Galvanized steel strip surface passivation film weight control system and control method thereof

A technology of control system and galvanized steel strip, applied in hot-dip galvanizing process, coating, metal material coating process, etc., can solve problems such as poor adjustment accuracy, lagging adjustment process, poor film weight control effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

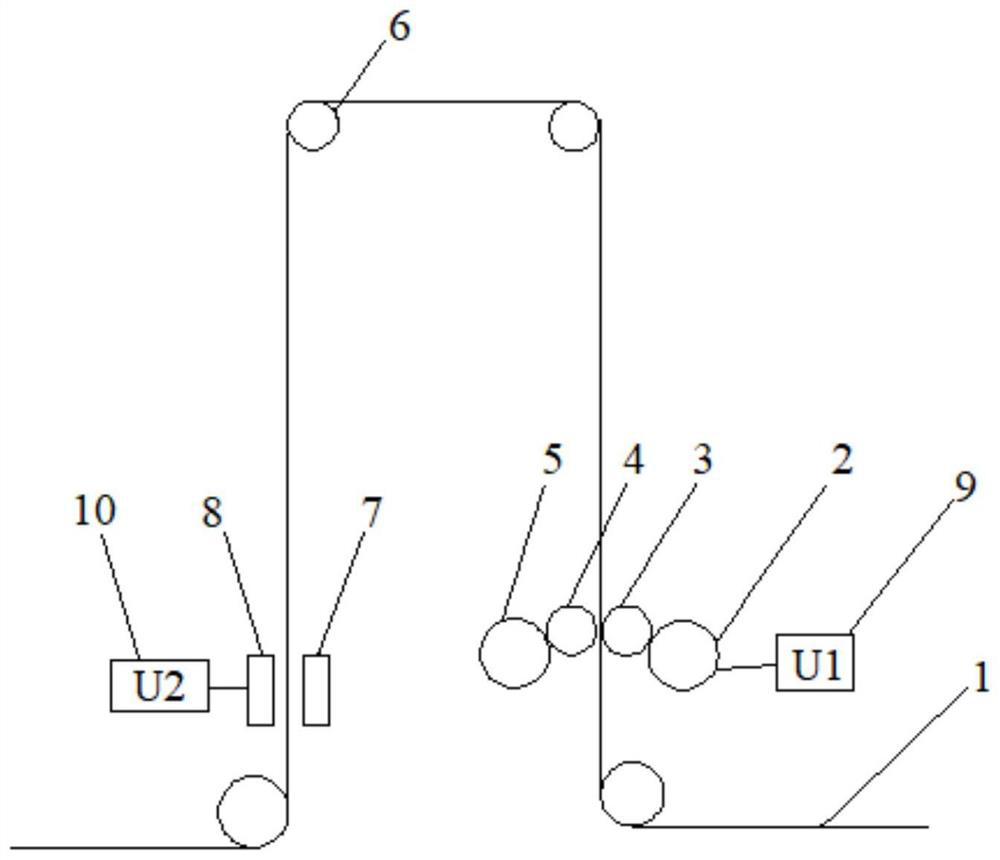

[0066] Its control system includes two parts: roller coater system and online film thickness meter system, and its specific composition, structure and function are as mentioned above.

