Patents

Literature

35results about How to "Realize the purpose of cost reduction and efficiency increase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

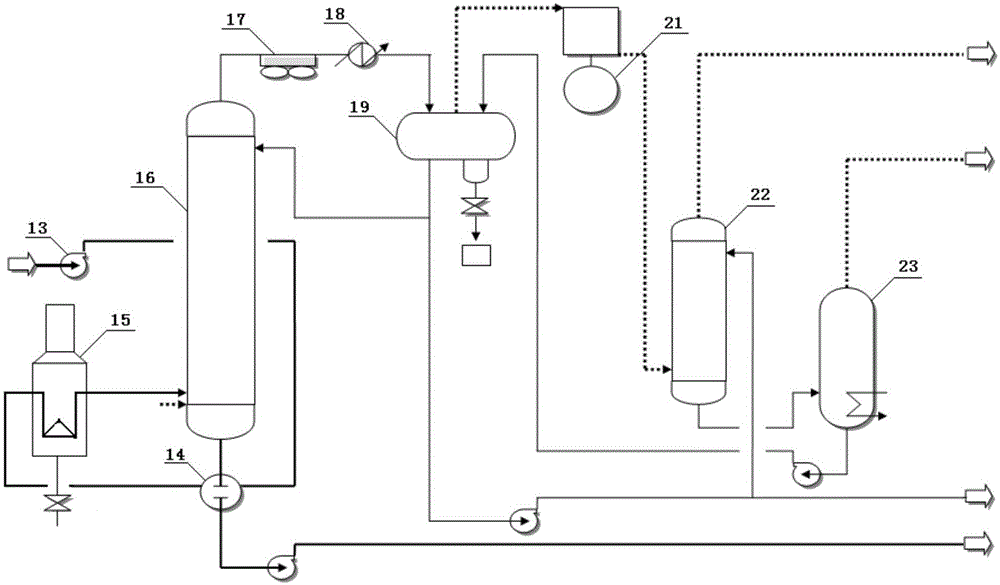

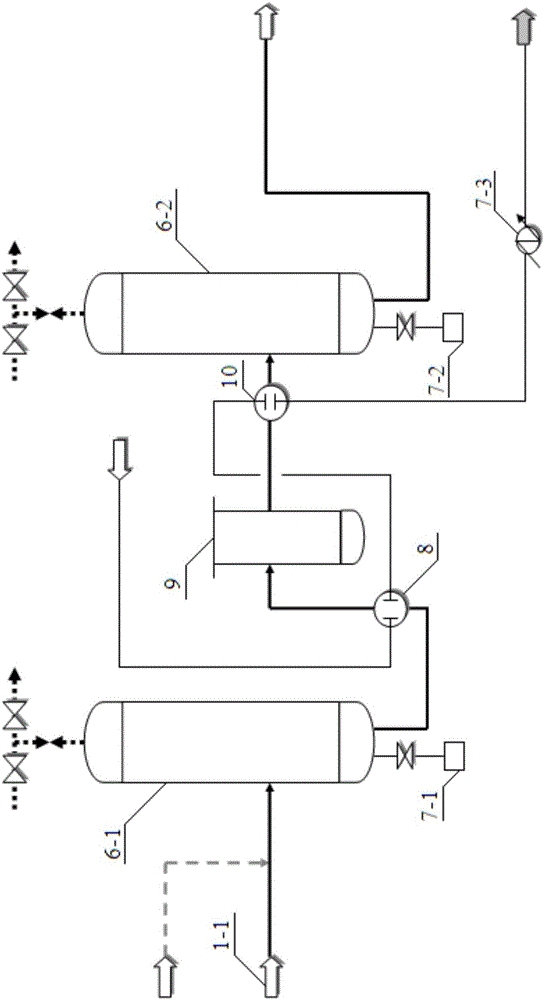

Method for preparing catalytic thermal cracking raw materials from full-fraction shale oil

ActiveCN105154134AImprove utilization efficiencyImprove the level of comprehensive utilizationDispersed particle separationTreatment with hydrotreatment processesPetroleum naphthaResidual oil

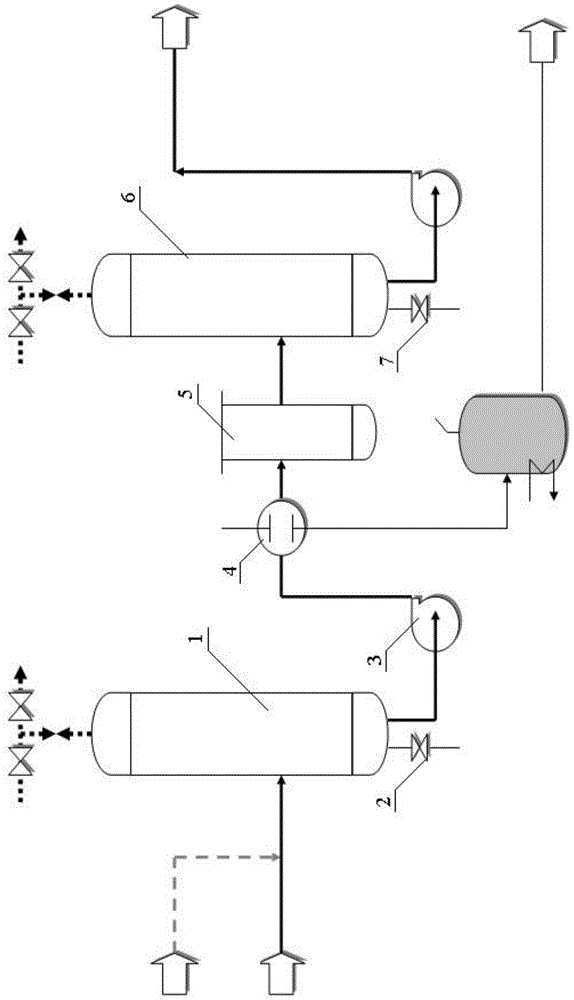

The invention discloses a method for preparing catalytic thermal cracking raw materials from full-fraction shale oil, relates to a full-fraction shale oil deep processing process, and aims to solve the technical problems of 'more money on exhibit and less money on counterfoil' and insufficiency in 'oil-chemical' combination degree of the current oil shale industrial structure in the conventional method. The method is conducted in the following units: 1, a raw material pretreatment unit; 2, an atmospheric distillation unit; 3, a reduced pressure distillation unit; 4, a hydrotreating unit; 5, a product fractional distillation unit. According to the method, the utilization ratio of the shale oil resource is effectively increased; the main product is hydrofined wax oil used as the raw material for a follow-up catalytic thermal cracking device; the by-products are high-value LPG, hydrogenated petroleum naphtha and hydrogenated diesel oil; light shale oil (lower than or equal to 350 DEG C) and residual oil (higher than 500 DEG C) which are thrown away from the process device can be further processed and utilized in a downstream device. The method belongs to the field of full-fraction shale oil deep processing.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE

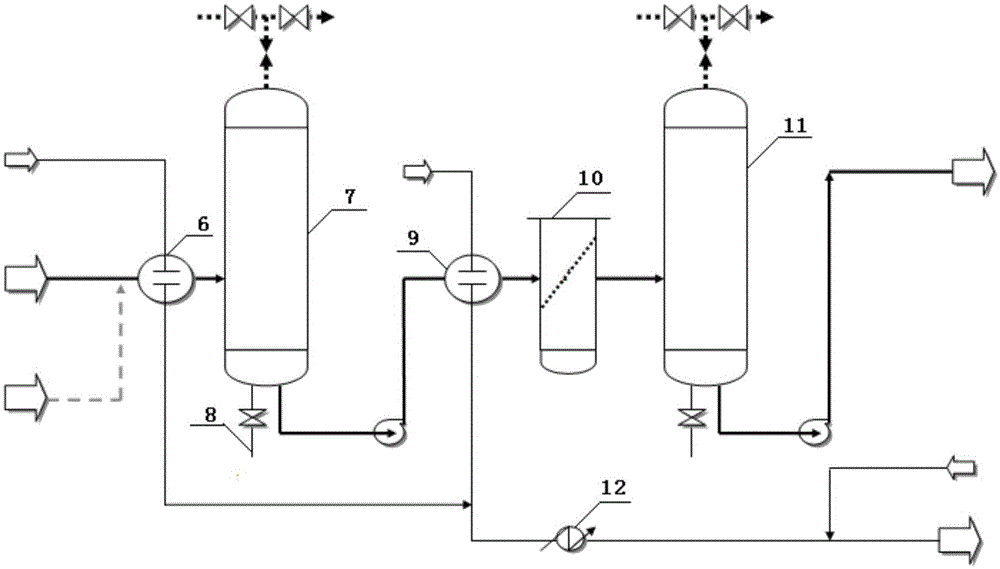

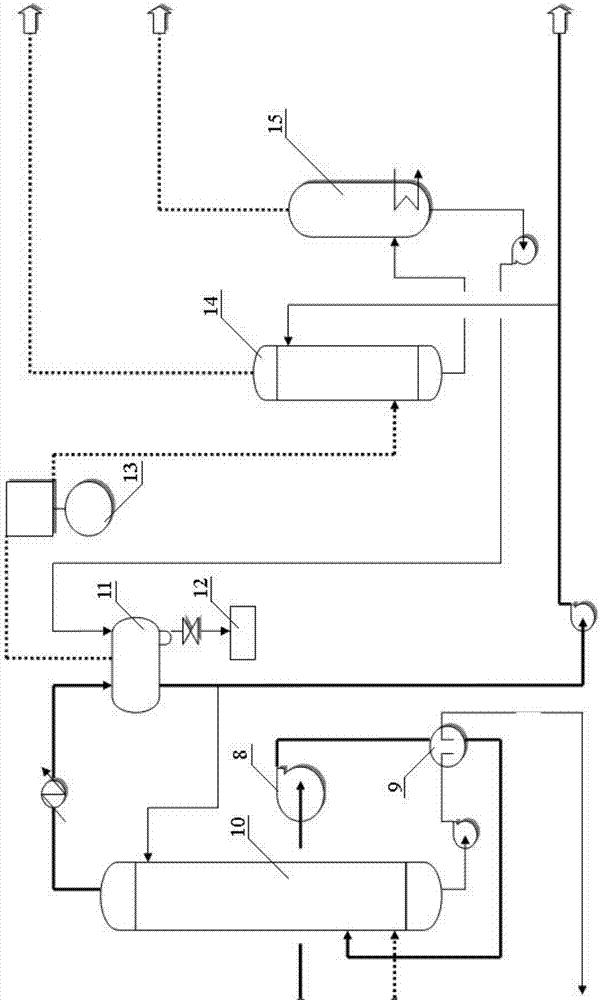

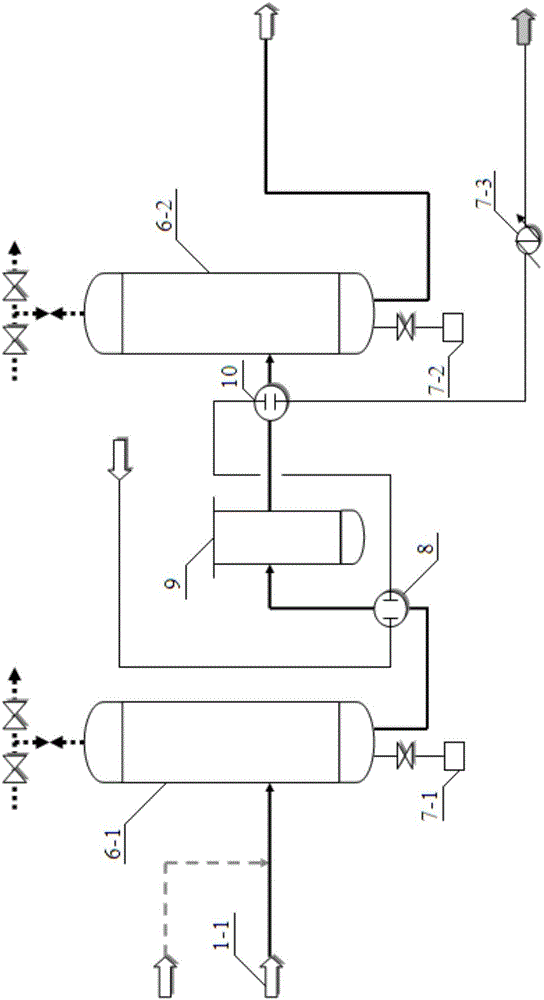

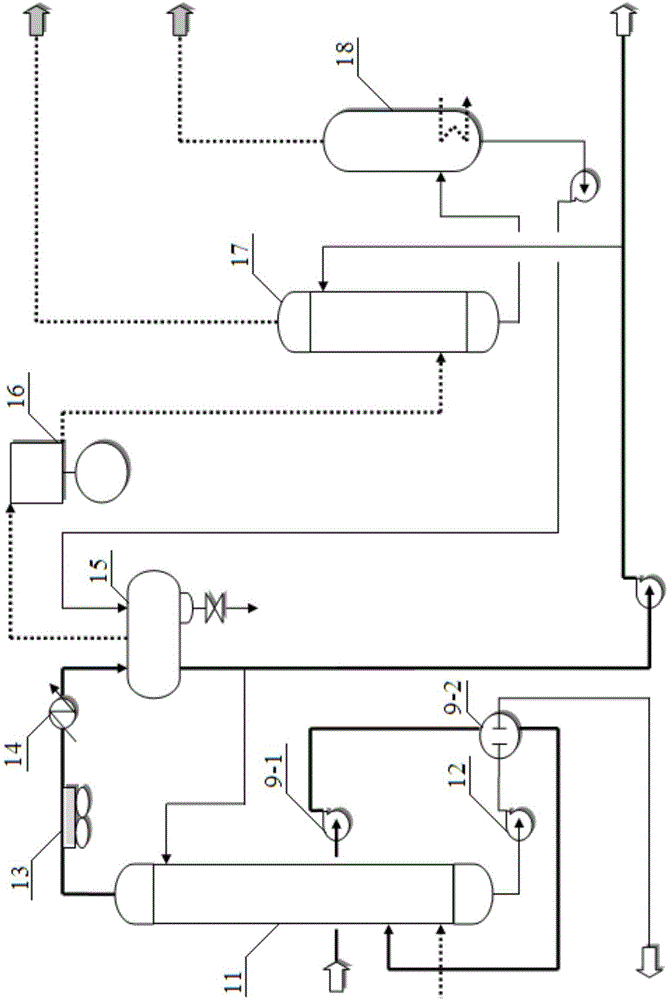

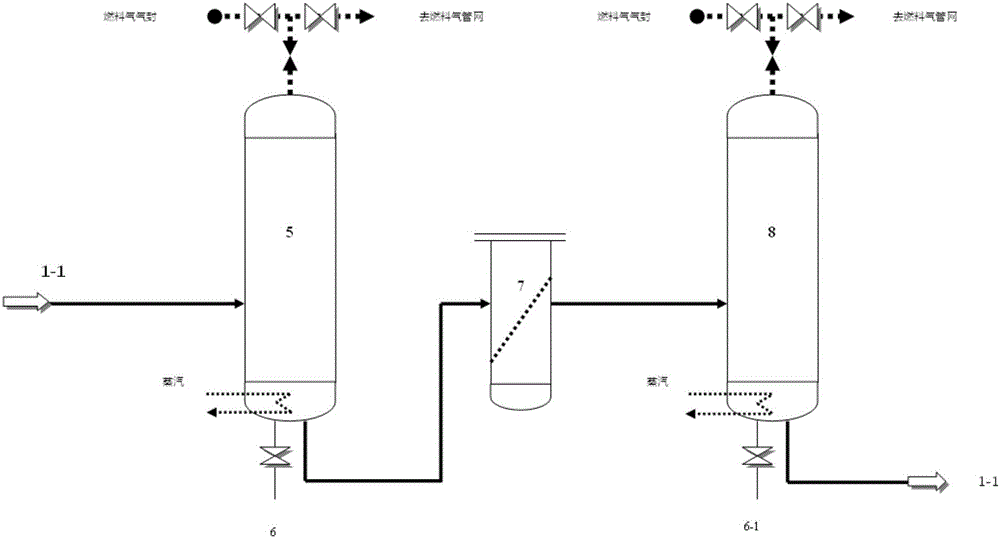

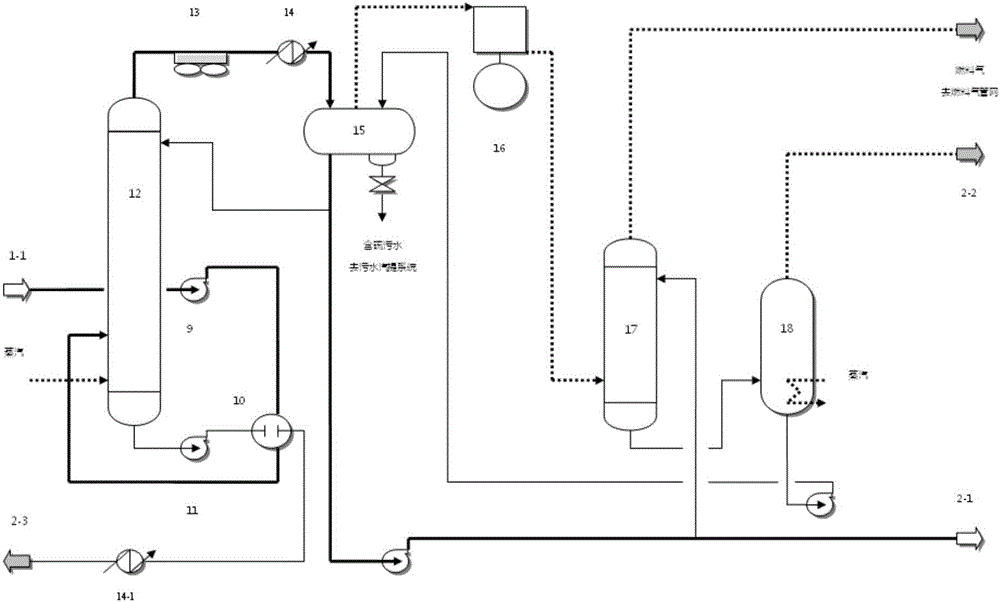

Method of producing low-sulfur low freezing point diesel by full-range shale oil

ActiveCN103497782AHigh yieldFlexible product planTreatment with hydrotreatment processesNaphthaOperational costs

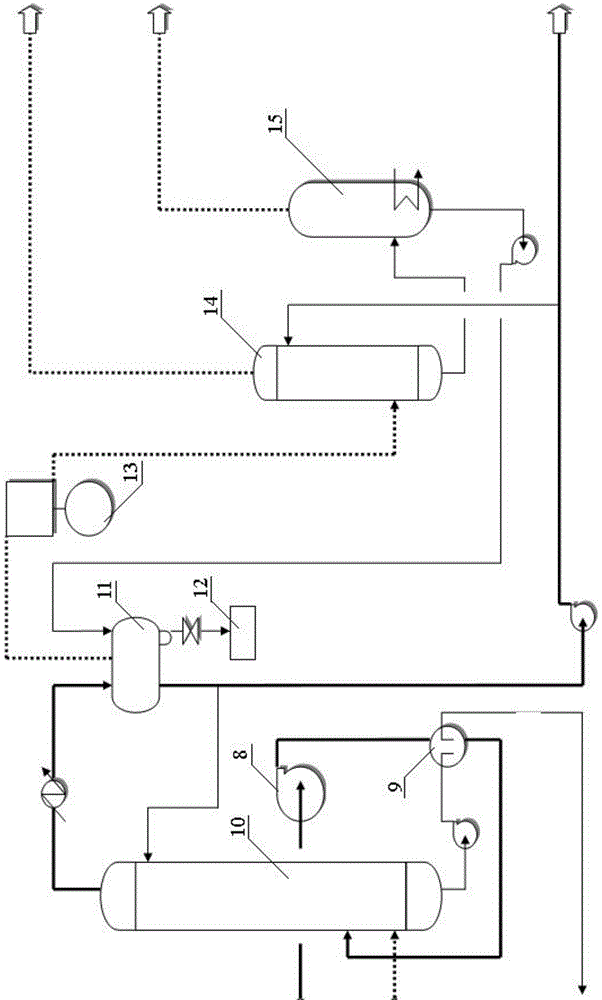

The invention relates to a method of producing low-sulfur low freezing point diesel by full-range shale oil, relates to a production method of low-sulfur low freezing point diesel and solves the technical problems that the existing method of producing diesel by shale oil is complex in process and high in investment and operational cost. A material pre-fractionation unit, a reaction unit and a fraction unit are adopted in the method. The method has the advantages that finished diesel yield is high during processing of the full-range shale oil; the quality of the low-sulfur low freezing point diesel meets the national standard IV; a product scheme is flexible, the production of refined diesel and the production of the low-sulfur low freezing point diesel are both considered, and product distribution is adjusted; during the processing of the full-range shale oil, the material pre-fractionation unit is additionally provided with an absorbing column and a flash tank, lightweight shale oil is used as absorbent, LPG components in noncondensable gas can be recycled, applying a product stabilization column to the product fractionation unit to separate LPG and naphtha is avoided, and cost reduction and efficiency increasing are achieved. The invention belongs to the field of diesel production.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE

