A kind of cutting method of silicon wafer below 140μm thickness

A silicon wafer and stage technology, applied in the cutting field of silicon wafers with a thickness of less than 140μm, can solve the problems of slow yield and other problems, and achieve the effects of reducing thickness, narrowing groove pitch, and improving the utilization rate of silicon material.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A method for cutting silicon wafers with a thickness of less than 140 μm, comprising the following steps:

[0020] (1) Replace the main roller: remove the main roller on the equipment, and replace the main roller that matches the groove pitch and sheet thickness;

[0021] (2) Wiring net: the main roller is covered with wire net;

[0022] (3) Upper rod: place the crystal rod in the slicer, and after setting the zero point, raise the crystal rod to the highest;

[0023] (4) Call process: read the process after compiling it;

[0024] (5) Heat engine: Install the nozzle, adjust the position and start to set the heat engine time to 5min, click the automatic operation button to start the heat engine;

[0025] (6) Power on: Click the automatic operation button to automatically cut;

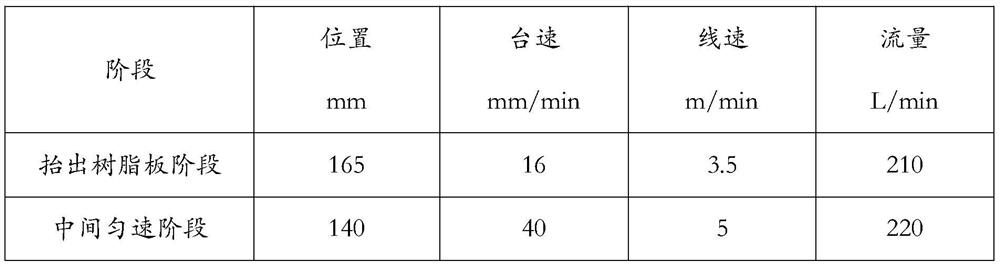

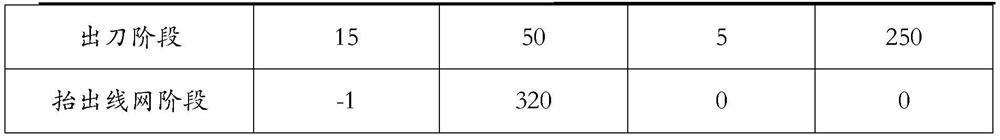

[0026] (7) Lowering the bar: the lowering process includes a stage of lifting out the resin plate, a stage at a constant speed in the middle, a stage of pulling out a knife and a stage of pulli...

Embodiment 2

[0034] A method for cutting silicon wafers with a thickness of less than 140 μm, comprising the following steps:

[0035] (1) Replace the main roller: remove the main roller on the equipment, and replace the main roller that matches the groove pitch and sheet thickness;

[0036] (2) Wiring net: the main roller is covered with wire net;

[0037] (3) Upper rod: place the crystal rod in the slicer, and after setting the zero point, raise the crystal rod to the highest;

[0038] (4) Call process: read the process after compiling it;

[0039] (5) Heat engine: Install the nozzle, adjust the position and start to set the heat engine time to 5min, click the automatic operation button to start the heat engine;

[0040] (6) Power on: Click the automatic operation button to automatically cut;

[0041] (7) Lowering the bar: the lowering process includes a stage of lifting out the resin plate, a stage at a constant speed in the middle, a stage of pulling out a knife and a stage of pulli...

Embodiment 3

[0049] A method for cutting silicon wafers with a thickness of less than 140 μm, comprising the following steps:

[0050] (3) Replace the main roller: remove the main roller on the equipment, and replace the main roller that matches the groove pitch and sheet thickness;

[0051] (4) Wiring net: the main roller is covered with wire net;

[0052] (3) Upper rod: place the crystal rod in the slicer, and after setting the zero point, raise the crystal rod to the highest;

[0053] (4) Call process: read the process after compiling it;

[0054] (5) Heat engine: Install the nozzle, adjust the position and start to set the heat engine time to 5min, click the automatic operation button to start the heat engine;

[0055] (6) Power on: Click the automatic operation button to automatically cut;

[0056] (7) Lowering the bar: the lowering process includes a stage of lifting out the resin plate, a stage at a constant speed in the middle, a stage of pulling out a knife and a stage of pulli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com