Anti-corrosion rubber composition and anti-corrosion rubber lining

A technology of anti-corrosion rubber and composition, which is applied in the field of anti-corrosion rubber composition and anti-corrosion rubber lining, which can solve the problems that the high-temperature adhesive performance cannot meet the requirements of the eleventh-stage flash evaporation device, etc., so as to improve heat resistance, eliminate air bubbles, Guaranteed fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

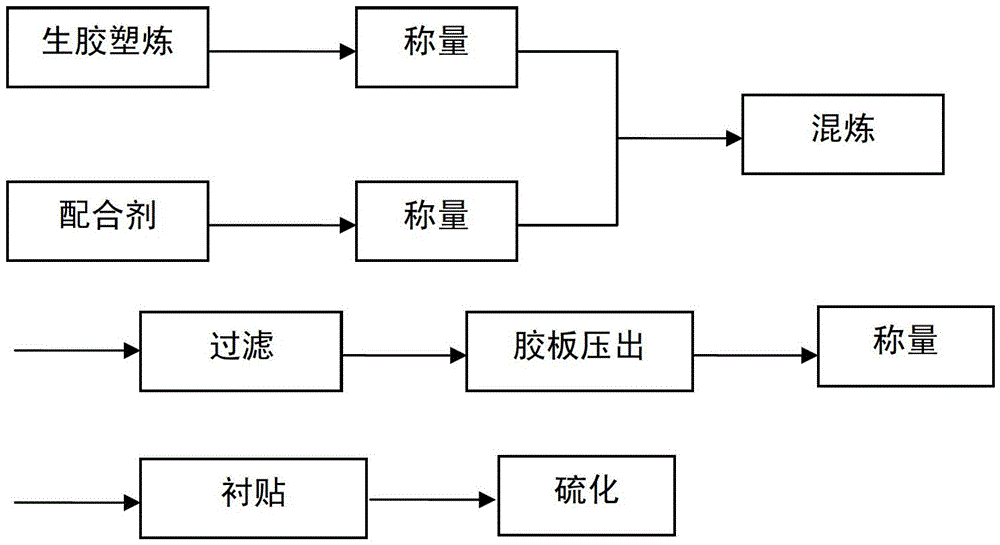

Method used

Image

Examples

Embodiment 1

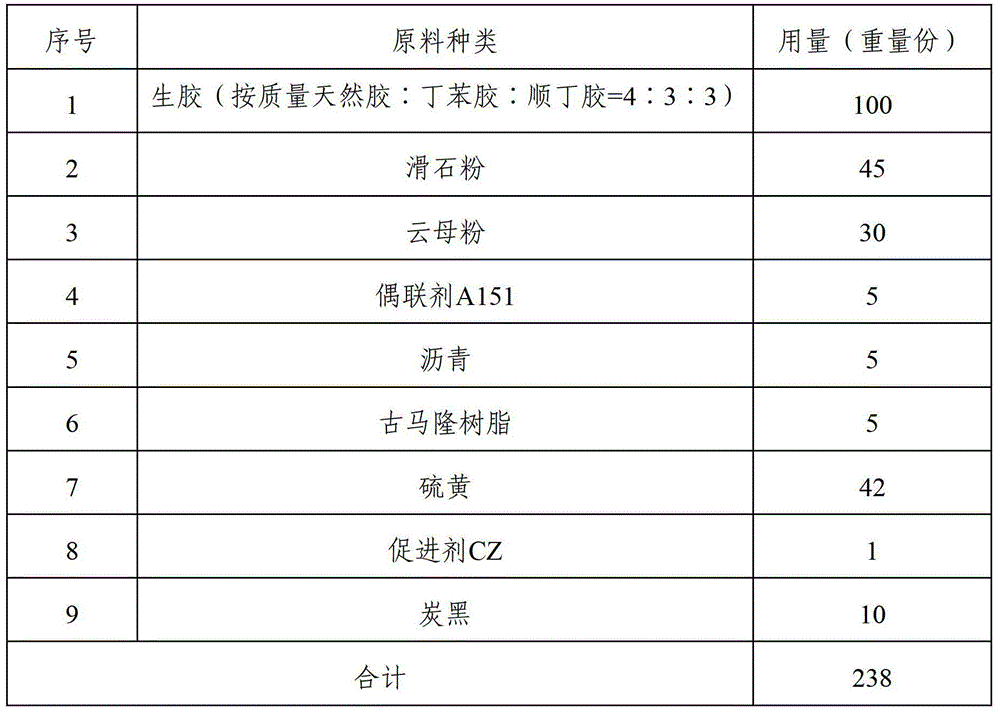

[0044] Prepare the rubber lining according to the components shown in Table 1 and the proportioning ratio, and the performance parameters of the gained rubber lining are as shown in Table 2:

[0045] The ratio of each component of the sizing material in Table 1 Example 1

[0046]

[0047] The sizing material performance parameter of table 2 embodiment 1