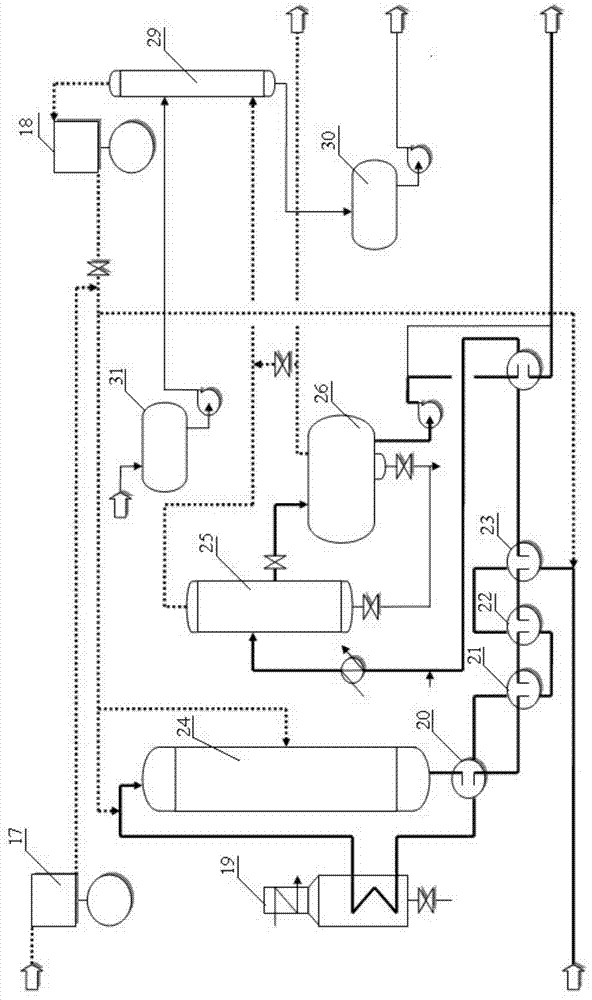

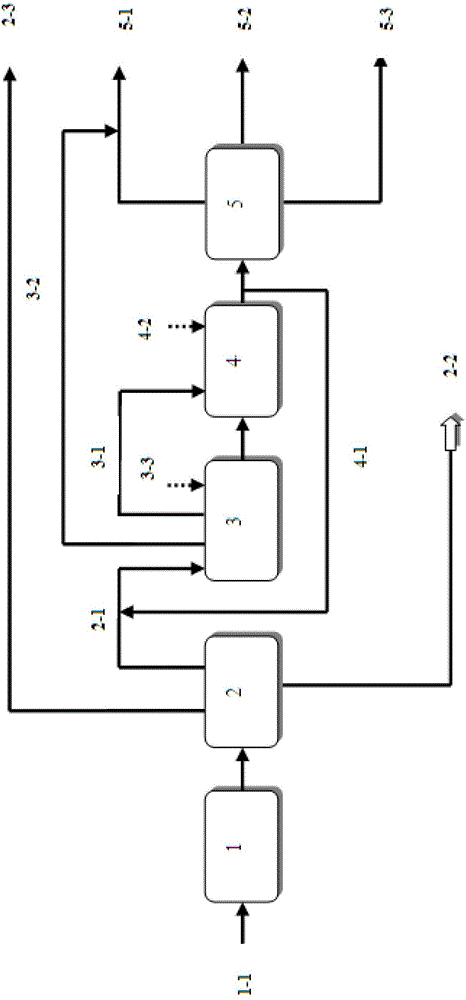

Method for improving shale oil hydrorefining denitrification rate

ActiveCN105838418AImprove utilization efficiencyImprove the level of comprehensive utilizationTreatment with hydrotreatment processesHydrocarbon oils treatment productsNaphthaFractionation

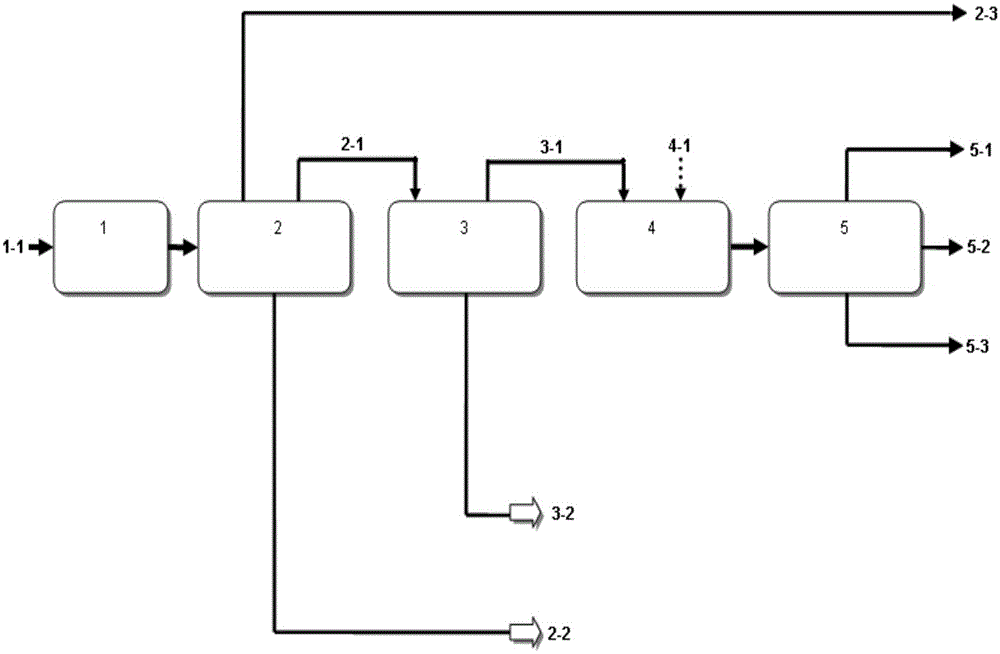

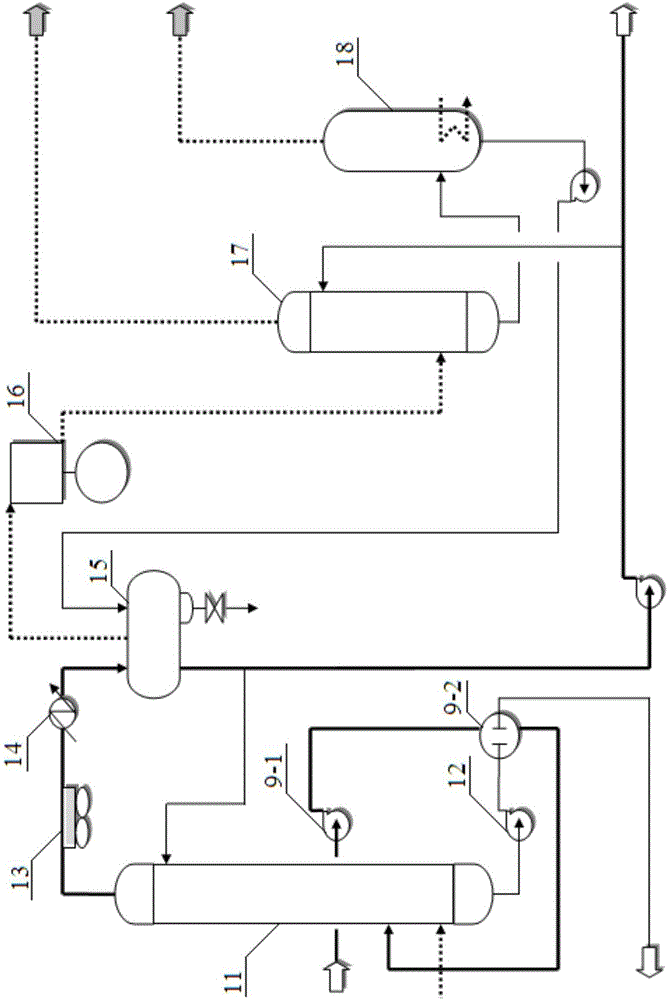

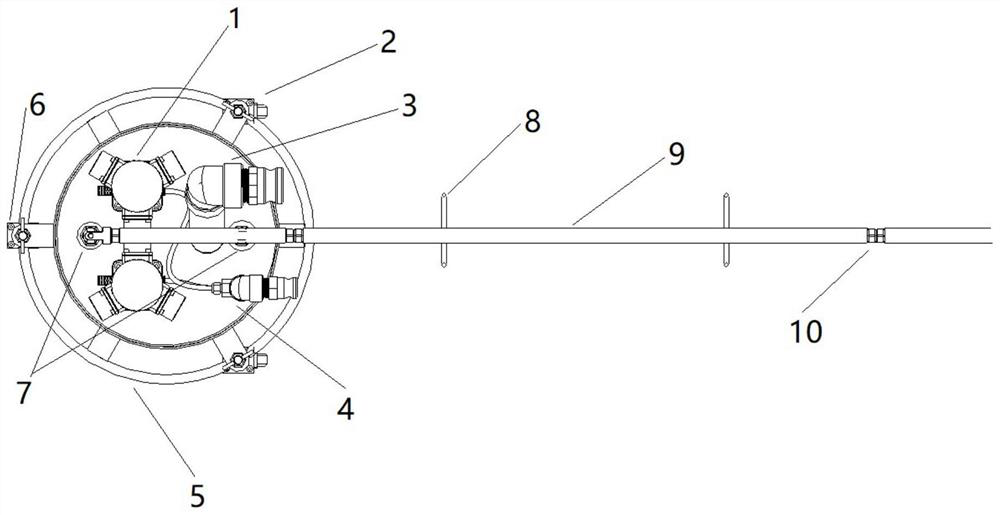

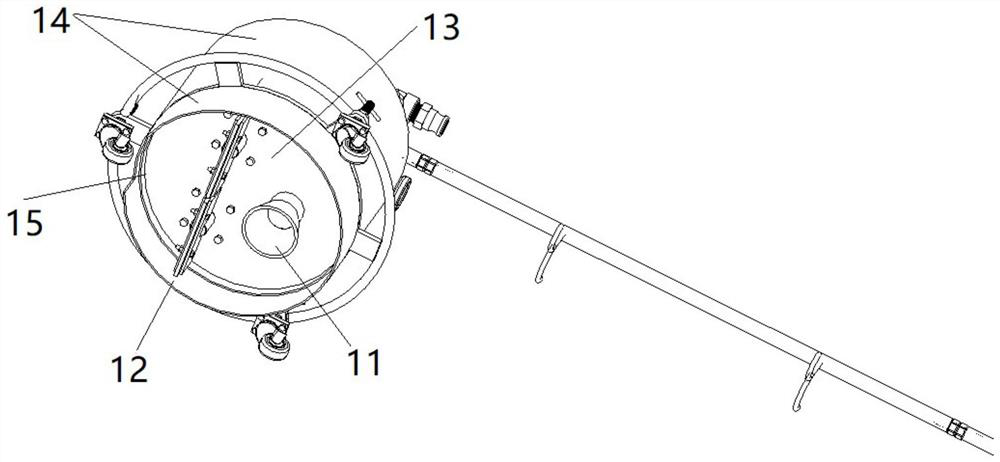

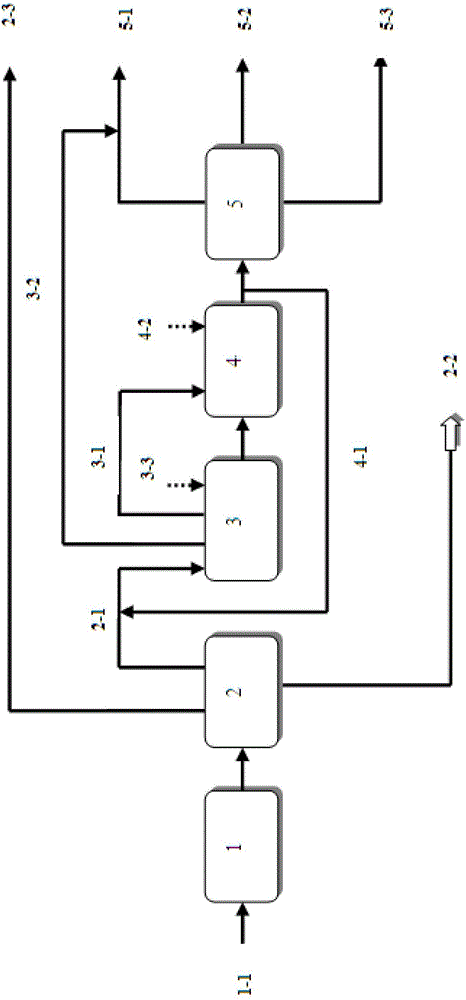

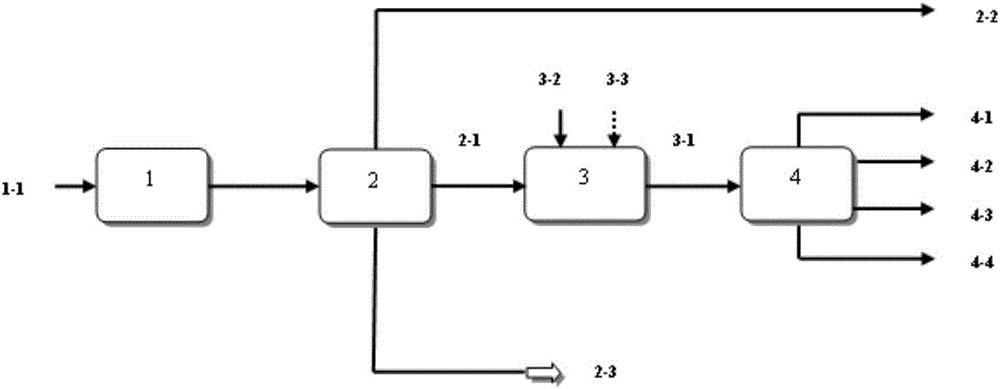

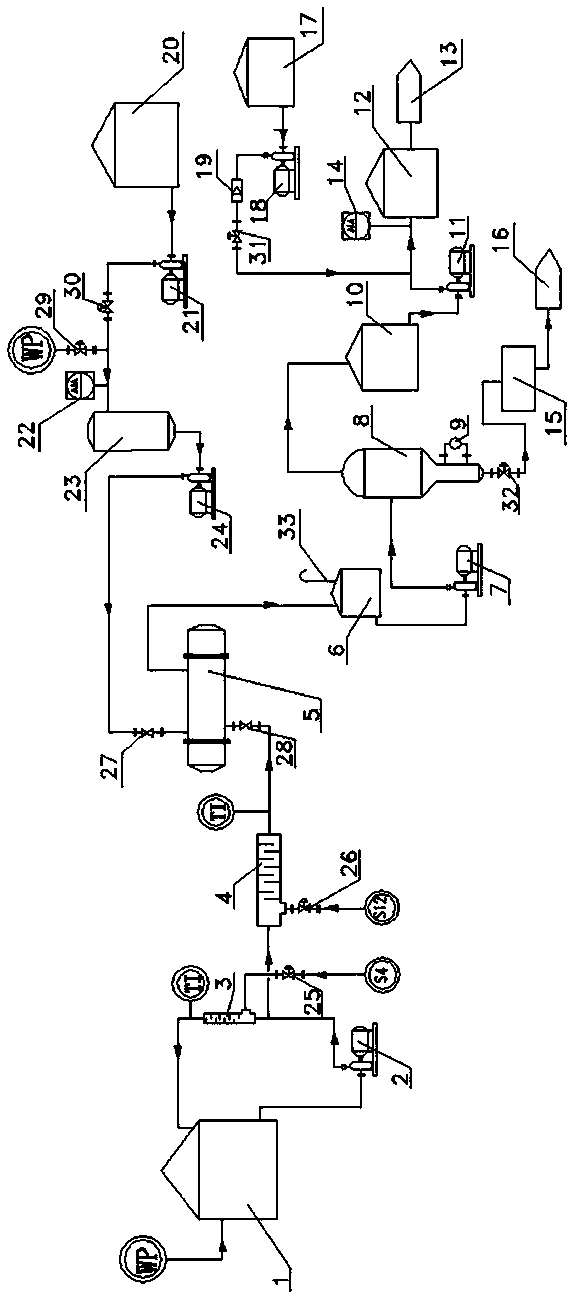

The invention provides a method for improving the shale oil hydrorefining denitrification rate, and relates to a whole fraction shale oil hydro-denitrification process. The method aims at solving the technical problems that in the existing method for producing diesel oil through shale oil hydrorefining, the stability of a diesel oil product is low, and the operation running period of a hydrorefining catalyst is short. According to the method, a raw material pretreatment unit 1, a raw material pre-fractionation unit 2, a primary hydrorefining reaction unit 3, a secondary hydrorefining reaction unit 4 and a product fractionation unit 5 are used. When the method provided by the invention is used for processing shale oil, the light oil yield is high; the nitrogen content of the diesel oil product is low; the chromaticity and the stability conform to national V standard requirements; the goal of light oil product deep denitrification can be achieved; the service life of the hydrorefining catalyst is prolonged; the operation running period of the catalyst is improved. A main product of the method is hydrorefining diesel oil; byproducts are high-value LPG and hydrogenated naphtha; heavy shale oil and hydrogenation tail oil thrown out in the technical process can be further processed and used in a downstream device. The method provided by the invention belongs to the field of whole-fraction shale oil deep processing.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE

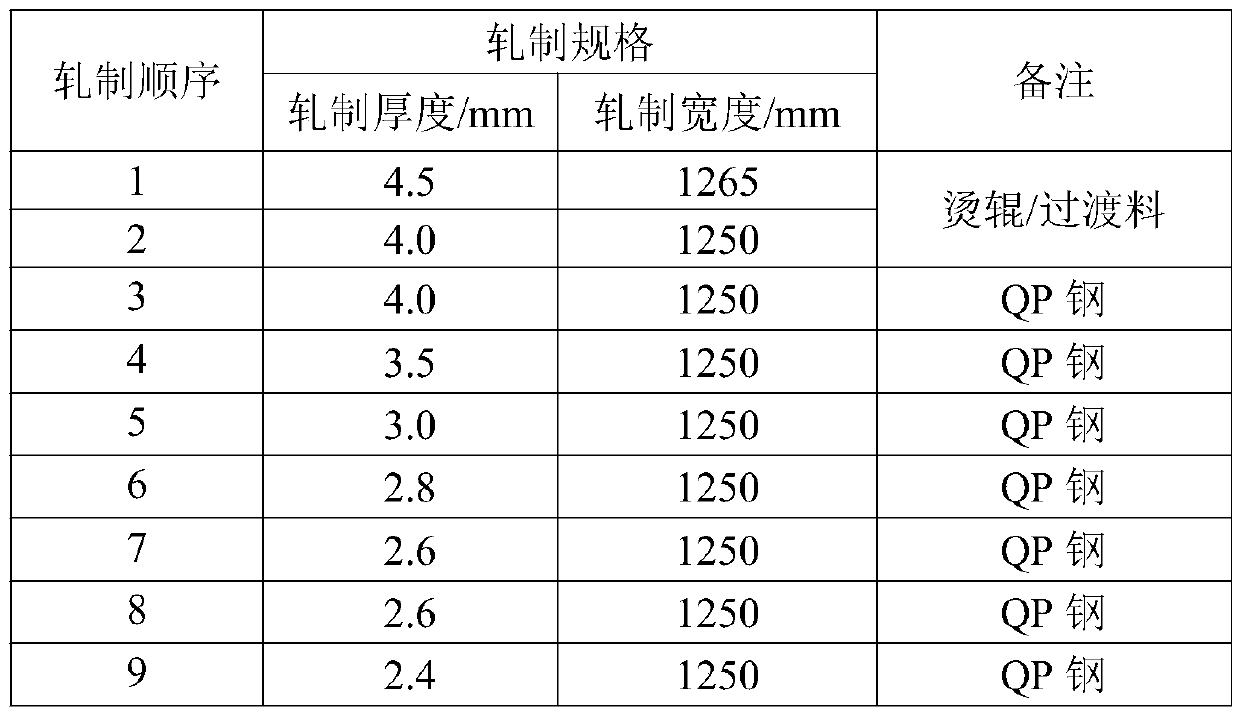

Stable production method for hot rolling of thin-gauge ultrahigh-strength quenching-partitioning steel

InactiveCN111097798AImprove shape qualityReduce vibrationTemperature control deviceWork cooling devicesProduction lineProcess engineering

The invention discloses a stable production method for hot rolling of thin-gauge ultrahigh-strength quenching-partitioning steel. The stable production method comprises the following steps of rollinglength transition, heating, rough rolling, finish rolling and coiling. The stable production method for hot rolling of the thin-gauge ultrahigh-strength quenching-partitioning steel effectively improves the production stability of a hot rolling production line of the thin-gauge ultrahigh-strength quenching-partitioning steel; optimization is conducted on the multiple aspects of the rolling gauge,the steel charging sequence, the heating process system, the rough rolling and finish rolling technology, coiling tension and the like, and the stable production method is used for guiding on-site production operation, improving the shape quality of the rolled piece, and effectively improving the rolling stability; finish rolling adopts the concepts of conducting acceleration and water reduction,lowering temperature drop of the process, reducing vibration of a rolling machine, preventing strip steel from tail whipping and the like to conduct stable rolling control; the stable production method achieves stable mass production in the hot rolling procedure of the thin-gauge quenching-partitioning steel which is quite high in production difficulty and achieves the purposes of lowing cost andincreasing benefits.

Owner:SD STEEL RIZHAO CO LTD

Fluorine-containing super-hydrophobic coating and preparing method and application thereof

InactiveCN107353724AEasy to synthesizeRealize the purpose of cost reduction and efficiency increaseCoatingsEmulsionSulfite salt

The invention discloses a fluorine-containing super-hydrophobic coating. The coating is prepared from, by mass, 15-25 parts of polyamide-imide resin, 30-50 parts of polytetrafluoroethylene emulsion solution, 2-6 parts of aluminum oxide, 1-3 parts of sodium sulfide, and 15-25 parts of deionized water. The fluorine-containing super-hydrophobic coating is easy to synthesize, the actual construction process can be completed simply through coating in one time, and thus the purpose of lowering the cost and increasing synergism is achieved; a composite dispersant is adopted, the dispersing effect on polytetrafluoroethylene is achieved, and further comprehensive effectiveness of the coating is improved; selected aluminum oxide and sodium sulfite serve as auxiliaries, and the self-layering performance of the super-hydrophobic coating is improved; the fluorine-containing super-hydrophobic coating has excellent performance of having high hydrophobicity, resisting acid-alkali resistance, resisting high-temperature resistance, resisting salt, and being high in adhesive force and rigidity.

