Technique device for conserving brick for building and method thereof

A technology for process equipment and construction, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of large investment, energy consumption, affecting product quality, etc., and achieve the effect of high product qualification rate, short maintenance period and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

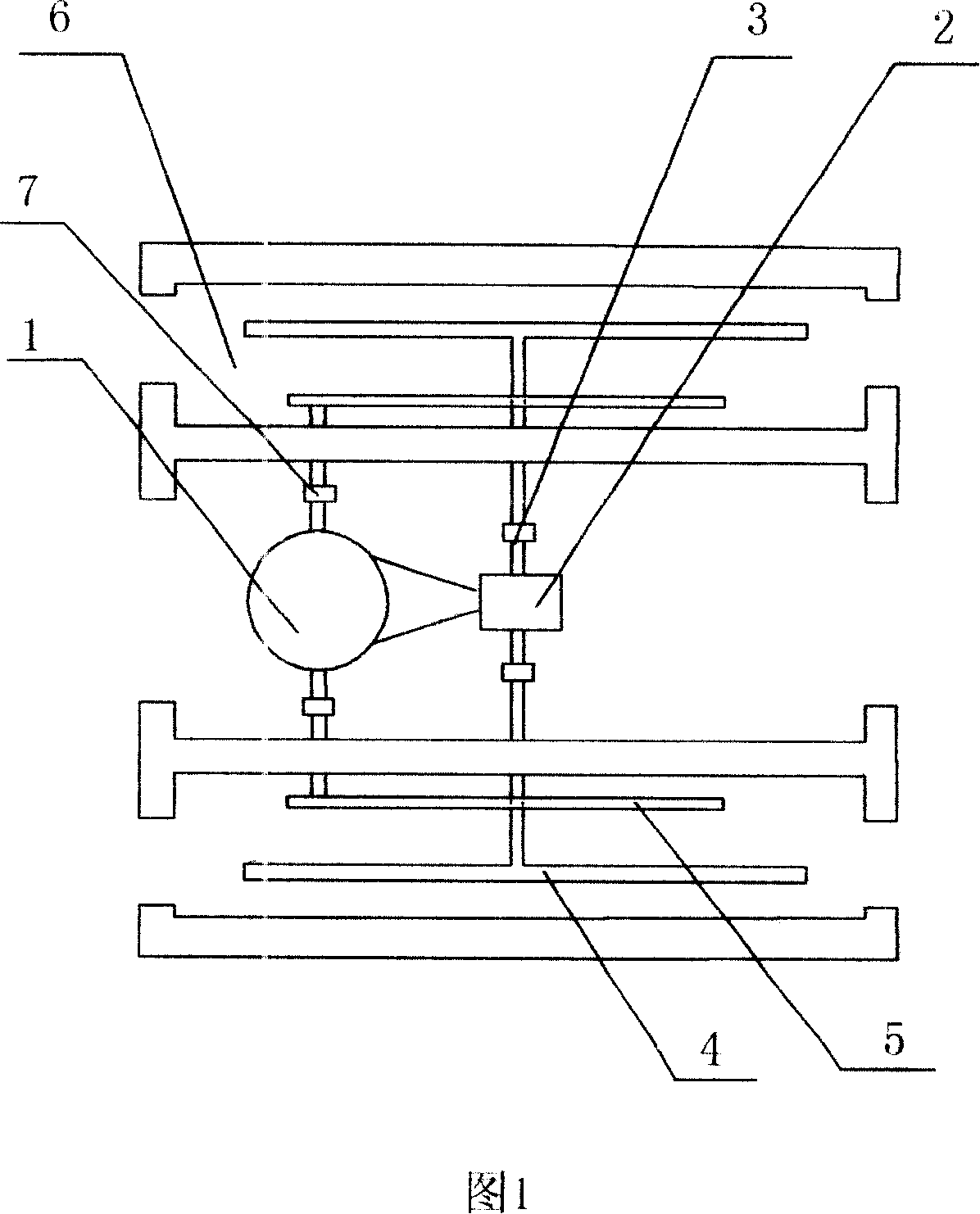

[0016] Below in conjunction with accompanying drawing embodiment, the technical equipment and the method of maintenance building brick of the present invention are further described:

[0017] What shown in accompanying drawing 1 is that can produce 6,000,000 building bricks maintenance process equipment structural layout diagrams per year, it comprises hot and cold air circulation reaction furnace 1, induced draft fan 2, gate valve, air supply pipe 4, return air pipe 5, four A curing room 6, wherein, the cold and hot air circulation reaction furnace 1 and the induced draft fan 2 are placed in the middle of the four maintenance rooms 6, and the air outlet of the cold and hot air circulation reaction furnace 1 is connected with the induced draft fan 2, the gate valve 3 and installed in the The air supply pipe 4 on the ground of the reaction chamber, the air inlet of the cold and hot air circulation reaction furnace 1 are sequentially connected to the gate valve 7 and the return a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com