, wear-resistant and anti-corrosion layer 2 is greater than 100um; The thickness of the adhesive layer is 120-260um; the protective layer 4 is composed of graphene, and the thickness of the protective layer 4 is 0.5-3.7um.

[0030] The preparation process of the graphene lubricated wear-resistant and anti-corrosion pipe is as follows:

[0031] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com