Owner:日氟荣高分子材料(上海)有限公司

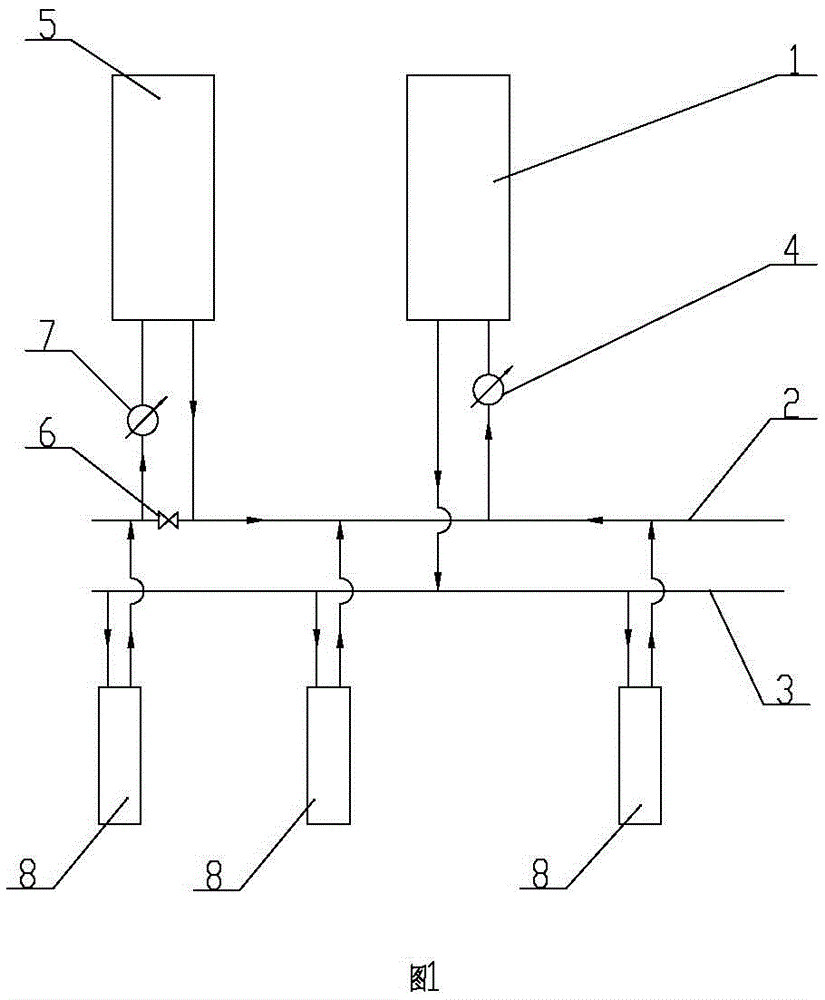

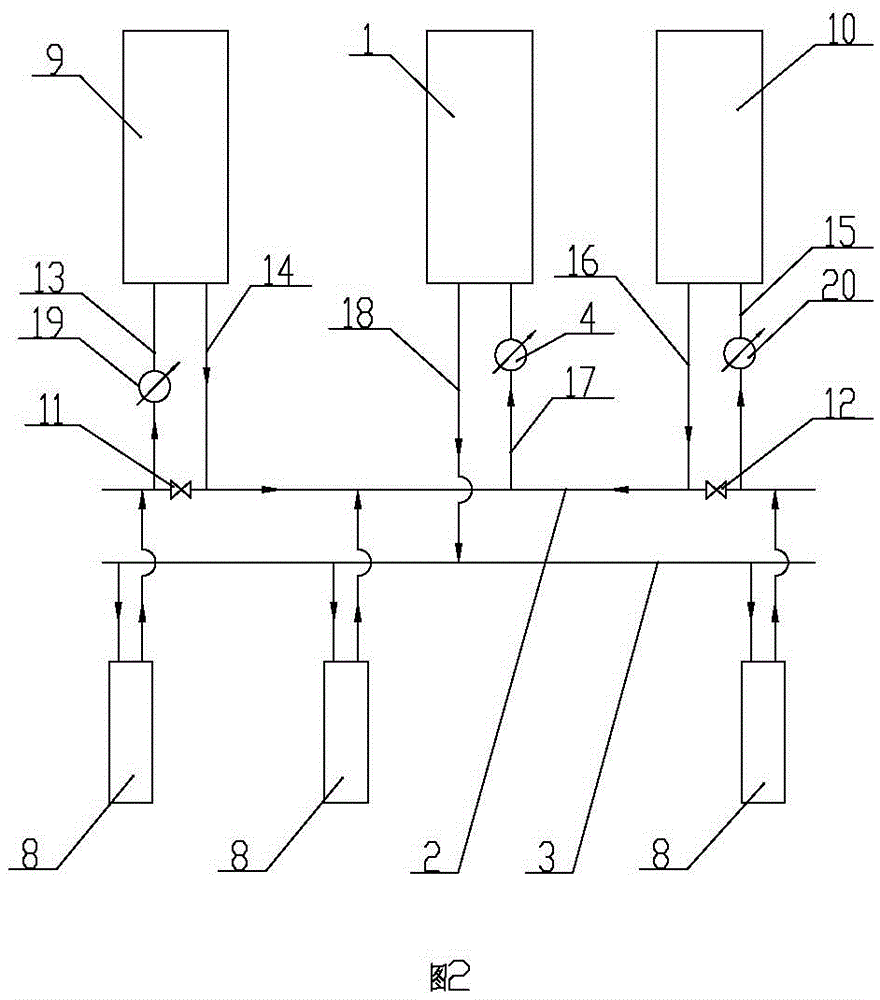

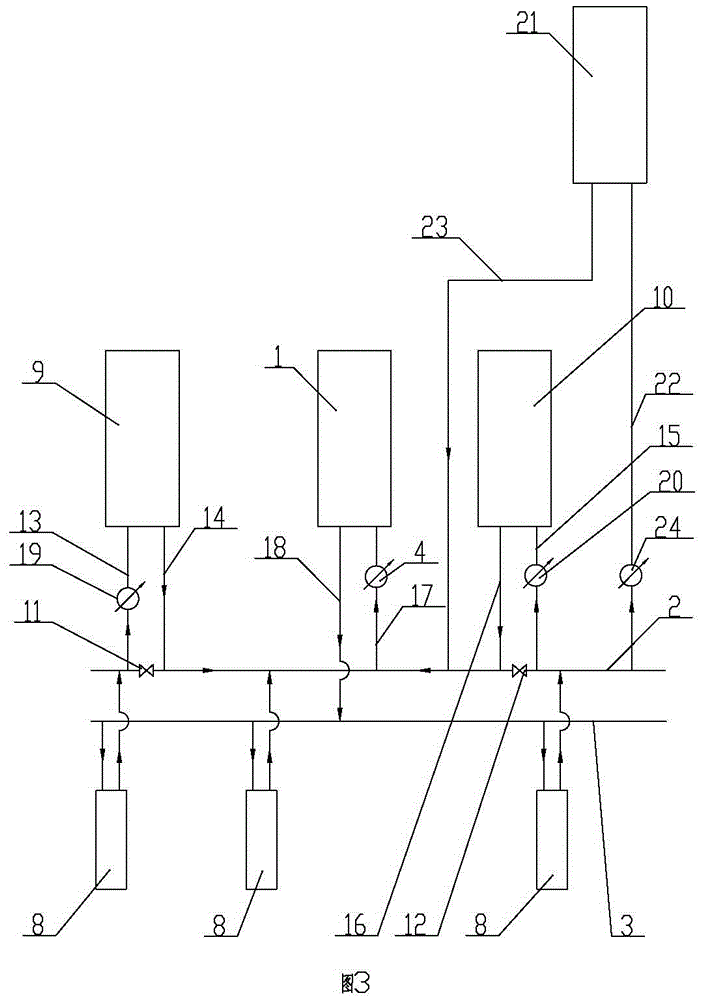

Main-auxiliary type multi-heat-source series-connection grid-connected heating device

InactiveCN105674377AIncrease profitCompact and reasonable structureLighting and heating apparatusSustainable buildingsEngineeringCirculating pump

The invention relates to the technical field of heating devices, in particular to a main-auxiliary type multi-heat-source series-connection grid-connected heating device. The main-auxiliary type multi-heat-source series-connection grid-connected heating device comprises a main heat source and at least one auxiliary heat source. One-way valves are arranged on a primary water return pipeline. Water inlets of the auxiliary heat sources communicate with the parts, on the outer sides of the one-way valves, of the primary water return pipeline. Water outlets of the auxiliary heat sources communicate with the parts, on the inner sides of the one-way valves, of the primary water return pipeline. A water inlet of the main heat source communicates with the part, on the inner sides of the one-way valves, of the primary water return pipeline. A water outlet of the main heat source communicates with a primary water supply pipeline. Auxiliary circulating pumps are arranged on pipelines between the water inlets of the auxiliary heat sources and the parts, on the outer sides of the one-way valves, of the primary water return pipeline. A main circulating pump is arranged on a pipeline between the water inlet of the main heat source and the part, on the inner sides of the one-way valves, of the primary water return pipeline. According to the main-auxiliary type multi-heat-source series-connection grid-connected heating device, the multiple heat sources are connected to a grid in series, the auxiliary heat sources only heat one side of the primary water return pipeline, a boiler is started and stopped according to the system heat requirement, the heat power of the boiler is fully used, and the purposes of regulating the peak, achieving standby application and increasing the utilization rate of the heat sources are realized.

Owner:XINJIANG NORTH TIANHENG ENERGY SAVING TECH CO LTD

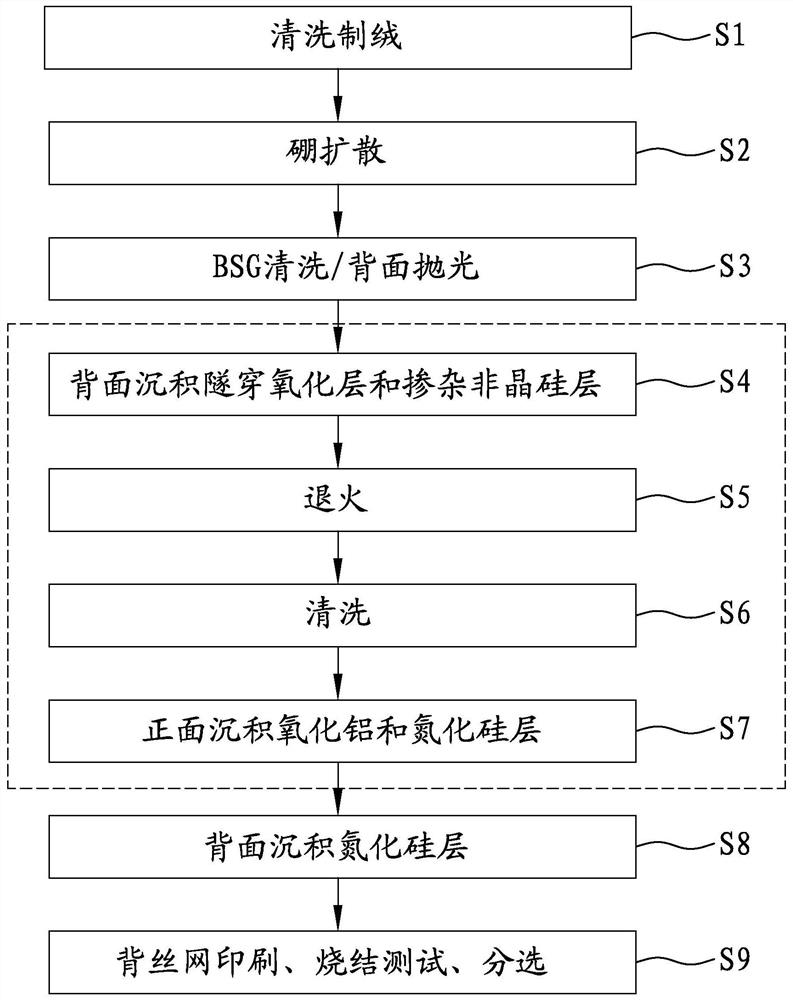

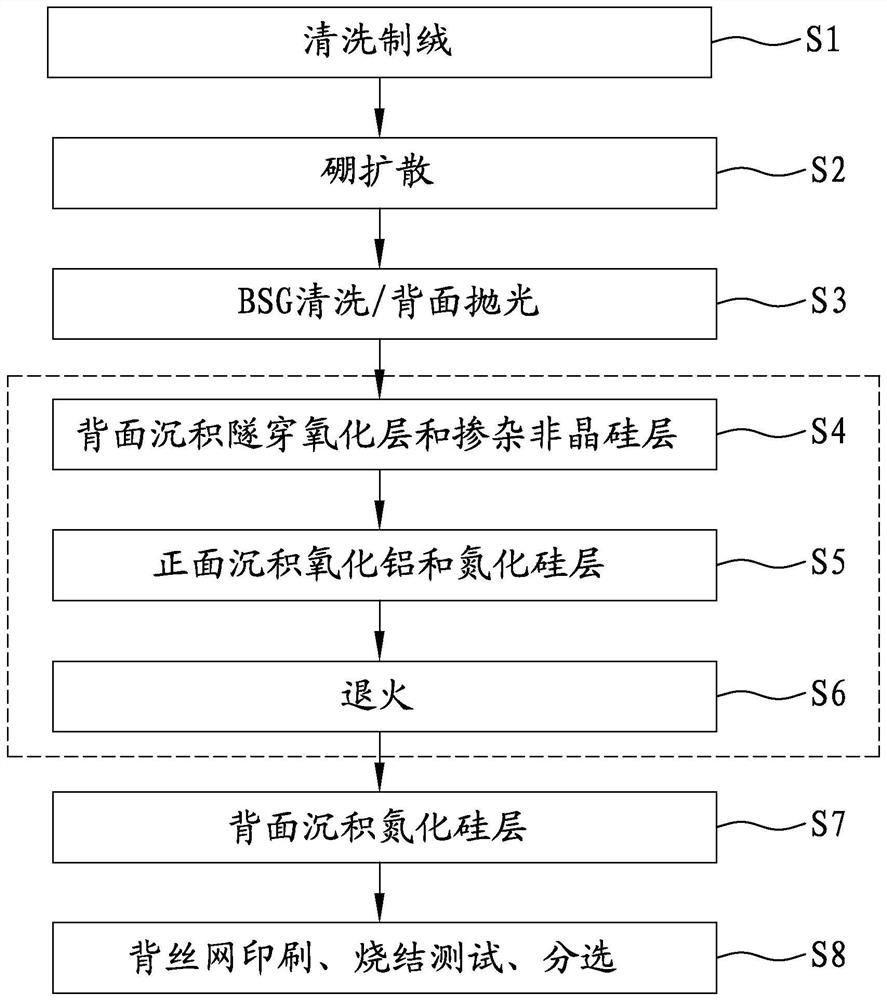

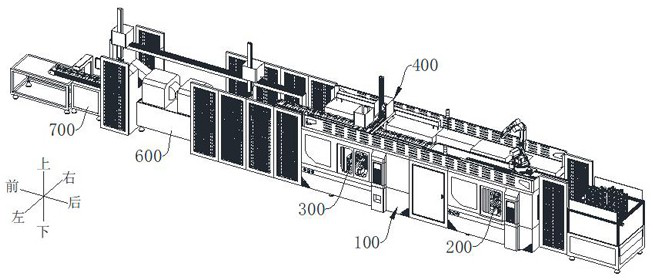

Solar cell manufacturing process and chained coating equipment

PendingCN113035997AImprove efficiencyAffect performanceFinal product manufacturePhotovoltaic energy generationCell fabricationEngineering

The invention discloses a solar cell manufacturing process. The solar cell manufacturing process comprises the following steps: S1, cleaning and texturing; S2, boron diffusing; S3, cleaning to remove the BSG layer and polishing the back surface; S4, depositing a tunneling oxide layer and a doped amorphous silicon layer on the back surface; S5, preparing an aluminum oxide and silicon nitride laminated layer on the front side; S6, annealing; S7, depositing a silicon nitride anti-reflection protection layer on the back surface; and S8, carrying out silk-screen printing, sintering testing and sorting. According to the invention, the process of depositing aluminum oxide and silicon nitride films in the front surface is adjusted to be before the annealing process, and the passivation capability of aluminum oxide and silicon nitride is fully excited by using long-time high temperature during annealing, so that the cell efficiency is improved; and secondly, the front surface of the silicon wafer is covered with an aluminum oxide film and a silicon nitride film in advance, so that the situation that impurities are introduced into the front surface during annealing to affect the battery performance is avoided, meanwhile, the cleaning procedure after annealing can be omitted, the technological process is simplified to 8 steps from 9 steps in the prior art, and therefore the production efficiency is effectively improved.

Owner:江苏杰太光电技术有限公司

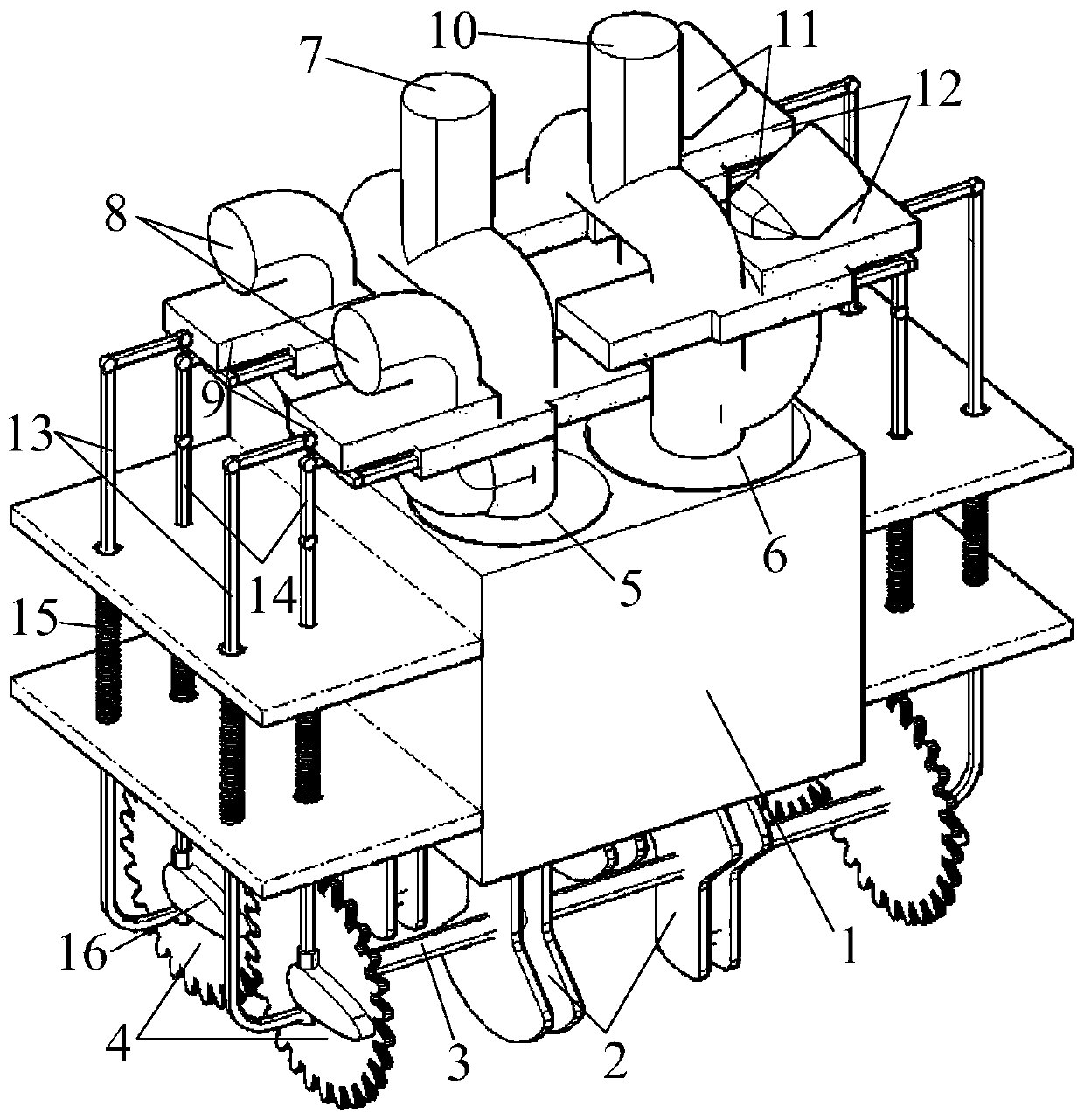

Deep-well mine auxiliary drainage device utilizing surface water potential energy

