Tank cleaning equipment for offshore oil platform and tank cleaning method

A technology for offshore oil and equipment, applied in the direction of cleaning methods, cleaning methods and utensils, chemical instruments and methods using gas flow, etc. problem, to achieve the effect of convenient operation, improve the cleaning effect, and reduce the possibility of injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

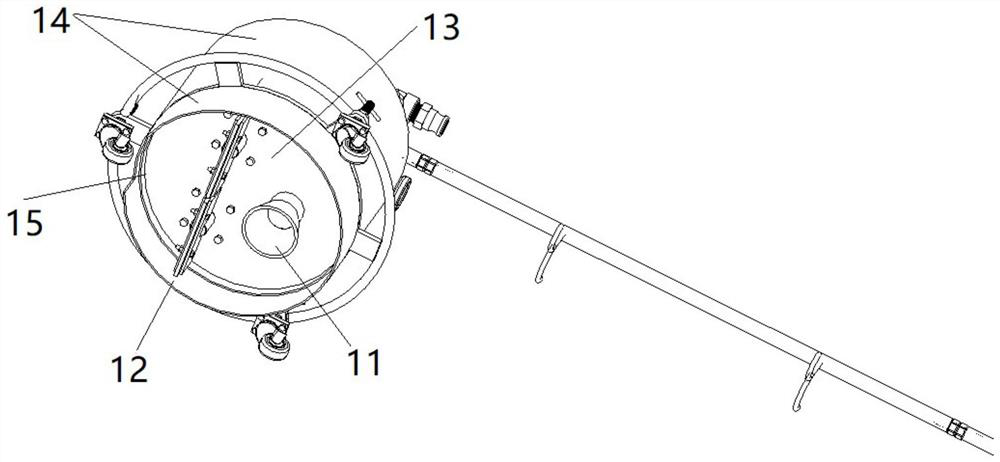

[0034] In order to better understand the purpose, structure and function of the present invention, a tank cleaning device and a tank cleaning method for an offshore oil platform of the present invention will be described in further detail below with reference to the accompanying drawings.

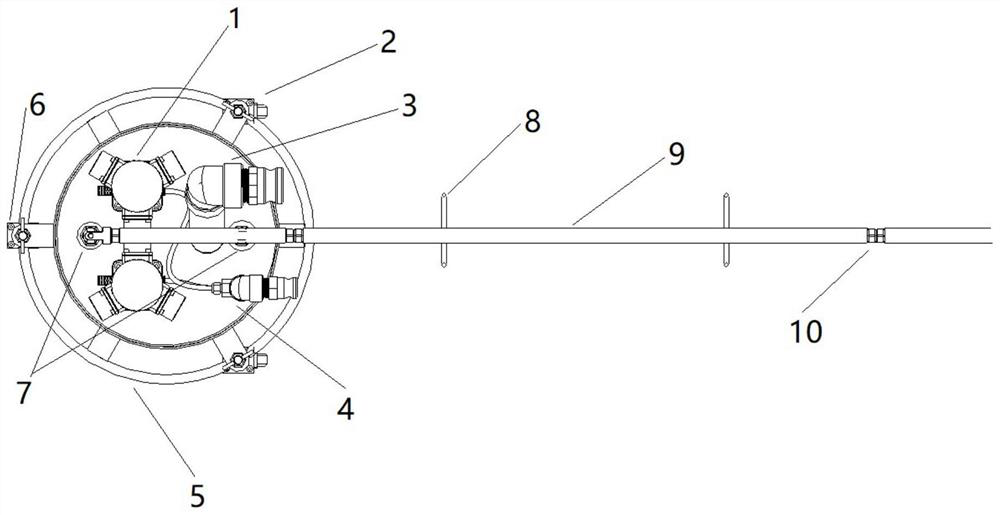

[0035] like figure 1 As shown, the present invention includes: a shield 14, a plurality of motors 1 (two in this embodiment) oppositely arranged in the shield 14, and an elongated push rod 9 installed between the motors 1; wherein,

[0036] An anti-collision guardrail 5 is set around the upper part of the shield 14, and a first quick connector 3 is installed at the bottom of the shield 14;

[0037] The above-mentioned anti-collision guardrail 5 is a ring-shaped structure as a handle, and several reinforcing ribs (six in this embodiment) are installed in the interior at a set distance, and several reinforcing ribs are connected with the shield 14; it ensures that the center of gravity of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com