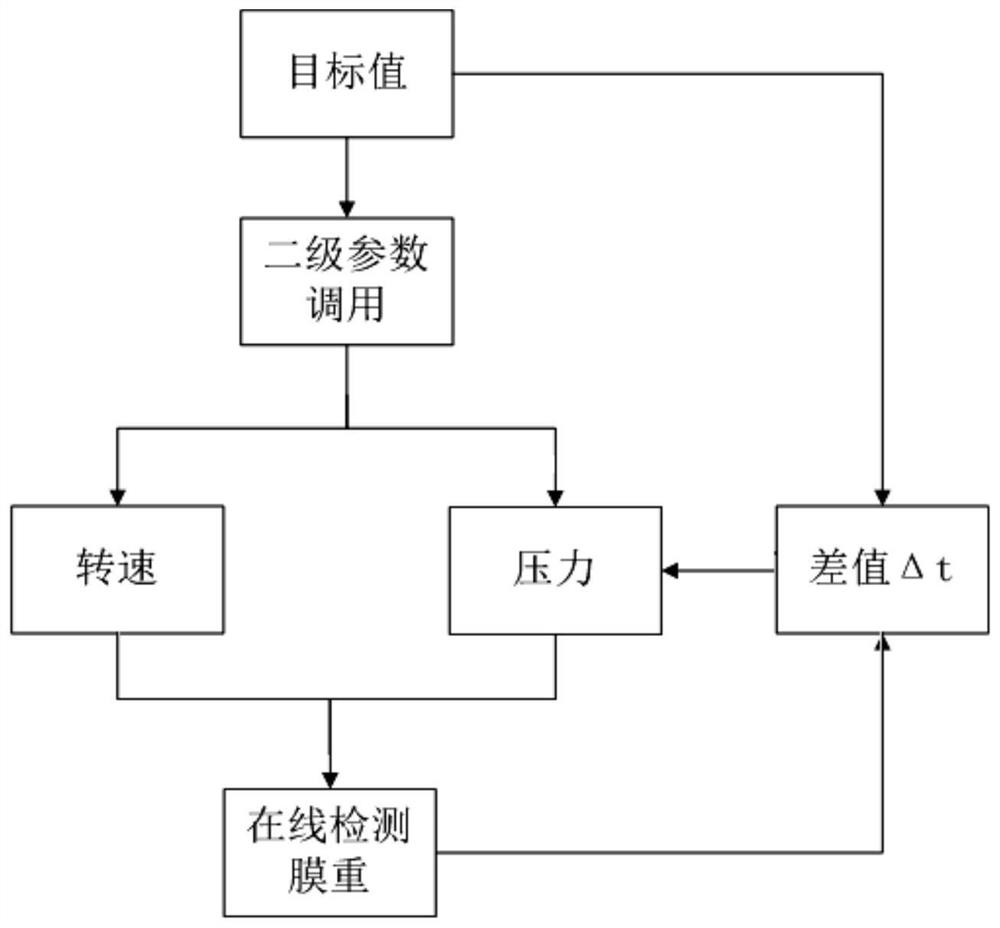

[0067] When the unit is producing the ordinary chromium-free passivation environmental protection product DX51D, the production line speed is 90m / min, and the passivation film weight is set at 1.0g / m 2 , the parameters given by the second level are used for the initial input, such as the second-level parameters, the pressure between the reclaiming roll and the coating roll is 2500N, the pressure between the coating roll and the strip is 2500N, and the speed difference between the reclaiming roll and the coating roll is -15% , The pressure range of coating roller and strip steel, reclaiming roller and coating roller in the control program is set to 300 ~ 8000N.

[0068] After the roller coating is input according to the second-level given parameters, the online film thickness meter will continuo...

Embodiment 2

[0072] The difference with Embodiment 1 is:

[0073] The roller coating controller has calculated and adjusted the pressure between the coating roller and the strip to the minimum of 300N, and the passivation film weight still does not meet the standard requirements. The controller then starts the pressure program of the reclaiming roller and coating roller, and the roller coating controller The pressure between the take-up roller, the coating roller and the steel strip is 2000N, and the average weight of the film within a continuous range of 100m after adjustment is 1.08g / m 2 , meeting the standard range, the roller coating parameters are maintained.

[0074] Others are the same as in Embodiment 1.

Embodiment 3

[0076] The difference with Embodiment 1 is:

[0077] The online film thickness meter detects that there is a deviation between the weight of the lower surface film and the weight of the upper surface film. The controller of the roller coater can independently adjust the pressure of the upper and lower gauges of the coating roller and the strip, and the reclaiming roller and the coating roller. For example, the pressure on the lower gauge of the coating roller and the strip is 2000N, and the upper gauge pressure of the coating roller and the strip is 1800N. After the adjustment is completed, the test result of the online film thickness meter is 1.12g / m 2 ,fulfill the standard.

[0078] Others are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com