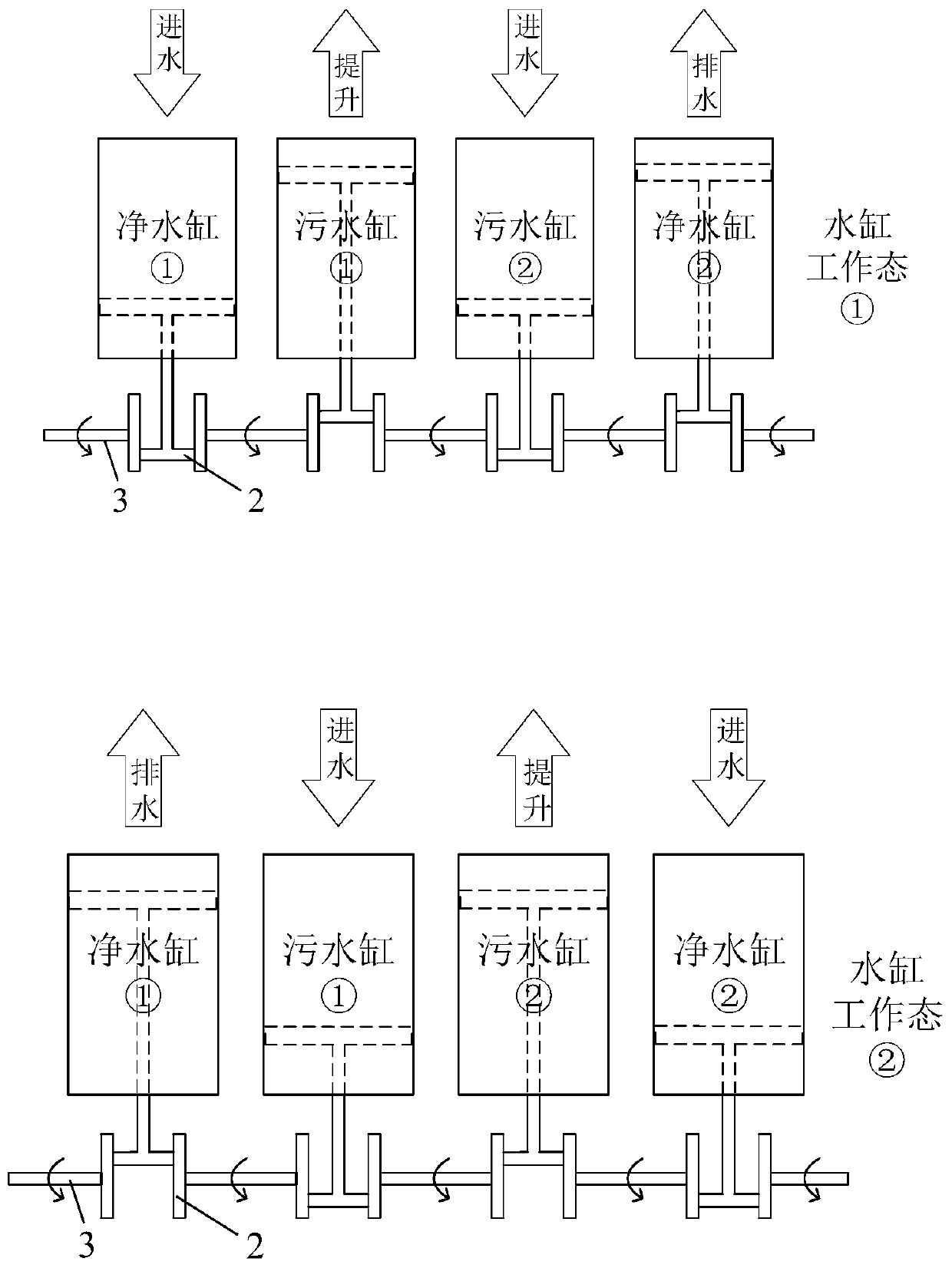

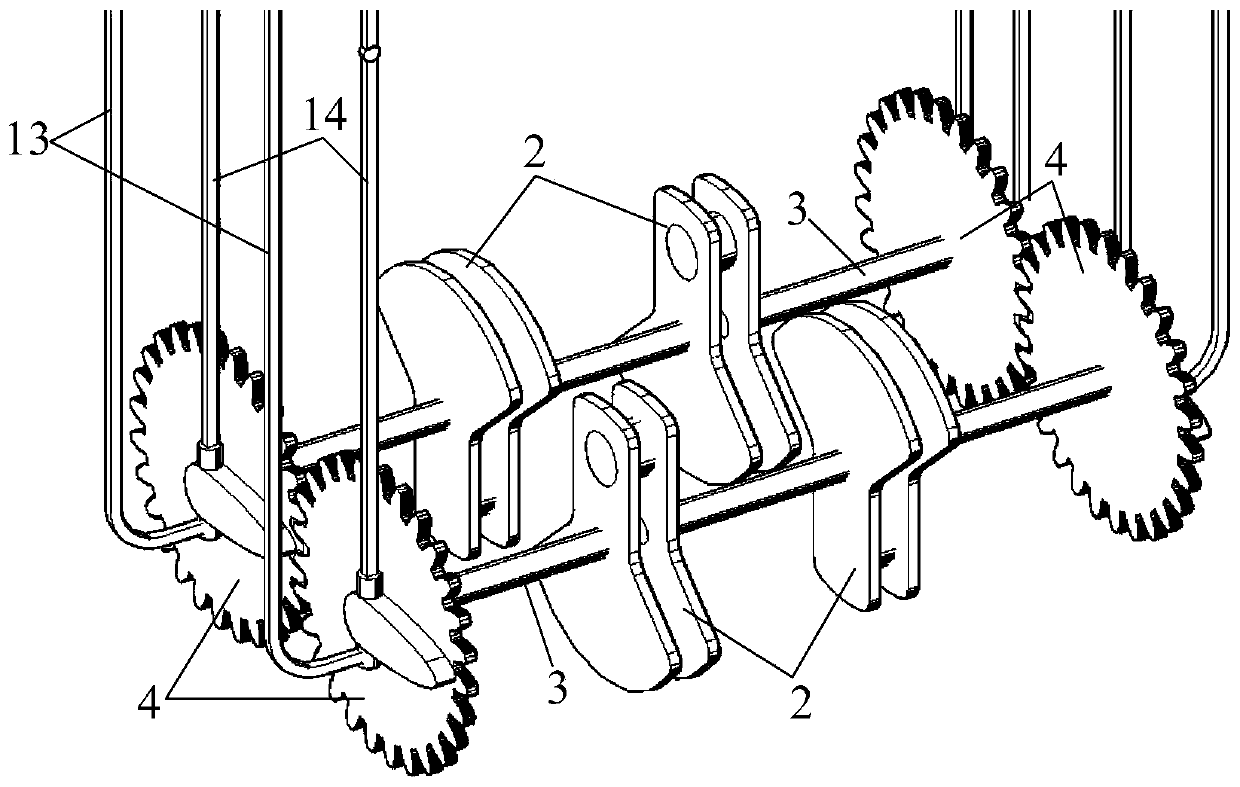

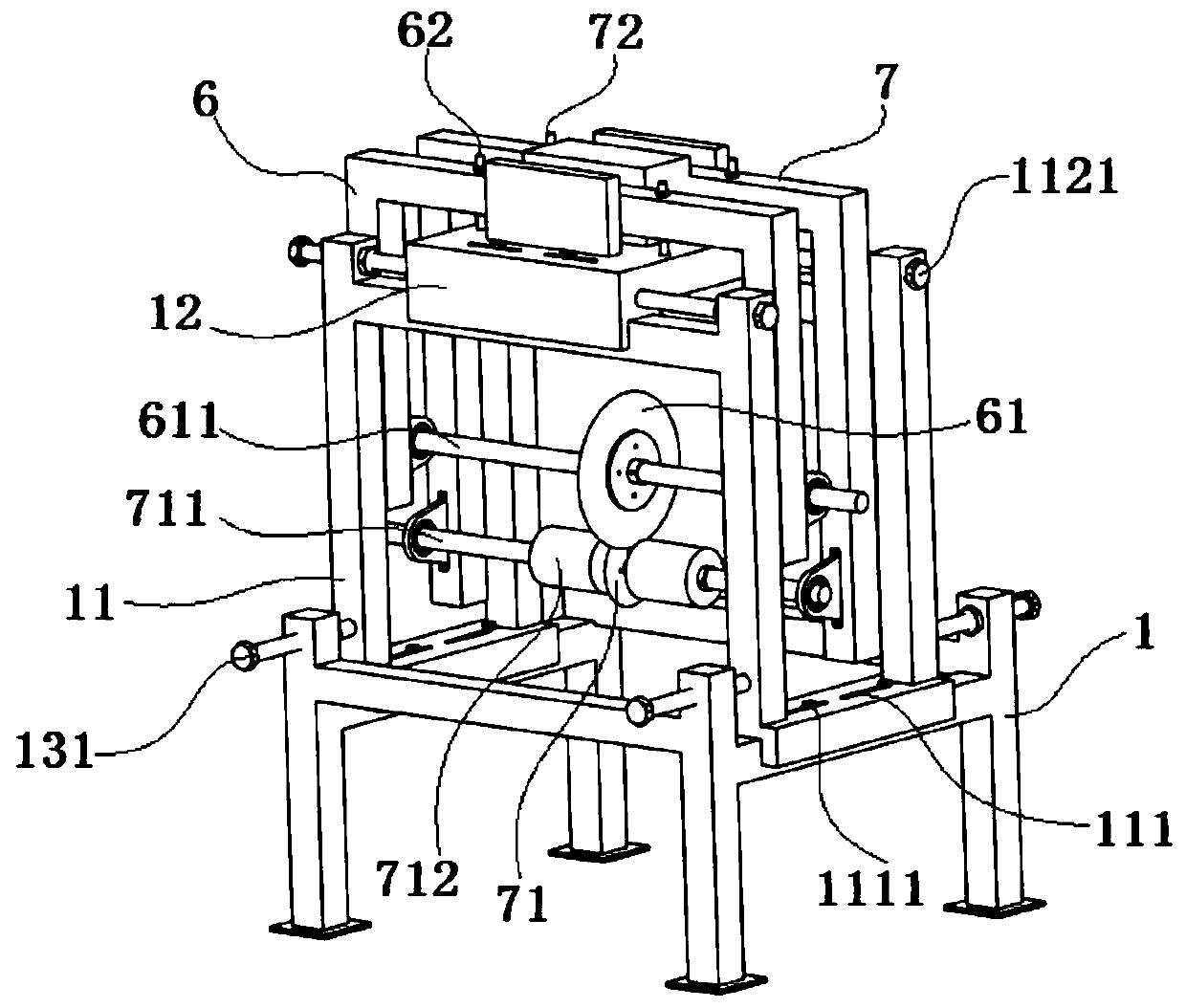

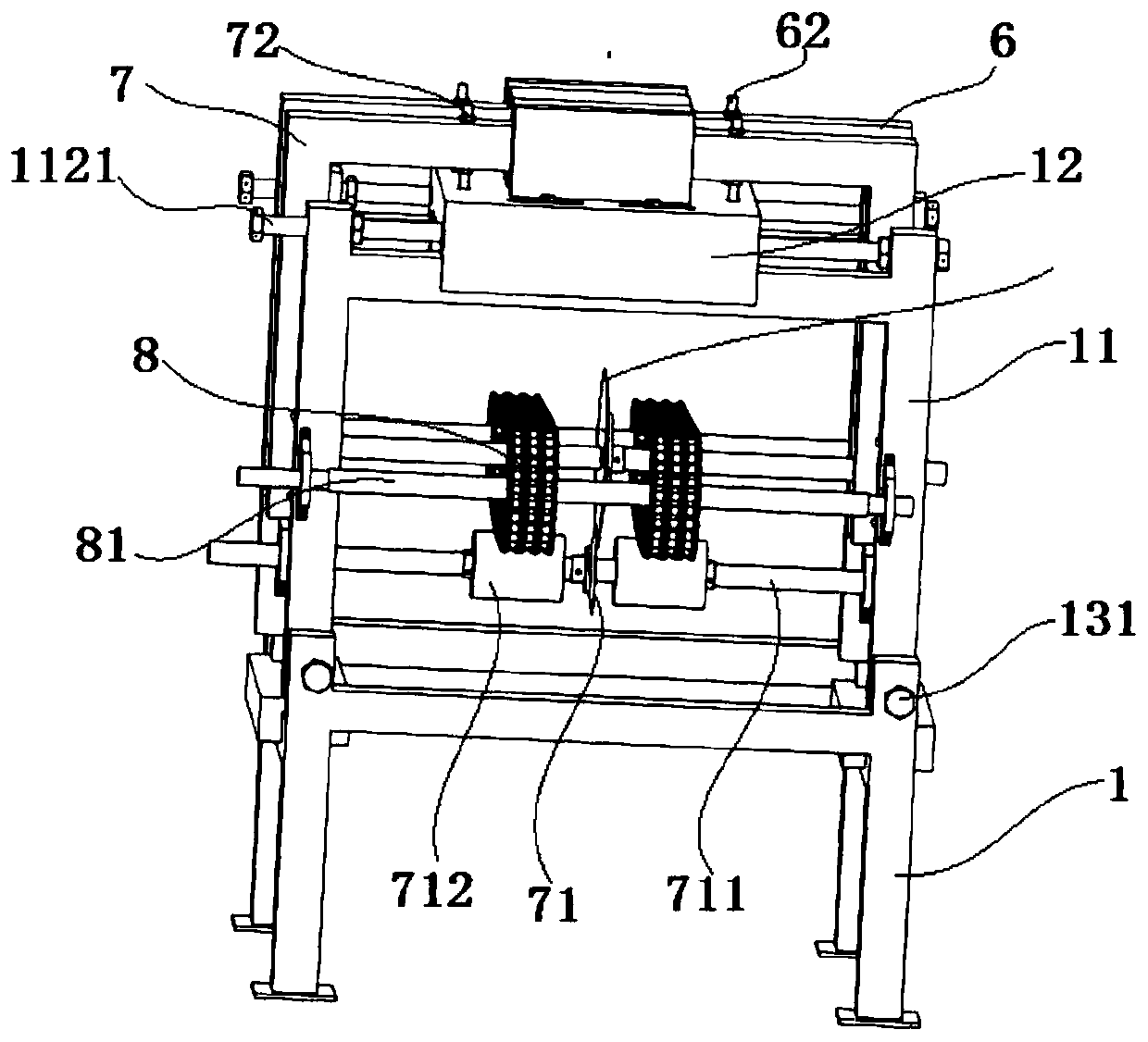

ActiveCN110056391AReduce lifting energy consumptionReduce energy consumptionOperating means/releasing devices for valvesMultiple way valvesWater qualitySewage

The invention discloses a deep-well mine auxiliary drainage device utilizing surface water potential energy. The deep-well mine auxiliary drainage device comprises five parts of a box, piston connecting rods, a gear transmission system, valves and pipelines; the box is internally provided with two purified water cylinders and two sewage cylinders; the device is mounted at the bottoms of main and auxiliary wells of a mine, during starting, surface water is injected into the purified water cylinders through the pipelines, the piston connecting rods are hydraulically driven to move downwards, pistons in the sewage cylinders move upwards through gear transmission, and sewage is lifted; the purified water cylinders and the sewage cylinders each have a water feeding stroke and a water draining stroke, at the same time, the two purified water cylinders always conduct the water feeding stroke and the water draining stroke at the same time, the two sewage cylinders always internally conduct thewater feeding stroke and the water draining stroke, thus the water continuously enters the device, and the sewage is lifted; and the water feeding and draining pipelines of the purified water cylinders and the sewage cylinders are switched through the valves, and the valves control the tail ends of the connecting rods to be tightly attached to cams on gears to achieve linkage. The high-potential-energy water, from the surface, in a deep well mining water supply system serves as a power source for lifting the sewage downhole, the purposes of energy saving and cost lowering of deep well miningare achieved, and the water quality of the downhole water is not affected.

Owner:CENT SOUTH UNIV

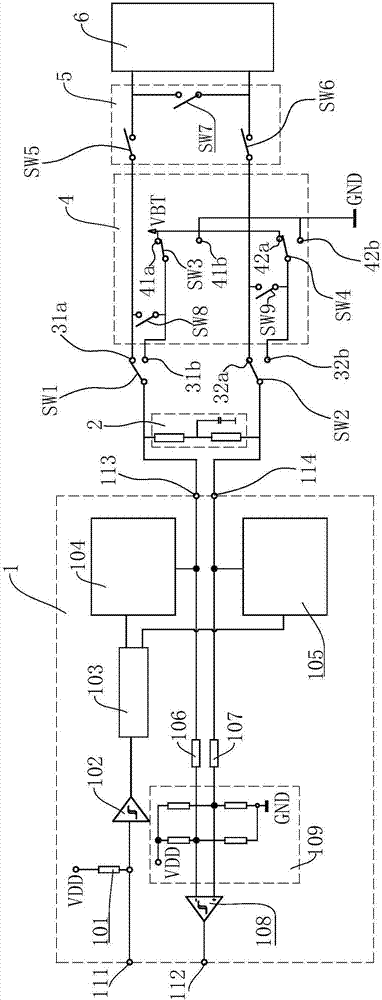

CAN bus work mode on-line simulation system

The invention discloses a CAN bus work mode on-line simulation system, which comprises a CAN transceiver simulation unit for simulating a CAN transceiver to send and receive signals. A load circuit is arranged between a CANH pin and a CANL pin of the CAN transceiver simulation unit. A mode switching unit comprises a node mode switching circuit and a bus mode switching circuit. The node mode switching circuit is used for switching a CAN node to a short-circuit-to-power-supply failure mode or a short-circuit-to-ground failure mode. The bus mode switching circuit is used for switching the CAN node to a normal working mode / open circuit fault mode / short circuit fault mode. The simulation system can simulate the normal working mode and the fault disturbance mode of a CAN bus, can quickly reproduce and locate fault states and can realize cost decreasing and benefit increasing in the CAN bus development and use process.

Owner:GUANGXI NORMAL UNIV

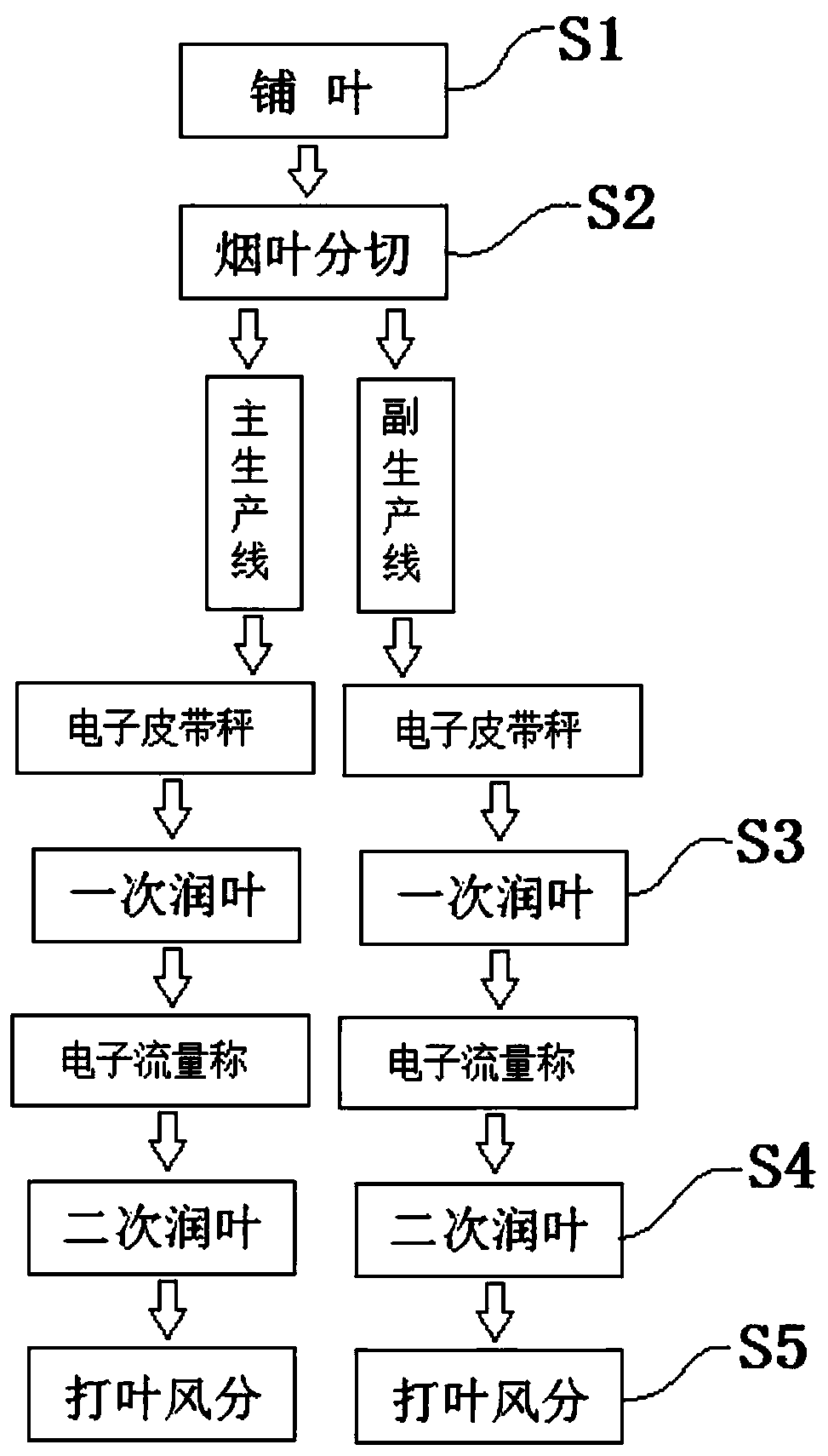

Double-line redrying-based processing method and processing device

PendingCN111165860AReduce loadReduce breakage rateTobacco preparationAgricultural engineeringThreshing

The invention discloses a double-line redrying-based processing method and a processing device. According to the method, one-cutter two-section type machining is adopted; tobacco leaves are cut into upper tobacco leaves with leaf tips and lower tobacco leaves with leaf bases from the middle; the upper and lower tobacco leaves respectively fall onto two belts which are arranged in parallel below acut-off machine; the rotating directions of the two belts are opposite; the cut upper and lower tobacco leaves are respectively conveyed to a main production line and an auxiliary production line forprocessing through two parallel belts in opposite directions; an electronic belt scale and an electronic flow scale are respectively arranged before primary wetting and secondary wetting to realize automatic flow regulation and control, and aiming at the physical processability of the upper and lower tobacco leaves, the upper and lower tobacco leaves are threshed and air-separated in a 'forced threshing and subdivision' manner and a 'soft threshing and subdivision' manner respectively, so that the breakage of the tobacco leaves in the threshing process is effectively reduced, and the product yield is improved.

