Intelligent interval pumping control method based on casing pressure test analysis

A control method and intelligent technology, which is applied in earthwork drilling, wellbore/well components, construction, etc., can solve problems such as failure to start and stop pumping units in time, difficulty in installation and debugging, and low control accuracy, so as to reduce manual labor The effect of strength, low cost, and simple calculation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

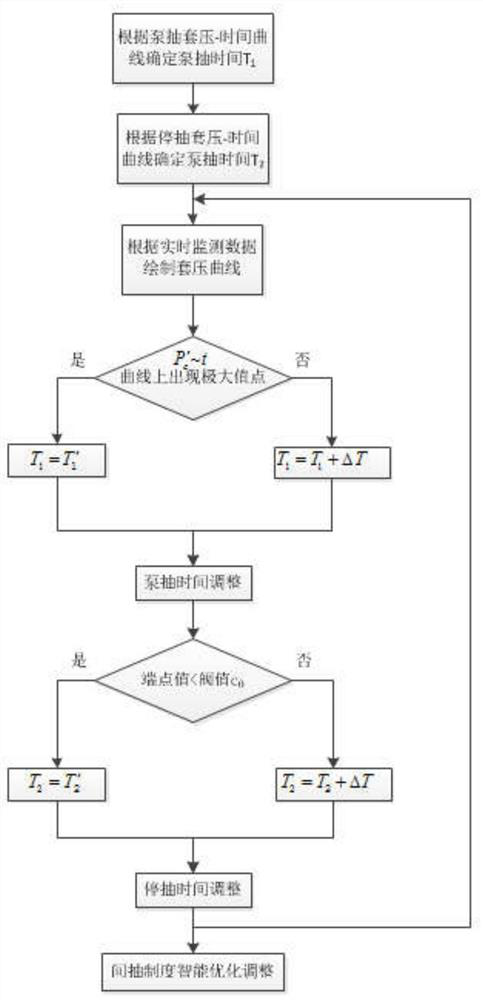

[0027]The invention proposes an intelligent pumping control method based on casing pressure well test analysis.

[0028]Such asimage 3As shown, the present invention includes the following steps:

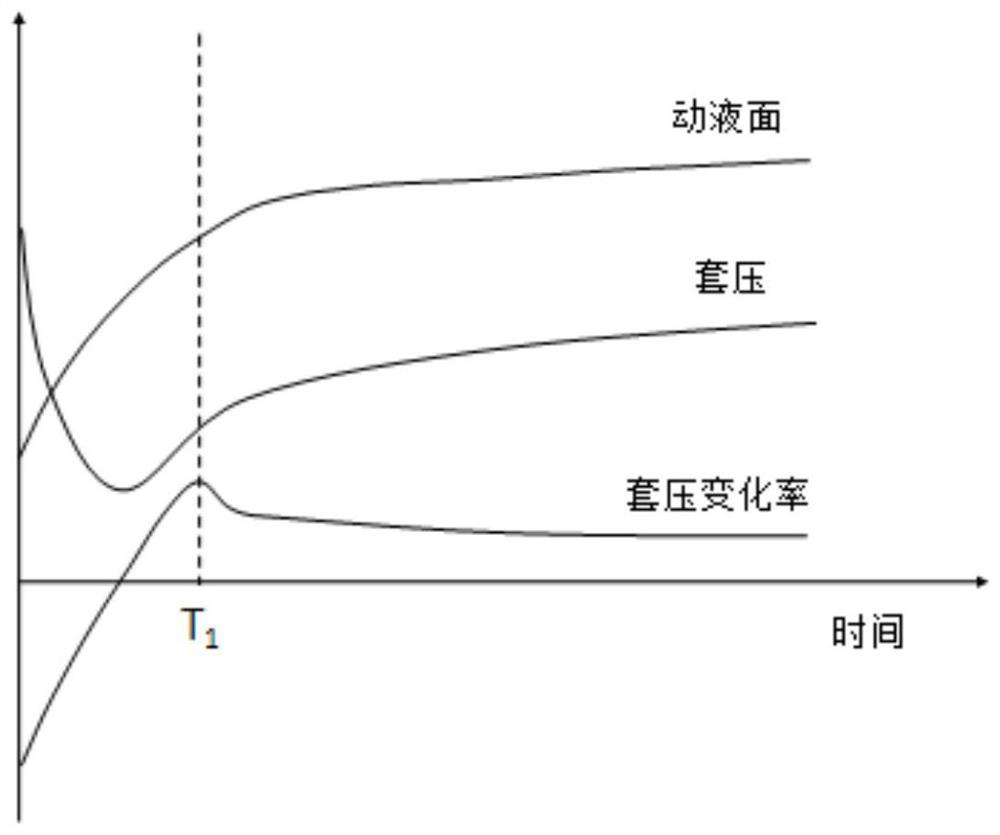

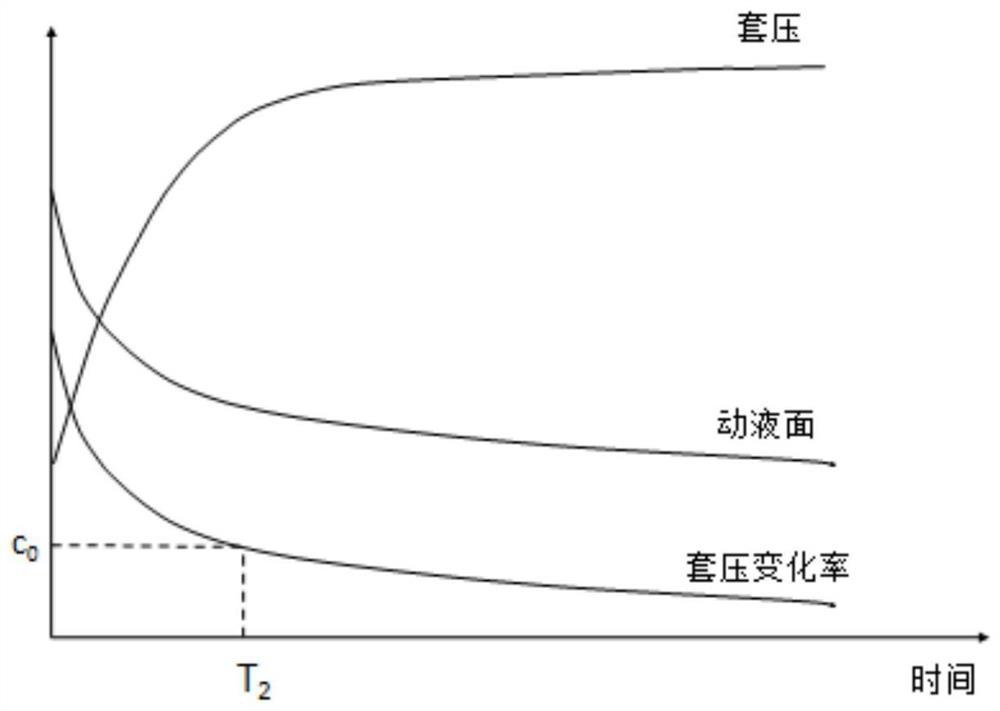

[0029]Step 1: Close the casing pressure valve, shut down the well for a period of time, and after the bottom of the well reaches a certain height, open the well for continuous and uninterrupted pumping, measure the casing pressure value during the pumping process, and draw the casing pressure-time relationship curve.

[0030]Step 2: According to the casing pressure-time relationship curve during pumping, draw the casing pressure change rate-time curve. The casing pressure change rate uses the following calculation formula:

[0031]

[0032]Where Pc′ Is the rate of change of casing pressure, ΔPcIs the amount of change in the casing pressure value within the time interval Δt.

[0033]On the casing pressure change rate-time relationship curve, take the time T corresponding to the maximum value of casing press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com