[0048] serial number

[0049] 7

Embodiment 2

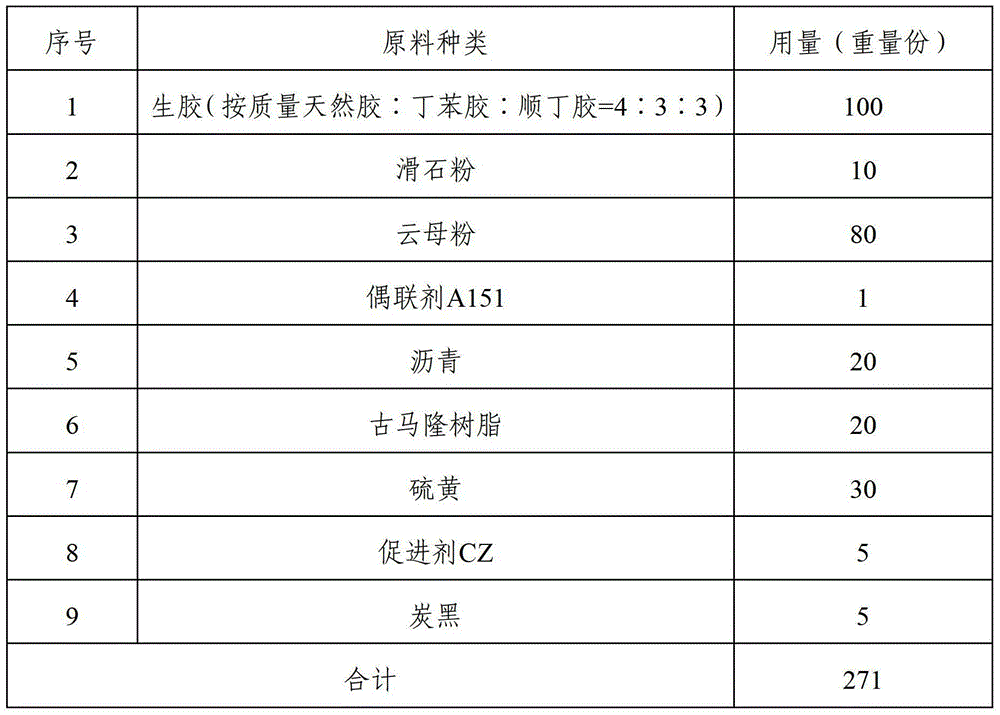

[0051] Prepare the rubber lining according to the components shown in Table 3 and the proportioning ratio, and the performance parameters of the gained rubber lining are as shown in Table 4:

[0052] The ratio of each component of the sizing material of table 3 embodiment 2

[0053]

[0054] The sizing material performance parameter of table 4 embodiment 2

[0055] serial number

Embodiment 3

[0057] Prepare the rubber lining according to the components shown in Table 5 and the proportioning ratio, and the performance parameters of the gained rubber lining are as shown in Table 6:

[0058] Each component distribution ratio of the sizing material of table 5 embodiment 3

[0059]

[0060]

[0061] The sizing material performance parameter of table 6 embodiment 3

[0062] serial number

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com