Owner:QILIN REDRYING FACTORY YUNNAN TOBACCO REDRYING

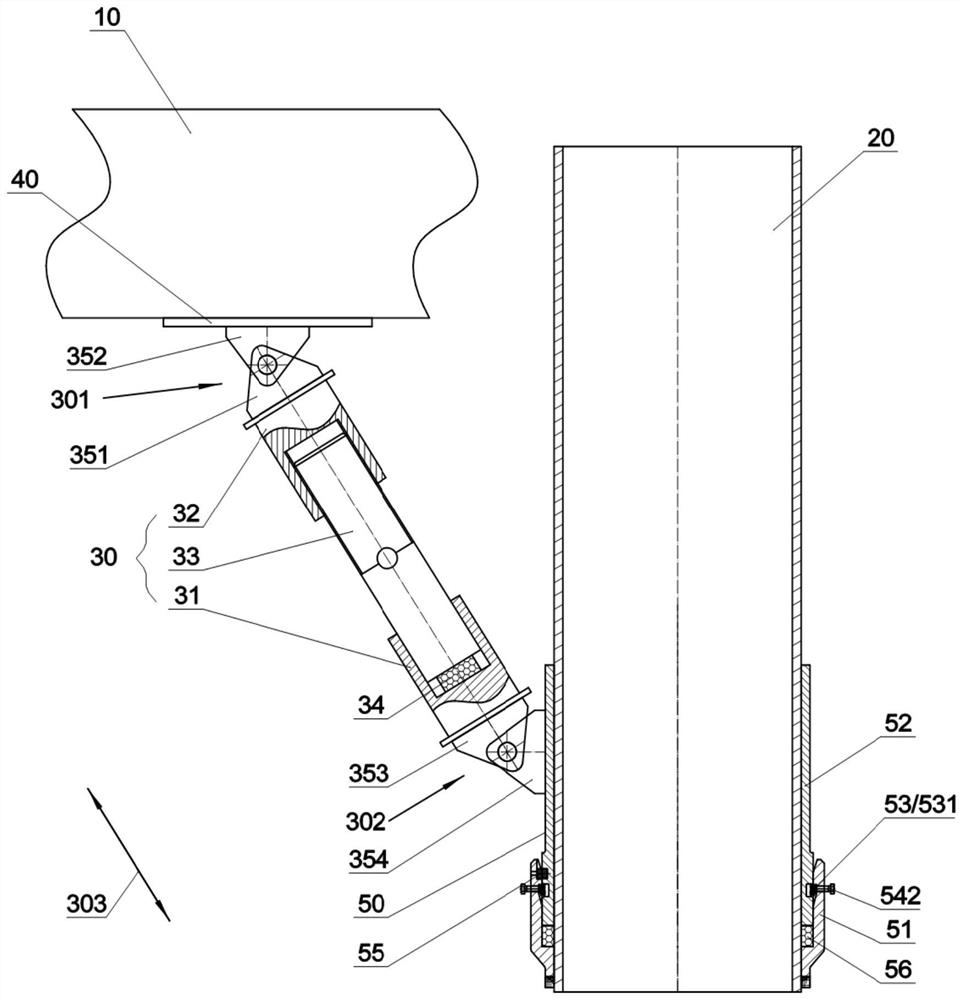

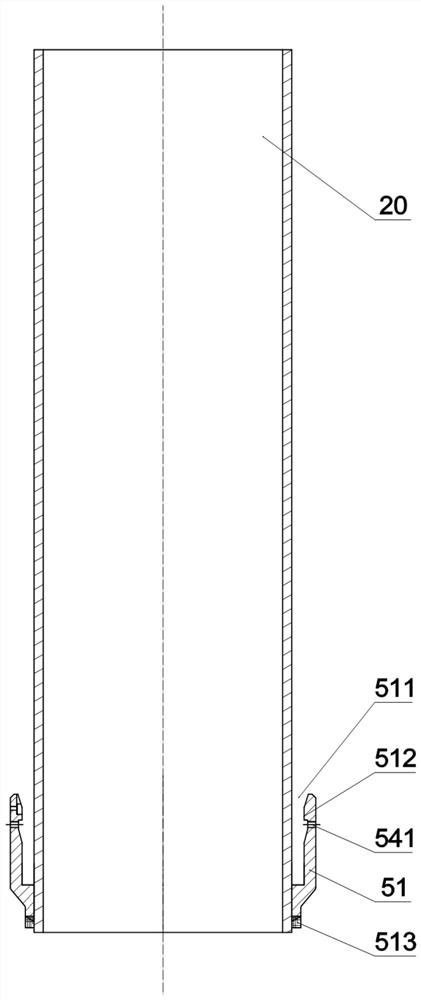

Offshore oil production platform, and bearing capacity transfer method and transfer device of drilling platform

PendingCN111810063AIncrease ultimate bearing capacityReduce design costArtificial islandsDrilling rodsWell drillingOil production

The invention provides an offshore oil production platform, and a bearing capacity transfer method and transfer device of a drilling platform. The bearing capacity transfer device of a riser and the drilling platform comprises a connecting rod body, a drilling platform connecting plate and a riser connecting structure, wherein the connecting rod body can transfer vertical load; the drilling platform connecting plate is connected to the first end of the connecting rod body and can be fixedly connected to the drilling platform; and the riser connecting structure is connected to the second end ofthe connecting rod body and can be fixedly connected to the riser. Through the offshore oil production platform, the ultimate bearing capacity of the drilling platform is increased, and safety guarantee is provided for subsequent development.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

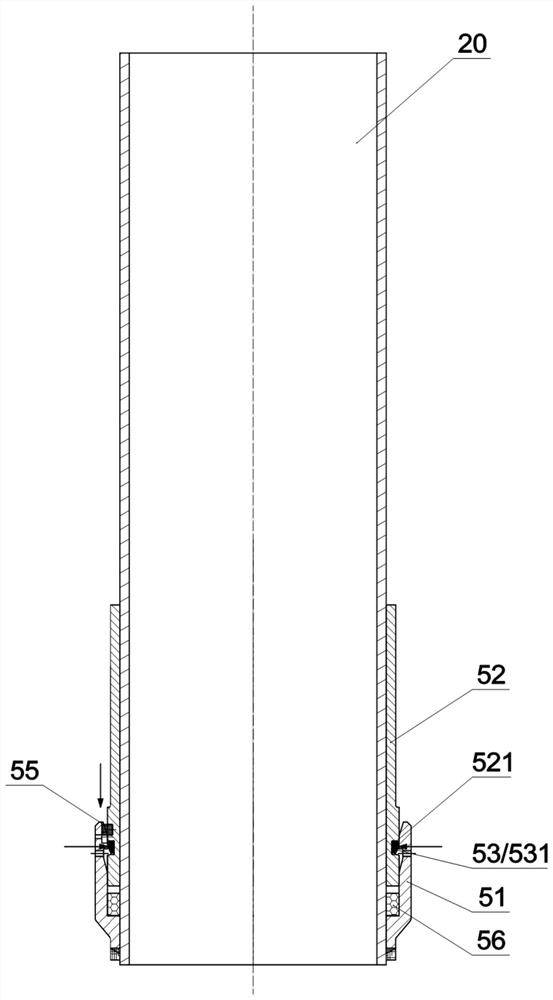

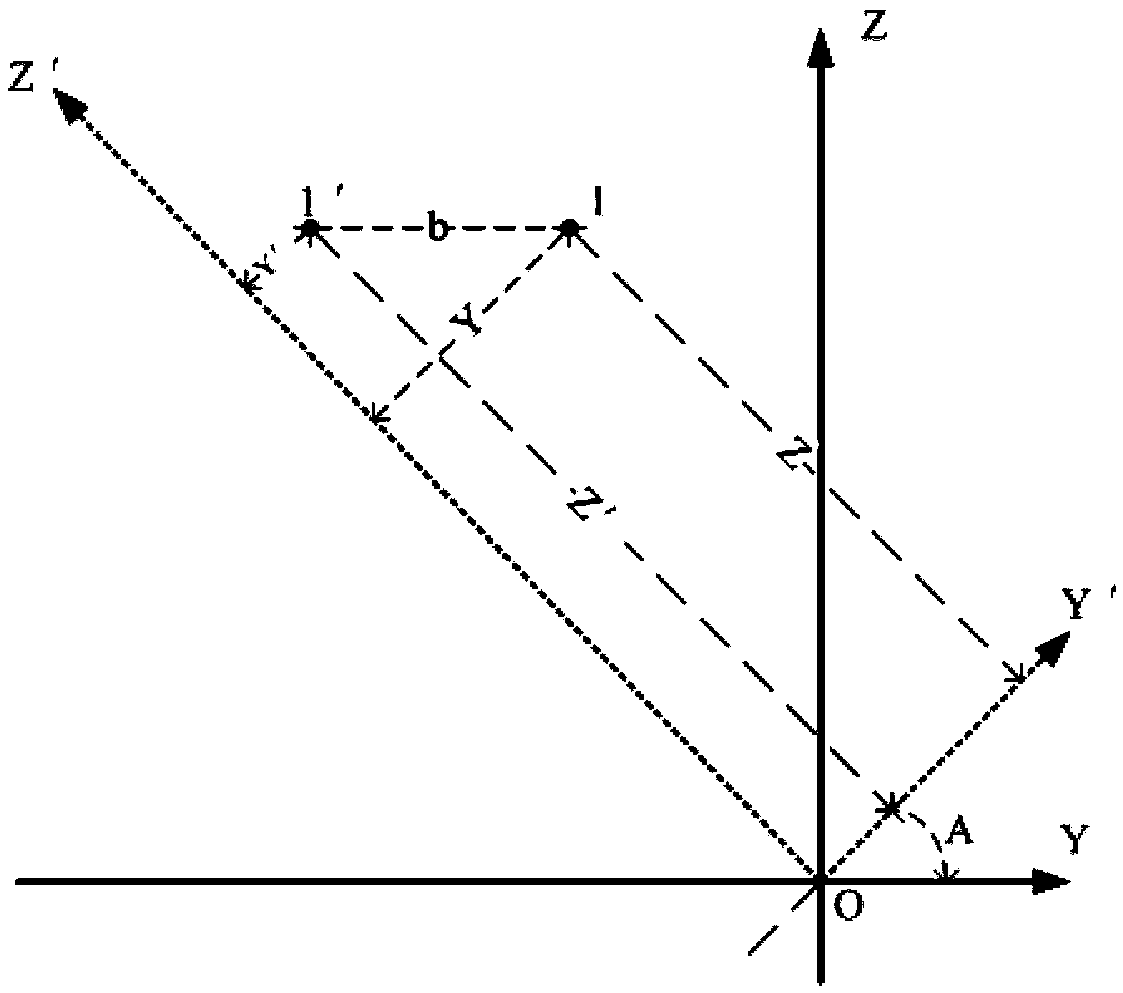

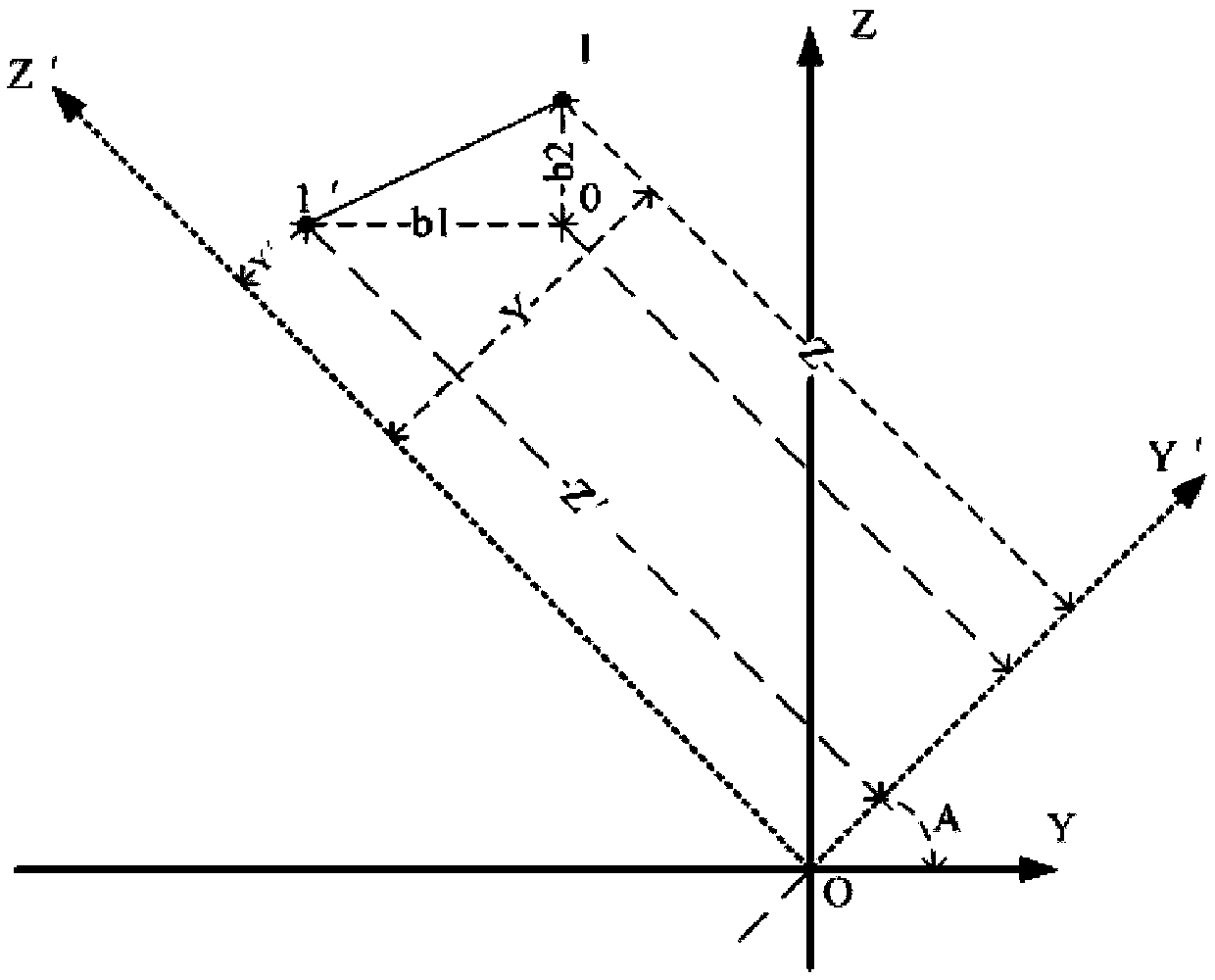

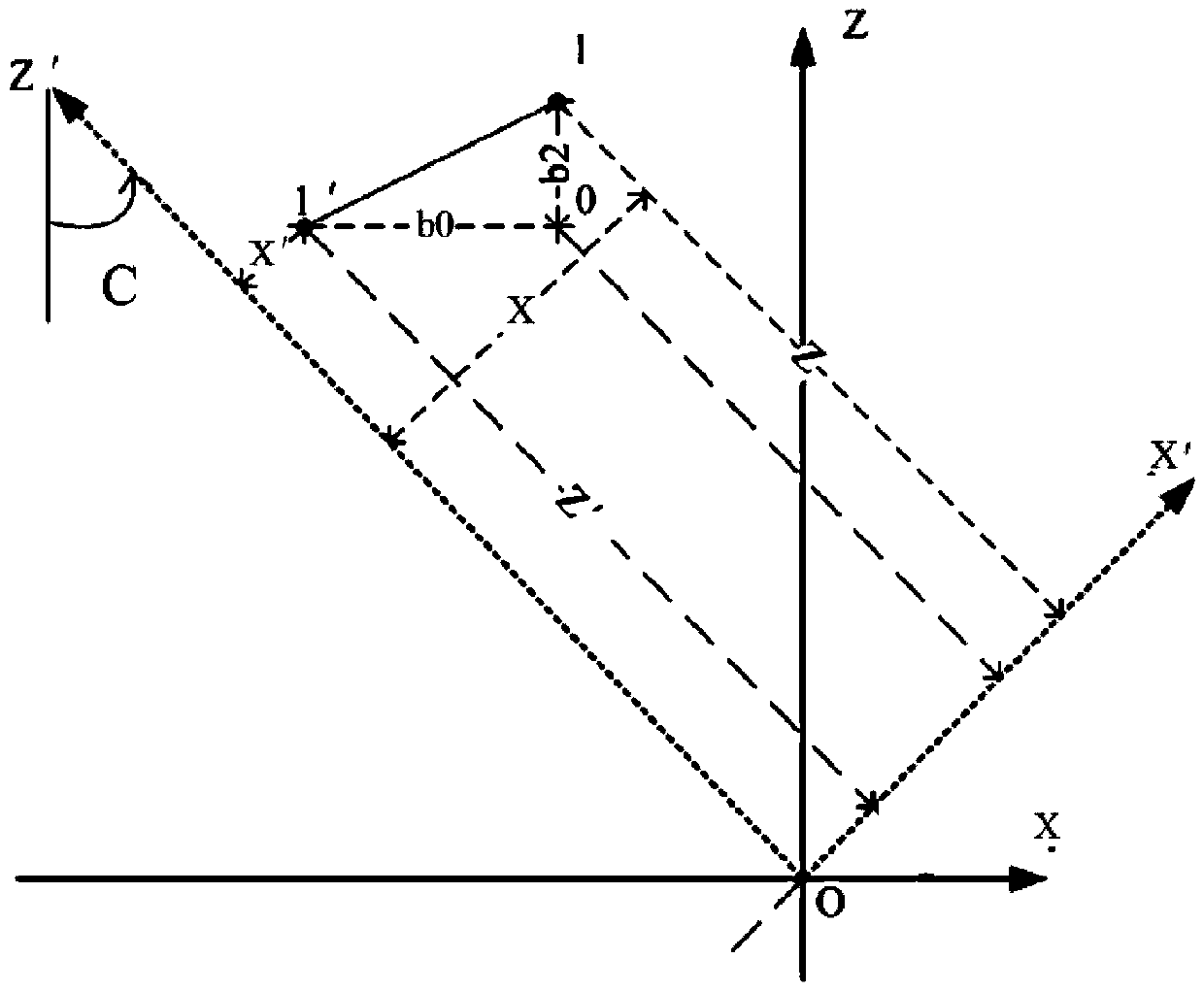

Steam turbine blade processing method based on molded line adjustment

ActiveCN105373074AReduce workloadRealize the purpose of cost reduction and efficiency increaseNumerical controlSteam turbine bladeEngineering

The invention discloses a steam turbine blade processing method based on molded line adjustment, and belongs to the field of processing control. In a conventional steam turbine blade processing process, blade molded lines with deviations are processed, and the problems of large workload and low work efficiency, caused when a programmer manually inputs a deviation modification amount are eliminated. According to the steam turbine blade processing method based on the molded line adjustment, when a machine tool is actually machined by use of movement along an X axis or a Y axis or a Z axis of a five-axis linkage program coordinate system, parameters moving along the X axis or the Y axis or the Z axis are converted into values under a workpiece coordinate system, and then addition and subtraction operation is carried out with X, Y and Z value vectors in G codes through the parameters after conversion. According to the method provided by the invention, reliance on TS85 software is eliminated in the process of controlling blade molded lines, an operator can an input program file and input modification data, the process of automatically generating a conversion file is realized and the method has the advantages of improving the processing efficiency and decreasing the cost.

Owner:HARBIN TURBINE

Tank cleaning equipment for offshore oil platform and tank cleaning method

PendingCN112296041AAdvantages of tank cleaning equipmentMerit methodHollow article cleaningCleaning using gasesOil sludgeNitrogen gas

The invention discloses tank cleaning equipment for an offshore oil platform and a tank cleaning method. The tank cleaning equipment comprises a protective cover, motors oppositely arranged in the protective cover, and a lengthened push rod which is mounted between the motors, the upper part of the protective cover is sleeved with an anti-collision guardrail, the bottom of the protective cover isprovided with a first quick connector, the first quick connector serves as a liquid phase outlet, a partition plate for protecting the motors from being damaged by dirty oil sludge and a liquid inletopening are arranged at the upper part of the protective cover, the motors are arranged at the bottom of the protective cover and are connected with a second quick connector through an air supply pipeline, the second quick connector serves as a nitrogen inlet, the nitrogen inlet has enough gas circulation amount and is convenient to disassemble and assemble, a plurality of push rod height adjusting screw rods are installed on the top of the lengthened push rod and the upper part of the lengthened push rod, and a plurality of push rod connecting threads are further arranged on the lengthened push rod. According to the tank cleaning equipment for the offshore oil platform and the tank cleaning method, operators do not need to enter a tank body, the whole tank cleaning process is achieved, and through the tank cleaning equipment, suspension impurities in a tank can be removed, and the dirty oil sludge deposited at the bottom of the tank can further be removed, so that the efficiency of tank cleaning operation is greatly improved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

A method for improving the denitrification rate of shale oil hydrotreating

ActiveCN105838418BImprove utilization efficiencyImprove the level of comprehensive utilizationTreatment with hydrotreatment processesHydrocarbon oils treatment productsNaphthaFractionation

The invention provides a method for improving the shale oil hydrorefining denitrification rate, and relates to a whole fraction shale oil hydro-denitrification process. The method aims at solving the technical problems that in the existing method for producing diesel oil through shale oil hydrorefining, the stability of a diesel oil product is low, and the operation running period of a hydrorefining catalyst is short. According to the method, a raw material pretreatment unit 1, a raw material pre-fractionation unit 2, a primary hydrorefining reaction unit 3, a secondary hydrorefining reaction unit 4 and a product fractionation unit 5 are used. When the method provided by the invention is used for processing shale oil, the light oil yield is high; the nitrogen content of the diesel oil product is low; the chromaticity and the stability conform to national V standard requirements; the goal of light oil product deep denitrification can be achieved; the service life of the hydrorefining catalyst is prolonged; the operation running period of the catalyst is improved. A main product of the method is hydrorefining diesel oil; byproducts are high-value LPG and hydrogenated naphtha; heavy shale oil and hydrogenation tail oil thrown out in the technical process can be further processed and used in a downstream device. The method provided by the invention belongs to the field of whole-fraction shale oil deep processing.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE

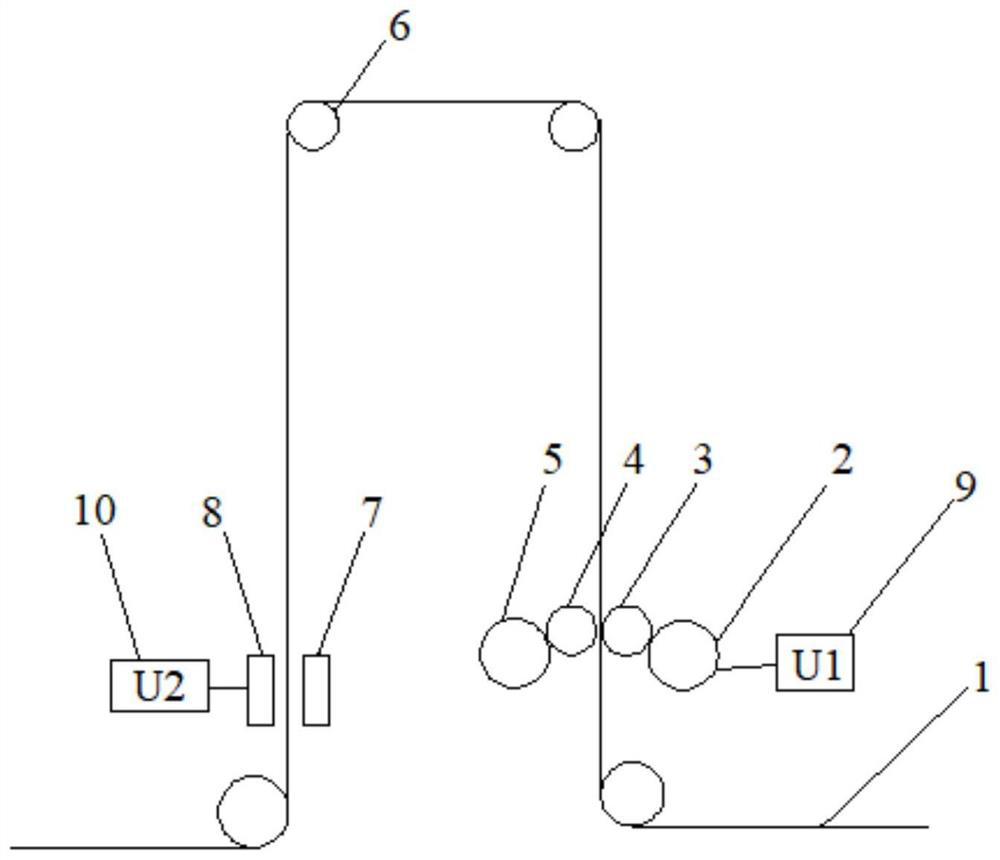

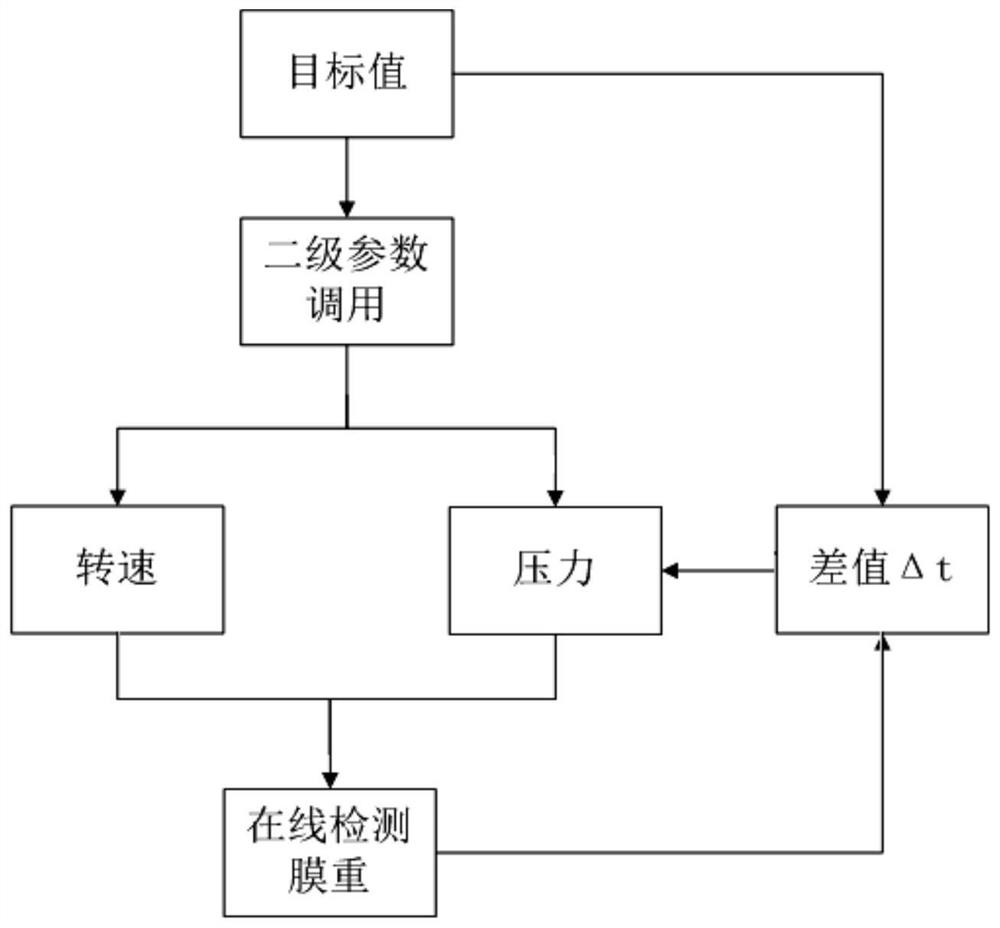

Galvanized steel strip surface passivation film weight control system and control method thereof

PendingCN113073317AHigh control precisionReduce revisionsHot-dipping/immersion processesControl systemEngineering

The invention discloses a galvanized steel strip surface passivation film weight control system which comprises a roller coater and a film thickness gauge. The control system is provided with four strip steel turning rollers, strip steel running on the horizontal plane is turned into a frame protruding upwards, the roller coater is arranged on the front side face of the frame, and the film thickness gauge is arranged on the rear side face of the frame. The invention further discloses a control method of the control system. By adopting the technical scheme, the film weight adjustment is more stable and timely, the lag of manual detection and adjustment is avoided, the film weight control precision is higher, the accurate control of the passive film weight is realized, the inconsistent judgment change amount of the passive film weight is reduced, and the quality loss is reduced; then, waste of a passivation solution caused by too high film weight is avoided, and the purposes of reducing cost and improving efficiency are achieved; and the automation rate of the production process is further improved, and human resources are optimized.

Owner:MAANSHAN IRON & STEEL CO LTD

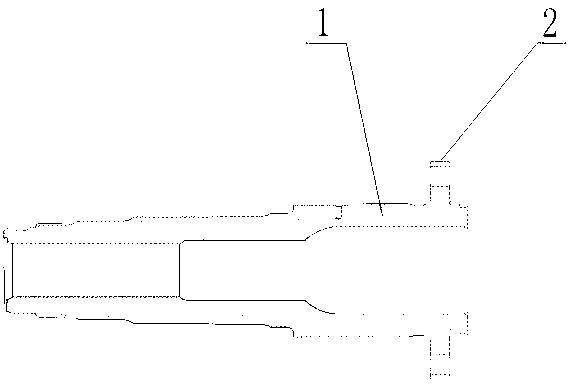

Novel flange connection type hub axle tube

InactiveCN103009923AGuarantee high precision and high performance requirementsLow costAxle unitsAutomotive engineeringFlange

The invention discloses a novel flange connection type hub axle tube, which comprises a hub axle tube (1). A flange plate structure (2) is arranged at the end part of the hub axle tube (1); and the flange plate structure (2) is integrally arranged with the hub axle tube (1). When in use, the hub axle tube is connected to an axle housing through bolts. According to the hub axle tube, the high precision and high performance requirements of the axle housing assembly can be effectively ensured; the hub axle tube is simple in structure and convenient to mount; the cost can be effectively reduced; and the purpose of reducing cost and increasing benefit is achieved.

Owner:QINGTE GRP

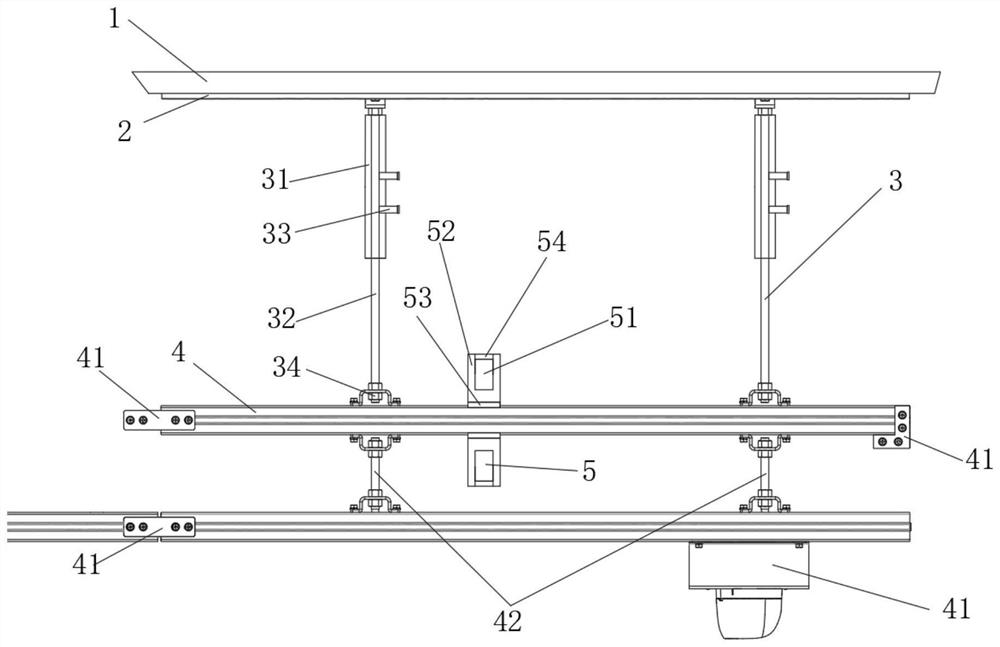

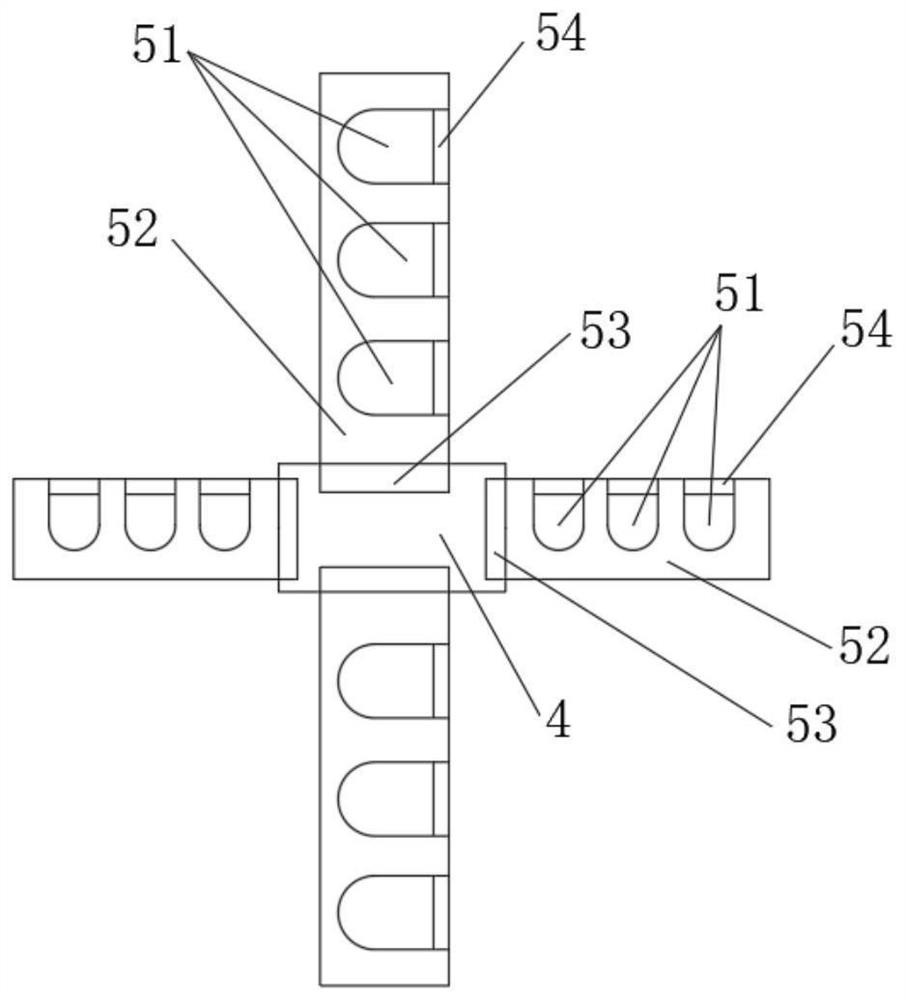

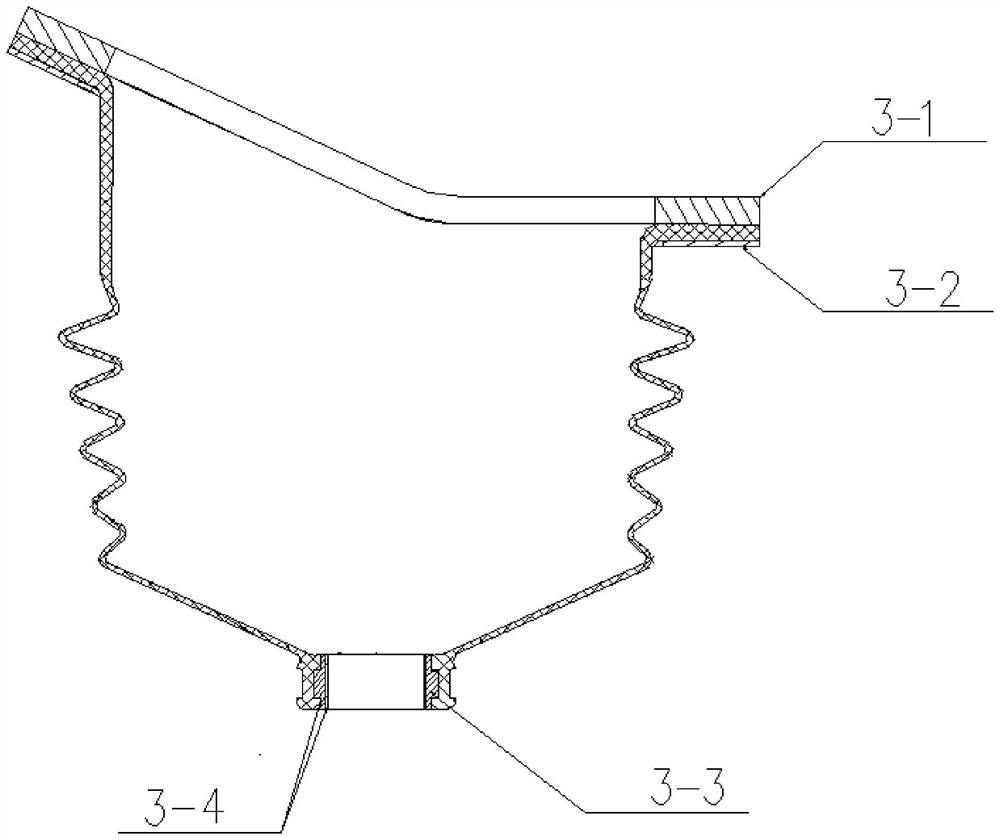

Pipeline support assembly convenient to mount and dismount and using method

The invention belongs to the technical field of pipeline fixing, and relates to a pipeline support assembly convenient to mount and demount, which can be connected with a steel beam, and is characterized by comprising a guide rail, a suspender, a support main body and a pipeline component, the guide rail is connected with the support main body through the suspender, and the pipeline component is arranged on the support main body. A through hole for a pipeline to penetrate through is formed in the pipeline assembly, the guide rail can drive the support body and the pipeline assembly to slide along the bottom of the steel beam, and then the through hole is driven to move. The invention has the beneficial effects that different types of pipelines can be systematically classified and integrated, so that not only is pipeline cable laying facilitated, but also equipment mounting can be assisted, multi-directional and multi-angle extension is realized, multi-point repeated arrangement of independent brackets is reduced, and construction material resources are saved.

Owner:MCC TIANGONG GROUP

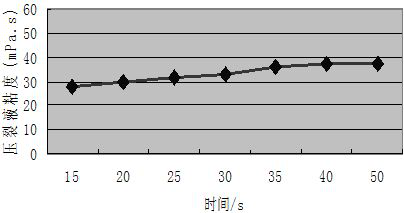

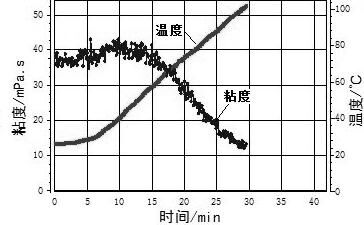

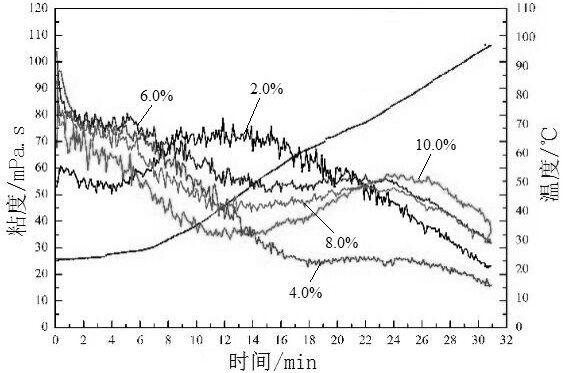

A kind of thickener and its application

The invention provides a thickening agent and application thereof. The thickening agent is prepared from the following materials in percentage by weight, 50-65% of surfactants, 15-25% of organic solvent and the balance of water. The thickening agent has the advantages that according to salt tolerance differences among the surfactants and intermolecular synergistic promotion effects, different types of the surfactants are selected for compounding and taking effect at different mineralization degrees; growth of rod-shaped and worm-shaped micelles is promoted along with salinity increase, the micelles are enlarged gradually, and accordingly, system viscosity is improved rapidly; the thickening agent has the characteristics of hypersalinity resistance, reutilization and the like, does not needchemical treatment under hypersalinity conditions, and can be directly applied to preparation of fracturing fluids or oil-displacing agents, and accordingly, reutilization of various types of flowback fluids is realized; an on-site construction mode of preparing the fracturing fluids by clear water-preparing the fracturing fluids by the flowback fluids-preparing the oil-displacing agents by the tail-end flowback fluids is adopted, and accordingly, zero pollution and zero emission in oil field operation are realized.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

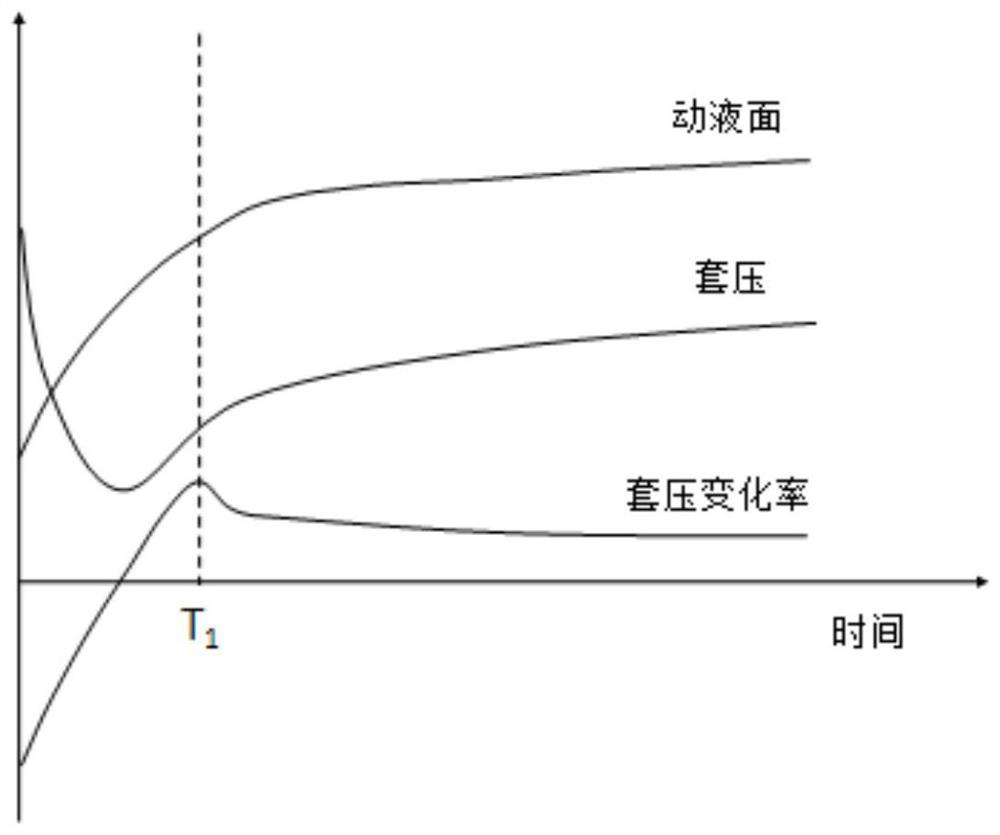

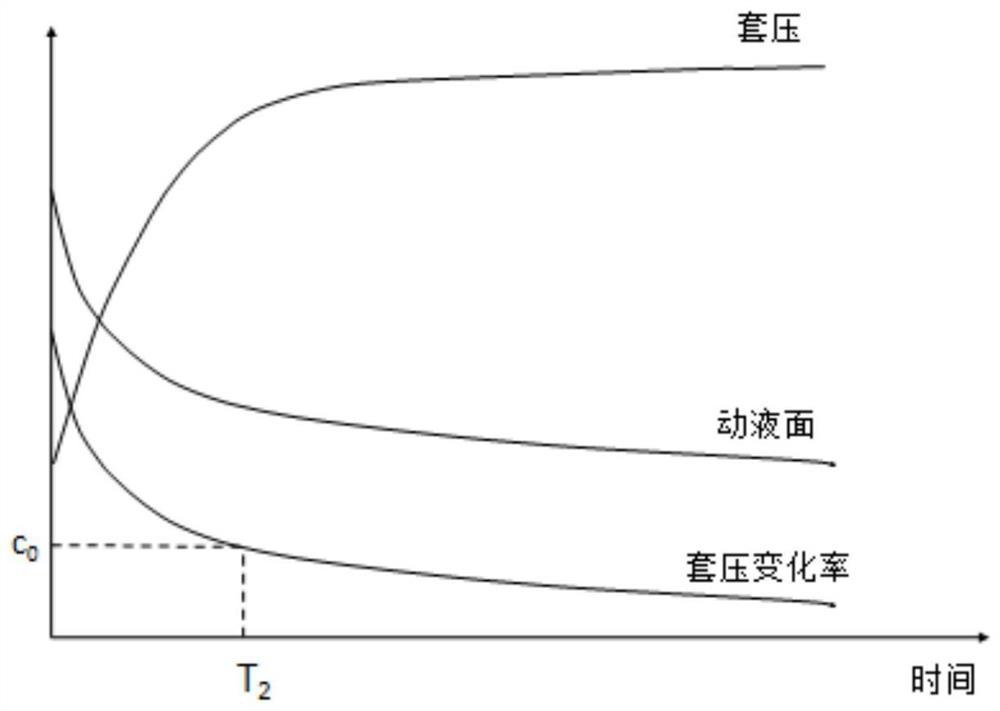

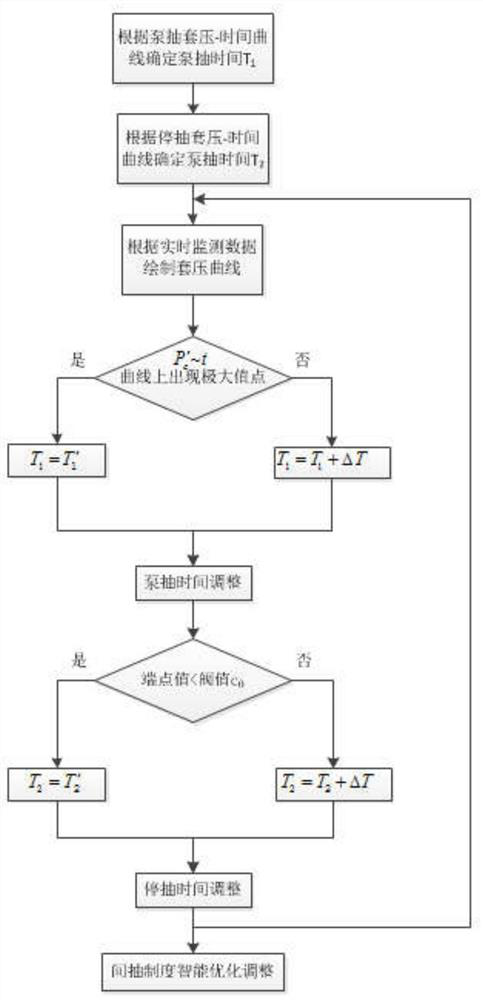

Intelligent interval pumping control method based on casing pressure test analysis

ActiveCN109882137BReasonable yield productionRealize automatic collectionSurveyConstructionsControl engineeringTest analysis

The invention relates to an intelligent intermittent pumping control method based on casing pressure well test analysis. According to the casing pressure-time relationship curve during the pumping period, the casing pressure change rate-time curve is drawn; the pumping time is determined as T 1 ; According to the casing pressure recovery curve during the withdrawal period, draw the casing pressure change rate-time curve; determine the withdrawal stop time as T 2 ; Oil well according to the interval pumping period T 1 +T 2 Run, draw the casing pressure-time relationship curve and casing pressure change rate-time curve during pumping period and stop pumping period respectively; update pumping time and stop pumping time according to the curve. The invention continuously monitors the casing pressure of the oil well, draws the casing pressure-time curve and the casing pressure change rate time curve, analyzes the variation law of the casing pressure and the dynamic liquid level, and determines the reasonable opening time and closing time; According to the production status, real-time optimization and adjustment of the pumping system is carried out to realize the intelligent control of low-yield and low-efficiency wells. While giving full play to the production potential of low-yield wells, the purpose of saving energy and reducing consumption and reducing the loss of pumping units and their equipment is achieved. .

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Method of producing low-sulfur low freezing point diesel by full-range shale oil

ActiveCN103497782BHigh yieldFlexible product planTreatment with hydrotreatment processesNaphthaOperational costs

The invention relates to a method of producing low-sulfur low freezing point diesel by full-range shale oil, relates to a production method of low-sulfur low freezing point diesel and solves the technical problems that the existing method of producing diesel by shale oil is complex in process and high in investment and operational cost. A material pre-fractionation unit, a reaction unit and a fraction unit are adopted in the method. The method has the advantages that finished diesel yield is high during processing of the full-range shale oil; the quality of the low-sulfur low freezing point diesel meets the national standard IV; a product scheme is flexible, the production of refined diesel and the production of the low-sulfur low freezing point diesel are both considered, and product distribution is adjusted; during the processing of the full-range shale oil, the material pre-fractionation unit is additionally provided with an absorbing column and a flash tank, lightweight shale oil is used as absorbent, LPG components in noncondensable gas can be recycled, applying a product stabilization column to the product fractionation unit to separate LPG and naphtha is avoided, and cost reduction and efficiency increasing are achieved. The invention belongs to the field of diesel production.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE

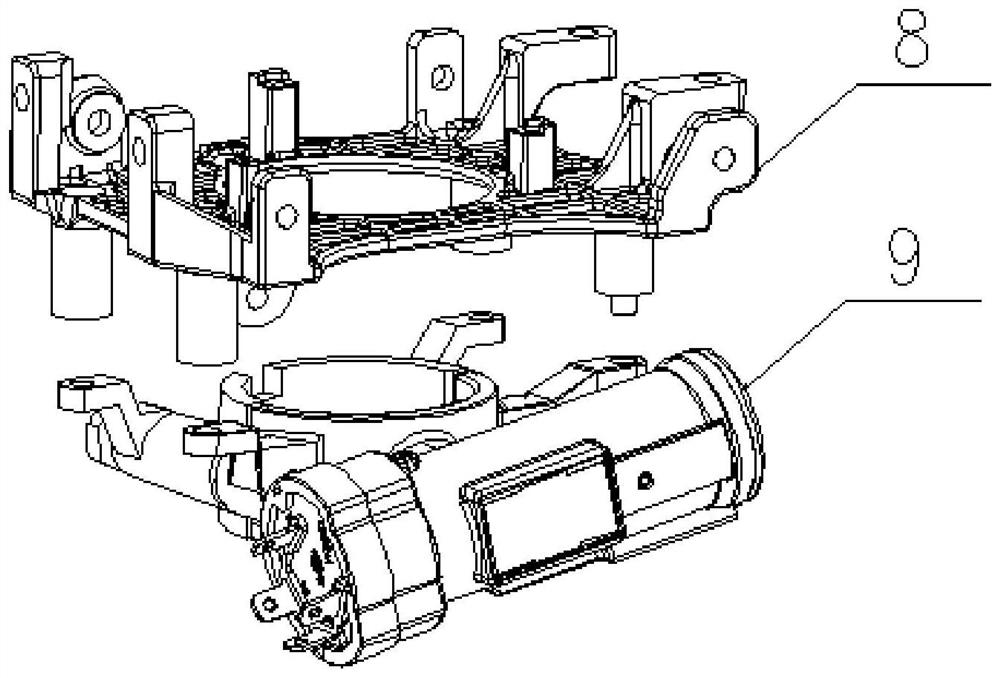

Steering column device

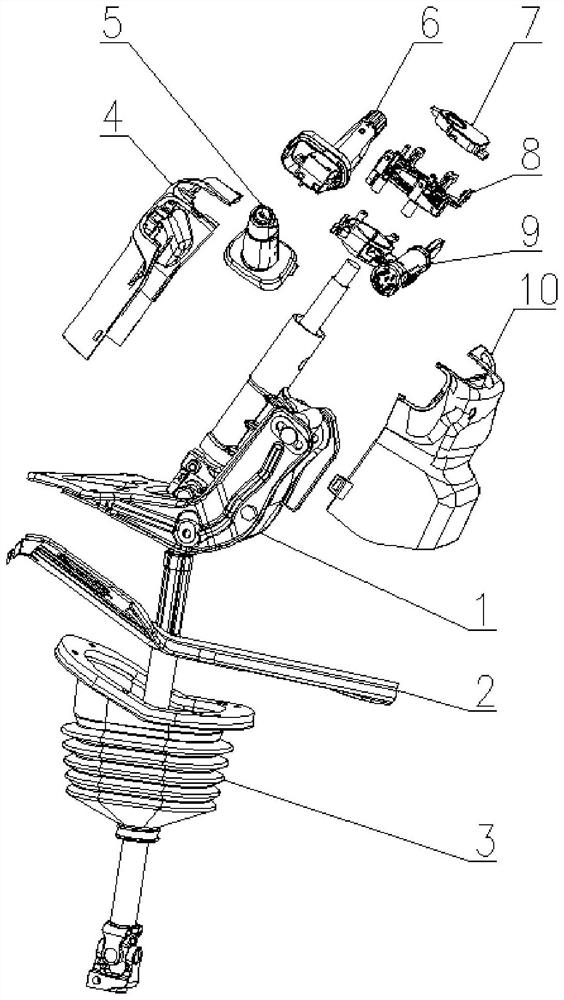

PendingCN112722053AStrong dust resistanceStrong sound insulationAnti-theft devicesSteering columnsInterference fitSteering column

The invention provides a steering column device. The device comprises a steering column, a dustproof sleeve and an automobile body metal plate floor located at the bottom of a cockpit, sponge is bonded to the mounting face, making contact with the automobile body metal plate floor, of the dustproof sleeve, a nylon bush is mounted on the inner side of an extending opening, a circle of protrusion is arranged in the middle of the outer side of the nylon bush, a circle of groove is further formed in the middle of the inner wall of the extending opening, the shape of the groove matches the shape of the protrusion, and the nylon bush is in interference fit with the dustproof sleeve. A lock hole is formed in the end, located in the cockpit, of the steering column, the steering column is connected with an ignition lock through the lock hole, at least two support installation platforms are arranged on the ignition lock, and combined switch supports are detachably installed on the support installation platforms. The steering column device has the beneficial effects that the dustproof function of a heavy truck is improved, the noise in the cab is reduced, the assembly of related accessories such as a combination switch is simplified, the assembly precision is improved, and the product reliability is greatly improved.

Owner:SINO TRUK JINAN POWER

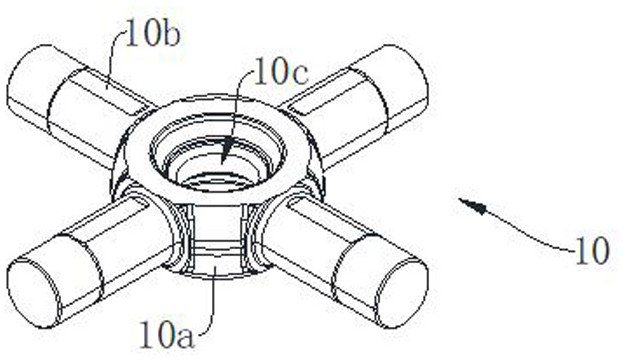

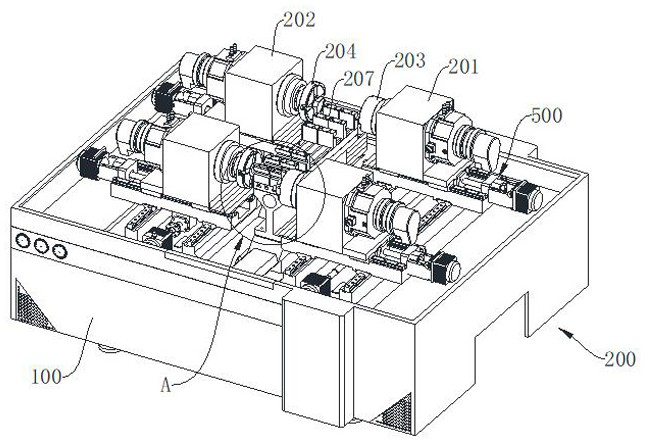

A combined machine tool and working method

ActiveCN114434152BSmall footprintReduce energy consumptionOther manufacturing equipments/toolsMetal working apparatusMachine toolIndustrial engineering

Owner:宁波佳比佳智能科技有限公司

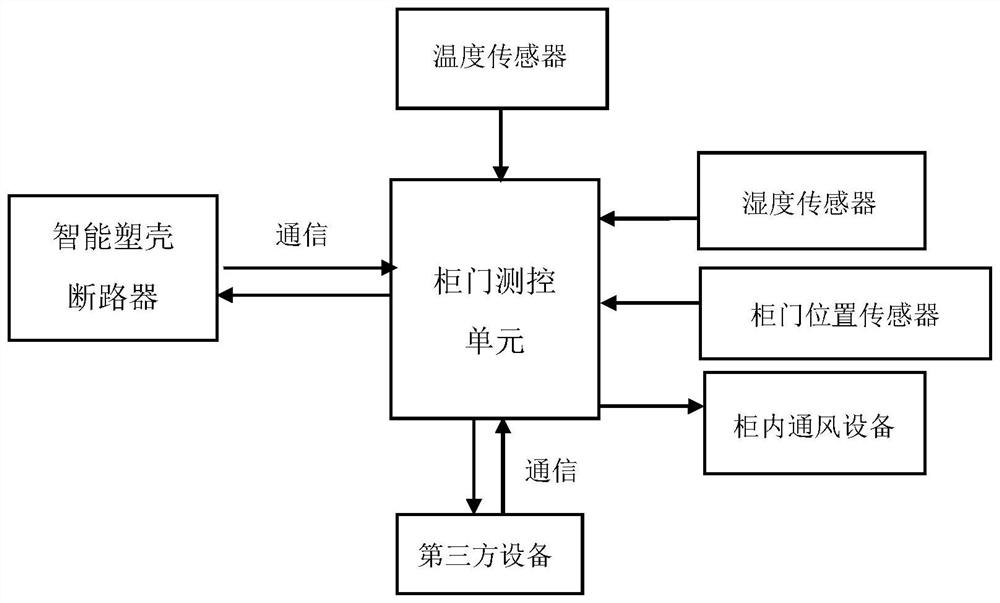

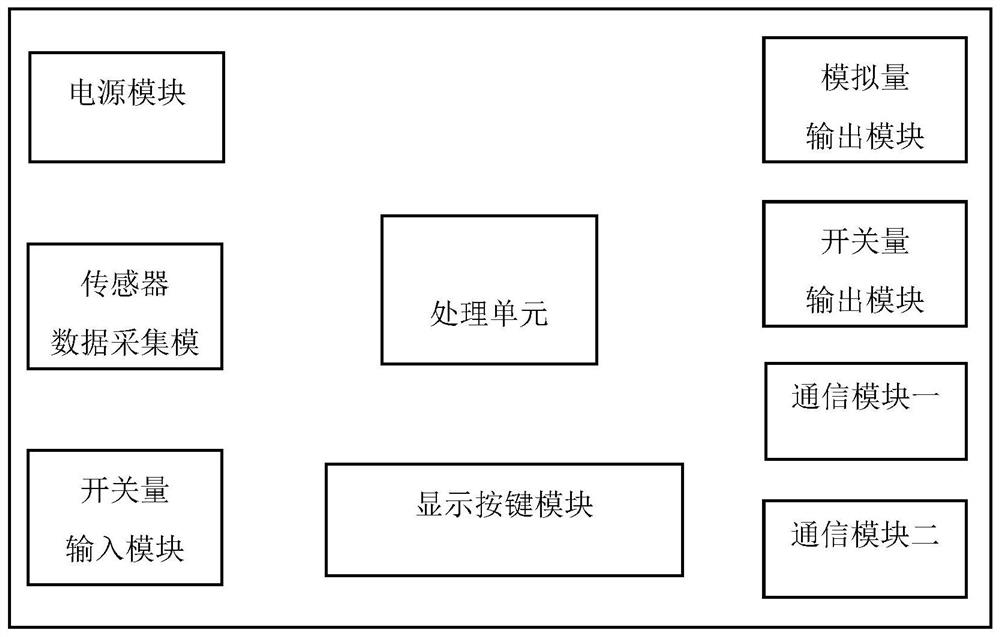

Low-voltage cabinet measurement and control system

PendingCN112344997ASave temperature controllerReduce connecting wiresProgramme controlComputer controlThird partyTemperature control

The invention discloses a low-voltage cabinet measurement and control system. The low-voltage cabinet measurement and control system comprises a temperature sensor, a humidity sensor, a cabinet door position sensor, an intelligent molded case circuit breaker, third-party equipment, in-cabinet ventilation equipment, a power supply module, a sensor data acquisition module, a display key module, a communication module I, a communication module II, a switching value input module, a switching value output module, an analog quantity output module and a processing unit; through association with the intelligent molded case circuit breaker and related sensors, an external current sensor in the cabinet is saved, a temperature controller in the cabinet is saved, connecting wires in the cabinet are saved, and since the intelligent molded case circuit breaker provides voltage, current, electric quantity, harmonic wave, power and power factor, the intelligent molded case circuit breaker also provides state and event information of the switch body. Multiple functions of setting parameters of the intelligent molded case circuit breaker, monitoring the temperature and humidity in the cabinet, starting ventilation equipment and the like are achieved, the purposes of reducing the cost and increasing the efficiency of the low-voltage cabinet are achieved, and digital integration of the low-voltagecabinet is promoted.

Owner:JIANGSU DAQO KFINE ELECTRIC

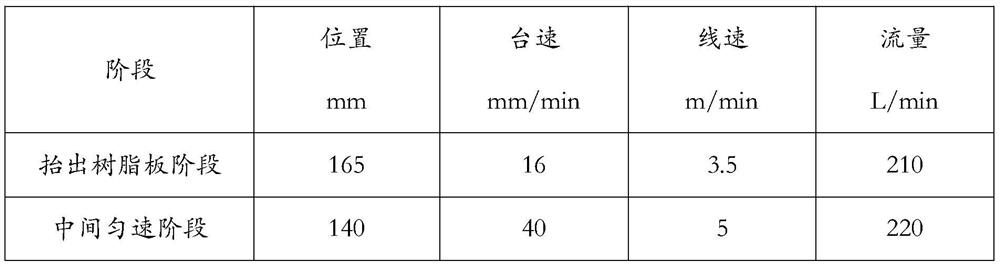

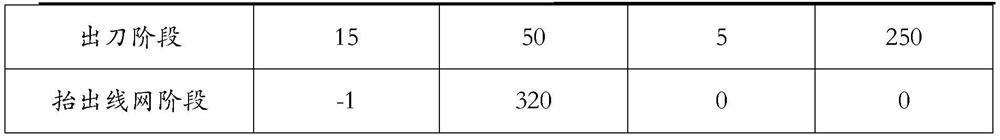

A kind of cutting method of silicon wafer below 140μm thickness

The invention discloses a method for cutting silicon wafers with a thickness of less than 140 μm, belonging to the technical field of crystalline silicon processing. The process of lowering the rod includes the stage of lifting out the resin plate, the stage of uniform speed in the middle, the stage of cutting out the knife and the stage of lifting the wire mesh. Using this invention for slicing can reduce the thickness of the silicon wafer, reduce the slot pitch, and increase the number of slices. At the end, the utilization rate of silicon material is obviously improved to achieve the purpose of reducing cost and increasing efficiency.

Owner:盐城高测新能源科技有限公司

Medium-temperature curing type composite soft insulation material

The invention relates to a medium-temperature curing type composite soft insulation material, which solves the problems of high heating temperature, long curing time, and low adhering strength after curing in the existing material. The medium-temperature curing type composite soft insulation material is prepared by compounding synthetic resin, an alkali-free glass cloth and an alkali-free glass felt on a compounding machine. The synthetic resin is prepared from the following components in parts by weight according to a formula: 330 to 350 parts of epoxy resin E44, 95 to 105 parts of epoxy resin E12, 57 to 63 parts of tung-ma anhydride, 4 to 6 parts of imidazole, and dimethylformamide. The medium-temperature curing type composite soft insulation material has the advantages that the production energy consumption is decreased, the production efficiency is improved, and the product quality is ensured; the purposes of reducing cost and improving efficiency are realized.

Owner:DEYANG XIETONGDA PLASTIC MATERIALS

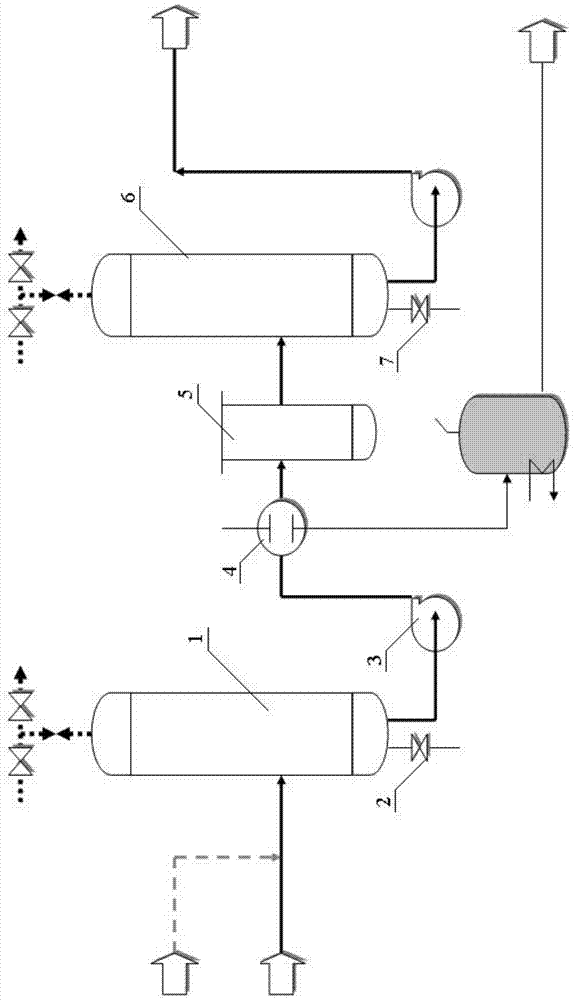

Method for upgrading and converting wood tar into diesel oil

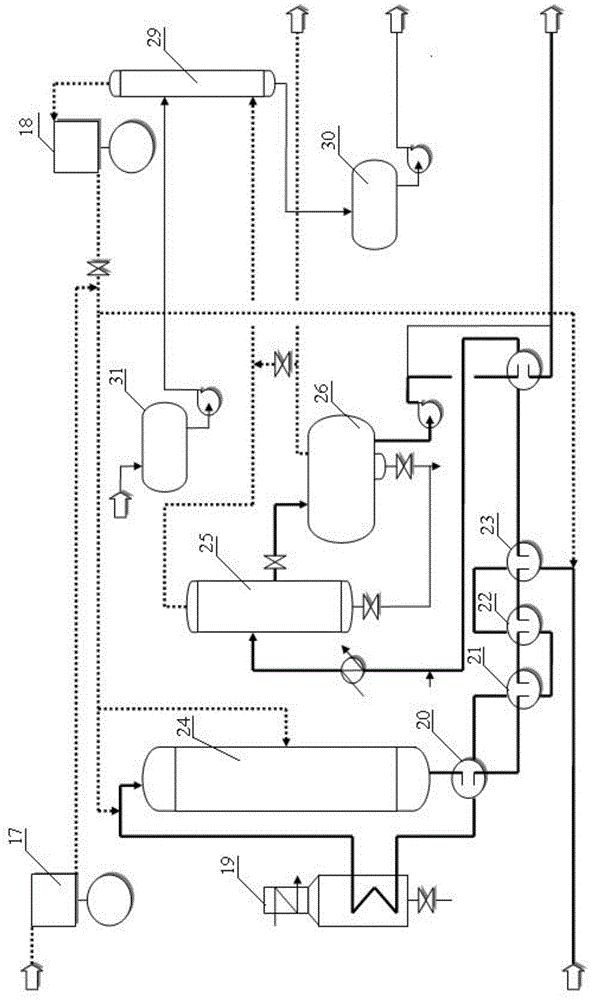

InactiveCN106433774AIncrease profitLow acid valueTreatment with hydrotreatment processesHydrocarbon oils treatment productsFractionationAgricultural residue

A method for upgrading and converting wood tar into diesel oil belongs to the field of deep processing of biomass oils. The invention is intended to solve the technical problem that since wood tar used in existing diesel production from wood tar features low oxygen content, high corrosiveness and poor stability, finished diesel oil of the wood tar is low in quality and insufficient in fuel energy; a transportation fuel is produced by subjecting full-range wood tar to material pretreatment and material pre-fractionation and passing through a hydrofining reaction unit and a product fractionation unit, with hydrogenated diesel oil as a main product and light oil and fuel gas as byproducts; heavy wood tar and hydrogenated tail oil thrown away in the technical process may be charged to downstream equipment for further processing and utilization, and an effective method for upgrading and converting wood tar into diesel oil is provided for biomass deep processing enterprises. By using the method, emerging industries can be opened for the countryside of China, the ecological problems such as air pollution and fire due to combustion of forestry and agricultural residues, such as stalks, can be solved, and reasonable development and sustainable utilization of biomass resources of China can be promoted.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE

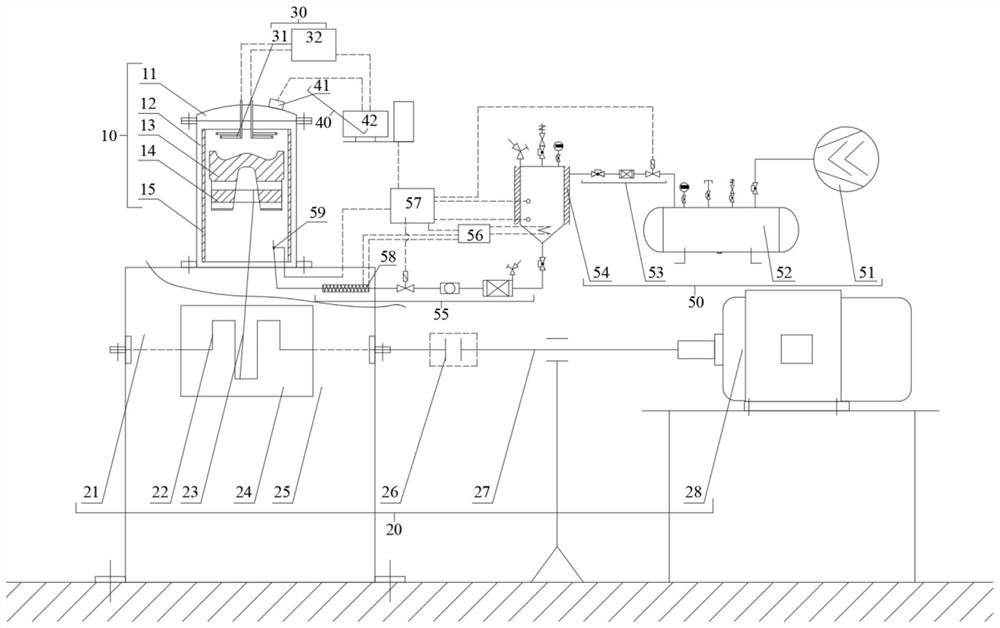

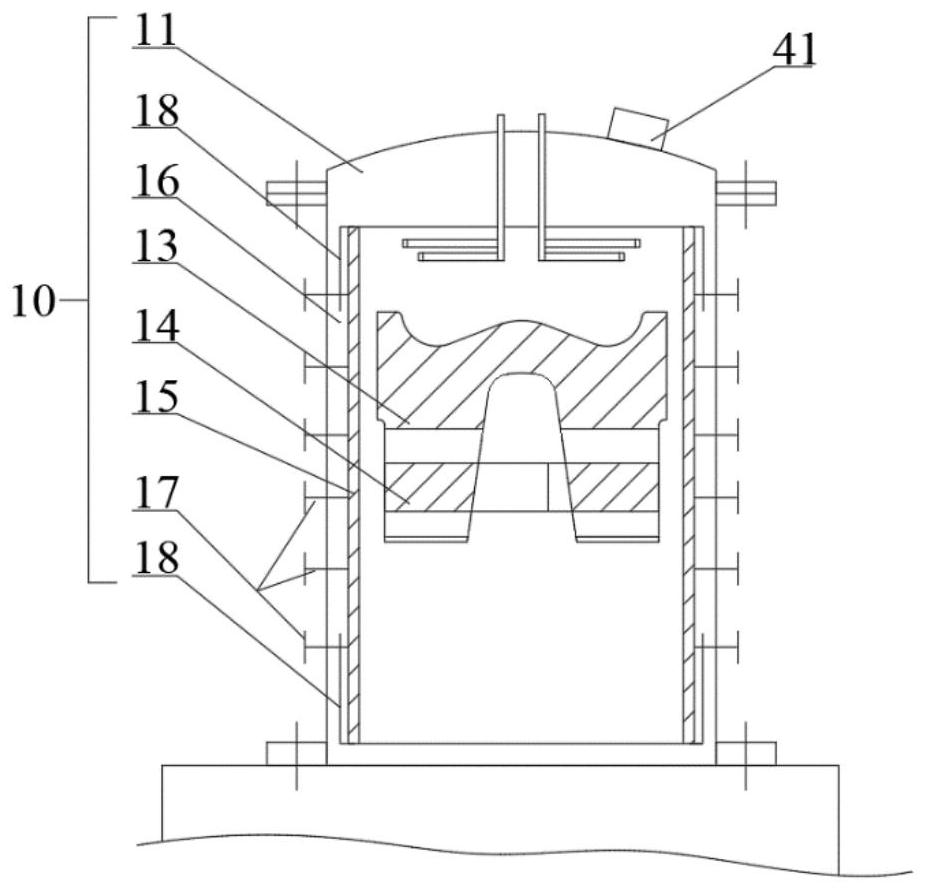

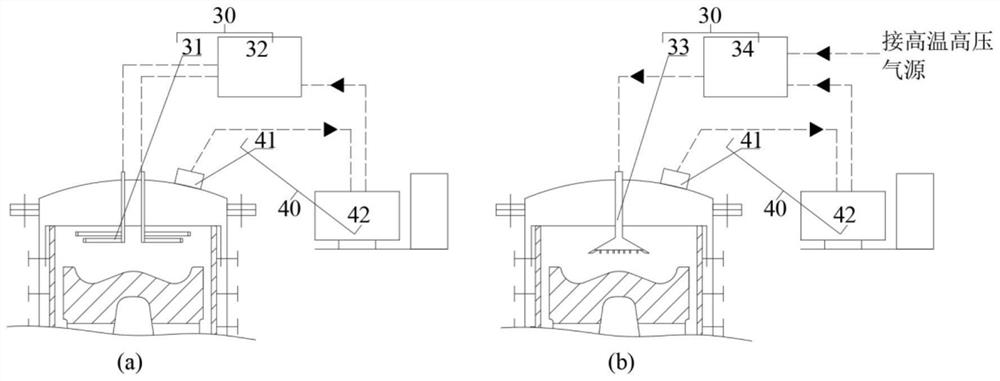

Engine piston remote measurement system reliability detection device and test method

ActiveCN114544182AEasy to control temperatureRealize reciprocating motionInternal-combustion engine testingSustainable transportationPistonElectrical and Electronics engineering

The invention discloses an engine piston remote measurement system reliability detection device and a test method, and belongs to the field of engine test. The invention mainly aims to provide a reliability detection device for an engine piston telemetering system. The reliability detection device comprises a detection part, a driving and lubricating mechanism, a heating part, a temperature detection and control part and a simulation oil injection part, the reliability detection device can detect the reliability and the stability of the engine piston telemetering system in advance, the test cost is reduced, and the whole engine test efficiency is improved. The device is high in universality, is suitable for multiple working conditions, also has dynamic temperature detection and calibration effects, and improves the precision of a telemetering system. The second purpose of the invention is to provide a test method of the engine piston telemetering system based on the device, the simulation of the temperature, the operation parameters and the oil stain washing environment under the steady and dynamic operation conditions can be quickly realized by controlling the hardware of the device, and the device has the advantages of enhancing the detection effect and improving the detection efficiency.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

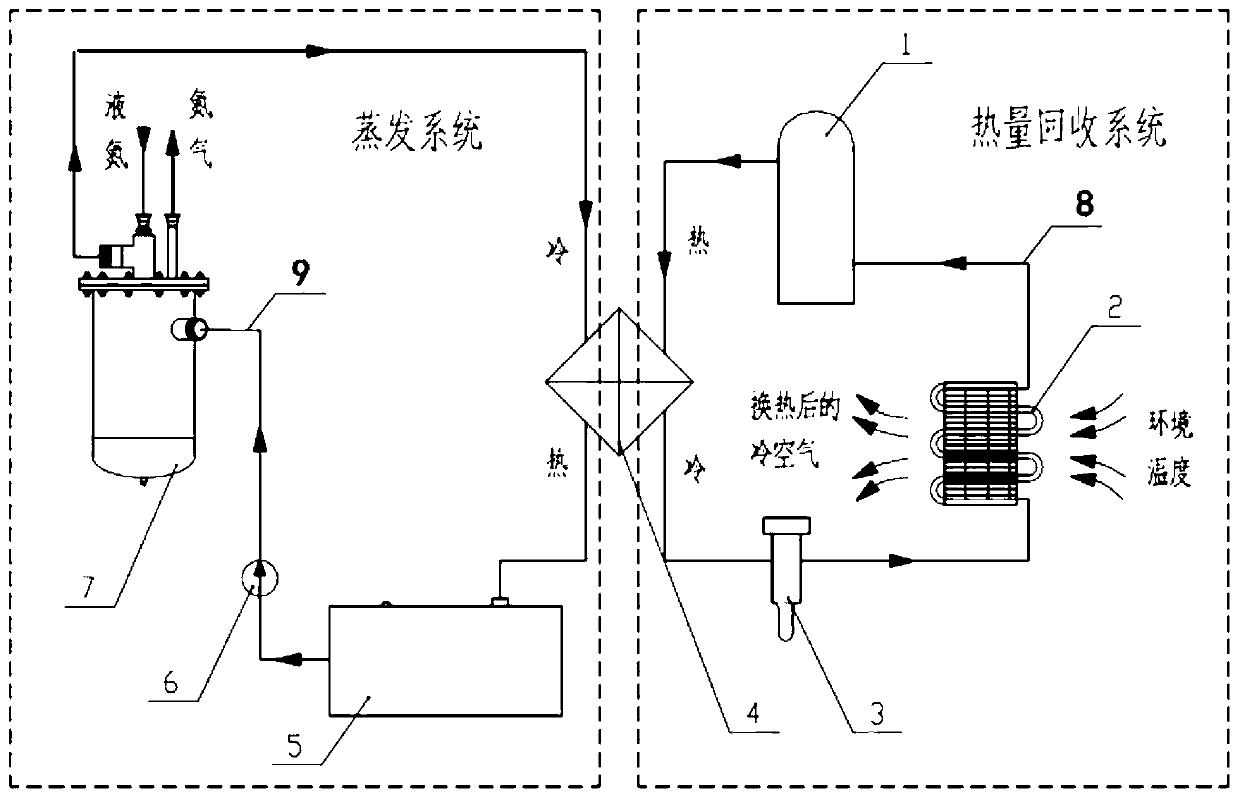

Heat recovery liquid nitrogen evaporation system suitable for oil and gas fields

PendingCN109882131AReduce dosageReduce leak pointsHeat pumpsFluid removalEnvironmental resistanceEvaporation

The invention belongs to the technical field of oil and gas field development equipment, and particularly relates to a novel heat recovery liquid nitrogen evaporation system suitable for oil and gas fields. The novel heat recovery liquid nitrogen evaporation system comprises a relatively independent evaporation system and a heat recovery system, wherein the evaporation system and the heat recoverysystem are connected through a heat exchanger, and the evaporation system and the heat recovery system exchange heat by the heat exchanger; the heat recovery system comprises an air heat exchanger, aheat pump compressor and an expansion valve which are sequentially connected to a first medium transmission pipeline; and the evaporation system comprises a liquid storage tank, a booster pump and anevaporator which are sequentially connected to a second medium transmission pipeline. The novel heat recovery liquid nitrogen evaporation system keeps the operation process clean, the requirements ofenvironmental protection are met, the power consumption in the operation process is greatly reduced, and the operation cost is saved.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

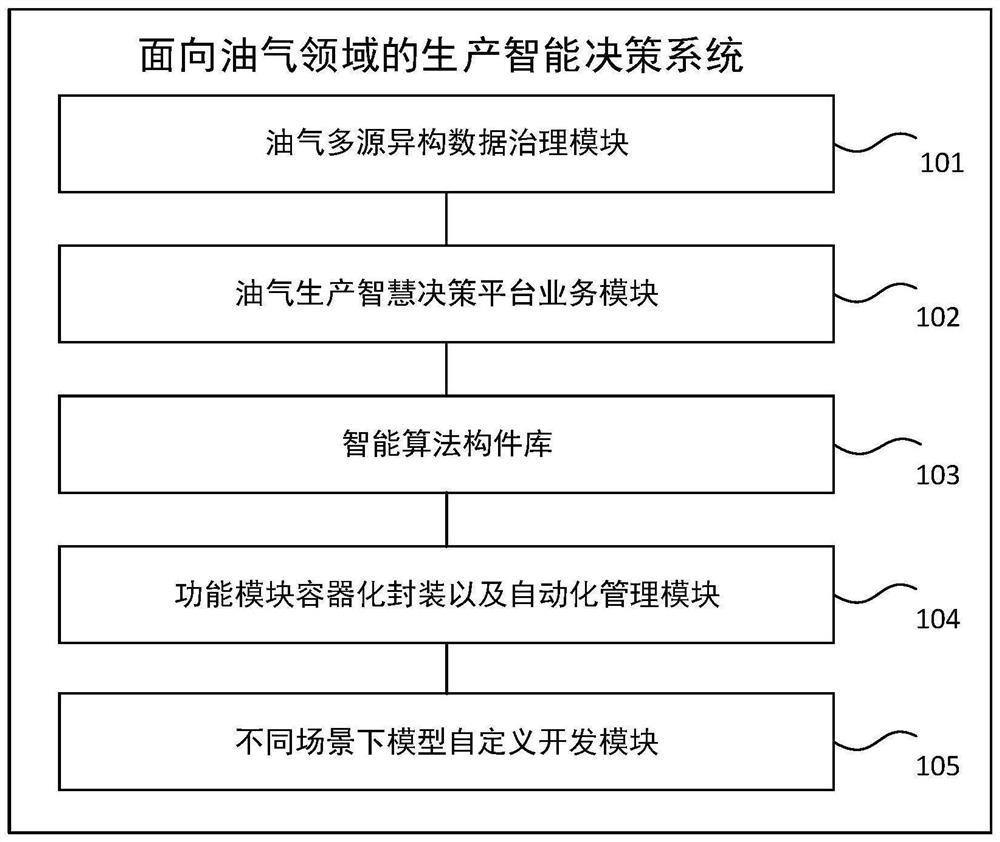

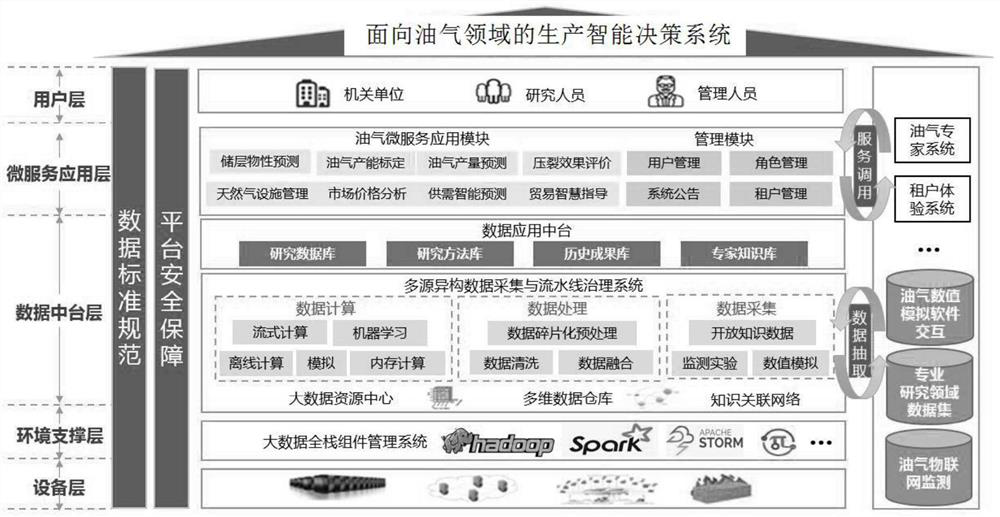

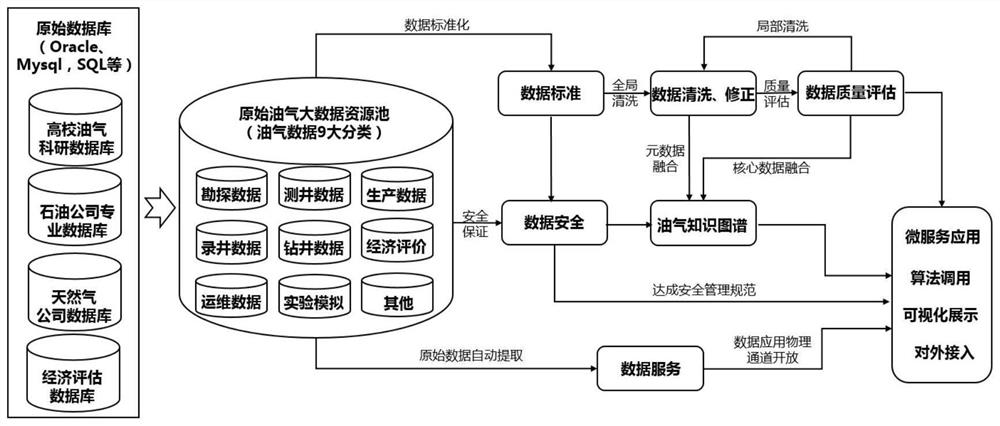

Production intelligent decision-making system and method for oil and gas field

PendingCN114676978ARealize integrated governanceRealize the purpose of cost reduction and efficiency increaseDatabase management systemsMachine learningContainerizationSystems management

The invention provides an intelligent production decision-making system and method for the oil and gas field, and belongs to the field of oil and gas development. The system comprises an oil-gas multi-source heterogeneous data governance module used for realizing oil-gas field data integrated governance; the oil and gas production intelligent decision platform business module is used for realizing oil and gas production intelligent decision, intelligent storage, transportation, gathering and transportation, intelligent operation and sales and system management, operation and maintenance; the intelligent algorithm component library is used for providing a basic algorithm and an intelligent algorithm developed based on specific scene customization; the function module containerization packaging and automatic management module is used for carrying out containerization packaging on the oil-gas multi-source heterogeneous data, the intelligent algorithm component library and the intelligent service component library and carrying out container unified scheduling and management; and the model custom development module under different scenes is used for building specialized models oriented to different scenes. The method solves the problem of less business scene association in oil and gas industry production, and plays an important role in digital and intelligent development of the oil and gas industry.

Owner:北京中科智上科技有限公司 +1

Device for removing scale of trioxane heat exchanger

The invention provides a device for removing scale of a trioxane heat exchanger. The device comprises a steam heating system, an alkali preparation system and a waste liquid recycling system. By meansof the device, material waste can be reduced, the pressure of sewage treatment is reduced, the device running period is prolonged, and the aims of saving energy, reducing consumption, reducing cost and increasing efficiency are achieved. The heat exchanger washing effect is good, the comprehensive energy consumption of a production system is reduced, the device running period is prolonged, the pressure and difficulty of sewage treatment are reduced, the risk of environment protection accidents is avoided, and great significance is achieved for the whole production system.

Owner:KAIFENG LONGYU CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com